belt DATSUN B110 1969 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 8 of 136

ainteDaDee

TUDe

up

VAL

VE

CLEARANCES

Valve

clearance

adjustment

should

be

made

while

engme

IS

stationary

To

adjust

proceed

as

follows

Start

engme

and

run

It

until

It

IS

heated

to

operatIng

temperature

or

at

least

more

than

17S

of

engIne

011

temperature

then

stop

engIne

Rotate

crankshaft

to

bnng

No

1

cylInder

In

top

dead

center

on

ItS

compressIOn

stroke

Remove

valve

rocker

cover

to

gaIn

access

to

valve

operatIng

mechamsm

Adjust

valve

clearance

at

follOWing

four

pOints

while

engIne

IS

still

hot

1

Exhaust

valve

of

No

1

cylinder

2

Intake

valve

of

No

1

cylinder

3

Intake

valve

of

No

2

cylinder

5

Exham

t

valve

of

No

3

cylInder

ote

Numbers

in

parenthesis

agree

with

those

10

accompanY1Og

sketch

AgaIn

rotate

crankshaft

one

turn

so

that

No

4

piston

IS

In

top

dead

center

on

ItS

com

pressIOn

stroke

Adjust

follOWIng

valves

4

Exhaust

valve

of

No

2

cylinder

6

Intake

valve

of

No

3

cylinder

7

Intake

valve

of

No

4

cylInder

8

Exhaust

valve

of

No

4

cylinder

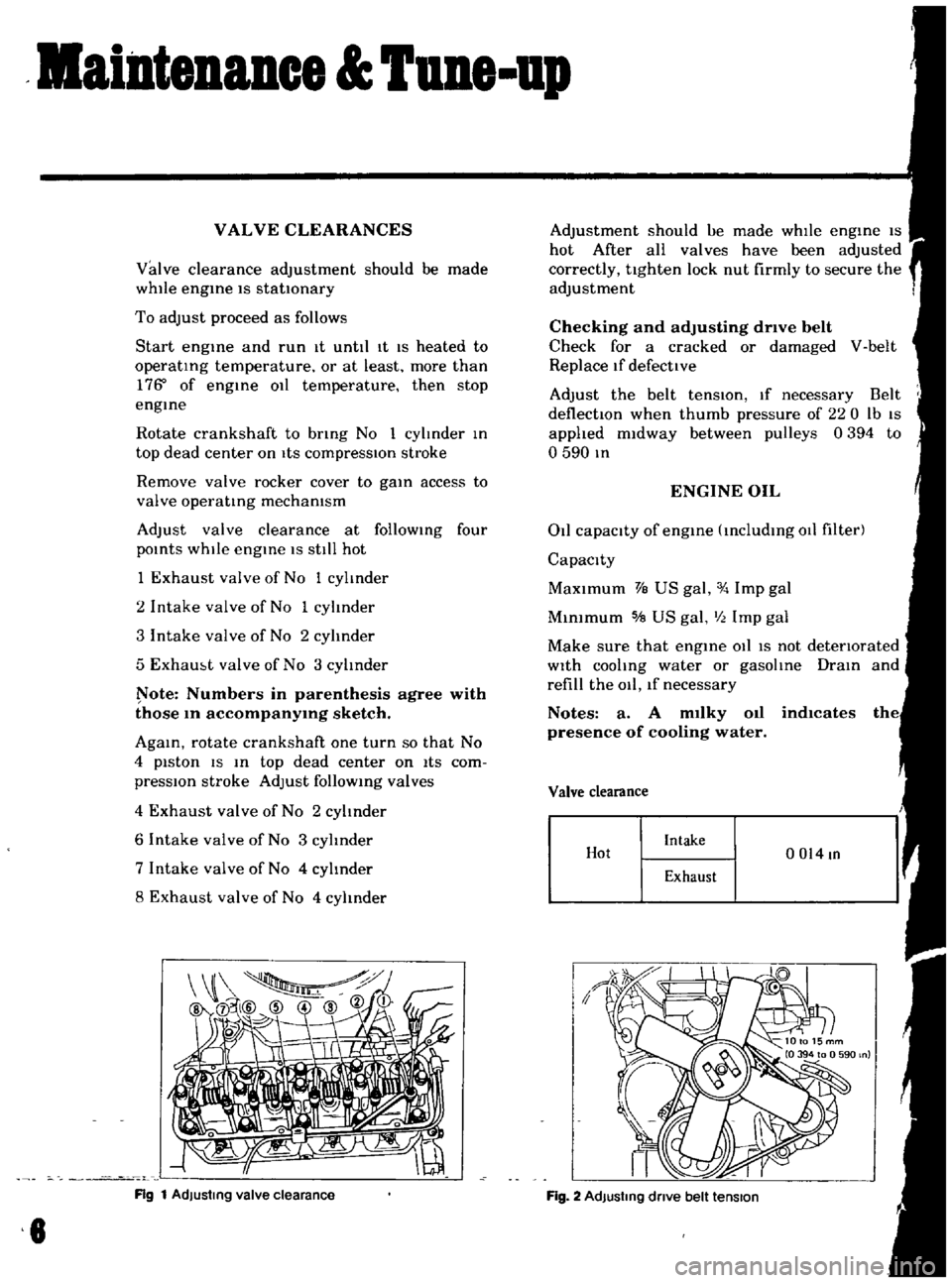

Rg

1

AdJustmg

