battery DATSUN B110 1969 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 4 of 136

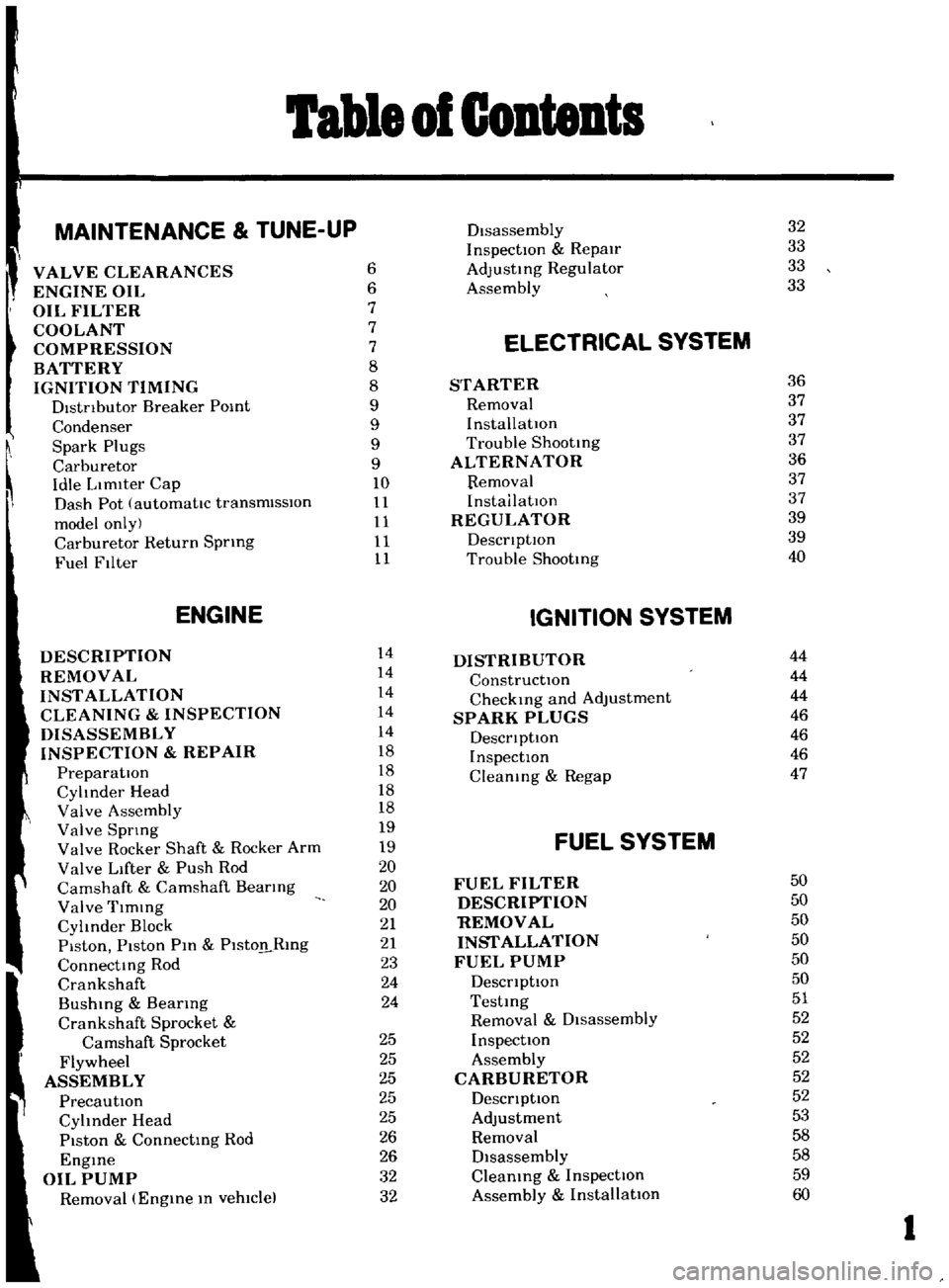

able

of

Contents

MAINTENANCE

TUNE

UP

DIsassembly

32

InspectIOn

RepaIr

33

VALVE

CLEARANCES

6

AdJustmg

Regulator

33

ENGINE

OIL

6

Assembly

33

OIL

FILTER

7

COOLANT

7

COMPRESSION

7

ELECTRICAL

SYSTEM

BATTERY

8

IGNITION

TIMING

8

STARTER

36

DIstributor

Breaker

Pomt

9

Removal

37

Condenser

9

InstallatIOn

37

Spark

Plugs

9

Trouble

Shootmg

37

Carburetor

9

ALTERNATOR

36

Idle

LImIter

Cap

10

Removal

37

Dash

Pot

automatic

transmISSIOn

11

InstallatIOn

37

model

only

11

REGULATOR

39

Carburetor

Return

Sprmg

11

DeSCriptIOn

39

Fuel

Filter

11

Trouble

Shootmg

40

ENGINE

IGNITION

SYSTEM

DESCRIPTION

14

DISTRIBUTOR

44

REMOVAL

14

ConstructIOn

44

INSTALLATION

14

Checkmg

and

Adjustment

44

CLEANING

INSPECTION

14

SP

ARK

PLUGS

46

DISASSEMBL

Y

14

DeSCriptIOn

46

INSPECTION

REPAIR

18

InspectIOn

46

PreparatIOn

18

Cleamng

Regap

47

Cyltnder

Head

18

Valve

Assembly

18

Valve

Spnng

19

Valve

Rocker

Shaft

Rocker

Arm

19

FUEL

SYSTEM

Valve

LIfter

Push

Rod

20

Camshaft

Camshaft

Bearmg

20

FUEL

FILTER

50

Valve

Tlmmg

20

DESCRIPTION

50

Cyltnder

Block

21

REMOVAL

50

PIston

Piston

Pm

Plsto

LRmg

21

INSTALLATION

50

Connectmg

Rod

23

FUEL

PUMP

50

Crankshaft

24

DeSCriptIOn

50

Bushmg

Bearing

24

Testmg

51

Crankshaft

Sprocket

Removal

DIsassembly

52

Camshaft

Sprocket

25

InspectIOn

52

Flywheel

25

Assembly

52

ASSEMBL

Y

25

CARBURETOR

52

PrecautIOn

25

DeSCription

52

Cyltnder

Head

25

Adjustment

53

PIston

ConnectIng

Rod

26

Removal

58

Engme

26

DIsassembly

58

OIL

PUMP

32

Cleanmg

InspectIOn

59

Removal

Engme

m

vehicle

32

Assembly

InstallatIOn

60

I

Page 10 of 136

aiDtenaDce

TUDe

up

ting

tightly

m

spark

plug

hole

of

a

cylin

der

The

tester

is

used

to

determme

whether

cylinder

can

hold

compression

or

whether

there

IS

excessive

leakage

past

rings

etc

