stop start DATSUN B110 1969 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 8 of 136

ainteDaDee

TUDe

up

VAL

VE

CLEARANCES

Valve

clearance

adjustment

should

be

made

while

engme

IS

stationary

To

adjust

proceed

as

follows

Start

engme

and

run

It

until

It

IS

heated

to

operatIng

temperature

or

at

least

more

than

17S

of

engIne

011

temperature

then

stop

engIne

Rotate

crankshaft

to

bnng

No

1

cylInder

In

top

dead

center

on

ItS

compressIOn

stroke

Remove

valve

rocker

cover

to

gaIn

access

to

valve

operatIng

mechamsm

Adjust

valve

clearance

at

follOWing

four

pOints

while

engIne

IS

still

hot

1

Exhaust

valve

of

No

1

cylinder

2

Intake

valve

of

No

1

cylinder

3

Intake

valve

of

No

2

cylinder

5

Exham

t

valve

of

No

3

cylInder

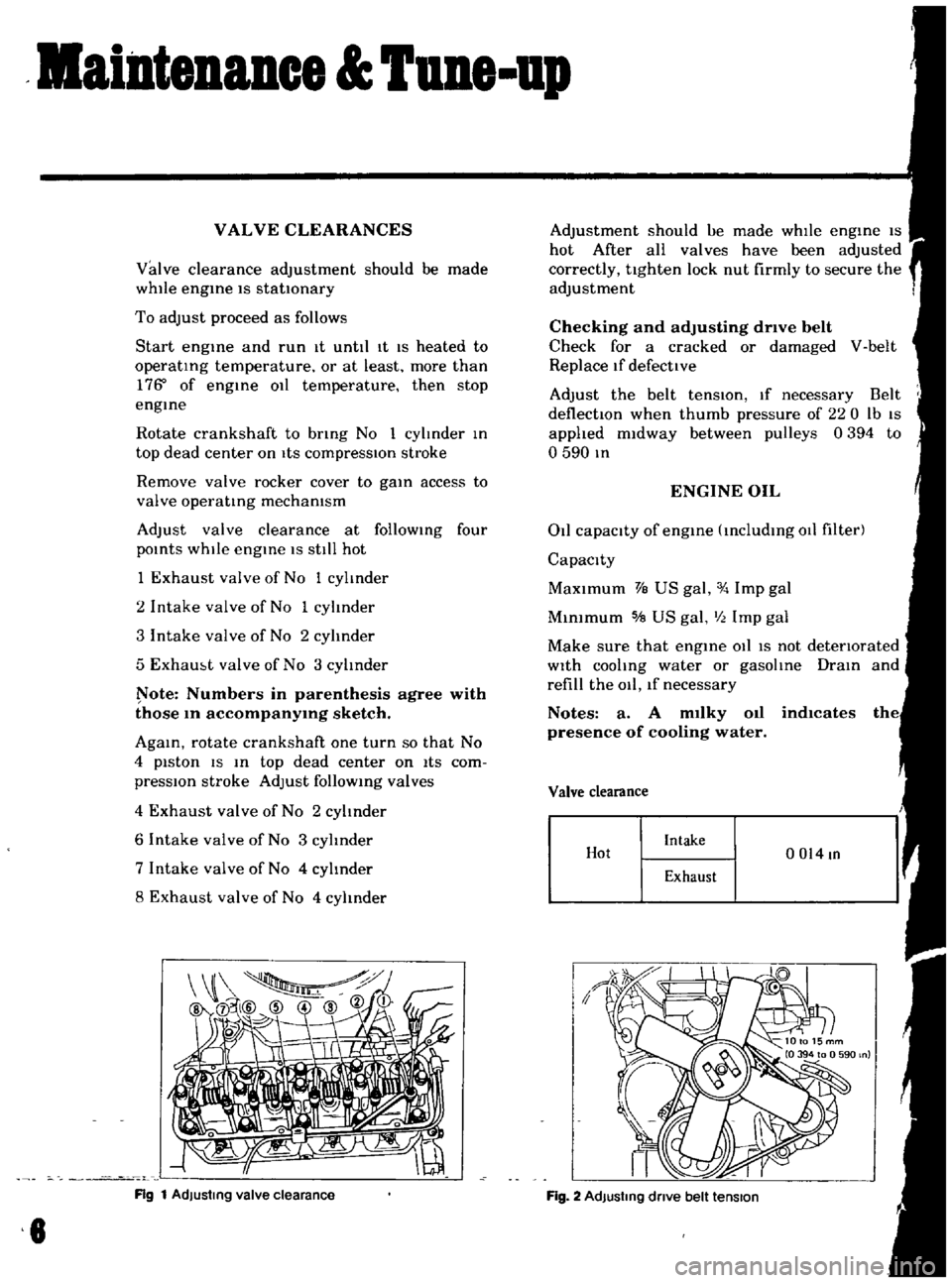

ote

Numbers

in

parenthesis

agree

with

those

10

accompanY1Og

sketch

AgaIn

rotate

crankshaft

one

turn

so

that

No

4

piston

IS

In

top

dead

center

on

ItS

com

pressIOn

stroke

Adjust

follOWIng

valves

4

Exhaust

valve

of

No

2

cylinder

6

Intake

valve

of

No

3

cylinder

7

Intake

valve

of

No

4

cylInder

8

Exhaust

valve

of

No

4

cylinder

Rg