valve

clearance

8

Adjustment

should

ue

made

whIle

engIne

IS

hot

After

all

valves

have

been

adjusted

correctly

tighten

lock

nut

firmly

to

secure

the

adjustment

Checking

and

adjusting

drive

belt

Check

for

a

cracked

or

damaged

V

belt

Replace

If

defective

Adjust

the

belt

tenSIOn

If

necessary

Belt

deflectIOn

when

thumb

pressure

of

220

Ib

IS

applied

midway

between

pulleys

0394

to

o

590

In

ENGINE

OIL

011

capacity

of

engIne

IncludIng

011

filter

Capacity

MaXimum

VB

US

gal

Imp

gal

MInimum

5IB

US

gal

III

Imp

gal

Make

sure

that

engIne

011

IS

not

detenorated

With

cooling

water

or

gasolIne

DraIn

and

refill

the

011

lf

necessary

Notes

a

A

m1lky

011

indlcates

presence

of

cooling

water

Valve

clearance

Hot

Intake

0014

In

Exhaust

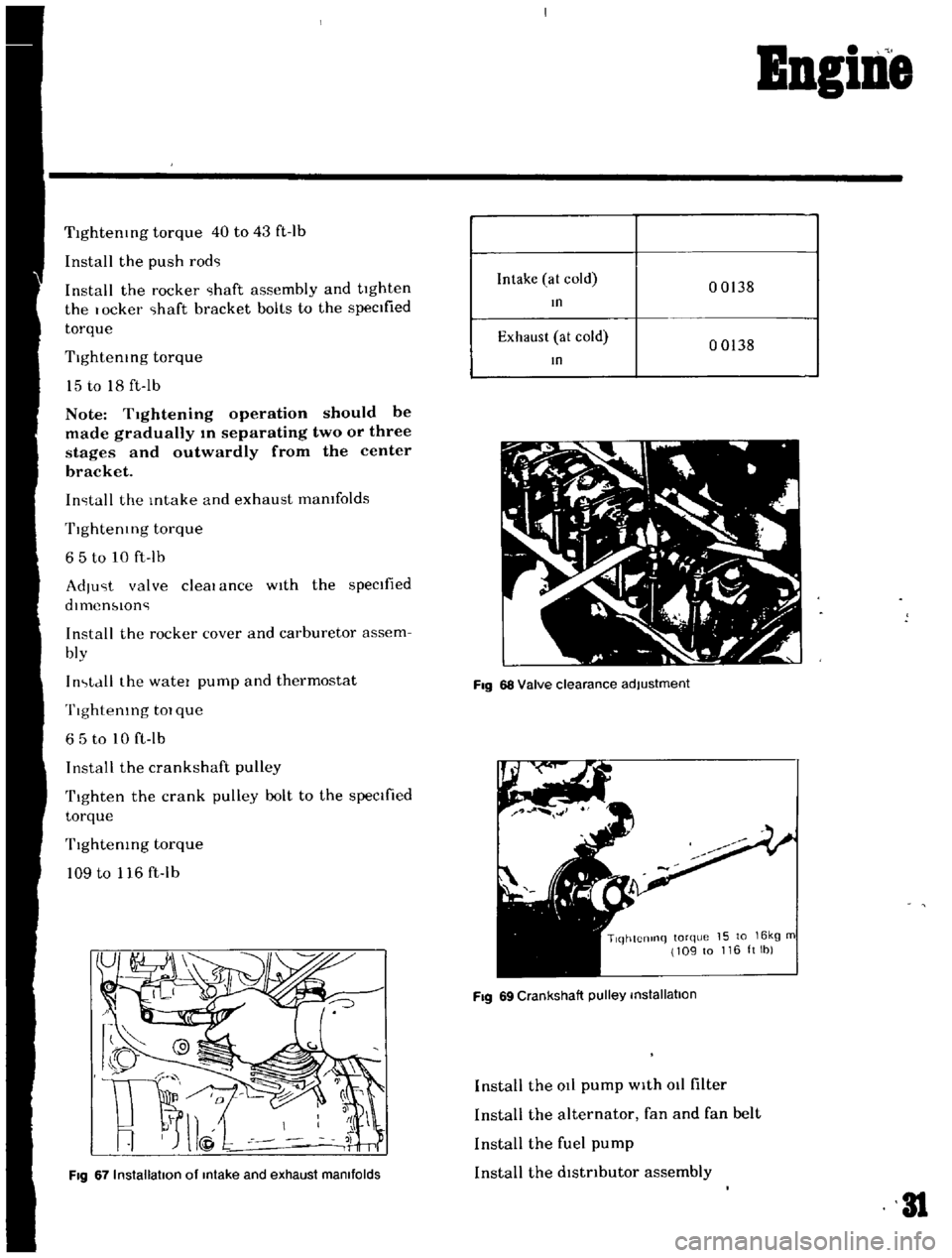

Fig

2

AdJustmg

dnve

belt

tension

Page 31 of 136

BDgiDe

TIghtening

torque

40

to

43

ft

Ib

Install

the

push

rod

Install

the

rocker

haft

assembly

and

tighten

the

I

ocker

haft

bracket

bolts

to

the

specIfied

torque

Tightening

torque

15

to

18

ft

lb

Note

TIghtening

operation

should

be

made

gradually

10

separating

two

or

three