Test

compressIOn

wIth

engme

warm

all

spark

plugs

removed

and

throttle

and

choke

valve

opened

No

cyhnder

compressIOn

should

be

less

than

80

of

highest

cyhnder

s

Excessive

variatIOn

between

cyhnders

accompamed

by

low

speed

missing

of

the

cyllndel

usually

10

dlcates

a

valve

not

properly

seating

or

a

blOken

pIston

ring

Low

preSsures

even

though

umform

may

indIcate

worn

rings

ThIs

may

be

accompamed

by

excessive

011

consumptIOn

Test

Conclusion

If

one

or

more

cyhnders

read

low

Inject

about

one

tablespoon

of

engine

011

on

top

of

the

plstons

In

low

readmg

cyhnders

through

spark

plug

hole

Repeat

compressIOn

check

on

these

cy

II

nders

If

compressIOn

Improves

conSiderably

piston

rings

are

defectIve

If

compressIOn

does

not

Improve

valves

are

stIcking

or

seatIng

Improperly

If

two

adjacent

cyhnders

mdlcate

low

com

pressIOn

and

mjectmg

011

on

pistons

does

not

Increase

compreSSIOn

the

cause

may

be

a

cylInder

head

gasket

leak

between

the

cyhn

ders

Engine

011

and

coolant

In

cylInder

could

result

from

this

problem

CompressIOn

pressure

178

to

206

pSI

at

350

rpm

BATIERY

Check

electrolyte

level

10

each

battery

cell

Unscrew

each

filler

cap

and

Inspect

flUId

level

If

flUId

level

IS

low

add

dIstilled

water

to

bring

level

up

to

approximately

03937

to

07874

In

above

plates

Do

not

overfill

Mea

ure

P

illL

gravlty

of

pattery

el

c

trolyte

8

Clean

top

of

battery

and

terminals

With

a

solutIOn

of

baking

soda

and

water

Rinse

off

and

dry

WIth

compressed

atr

The

top

of

bat

tery

must

be

clean

to

prevent

current

leakage

between

terminals

and

from

poSItive

termlndl

to

hold

down

clamp

In

additIOn

to

current

leakage

prolonged

ac

cumulatIon

of

aCId

and

dirt

on

the

top

of

bat

tery

may

cause

bhstenng

of

the

material

covering

connector

straps

and

corrOSIOn

of

straps

After

tightening

terminals

coat

them

With

petrolatum

