service DATSUN B110 1969 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 2 of 136

lI

I

DATSUN

1200

RANGE

1971

1973

MAINTENANCE

REPAIR

BY

DRAKE

AUTOMOTIVE

EDITORS

Quick

Referencelodel

MAINTENANCE

TUNE

UP

5

STEERING

89

ENGINEERING

13

REAR

DRIVE

ELECTRICAL

SYSTEM

35

SUSPENSION

93

IGNITION

SYSTEM

43

CLUTCH

99

FUEL

SYSTEM

49

TRANSMISSION

103

COOLING

SYSTEM

63

BODY

WORK

111

BRAKES

67

SPECIFICATIONS

129

FRONT

SUSPENSION

83

The

purpose

of

this

manual

IS

to

provide

the

automobile

owner

and

mechanic

with

a

reference

source

with

which

he

can

perform

normal

service

operations

We

endeavor

to

lOcorporate

the

latest

manufacturing

design

changes

and

up

to

date

specifications

at

the

time

of

publication

While

every

effort

IS

made

to

attain

accuracy

the

Publisher

cannot

be

held

responsible

for

manufacturing

changes

typographical

errors

or

omiSSions

Upon

compIling

the

information

contained

herein

we

have

tried

to

be

brief

and

Simple

relvlng

on

the

combination

of

photographs

Illustrations

and

text

to

make

thIS

manual

a

useful

tool

DRAKE

PUBLISHERS

INC

361

PARK

AVENUE

SOUTH

NEW

YORK

NY

10016

Page 6 of 136

fable

of

Contents

BODY

WORK

SPECIFICATIONS

I

HOOD

112

SERVICE

DATA

130

Removal

112

ENGINE

134

InstallatIOn

112

General

SpeCificatIOn

134

HOOD

LOCK

112

Tlghtemng

Torque

134

Removal

112

SpeCIficatIOn

135

Adjustment

112

Coohng

System

139

LubncatlOn

114

Fuel

System

140

TRUNK

LID

LOCK

116

Starter

142

Removal

116

Alternator

143

Adjustment

116

Regulator

144

TRUNK

LID

TORSION

BAR

116

Dlstnbutor

145

DOOR

CONSTRUCTION

117

IgnItIOn

Cot

145

WIRING

DIAGRAMS

118

CLUTCH

146

BULB

SPECIFICATIONS

120

NOTES

174

HEADLAMP

121

THERMOMETER

AND

FUEL

METER

122

OIL

PRESSURE

AND

IGNITION

WARNING

LAMPS

126

I

I

t

I

3

Page 20 of 136

Bn

in1l

If

camshaft

bearmg

clearance

IS

exceSS1ve

replace

the

camshaft

bearmgs

with

service

parts

When

valve

contact

surface

of

the

valve