stages

and

outwardly

from

the

center

bracket

In

tall

the

Intake

and

exhaust

mamfolds

TIghtening

torque

65

to

10

ft

lb

AdJu

t

valve

clemance

wIth

the

specIfied

dlmenblOn

Install

the

rocker

cover

and

carburetor

assem

bly

I

n

tdll

the

watel

pump

and

thermostat

Tlghtemng

tOl

que

65

to

10

ft

lb

I

nstall

the

crankshaft

pulley

Tighten

the

crank

pulley

bolt

to

the

specIfied

torque

TIghtenIng

torque

109

to

116

ft

lb

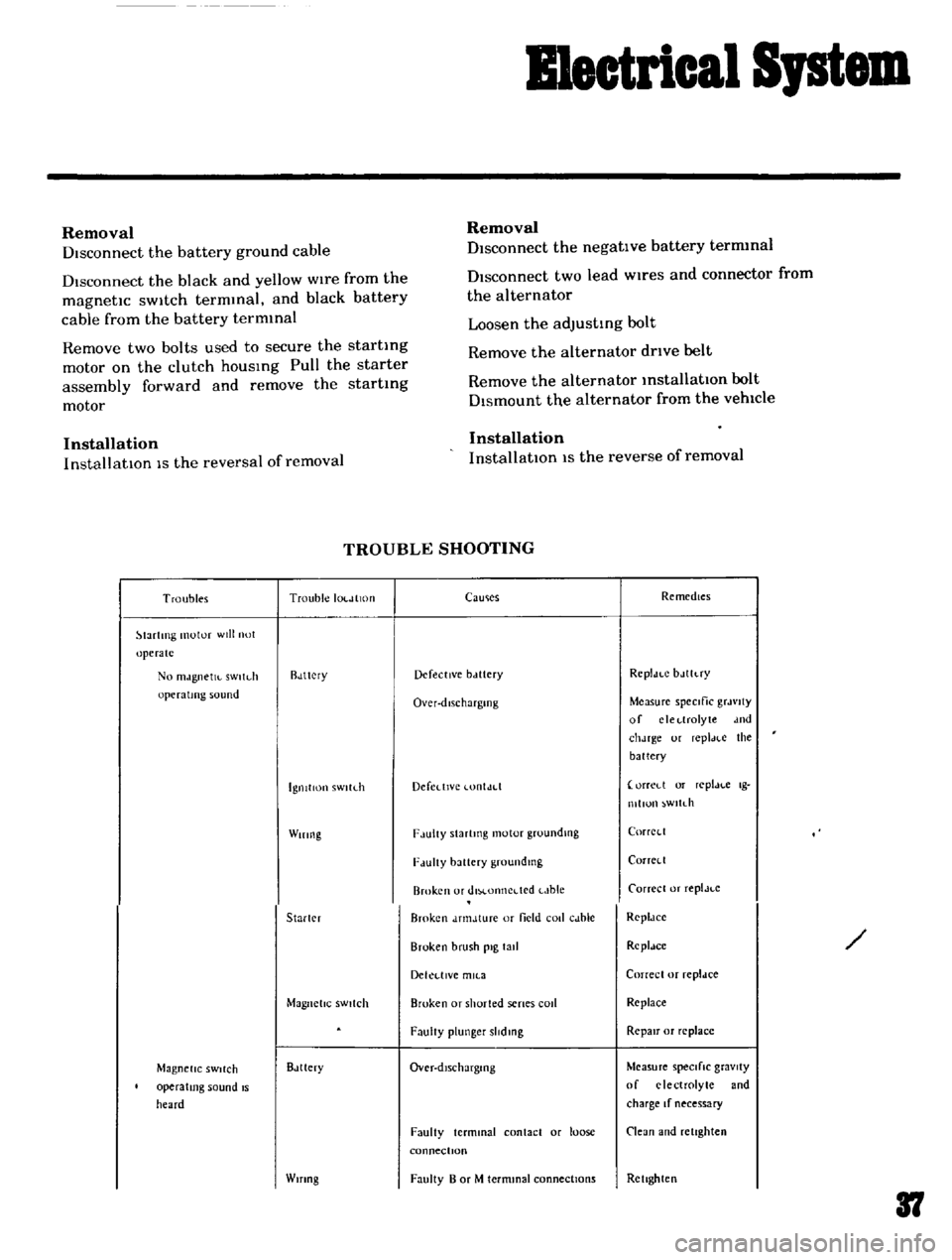

Fig

67

Installation

of

Intake

and

exhaust

manifolds

Intake

at

cold

00138

In

Exhaust

at

cold

00138

In

Fig

68

Valve

clearance

adjustment

TlqhtCnlnq

torque

15

to

16kg

m

109

to

116ltlb

Fig

69

Crankshaft

pulley

installation

Install

the

at

pump

with

011

filter

Install

the

alternator

fan

and

fan

belt

Install

the

fuel

pump

Install

the

dlstnbutor

assembly

31

Page 36 of 136

B1eetrical

Iptem

Removal

DIsconnect

the

battery

ground

cable

Disconnect

the

black

and

yellow

wIre

from

the

magnetic

sWitch

termmal

and

black

battery

cable

from

the

battery

termmal

Remove

two

bolts

used

to

secure

the

startmg

motor

on

the

clutch

housing

Pull

the

starter