vasehnel

to

protect

them

from

corrosIOn

IGNITION

TIMING

Check

spark

plugs

and

dIstributor

breaker

pOints

for

conditIon

I

I

Thoroughly

wipe

off

dIrt

and

dust

from

tlmmg

j

marks

on

crank

pulley

and

front

cover

Warm

up

engine

suffiClently

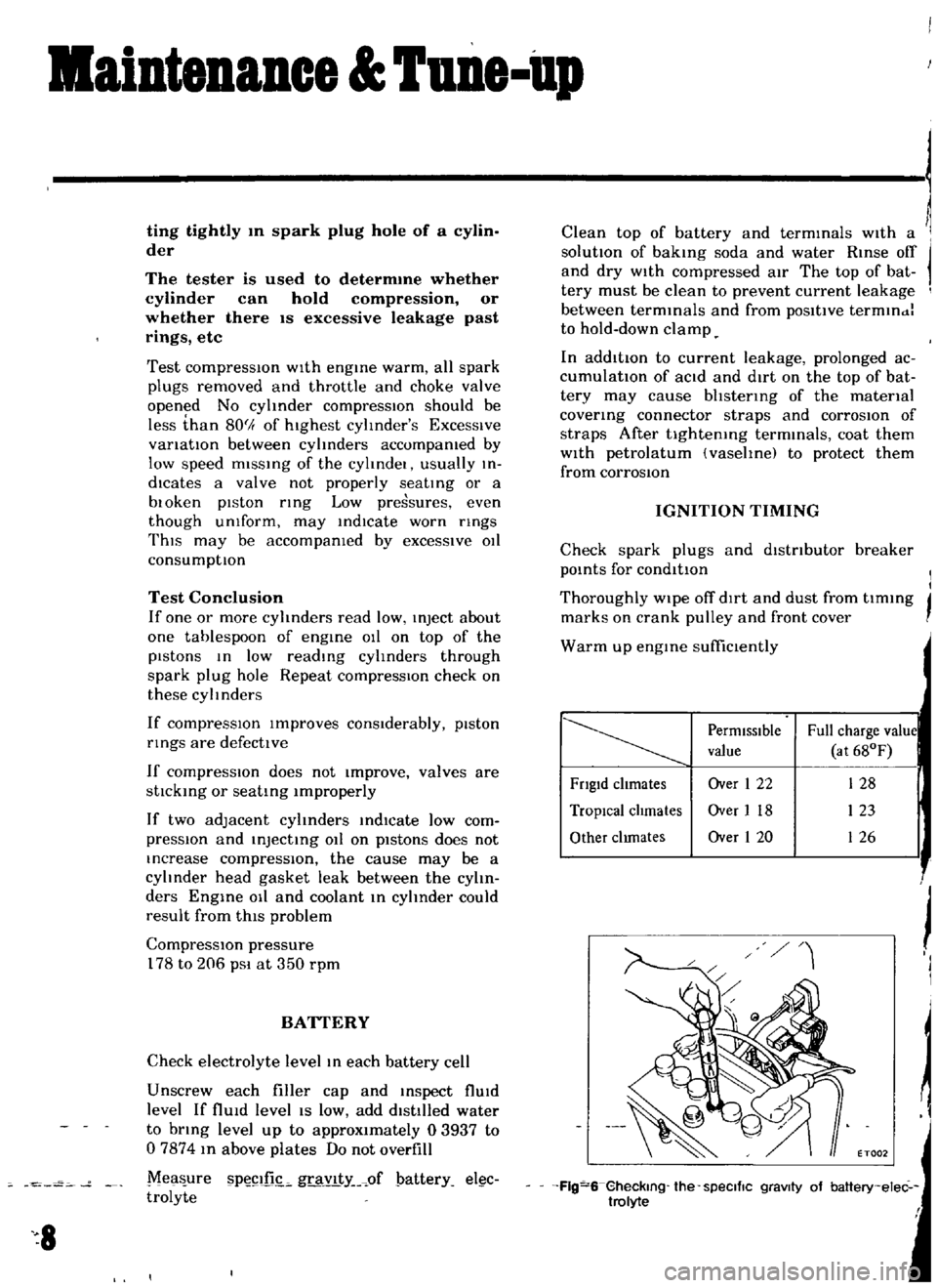

PermIssIble

Full

charge

value

value

at

68OF

Fngld

chmates

Over

1

22

128

TropIcal

chmates

Over

I

18

123

Other

clunates

Over

1

20

126

j

J

I

ET002

Flg

S

Gheckmg

the

speCific

gravity

of

baltery

elec

trolyte

f

Page 14 of 136

IQgiDe

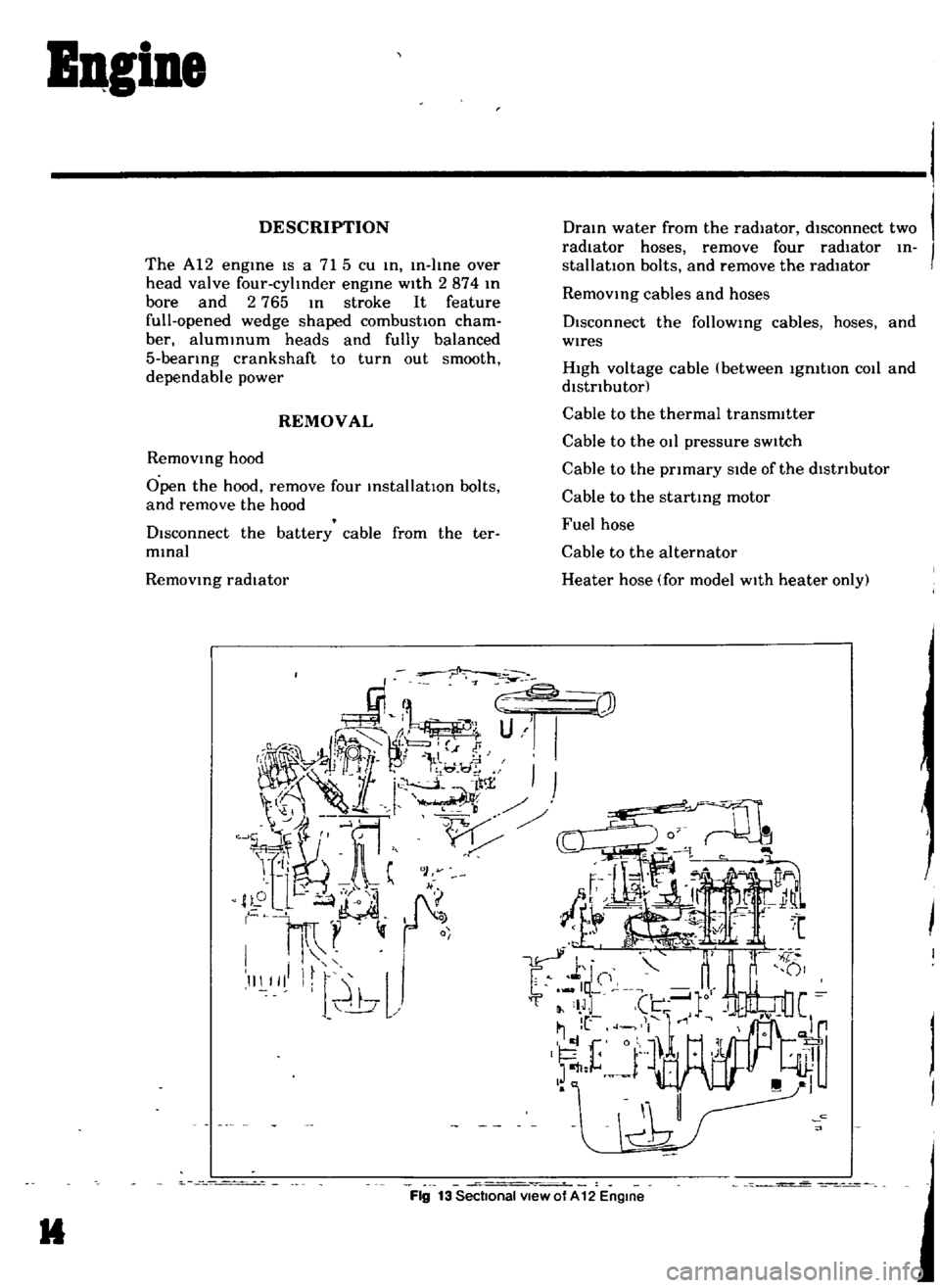

DESCRIPTION

The

A12

engme

IS

a

715

cu

m

In

I

me

over

head

valve

four

cyltnder

engine

with

2874

m

bore

and

2

765

m

stroke

It

feature

full

opened

wedge

shaped

combustIOn

cham

ber

alummum

heads

and

fully

balanced

5

bearmg

crankshaft

to

turn

out

smooth

dependable

power

REMOVAL

Removmg

hood

Open

the

hood

remove

four

mstallatlOn

bolts

and

remove

the

hood

Disconnect

the

battery

cable

from

the

ter

mmal

Removmg

radIator

Dram

water

from

the

radiator

disconnect

two

radIator

hoses

remove

four

radIator

m

stallatlOn

bolts

and

remove

the

radiator

Removmg

cables

and

hoses

Disconnect

the

followmg

cables

hoses

and

wires

High

voltage

cable

between

Igmtton

COlI

and

distributor

Cable

to

the

thermal

transmitter

Cable

to

the

011

pressure

sW1tch

Cable

to

the

primary

Side

of

the

distributor

Cable

to

the

startmg

motor

Fuel

hose

Cable

to

the

alternator

Heater

hose

for

model

With

heater

only

I

Fig

13

Sectional

view

of

A

12

Engine

It

Page 36 of 136

B1eetrical

Iptem

Removal

DIsconnect

the

battery

ground

cable

Disconnect

the

black

and

yellow

wIre

from

the

magnetic

sWitch

termmal

and

black

battery

cable

from

the

battery

termmal

Remove

two

bolts

used

to

secure

the

startmg

motor

on

the

clutch

housing

Pull

the

starter

assembly

forward

and

remove

the

starting

motor

Installation