1

AdJustmg

valve

clearance

8

Adjustment

should

ue

made

whIle

engIne

IS

hot

After

all

valves

have

been

adjusted

correctly

tighten

lock

nut

firmly

to

secure

the

adjustment

Checking

and

adjusting

drive

belt

Check

for

a

cracked

or

damaged

V

belt

Replace

If

defective

Adjust

the

belt

tenSIOn

If

necessary

Belt

deflectIOn

when

thumb

pressure

of

220

Ib

IS

applied

midway

between

pulleys

0394

to

o

590

In

ENGINE

OIL

011

capacity

of

engIne

IncludIng

011

filter

Capacity

MaXimum

VB

US

gal

Imp

gal

MInimum

5IB

US

gal

III

Imp

gal

Make

sure

that

engIne

011

IS

not

detenorated

With

cooling

water

or

gasolIne

DraIn

and

refill

the

011

lf

necessary

Notes

a

A

m1lky

011

indlcates

presence

of

cooling

water

Valve

clearance

Hot

Intake

0014

In

Exhaust

Fig

2

AdJustmg

dnve

belt

tension

Page 12 of 136

aiDteDaDce

UDe

up

Adjust

throttle

adjusting

screw

so

that

engme

speed

1S

800

rpm

m

N

positIOn

for

automatic

transmIssIOn

Check

IgnitIOn

tlmmg

If

necessary

adjust

1t

to

the

specIficatIOns

IgnitIOn

timing

50

800

rpm

Adjust

Idle

adjusting

screw

so

that

CO

percen

tage

IS

1

5

t0

5

ff

Repeat

the