assembly

forward

and

remove

the

starting

motor

Installation

InstallatlOn

IS

the

reversal

of

removal

Removal

Disconnect

the

negatIve

battery

termmal

DIsconnect

two

lead

wires

and

connector

from

the

alternator

Loosen

the

adjusting

bolt

Remove

the

alternator

drIve

belt

Remove

the

alternator

installation

bolt

Dismount

the

alternator

from

the

vehIcle

Installation

InstallatlOn

1S

the

reverse

of

removal

TROUBLE

SHOOTING

Troubles

Trouble

IOl

JlltHI

lartlTlg

motor

will

not

operate

No

mJgnetJl

sWltdl

operating

sound

Rdttcry

IgnitIon

sWltLh

Wiring

Starler

Magnetic

SWitch

Magnetic

SWitch

operating

sound

IS

heard

Bdttery

Wifing

CaUlies

Remedies

Defective

bclttery

Rcpldt

C

bJlh

ry

Over

dlschargmg

Measure

speCific

grJvlty

of

clcl

lrolyte

dnd

chJrge

ur

repl

H

e

the

battery

Defedlvc

lontJd

orreLl

or

replJl

c

Ig

mllun

wltdl

F

lulty

Slartmg

motor

groundlllg

CorrCl

l

F

lUlty

battery

groundmg

Corrcll

Broken

or

dlM

onncdcd

t

Jble

Carrece

or

replJt

c

Broken

dnnJture

or

field

coli

cJble

RcpldCC

Broken

brush

pig

tall

Rcpldce

Dekl

llVe

mll

3

Correcl

or

repldce

Broken

or

shorted

senes

cod

Replace

FaulIy