InstallatlOn

IS

the

reversal

of

removal

Removal

Disconnect

the

negatIve

battery

termmal

DIsconnect

two

lead

wires

and

connector

from

the

alternator

Loosen

the

adjusting

bolt

Remove

the

alternator

drIve

belt

Remove

the

alternator

installation

bolt

Dismount

the

alternator

from

the

vehIcle

Installation

InstallatlOn

1S

the

reverse

of

removal

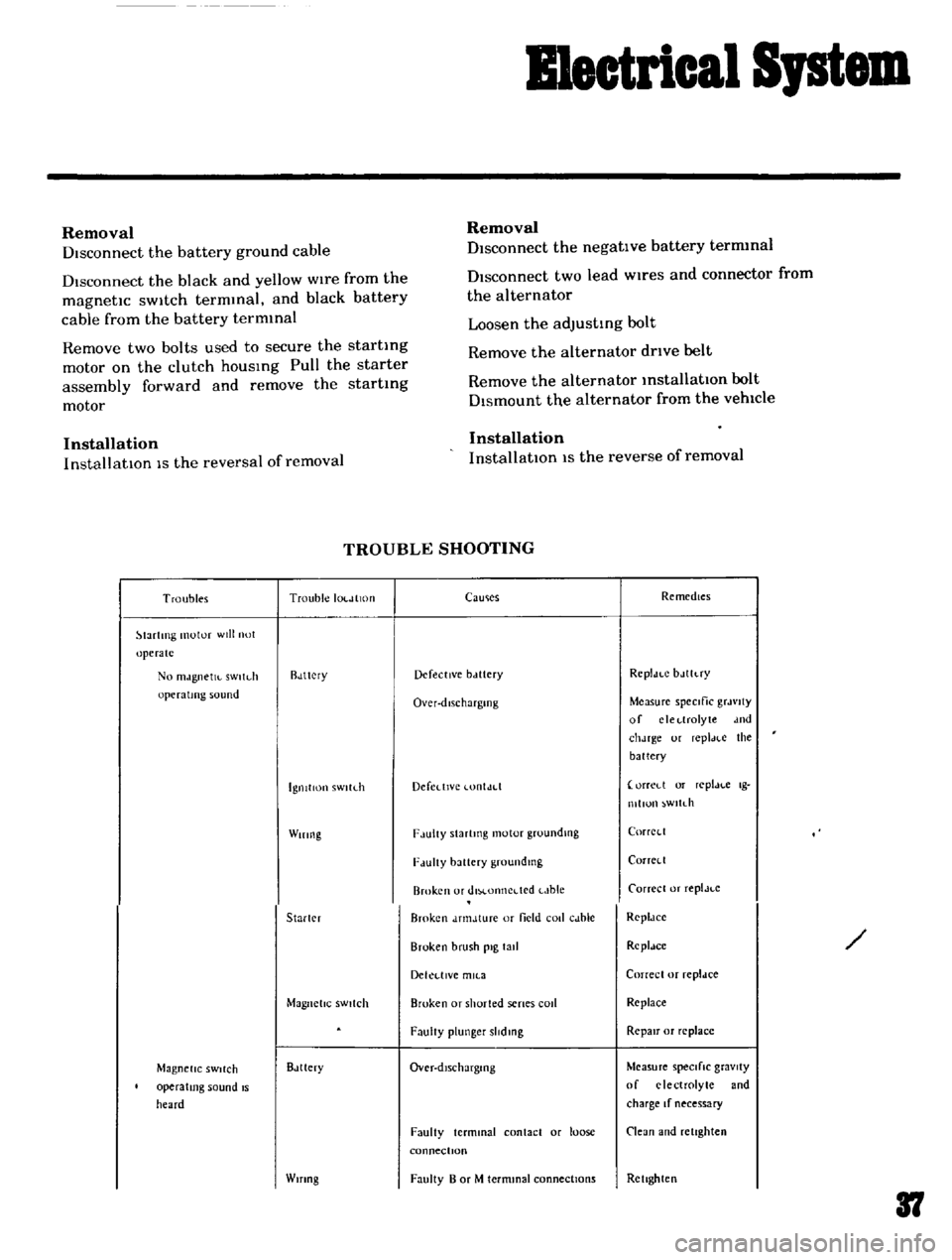

TROUBLE

SHOOTING

Troubles

Trouble

IOl

JlltHI

lartlTlg

motor

will

not

operate

No

mJgnetJl

sWltdl

operating

sound

Rdttcry

IgnitIon

sWltLh

Wiring

Starler

Magnetic

SWitch

Magnetic

SWitch

operating

sound

IS

heard

Bdttery

Wifing

CaUlies

Remedies

Defective

bclttery

Rcpldt

C

bJlh

ry

Over

dlschargmg

Measure

speCific

grJvlty

of

clcl

lrolyte

dnd

chJrge

ur

repl

H

e

the

battery

Defedlvc

lontJd

orreLl

or

replJl

c

Ig

mllun

wltdl

F

lulty

Slartmg

motor

groundlllg

CorrCl

l

F

lUlty

battery

groundmg

Corrcll

Broken

or

dlM

onncdcd

t

Jble

Carrece

or

replJt

c

Broken

dnnJture

or

field

coli

cJble

RcpldCC

Broken

brush

pig

tall

Rcpldce

Dekl

llVe

mll

3

Correcl

or

repldce

Broken

or

shorted

senes

cod

Replace

FaulIy

plunger

slidmg

RepaIr

or

replace

Over

dlschargmg

Measure

speCifiC

gravity

of

electrolyte

and

charge

If

necessary

Faulty

terminal

contact

or

loose

connectIOn

Clean

and

retighten

Faulty

B

or

M

termmal

connections

Rellghten

37

Page 37 of 136

Bmetrlcal

Spt

The

startmg

motor

rotates

PinIOn

gear

does

not

mtermec

h

with

flOg

gear

Pillion

mtermeshes

with

nng

gc

lT

Startmg

motor

roldles

Jud

pillion

Intermeshes

With

ring

gc

n

but

r

l

IlIan

IS

tou

slow

Startmg

motor

Magnetic

SWitch

Rmg

gear

Startmg

motor

Startmg

motor

Battery

Wiring

IgnitIOn

sWltl

h

Sldelmg

motor

38

Shorted

armature

or

field

cOIl

Worn

brush

or

Improper

spring

pressure

Contaminated

commutator

or

de

fective

mica

Faulty

brush

connection

Seized

metal

Armature

contacted

With

pole

core

Insufficient