adjustments

as

desctlbed

In

steps

3

above

so

that

CO

percentage

IS

15

t0

5

ff

at

800

rpm

Cautions

a

On

automatic

transmission

equipped

model

check

must

be

done

in

the

D

position

Be

sure

to

apply

parking

brake

and

to

lock

both

front

and

rear

wheels

wIth

wheel

chocks

b

Hold

brake

pedal

while

stepping

down

on

accelerator

pedal

Otherwise

car

will

rush

out

dangerously

On

automatic

transmISSIOn

eqUIpped

model

make

sure

that

the

adjustment

has

been

made

wIth

the

selector

lever

In

N

posItion

And

then

check

the

specificatIOns

with

the

lever

In

D

posItion

Insure

that

CO

percent

and

Idle

speed

are

as

follows

Idle

rpm

650

Idle

Limiter

Cap

CO

percentage

Do

not

remove

this

Idle

hm1ter

cap

unless

necessary

If

this

Unit

IS

removed

It

IS

I

with

lever

In

D

PoSitIOn

1

5

t

0

5

k

necessary

to

re

adJust

It

at

the

time

of

In

If

necessary

adjust

by

progIesslvely

turmng

stallatlon

To

adjust

proceed

as

follows

throttle

adJustlng

screw

and

Idle

adJustmg

Make

sure

that

the

percentage

oLCO

contents

screw

until

correct

adjustments

are

made

satisfies

the

specifications

I

I

I

I

J