rocker

arm

IS

worn

excessively

m

step

repair

by

means

of

a

valve

grinder

or

replace

Grinding

allowance

for

valve

contact

surface

of

the

valve

rocker

arm

IS

0

0197

In

or

less

Valve

Lifter

and

Push

Rod

Check

the

valve

hfter

for

wear

seizure

and

bevel

edge

contact

and

repair

or

replace

as

reqUIred

Measure

clearance

between

the

hfter

hole

on

the

cyhnder

block

and

valve

hfter

and

replace

the

valve

hfter

when

clearance

ex

ceeds

the

hmlt

Check

the

push

rod

for

bendmg

and

damage

and

repair

or

replace

as

reqUIred

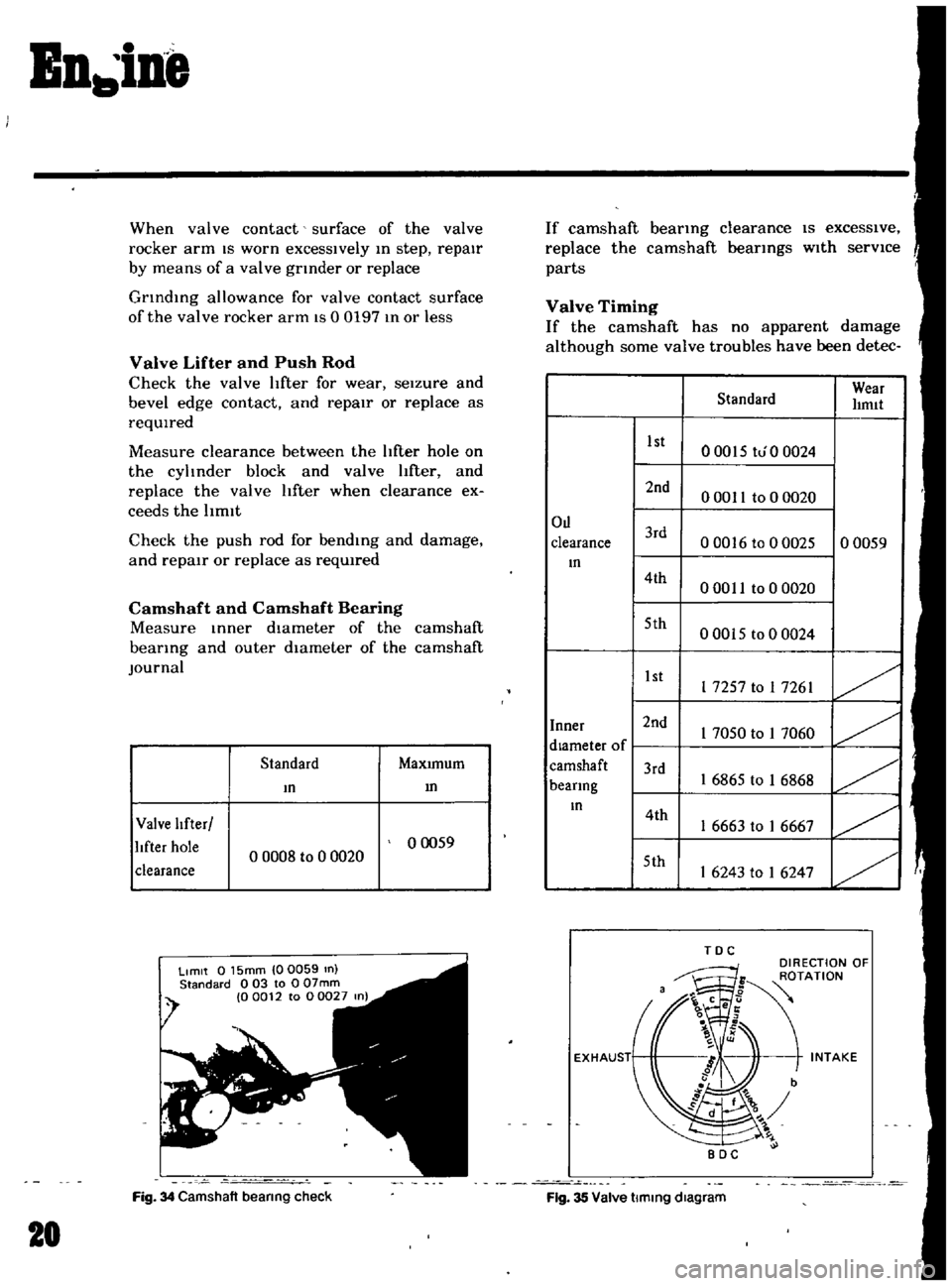

Camshaft

and

Camshaft

Bearing

Measure

mner

dIameter

of

the

camshaft

bearing

and

outer

diameter

of

the

camshaft

Journal

Standard

MaxlIDum

m

m

Valve

hfter

hfter

hole

o

0059

o

0008

to

0

0020

clearance

limit

0151010

00059

m

Standard

003

to

0071010

00012

to

00027

m

Fig

34

Camshaft

bearing

check

20

Valve

Timing

If

the

camshaft

has

no

apparent

damage

although

some

valve

troubles

have

been

detec

Standard

Wear

hm1t

1st

00015luOO024

2nd

00011

to

0

0020

Ot

3rd

clearance

00016

to

00025

o

0059

In

4th

00011

to

0

0020

5th

00015

toO

0024

1st

1

7257

to

I

7261

Inner

2nd

1

7050

to

1

7060

diameter

of

camshaft

3rd

beanng

1

6865

to

1

6868

m

4th

I

6663

to

I

6667

5th

1

6243

to

1

6247

TDC

DIRECTION

OF

ROTATION

EXHAUST

INTAKE

BDC

Fig

35

Valve

timing

diagram

Page 23 of 136

Square

rmg

m

bore

by

pushing

It

mto

pos1t1on

wIth

the

head

piston

Measure

gap

between

ends

of

rmg

with

feeler

gauge

Gap

should

be

as

hsted

above

Note

a

When

the

piston

ring

only

is

to

be

replaced

without

the

cylinder

bore

bemg

corrected

measure

gap

at

the

bottom

of

the

cylinder

where

the

wear

is

minor

b

Overs1ze

piston

rings

are

avaIlable

for

service

50

100

150

oversize

Measure

the

piston

pm

hole

m

relation

to

the

outer

dIameter

of

the

pm

If

wear

exceeds

the

hmlt

replace

such

piston

pm

together