plunger

L

dimenSIOn

Faulty

contact

Brok

en

or

shorted

shunt

call

wire

Worn

teeth

Weakened

pinion

sleeve

sprmg

Worn

pm

IOn

teeth

FJulty

plOlOJl

slldmg

Dropped

oft

lever

pill

EXl

hr

plunger

L

dlll1en

IOn

Defel

tlve

over

runnmg

dutch

Over

dlscharglOg

Improper

or

lome

termmdl

con

Lid

Improperly

tightened

connection

Rough

Lontact

urtJce

Shorted

armdture

COil

or

field

cOIl

Worn

brush

or

I11sufficlCnt

spnng

pressure

Conldmmated

Lomrnutator

or

Im

proper

brush

LonldLl

DercLllVe

nllca

Lack

or

metallubneallon

Armature

Lontdcted

With

pole

core

Repair

or

replace

Repair

or

replace

Cledn

or

repair

Repair

Replace

RepJlr

or

replace

AdjUst

ReplJee

Replace

ReplJee

Replnee

Rcpldce

RepJlr

Rep

m

Adjust

Re

place

Charge

battery

Repall

l11d

retIghten

Rellghten

RepJIr

or

replaLc

Repair

or

replace

Repair

or

replace

Repair

Repau

Repdlf

or

replace

Repair

or

replace

Page 42 of 136

lenition

Sptem

IGNITION

SECONDARY

COI

L

COI

L

CAP

BREAKER

POTNT

cr

r

7

W

tc

l

uToRI

8

TO

STARTER

l

J

ROTOR

HEAD

SPARK

PLUG

Fig

19

Igmtlon

system

Circuit

diagram

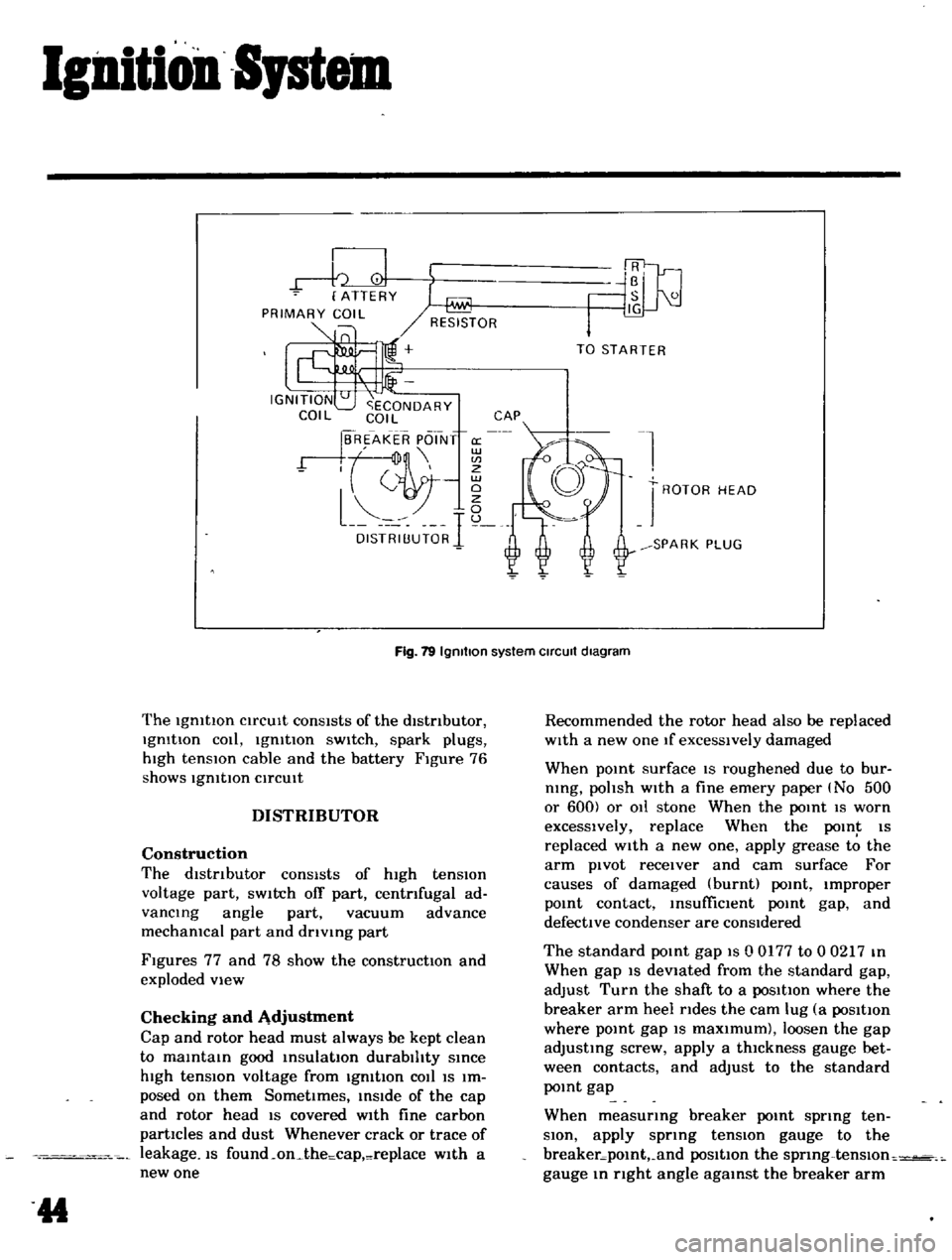

The

IgmtlOn

CirCUIt

conSIsts

of

the

distributor

IgmtIon

cOli

IgmtIon

sWitch

spark

plugs

hIgh

tensIOn

cable

and

the

battery

Figure

76

shows

IgmtlOn

CirCUIt

DISTRIBUTOR

Construction

The

dIstributor

consists

of

high

tension

voltage

part

SWitch

off

part

centrifugal

ad

vancing

angle

part

vacuum

advance

mechamcal

part

and

drlvmg

part

Figures

77

and

78

show

the

constructIOn

and

exploded

view

Checking

and

Adjustment

Cap

and

rotor

head

must

always

be

kept

clean

to

maintain

good

insulation

durability

since

high

tensIOn

voltage

from

IgmtIon

cOil

IS

Im

posed

on

them

SometImes

inside

of

the

cap

and

rotor

head

IS

covered

wIth

fine

carbon

partIcles

and

dust

Whenever

crack

or

trace

of

leakage

IS

found

on

the

cap

replace

w1th

a

new

one

44

Recommended

the