plunger

slidmg

RepaIr

or

replace

Over

dlschargmg

Measure

speCifiC

gravity

of

electrolyte

and

charge

If

necessary

Faulty

terminal

contact

or

loose

connectIOn

Clean

and

retighten

Faulty

B

or

M

termmal

connections

Rellghten

37

Page 39 of 136

Blectrical

Sptem

Troubles

Trouble

locatIon

Not

output

Alternator

Regulator

WIring

Low

output

Alterndtor

Regulator

Wifing

TROUBLE

SHOOTING

Causes

Sl1ckmg

brushes

Duty

brushes

and

slIp

nngs

Loose

connections

or

broken

leads

Open

stator

coLI

Open

rotor

cotl

DefectIVe

dJodes

Shorted

rotor

Shorted

stator

Grounded

A

ternunal

Broken

fan

belt

FJulty

voltage

regulator

pomt

con

tact

Broken

cable

or

disconnectIOn

of

chargIng

CIH

UIt

StIcking

brushes

Low

brush

spring

tenSion

Duty

slIp

nngs

Partially

shorted

ground

or

open

stator

cod

Partially

shorted

or

grounded

rotor

c01l

DefectIVe

dIOde

Loose

or

worn

fan

belt

Improper

voltage

regulator

adlust

Pl

n

I

Faulty

voltage

regulator

pomt

con

t

ct

Defective

operation

Faulty

chargmg

CUI

Ult

lead

WIn

connection

Remedies

Correct

or

replace

brush

and

brush

spnng

aean

RetIghten

or

solder

connection

Replace

leads

If

necessary

6