with

the

pIston

on

whIch

It

IS

mstalled

PI

ton

pill

dldmeter

06869

to

06871

PIston

pill

length

25681

to

5779

Piston

pm

hole

dta

meter

06874

to

0

6871

PIston

pm

to

piston

clearance

00002

to

OOUr

j

Interference

fit

of

piston

pm

to

connectmg

rod

o

0008

EM133

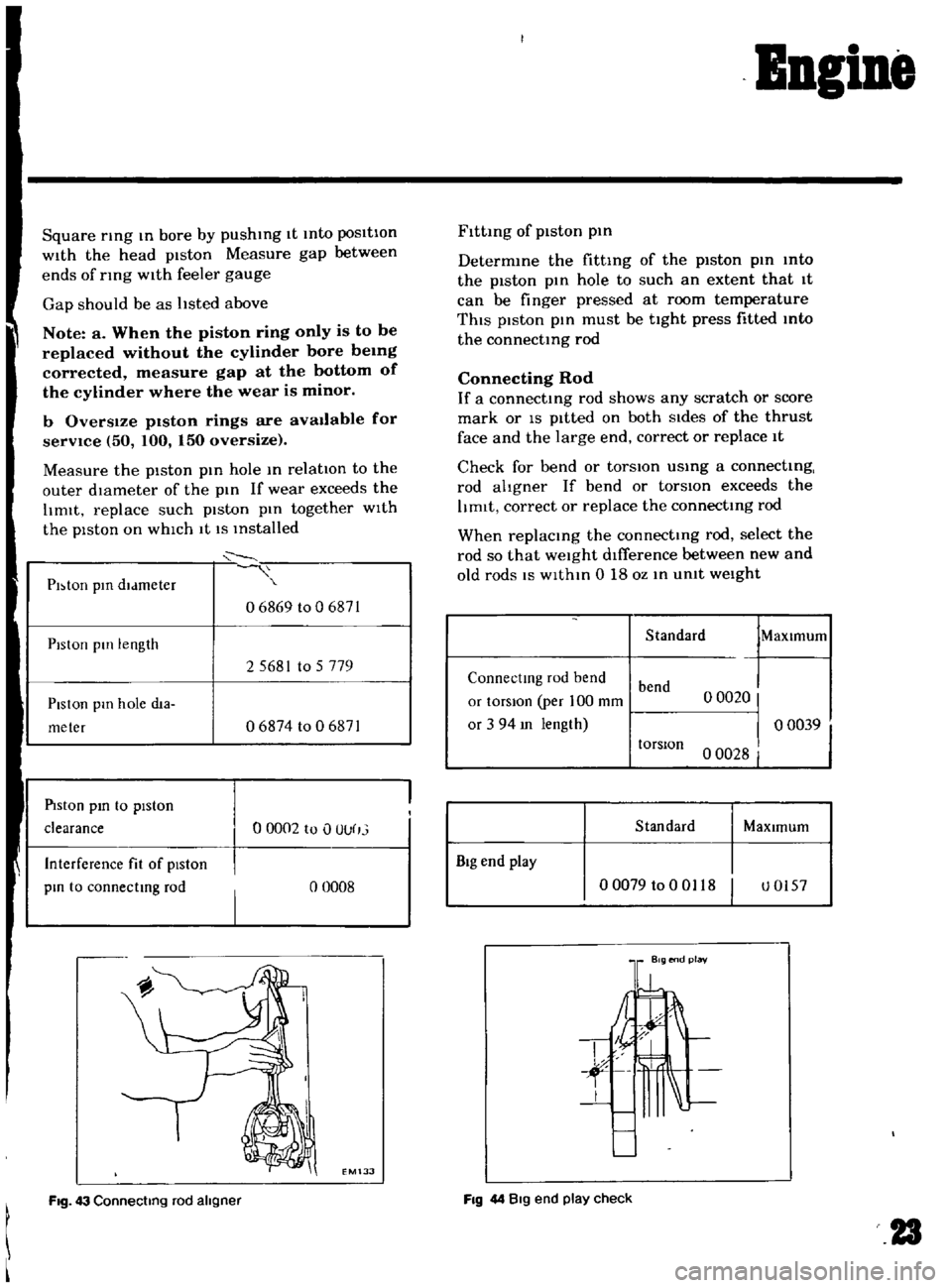

FIg

43

Connecting

rod

ahgner

Bngine

Flttmg

of

piston

pm

Determme

the

fittmg

of

the

piston

pm

mto

the

piston

pm

hole

to

such

an

extent

that

1t

can

be

finger

pressed

at

room

temperature

ThIS

piston

pm

rnust

be

tight

press

fitted

mto

the

connectmg

rod

Connecting

Rod

If

a

connectmg

rod

shows

any

scratch

or

score

mark

or

IS

pitted

on

both

Sides

of

the

thrust

face

and

the

large

end

correct

or

replace

It

Check

for

bend

or

torsIOn

usmg

a

connectmg

rod

ahgner

If

bend

or

torsIOn

exceeds

the

hmlt

correct

or

replace

the

connectmg

rod

When

replacing

the

connectmg

rod

select

the

rod

so

that

weight

difference

between

new

and

old

rods

IS

wlthm

0

18

oz

m

umt

weIght

Standard

MaXimum

Connectmg

rod

bend

bend

or

tOrsIon

per

100

mm

o

0020

or

3

94

m

length

o

00391

torsIOn

o

0028

I

Standard

MaXImum

BIg

end

play

00079

to

0

0118

I

U0157

FIg

44

Big

end

play

check

23

Page 47 of 136

ruel

Sptem

FUEL

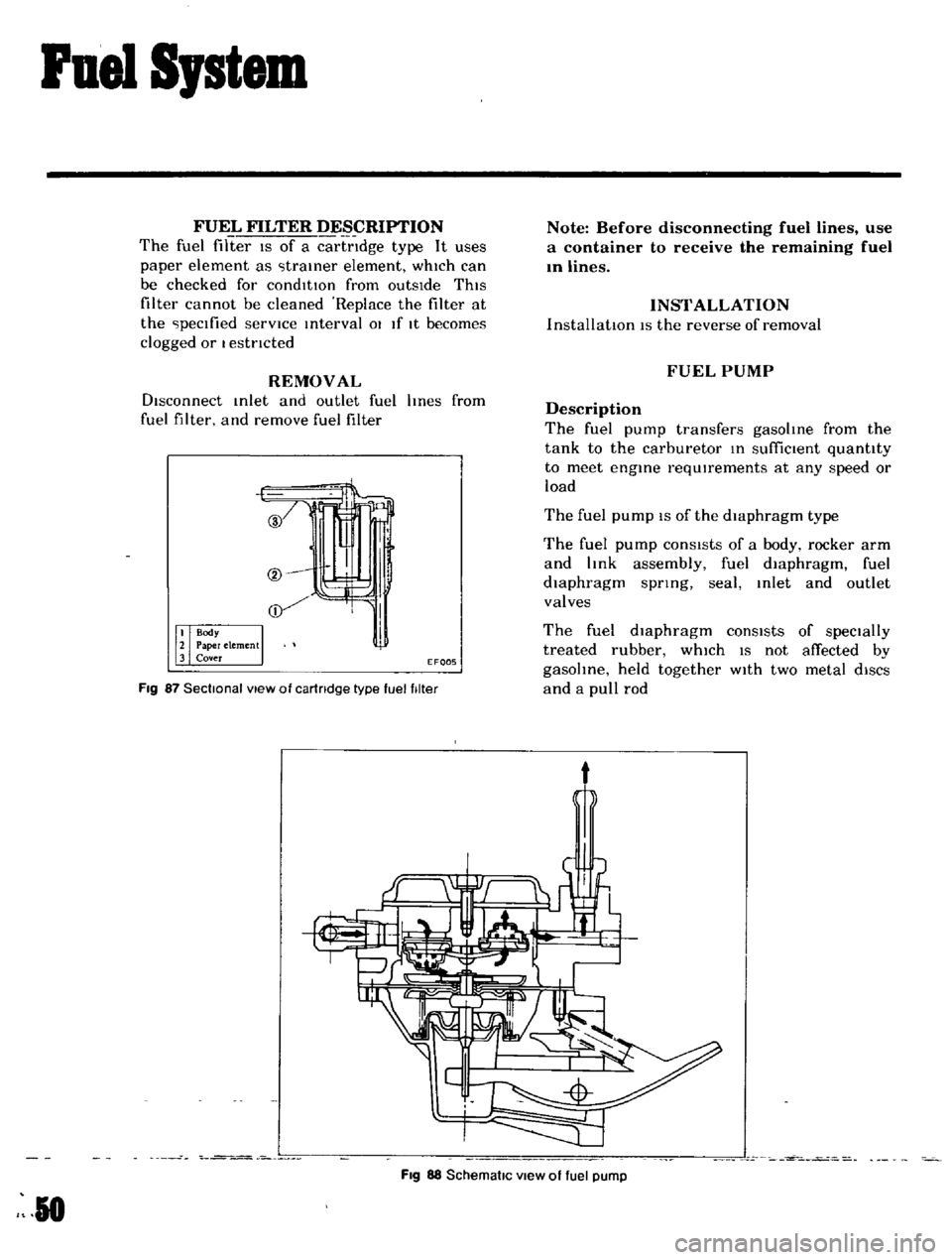

FILTER

DESCRIPTION

The

fuel

filter

IS

of

a

cartndge

type

It

uses

paper

element

as

traIner

element

which

can

be

checked

for

condItIOn

from

outsIde

ThIS

filter

cannot

be

cleaned

Replace

the

filter

at

the

peclfied

servICe

Interval

01

If

It

becomes

clogged

or

I

estncted

REMOVAL

DIsconnect

Inlet

and

outlet

fuel

hnes

from

fuel

filter

and

remove

fuel

filter

if

EF005

Fig

87

Sectional

view

of

cartridge

type

fuel

filter

Note

Before

disconnecting

fuel

lines

use

a

container

to

receive

the

remaining

fuel

In

lines

INSTALLATION

InstallatIOn

IS

the

reverse

of

removal

FUEL

PUMP

Description

The

fuel

pump