rotor

head

also

be

replaced

wIth

a

new

one

If

excessively

damaged

When

pomt

surface

IS

roughened

due

to

bur

nlng

polish

with

a

fine

emery

paper

No

500

or

600

or

011

stone

When

the

point

IS

worn

excessively

replace

When

the

POIn

IS

replaced

with

a

new

one

apply

grease

to

the

arm

pivot

receiver

and

cam

surface

For

causes

of

damaged

burnt

point

Improper

pomt

contact

msufficlent

point

gap

and

defective

condenser

are

conSidered

The

standard

pomt

gap

IS

0

0177

to

0

0217

m

When

gap

IS

devIated

from

the

standard

gap

adjust

Turn

the

shaft

to

a

posItIon

where

the

breaker

arm

heel

rides

the

cam

lug

a

posItIon

where

pomt

gap

IS

maxImum

loosen

the

gap

adjusting

screw

apply

a

thIckness

gauge

bet

ween

contacts

and

adjust

to

the

standard

pomt

gap

When

measurmg

breaker

pomt

spring

ten

SIOn

apply

sprmg

tensIOn

gauge

to

the

breaker

pomt

and

posItIon

the

sprmg

tenslOn

gauge

m

right

angle

agamst

the

breaker

arm

Page 121 of 136

Specifications

SERVICE

DATA

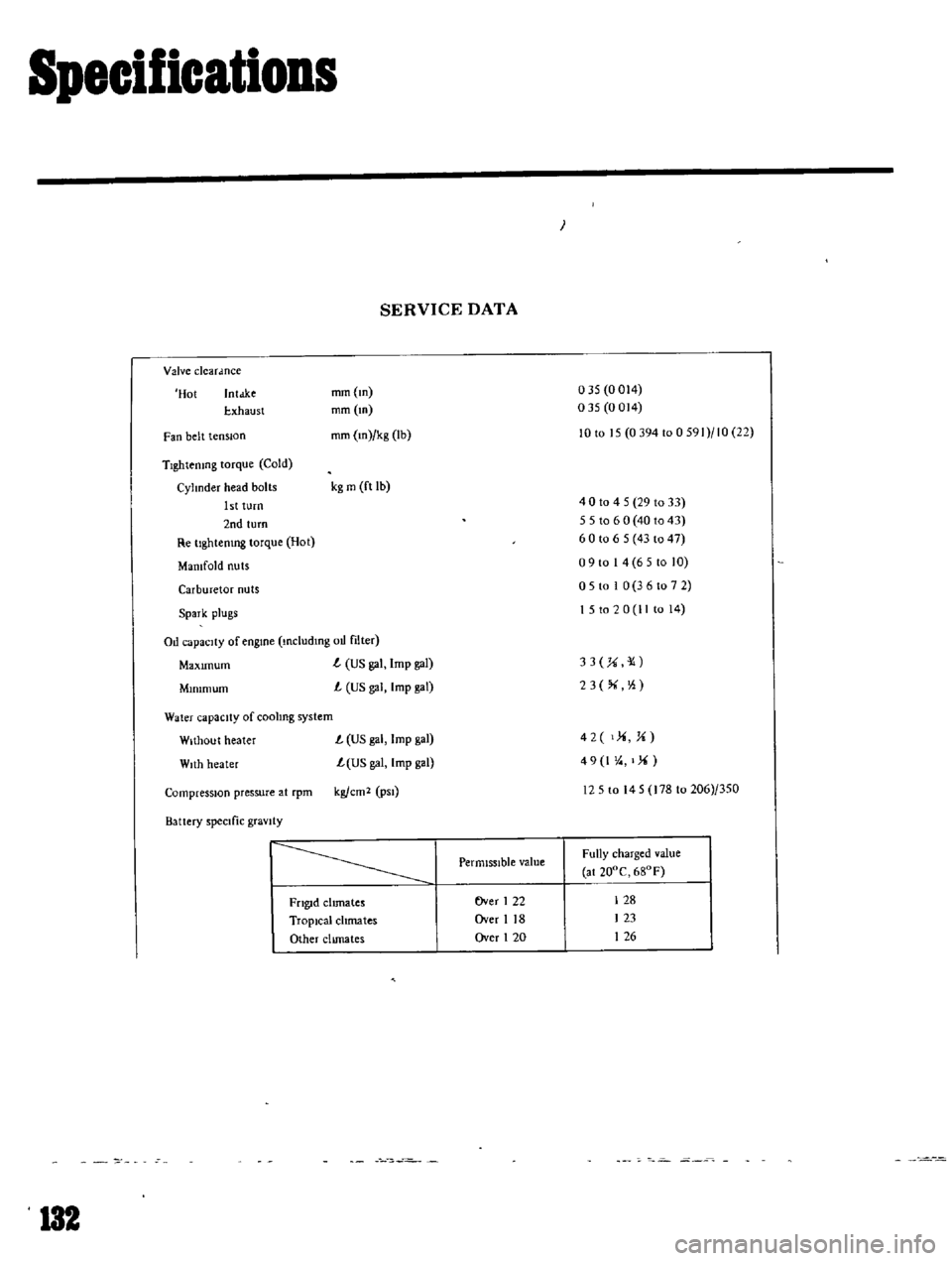

Valve

clearJnce

IHot

mm

In

mm

In

mm

In

kg

Ib

Intdke

exhaust

Fan

belt

tensIOn

Tlghtemng

torque

Cold

Cyhnder

head

bolts

kg

m

ft

Ib

1st

turn

2nd

turn

Re

l1ghtemng

torque

Hot

Mamfold

nuts

Carburetor

nuts

Spark

plugs

ad

capacIty

of

engine

including

od

filter

Maximum

L

US

gal

Imp

gal

L

US

gal

Imp

gal

Mmlmum

Water

capacity

of

coohng

system

Wllhout

heater

L

US

gal

Imp

gal

W

th

heater

L

US

gal

Imp

gal

CompressIOn

pressure

at

rpm

kg

cm2

PSI

Battery

specific

gravity

FrigId

climates

Tropical

clImates

Other

climates

132

Permlsslble

value

rlver

I

22

Over

118

Over

I

20

035

0014

035

0014

10

to

15

0

394

to

0

591

10

22

40

to

4

5

29

to

33

5

5

to

6

0

40

to

43

60

to

6

5

43

to

47

09toI4

65toI0

o

5

to

I

0

3

6

to

7

2

I

5

to

2

0

II

to

14

33

l

2

3

10

42

Ji

49

1

4

IJi

125

to

145

78

to