RepaIr

or

replace

the

stator

coLi

Replace

the

rotor

Replace

the

dIOde

assembly

Replace

the

rotor

RepaIr

or

replace

the

stator

Replace

the

Insulator

Replace

the

belt

RepdU

01

replace

the

regulator

Repdtr

or

replace

Correct

or

replace

brushes

If

neces

sary

Correct

or

replace

brush

Clean

Replace

the

stator

Replace

the

rotor

Replace

the

dIode

assembly

Rettghlen

or

replace

the

belt

Check

the

voltage

regulalor

op

eratIOn

no

rep

Jr

r

J

j

required

Repair

or

replace

the

regulator

Re

olf

or

rpla

e

t

J

Loose

baltery

leririmaJ

Rettghten

1

Page 61 of 136

GooliDI

Sptem

mechamsm

IS

adopted

to

prevent

the

water

leakage

and

nOIse

completely

Note

The

water

pump

must

not

be

disassembled

since

the

bearings

are

shrmkage

fitted

to

their

bores

If

any

part

of

water

pump

is

found

defective

replace

pump

assembly

Removal

Dram

coolmg

water

completely

Take

the

fan

belt

ofT

the

pulley

Remove

fan

and

pulley

Remove

the

water

pump

Installation

InstallatIOn

IS

the

reverse

of

removal

THERMOSTAT

A

pellet

type

thermostat

IS

used

m

the

water

outlet

passage

to

control

the

flow

of

coolant

provldmg

fast

engme