transfers

gasoline

from

the

tank

to

the

carburetor

In

suffiCient

quantity

to

meet

engine

requIrements

at

any

speed

or

load

The

fuel

pump

IS

of

the

diaphragm

type

The

fuel

pump

conSIsts

of

a

body

rocker

arm

and

link

assembly

fuel

diaphragm

fuel

diaphragm

spnng

seal

Inlet

and

outlet

valves

The

fuel

diaphragm

consists

of

specially

treated

rubber

whIch

IS

not

affected

by

gasohne

held

together

WIth

two

metal

diSCS

and

a

pull

rod

t

Fig

88

SchematiC

view

of

fuel

pump

R

0

Page 74 of 136

Brakes

Adjusting

shIm

thickness

for

selectIOn

o

0197

In

00315

In

o

0630

In

Note

When

adjusting

be

sure

to

use

ad

Jusbng

sh1ms

having

same

th1ckness

for

upper

and

lower

brake

master

cylinder

IOstallahon

bolts

Upon

completIOn

of

adjusting

shIm

adjust

ment

tighten

the

stopper

down

to

such

an

ex

tent

that

heIght

of

the

pedal

head

IS

5

57

pO

0787

In

and

tighten

the

lock

nut

becurely

Free

travel

of

the

brake

pedal

IS

0

197

to

0591

tn

and

the

stroke

IS

4

72

In

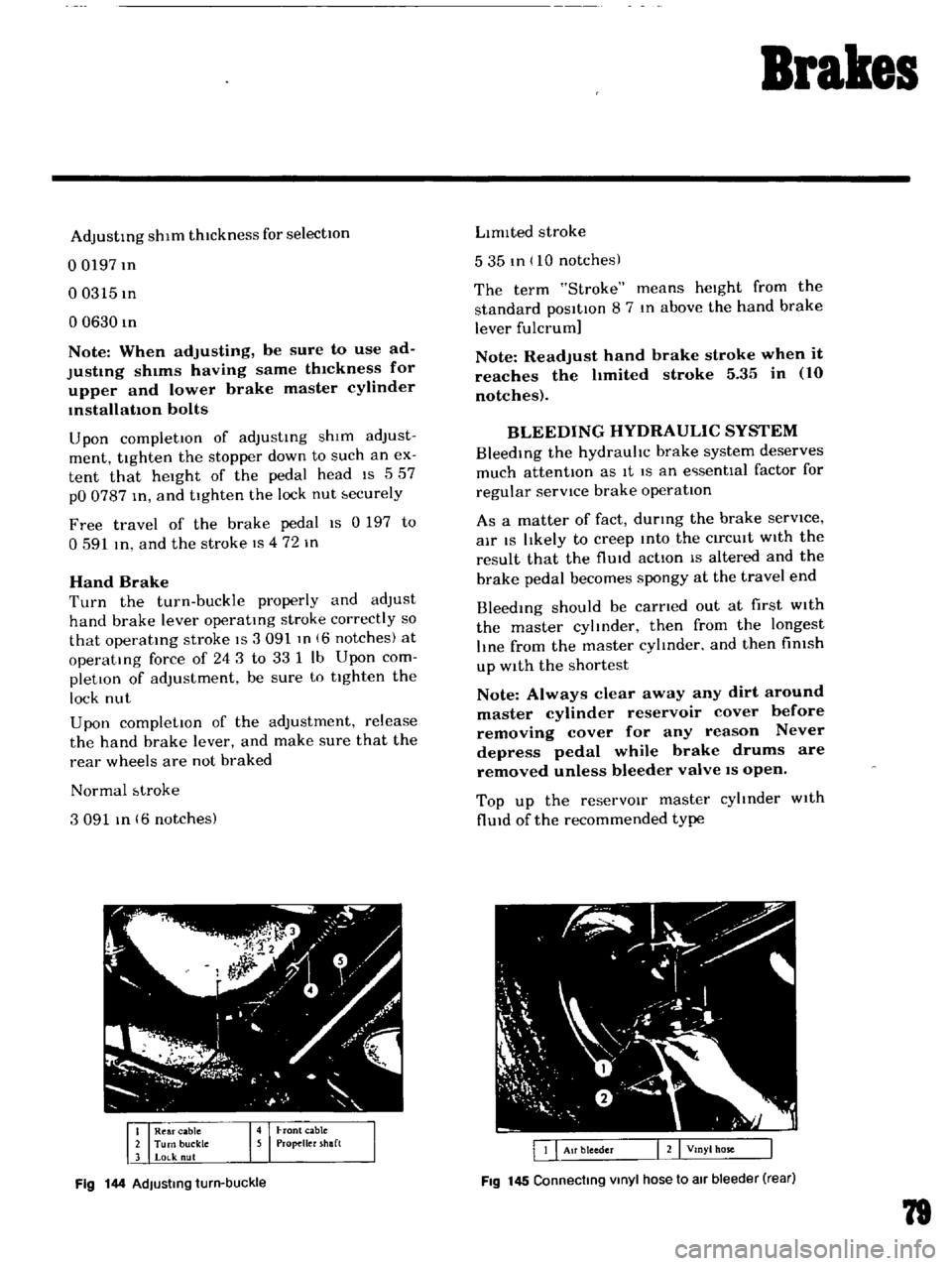

Hand

Brake

Turn

the

turn

buckle

properly

and

adjust

hand

brake

lever

operatmg

stroke

correctly

so

that

operatmg

stroke

IS

3

091

m

16

notches

at

operatIng

force

of

243

to

331

Ib

Upon

com

pletIOn

of

adjustment

be

sure

to

tIghten

the

lock

nut

Upon

completIOn

of

the

adjustment

release

the

hand

brake

lever

and

make

sure

that

the

rear

wheels

are

not

braked

Normal

btroke

3091

In

6

notches

Fig

144

AdJusting

turn

buckle

LImIted

stroke

535

tn

10

notches

The

term

Stroke

means

heIght

from

the

standard

posItIon

8

7

In

above

the

hand

brake

lever

fulcrum

Note

Readjust

hand

brake

stroke

when

it

reaches

the

hmited

stroke

5

35

in

10

notches

BLEEDING

HYDRAULIC

SYSTEM

BleedIng

the

hydrauhc

brake

system

deserves

much

attentIOn

as

It

IS

an

e

senttal

factor

for

regular

servICe

brake

operatIon

As

a

matter

of

fact

durmg

the

brake

serVice

air

IS

lIkely