206

350

Fully

charged

value

at

20

C

68

F

128

123

126

Page 136 of 136

f

Vltl

vf

@1rmml

IB

t

@

@

i

IICi

r

j

h

i

l

r

t

j

tr

f

t

t

r

Y

f

J

Jt

j

k

h

rl

il

o

J

0

r

t

J

I

l

I

AUTOBODYREP

IRINGANDREFINISHIiilG

bY

EB

Weston

I

J

l

J

1

f

Tills

book

delve

S

deeply

into

the

illghly

cqmp

tit1ve

auto

body

repair

trade

Every

possible

ph

e

1S

I

i

chscussed

and

explaIneg

in

hght

of

the

correct

repair

techniques

and

tools

to

be

used

to

return

a

damaged

auto

to

hke

new

conchtion

Topics

such

as

construction

matenals

welding

hand

tools

and

auto

body

des1gn

are

Just

a

fe

Y

of

the

major

areas

clearly

exp

a

ned

in

tills

text

Des1gned

to

serve

as

a

shop

manual

for

auto

body

men

and

as

a

reference

tool

for

the

owners

of

auto

repair

snops

1t

is

a

must

for

any

well

equ1pped

school

shop

or

hbrary

l

f

SBN

87749

030

9

8

95

m

r

MOTOR

RACING

THEGRANnPRIX

GltEATS

by

Barne

Gill

p

j

Barrie

Gill

the

internationally

famous

racmg

expert

has

created

a

book

that

offers

po

rtr

ts

Of

te

f

contenders

for

the

honor

of

bemg

the

greatest

dnver

of

them

all

Graham

Hdl

Strrhng

Moss

Jochen

of

Rmdt

Juan

Manuel

FangIO

Denny

Hulme

Mike

Hawthorn

Jun

Clark

JaCk

Brabham

Bruce

McLaren

f

and

J

ckie

tewart

Each

man

IS

chscussed

in

tills

book

by

the

spons

writers

who

knew

hun

the

best

and

who

shared

h1s

triumphs

and

trageches

Th1S

book

WIll

gIve

every

rac1ng

enthus1ast

a

fresh

lively

and

min

e

look

at

some

of

the

world

s

most

colorful

and

courageous

sportsmen

t

t

SBN

87749

229

8

5

95

f

i

1

1

j

r

i

I

f

i

if

r

r

e

i

f

f

I

1

q

I

ll

1

C

i

f

rt

A

t

MOTIVE

A

CESS

RiES

REPAIR

GUIDE

by

Edward

J

Mezo

4

t

1t

1

I

Ort

r

f

tPt

1

P

L

k

complete

treatise

on

the

latest

automotive

accessory

developments

and

repamng

adJustment

and

l

duiinoslsmeth6ds

or

the

automobde

oV

ller

and