warm

up

and

regulatmg

coolant

temperature

A

wax

pellet

m

the

ther

mo

tat

expands

when

heated

and

contracts

when

cooled

The

pellet

IS

connected

through

a

piston

to

a

valve

and

when

the

pellet

IS

heated

pressure

IS

exerted

agamst

a

rubber

dIaphragm

and

the

valve

opens

As

the

pellet

IS

cooled

the

contractIOn

allows

the

sprmg

to

close

the

valve

Removal

Dram

coohng

water

Remove

radiator

hose

Remove

water

outlet

elbow

Then

take

out

the

thermostat

Inspection

To

test

the

thermostat

for

proper

operatmg

temperature

submerg

he

umt

m

a

contamer

of

water

Heat

the

water

and

observe

the

tem

perature

Measure

temperature

when

the

thermostat

valve

Just

starts

rlsmg

If

thermostat

does

not

operate

at

the

above

specIfied

temperatures

It

must

be

replaced

Installation

When

mstalhng

the

thermostat

apply

adheSIve

Three

Bond

to

both

SIdes

of

the

packmg

for

preventIOn

of

water

leakage

In

stall

the

thermostat

m

reverse

sequence

of

removal

USA

Canadd

Olher

coun

t

nes

Valve

opemng

temperature

177

to

r8710

16710

F

183

193

173

Valve

lIft

O

oF

031

203

031

212

031

194

WI

fL

g

0

I

l

1

L

JI