to

creep

Into

the

CirCUIt

WIth

the

result

that

the

flUId

actIon

IS

altered

and

the

brake

pedal

becomes

spongy

at

the

travel

end

Bleedmg

should

be

carned

out

at

first

WIth

the

master

cylmder

then

from

the

longest

lIne

from

the

master

cylmder

and

then

fimsh

up

With

the

shortest

Note

Always

clear

away

any

dirt

around

master

cylinder

reservoir

cover

before

removing

cover

for

any

reason

Never

depress

pedal

while

brake

drums

are

removed

unless

bleeder

valve

IS

open

Top

up

the

reservOIr

master

cyltnder

With

flUId

of

the

recommended

type

Fig

145

Connecting

Vinyl

hose

to

air

bleeder

rear

79

Page 76 of 136

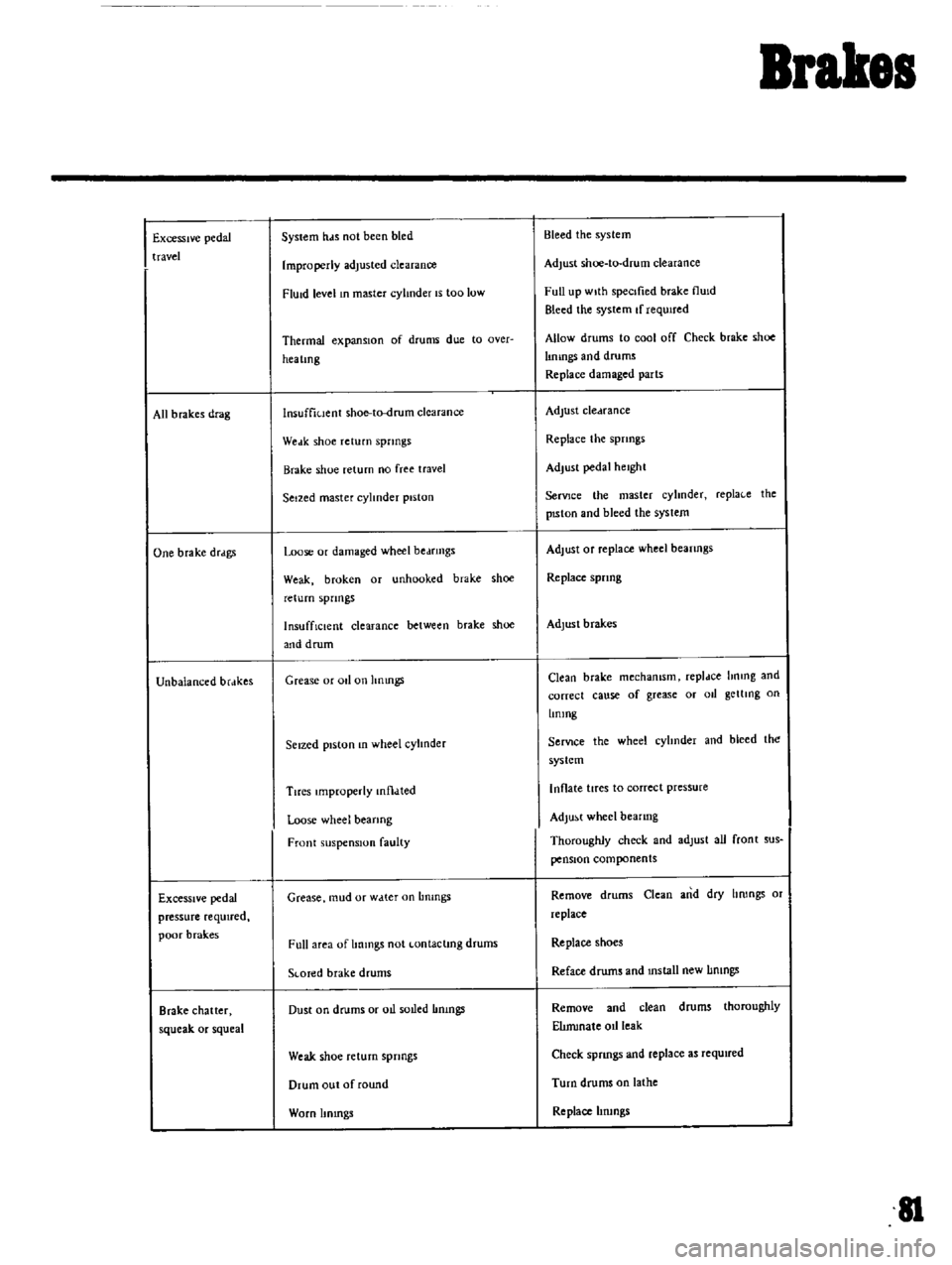

Brakes

Excessive

pedal

travel

All

b

rakes

drag

One

brake

drdgs

Unbalanced

brdkes

Excessive

pedal

pressure

required

poor

brak

es

Brake

chatter

squeak

or

squeal

System

hds

not

been

bled

Improperly

adjusted

clearance

FlUid

level

In

master

cylinder

IS

too

low

Thermal

expansIOn

of

drums

due

to

Qver

hea

lmg

lnsuffiuent

shoe

to

drum

clearance

Weak

shoe

return

springs

Brake

shoe

return

no

free

travel

Seized

master

cylinder

piston

Loose

or

damaged

wheel

bedfmgs

Weak

broken

or

unhooked

brake

shoe

return

spnngs

InsuffiCient

clearance

between

brake

shoe

and

drum

Grease

or

011

on

hnmgs

Seized

piston

In

wheel

cylInder

Tires

Improperly

mtl

lted

Loose

wheel

bearing

Front

suspension

faulty

Grease

mud

or

w

tter

on

Lmmgs

Full

area

of

Immgs

not

Lontaclmg

drums

SLOTed

brake

drums

Dust

on

drums

or

oIl

soLled

Immgs

Weak

shoe

return

springs

Drum

out

of

round

Worn

Itmngs

Bleed

the

system

Adjust

shoe

to

drum

clearance

Full

up

wIth

specIfied

brake

flUId

Bleed

the

system

If

requIred

Allow

drums

to

cool

off

Check

brake

shoe

lImngs

and

drums

Replace

damaged

parts

Adjust

cledrance

Replace

the

spnngs

Adjust

pedal

height

SerVJce

the

master

cyhnder

repla

e

the

pISton

and

bleed

the

syslem

Adjust

Of

replace