the

professional

mecharuc

r

t

The

book

discusses

air

conchtio

ning

brake

release

signals

cigarette

lighters

electnc

clocks

tiinI

slgnal

t

j

1

y

inchca

ors

ilOwer

seats

power

WIndow

hfts

speedomete

rs

and

WIndsh1eld

washers

and

WIpers

There

s

J1

even

a

spec1al

section

devoted

to

controls

for

the

hanchcapped

t

i

l

i

I

SOl

l

I

e

n

11

4

t

j

rh

f

J1

1

1

t

j

I

SBN

87749

1

28

3

pap

erqi

I

li

i

hv

r

I

f

SBN

87749

129

1

1

J

3

95

r

j

l

1

J

J

t

LECrRONIC

PRO

nj

OI

t

CAR

AND

GARAGE

by

R

M

Marston

1

f

y

q

lk

t

Tills

b60k

cOntains

a

oore

of

simple

and

very

useful

i

lectnc

devices

that

can

be

made

at

homeifbt

the

car

r

t

l

J

and

garage

Included

are

circuits

for

tHe

car

that

warD

of

danger

from

ice

and

overheating

an

automatiC

f

i

WIndsilleld

per

contro

and

an

automatic

sldelight

SWItch

Twc

projectll

that

WIl

be

of

a

h

p

in

th

e

C

1

garage

are

a

self

regulating

battery

charger

and

a

speed

control

for

electric

dnlls

I

t

Each

project

1S

descnbed

by

luc1d

and

easily

understandable

instructions

and

dlust

r

ated

I

lY

clear

diagrams

All

necessary

components

are

listed

for

each

device

Tills

book

will

be

of

great

value

to

all

car

owners

mecharucs

and

electnc1ans

SBN

87749

132

1

595

t

t

1

f

r

TUNING

YOBR

BRITISH

SPORTSCAR

by

Charles

Williams

1

This

book

WIll

help

owners

ofj

rit1sh

made

cars

tune

them

for

maxunum

power

and

sPeOO

TUNING

1

r

YOUR

BRITISH

SPORTSCAR

gives

a

non

technIcal

but

practical

gu1de

to

how

famdy

cars

can

be

made

f

to

behave

more

h

te

port

cars

AI

added

feature

1S

a

hst

of

major

American

suppliers

of

the

British

made

r

t

auto

parts

d1Scussoo

m

tills

book

TUNING

YOUR

BRITISH

SPORTSCAR

is

profusely

1llustrate9

WIth

1

many

photos

and

diagrams

H

l

SBN

87749

165

8

7

95

t

DRAKE

RUBUSHERS

INC

381

P

ARKAVENUESQUTH

N

Y

N

Y

10016

cp

l