I

I

I

I

a

J

i

o

wa

r

outlet

EI

Thermostat

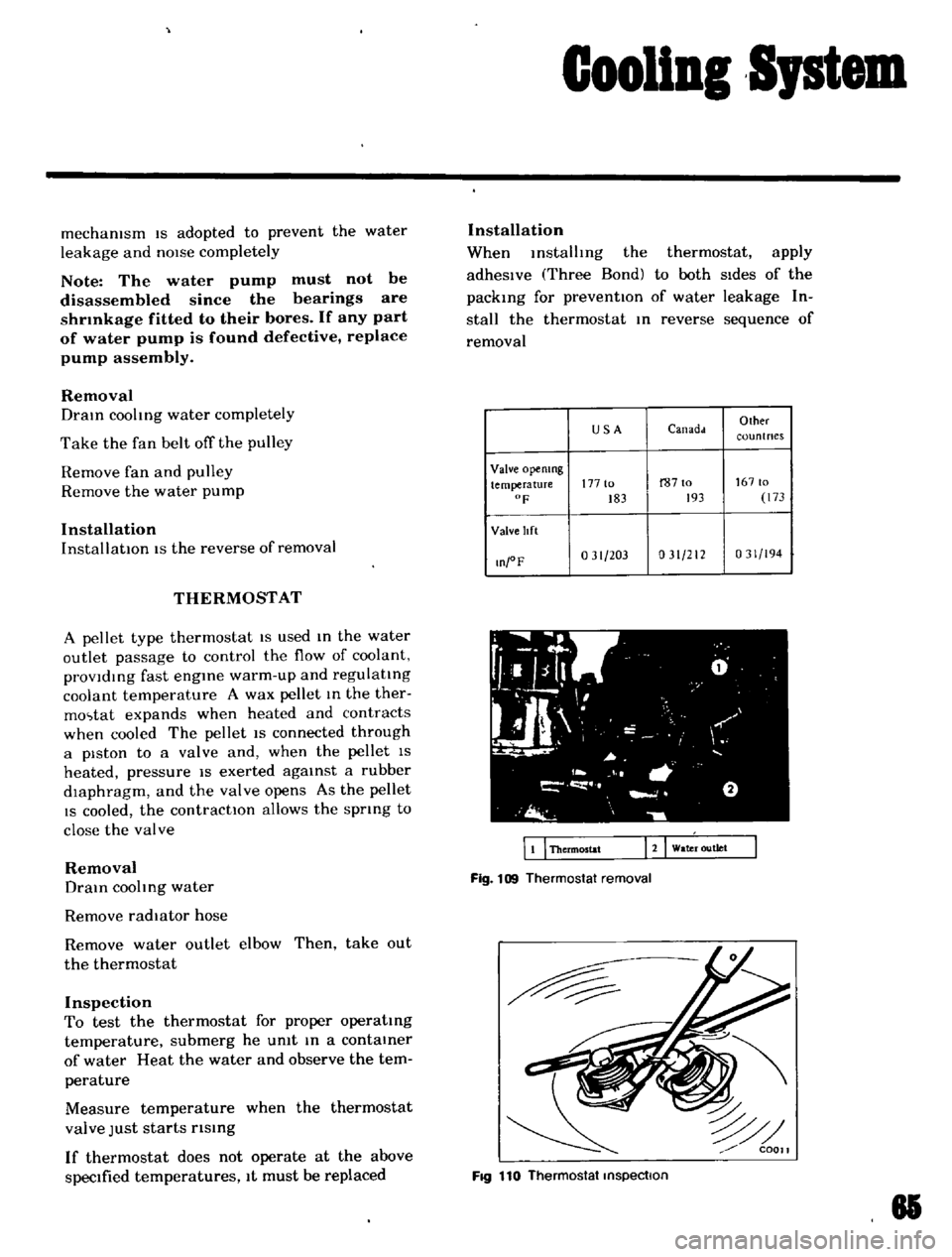

Fig

109

Thermostat

removal

FIQ

110

Thermostat

inspection

81

Page 121 of 136

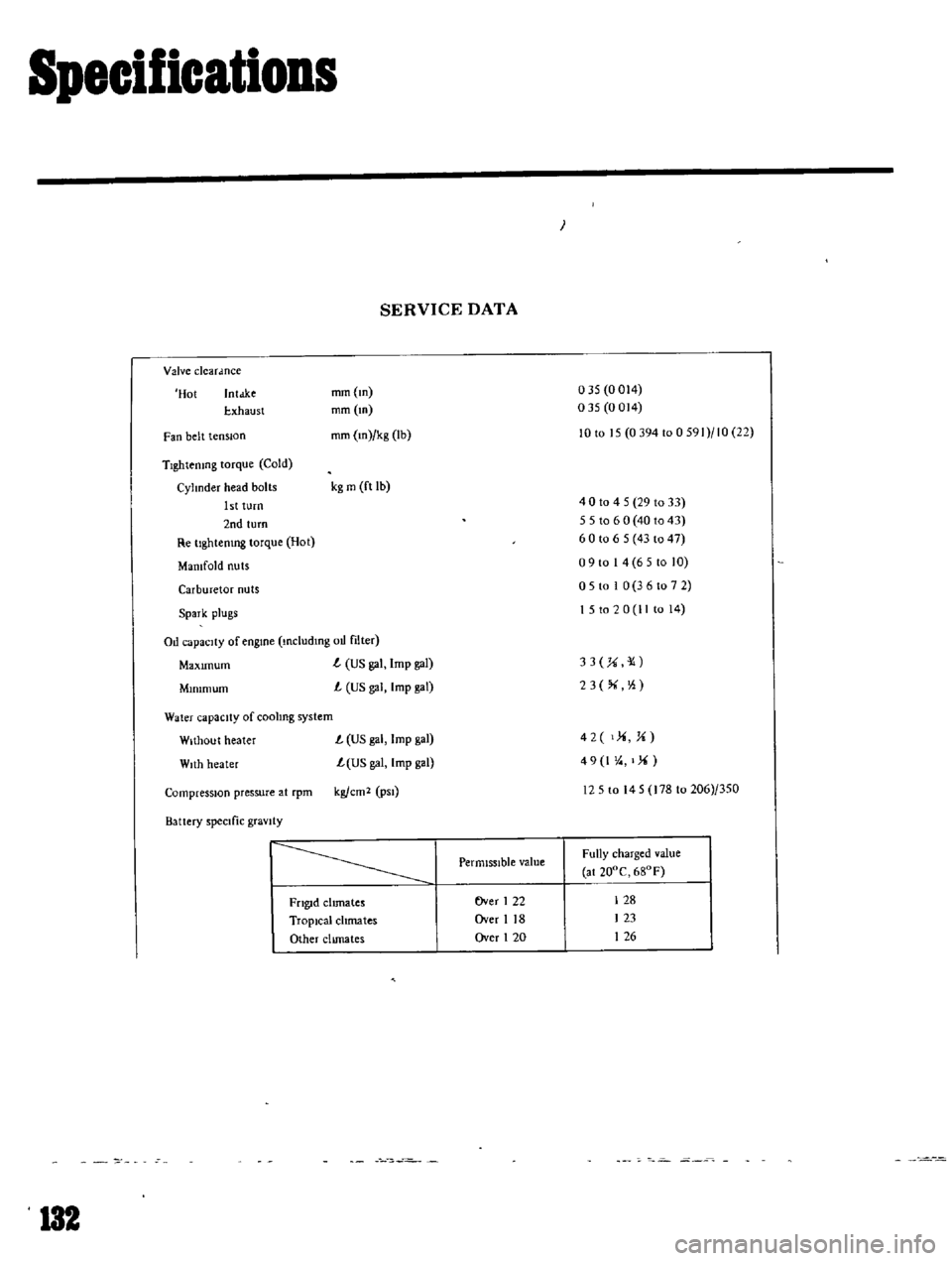

Specifications

SERVICE

DATA

Valve

clearJnce

IHot

mm

In

mm

In

mm

In

kg

Ib

Intdke

exhaust

Fan

belt

tensIOn

Tlghtemng

torque

Cold

Cyhnder

head

bolts

kg

m

ft

Ib

1st

turn

2nd

turn

Re

l1ghtemng

torque

Hot

Mamfold

nuts

Carburetor

nuts

Spark

plugs

ad

capacIty

of

engine

including

od

filter

Maximum

L

US

gal

Imp

gal

L

US

gal

Imp

gal

Mmlmum

Water

capacity

of

coohng

system

Wllhout

heater

L

US

gal

Imp

gal

W

th

heater

L

US

gal

Imp

gal

CompressIOn

pressure

at

rpm

kg

cm2

PSI

Battery

specific

gravity

FrigId

climates

Tropical

clImates

Other

climates

132

Permlsslble

value

rlver

I

22

Over

118

Over

I

20

035

0014

035

0014

10

to

15

0

394

to

0

591

10

22

40

to

4

5

29

to

33

5

5

to

6

0

40

to

43

60

to

6

5

43

to

47

09toI4

65toI0

o

5

to

I

0

3

6

to

7

2

I

5

to

2

0

II

to

14

33

l

2

3

10

42

Ji

49

1

4

IJi

125

to

145

78

to

206

350

Fully

charged

value

at

20

C

68

F

128

123

126