wheel

beanngs

Replace

spnng

Adjust

brakes

Clean

brake

mechamsm

repldce

hnmg

and

correct

cause

of

grease

or

011

getllng

on

Lmmg

SerVIce

the

wheel

cyhnder

and

bleed

the

system

Inflate

tires

to

correct

pressure

Adjust

wheel

bearing

Thoroughly

check

and

adlust

all

front

sus

pensIOn

components

Remove

drums

Clean

and

dry

hrongs

or

replace

Replace

shoes

Reface

drums

and

mstall

new

IImngs

Remove

and

clean

drums

thoroughly

ElImmale

oIl

leak

Check

spnngs

and

replace

as

required

Turn

drums

on

lathe

Replace

hrungs

II

Page 99 of 136

Transmission

AUTOMATIC

TRANSMISSION

The

model

3N71B

automatic

transmiSSIOn

IS

a

fully

automatic

Unit

consisting

pnmanly

of

3

element

hydrauhc

torque

converter

and

two

planetary

gear

sets

Two

multiple

disc

clut

ches

a

multiple

disc

brake

a

band

brake

and

a

one

way

sprag

clutch

provide

the

fnctlon

elements

reqUired

to

obtain

the

deSired

fun

tlon

of

the

two

planetary

gear

sets

The

two

planetary

gear

sets

give

three

for

ward

ratIOs

and

one

reverse

Changing

of

the

gear

ratIOs

IS

fully

automatic

In

relation

to

vehicle

speed

and

engine

torque

Input

Vehicle

speed

and

engine

mamfold

vacuum

Signals

are

constantly

fed

to

the

transmiSSIOn

to

prOVide

the

proper

gear

ratIO

for

maximum

effiCiency

and

performance

at

all

throttle

openmgs

The

Model

3N71B

has

SIX

selector

poSitIOns

P

R

N

D

2

1

p

Park

pOSitIOn

posItively

locks

the

out

put

shaft

to

the

transmiSSIOn

case

by

means

of

a

lockmg

pawl

to

prevent

the

vehicle

from

rollmg

either

directIOn

ThiS

pOSitIOn

should

be

selected

whenever

the

dnver

leaves

the

vehicle

The

engme

may

be

started

m

Park

pOSition

R

Reverse

range

enables

the

vehicle

to

be

operated

m

a

reverse

direction

N

Neutral

pOSitIOn

enables

the

engine

to

be

started

and

run

Without

dnvIngthe

vehicle

0

Drive

range

IS

used

for

all

normal

driVing

conditions

Dnve

range

has

three

gear

ratios

from

the

startmg

ratIO

to

direct

dnve

2

2

range

prOVides

performance

for

dnvIng

onshppery

surfaces

2

range

can

also

be

used

for

engine

brakmg

2

range

can

be

selected

at

any

vehicle

speed

and

prevents

the

transmlsslOn

from

shifting

out

of

second

gear

108

Rg

162

Idenllflcatlon

number

I

1

range

can

be

selected

at

any

vehicle

speed

and

the

transmiSSIOn

will

shift

to

second

gear

and

remain

m

second

until

vehicle

speed

IS

reduced

to

approximately

25

to

31

MPH

1

range

posItion

prevents

the

transmiSSIOn

from

shlftmg

out

of

low

gear

ThiS

IS

par

tlcularly

benefiCial

for

mamtamIng

maximum

engine

brakmg

when

continUOUS

low

gear

operation

IS

deSirable

The

torque

converter

assembly

IS

of

welded

constructIOn

and

can

not

be

dlssassembled

for

service

FlUld

Recommendatwn

Use

automatic

transmiSSIOn

flUid

haVing

DEXRON

IdentificatIOns

only

m

the

3N71B

automatic

transmiSSIOn

denttficatwn

Number

Stamped

posttwn

The

plate

attached

to

the

rIght

hand

Side

of

transmission

case

as

shown

m

Figure

161

denttficatwn

of

number

arrangements

See

Page

109

RECOMMENDATIONS

Due

to

the

compleXity

of

setting

up

a

disassembled

transmissIOn

as

well

as

the

special

tools

necessary

It

IS

recommended

thaL

nternal

epalrs

be

left

to

a

fully

eqUip

ped

shop

Page 114 of 136

i

II

Ii

I

I

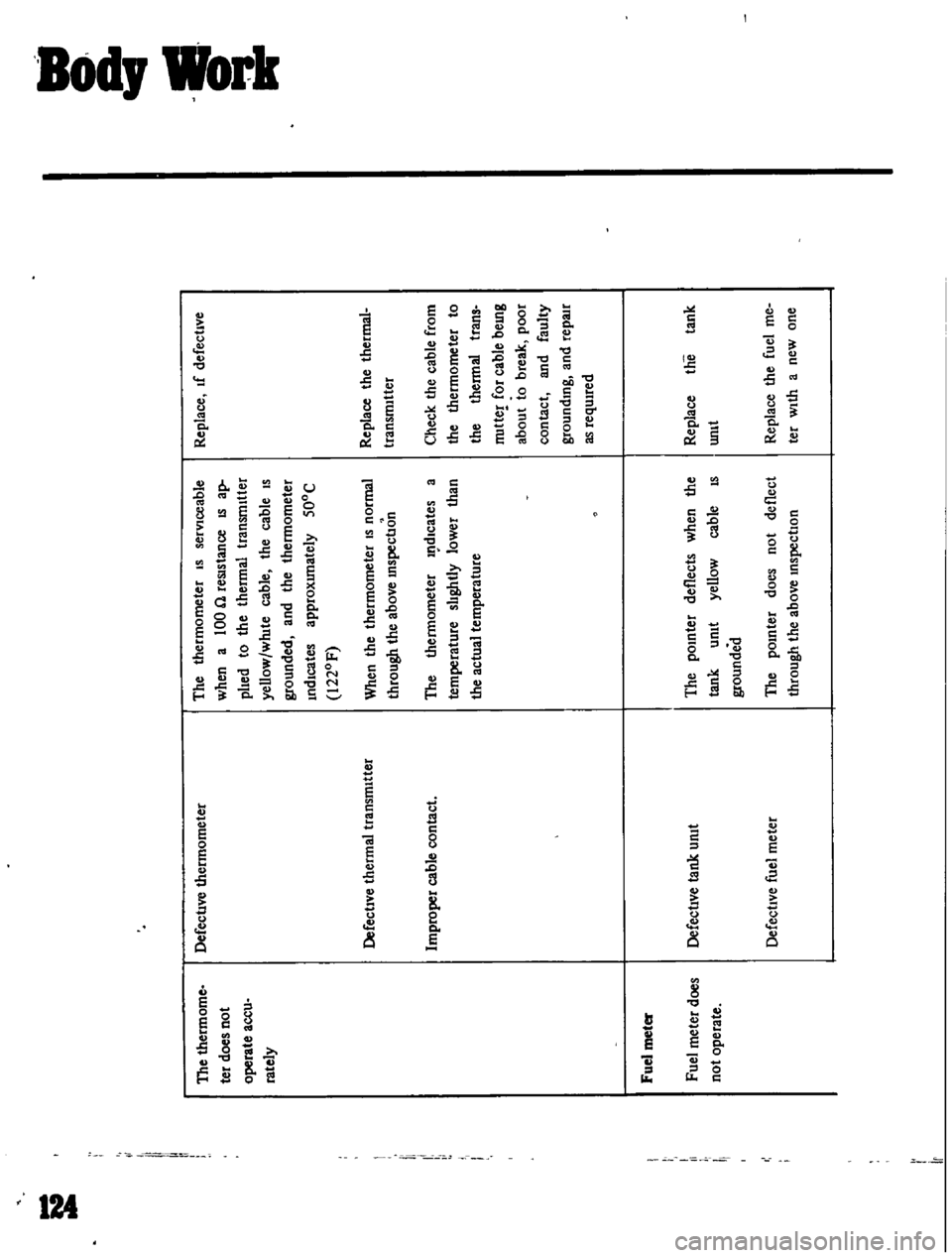

The

thermome

ter

does

not

operate

accU

rately

Fuel

meter

I

II

i

Fuel

meter

does

not

operate

Defective

thermometer

DefectIve

thermal

transmItter

Improper

cable

contact

DefeCtlve

tank

umt

Defective

fuel

meter

The

thermometer

IS

serVIceable

when

a

100

a

reSIstance

IS

ap

plied

to

the

thermal

transmItter

yeUowlwlute

cable

the

cable

IS

grounded

and

the

thermometer

Uldlcates

approxunately

SOoC

1220F

When

the

thermometer

IS

normal

through

the

above

UlSpeCtlOn

The

thermometer

19d1cates

a

temperature

slightly

lower

than

the

actual

temperature

The

pOUlter

tank

umt

grounded

deflects

when

the

yellow

cable

IS

The

pOUlter

does

not

deflect

through

the

above

mspectlon

Replace

If

defective

1

1

0

a

iii

Replace

the

thermal

transmitter

Check

the

cable

from

the

thermometer

to

the

thermal

trans

nutter

for

cable

bemg

about

to

break

poor

contact

and

faulty

groundmg

and

repalI

as

reqUired

Replace

wut

tile

tank

Replace

the

fuel

me

ter

With

a

new

one

Page 120 of 136

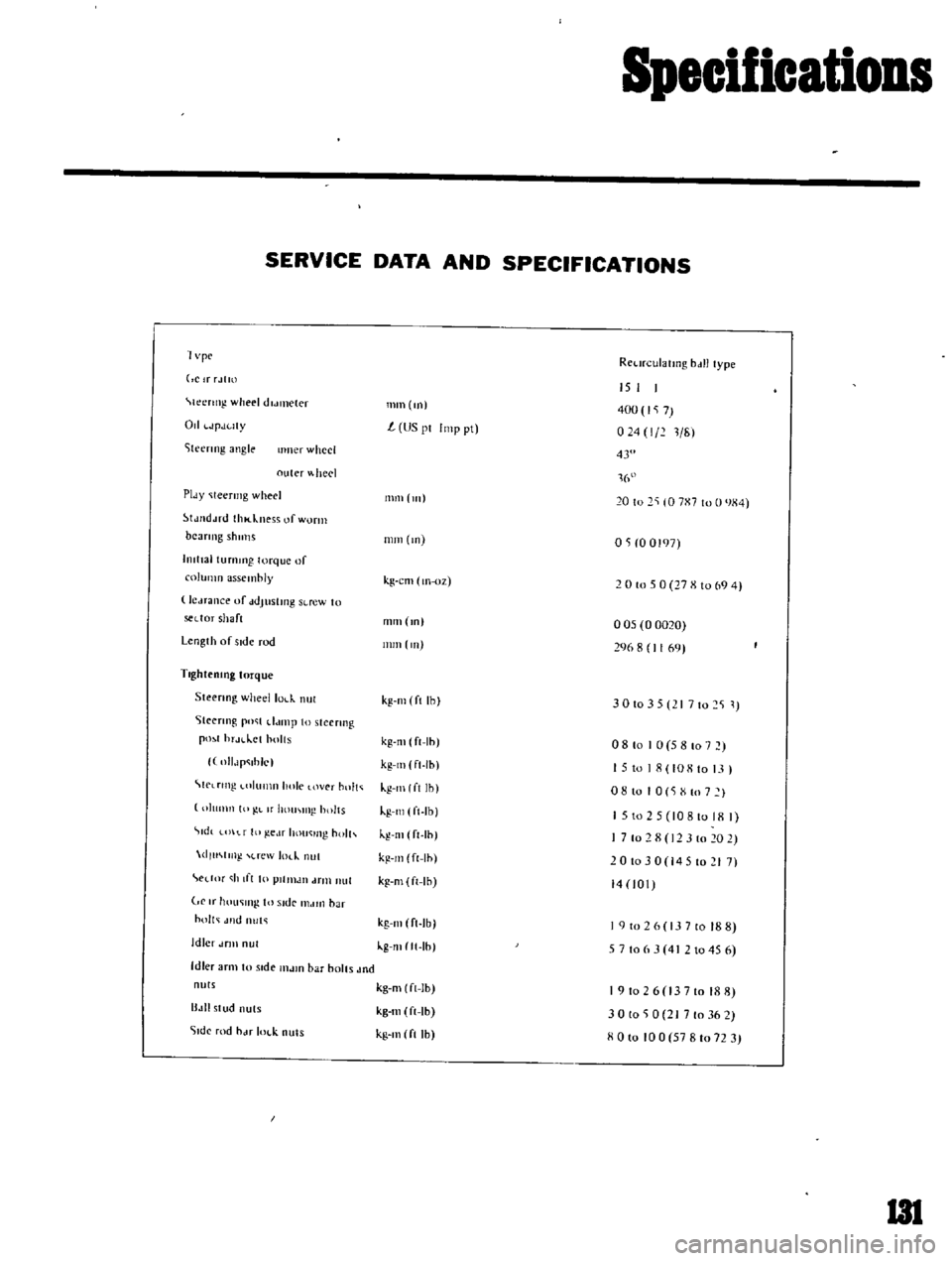

Specifications

SERVICE

DATA

AND

SPECIFICATIONS

1

vpc

RCl

n

ulatlllg

bdll

type

ClrrJtm

Ieertng

wheel

dldl1lCler

Od

JpJuty

iteenng

angle

IImer

wheel

outer

heel

PIdY

Ieermg

wheel

tJJ

d

ud

thl

kness

of

worm

beaTIng

shulls

hllttal

turnmg

torque

of

column

assembly

le

Hance

uf

ddJustmg

SLrew

to

sedor

shaft

Length

of

side

rod

TlghteolOg

torque

Steenng

wheellol

k

nul

Steenng

po

t

d

unp

to

steermg

pO

1

hr

H

lct

holts

llIlJp

ihlc

C

lrtng

llImn

hole

over

hnlt

IllImn

10

L

If

hOUI

IIl

holts

tdt

t

f

III

ge

lf

hou

lIl

holh

dlu

m

l

rew

m

nut

edM

h

If

I

10

plllllJIl

drill

nut

If

hOll

lI1g

In

Side

I1MIIl

bar

holt

Jlld

nut

Idler

dflll

nul

Idler

arm

to

stde

l1lJlO

bar

bolts

Jnd

nuts

B

III

stud

nuts

51dc

rod

hJf

IOl

k

nuts

mm

m

15

I

400

7

024

1

211

L

US

pI

Imp

pt

43

1

16

111111

111

20

to

2

10

7X7

to

0

JX4

mm

m

OS

0

0197

kg

cm

lIl

oz

2

0

to

5

0

27

X

10

69

4

mm

m

005

0

0020

296

8

1169

nun

Ill

kg

Ill

ft

Ihl

3

0

10

3

5

I

7

10

2

S

1

kg

m

ft

Ih

kg

Ill

ft

Ih

kg

Ill

I

ft

Ih

kg

Ill

ft

Ib

kg

Ill

ft

Ih

kg

m

ft

Ih

kg

m

ft

Ih

08

to

I

0

5

8

107

15

to

18

108

to

13

I

o

8

10

I

0

S

X

to

7

I

1

5

to

2

5

10810

18

I

7

10

2

8

12

3

10

20

2

201030

14510217

14

101

kg

Ill

ft

Ib

kg

mltt

Ih

I

9

to

2

6

13

7

to

18

8

5

7

106

3

4

2

1045

6

kg

m

ft

Ib

kg

m

ft

Ib

kg

Ill

ft

Ih

191026

13710188

30

to

0

21

7

to

36

2

XOlo

100

57810723

I3l