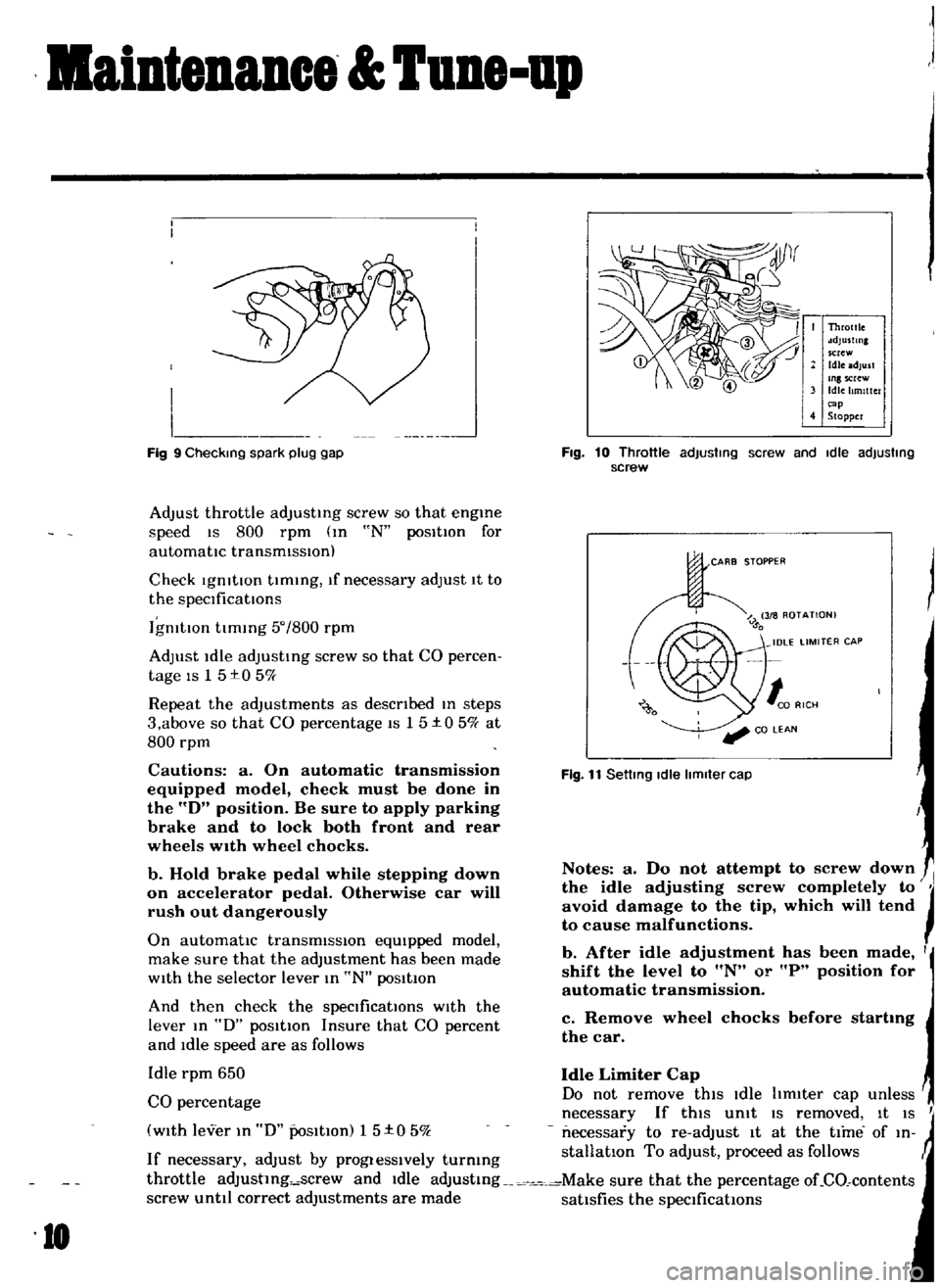

Fig

9

Checking

spark

plug

gap

10

Throttle

sdJustlnl

screw

Idle

adjust

Inlscrew

Idle

Itmlttc

r

cap

4

Stopper

Fig

10

Throttle

adjusting

screw

and

Idle

adjusting

screw

CARB

STOPPER

Fig

11

Setting

Idle

limiter

cap

Notes

a

Do

not

attempt

to

screw

down

the

idle

adjusting

screw

completely

to

JI

avoid

damage

to

the

tip

which

will

tend

to

cause

malfunctions

b

After

idle

adjustment

has

been

made

I

shift

the

level

to

N

or

P

position

for

automatic

transmission

c

Remove

wheel

chocks

before

startmg

the

car

Page 35 of 136

Bleatriall

System

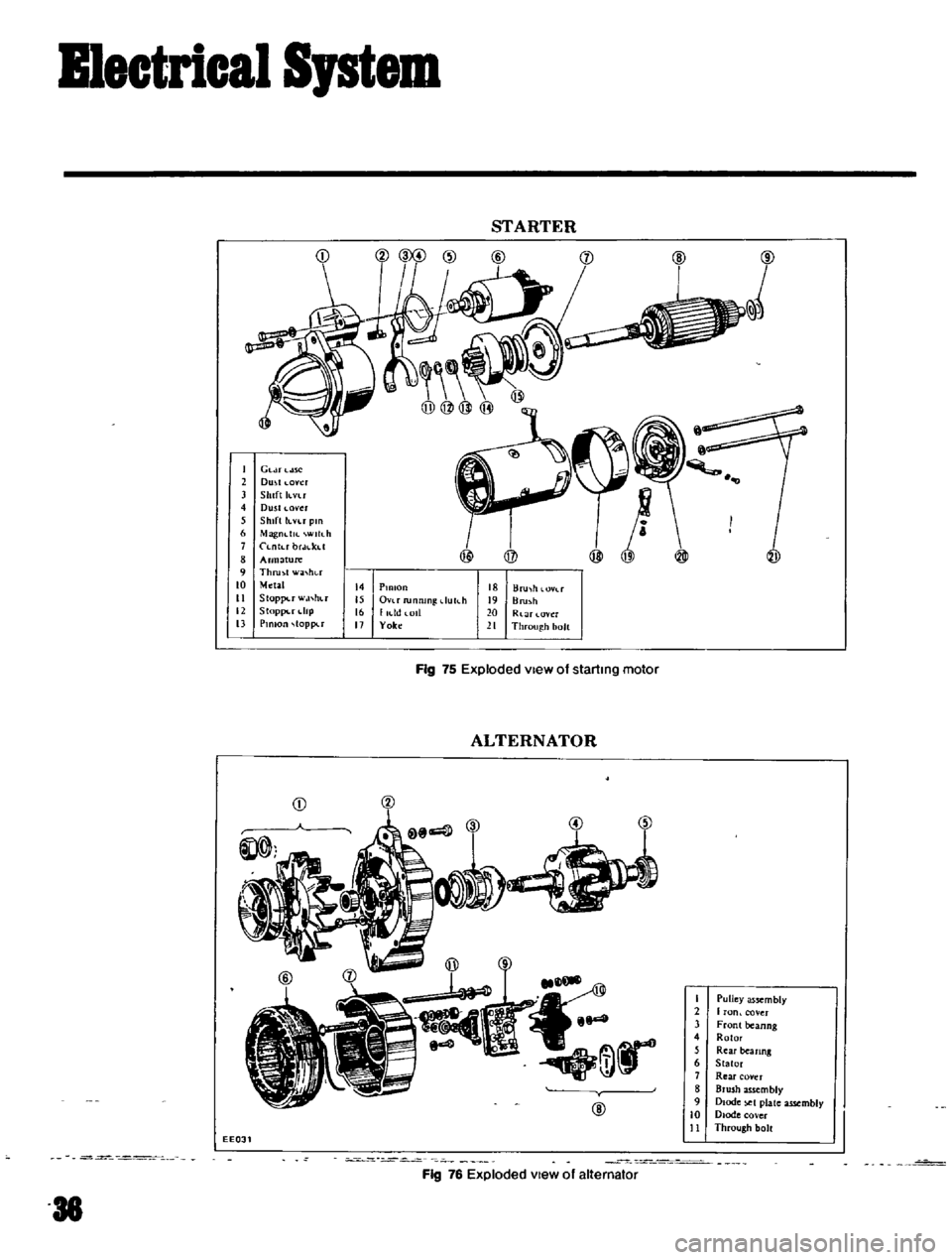

STARTER

I

Gl

U

ne

2

Dmt

oyer

3

Shift

h

vu

4

Dusll

ovcr

5

Shift

knr

pm

6

Magndlf

Wlllh

1

Lntubr

f

t

8

Arlll

ture

9

Thru

ot

w

L

ht

t

to

Metal

it

Stoppu

w

l

hu

12

Stoppt

rdlP

13

Pinion

toppu

@

@

@

@

I

15

16

17

Pmlon

Ovu

rumuRl

dukb

I

KId

lOll

Yok

18

Uru

h

19

Bru

l

b

20

Rl

ar

t

r

11

Through

bolt

Fig

75

Exploded

view

of

starting

motor

ALTERNATOR

CD

@OO

@

@

@

I

Pulley

assembly

2

f

on

cover

3

Front

beanng

4

Rotor

5

Rear

beanng

6

Stator

1

Rea

r

covet

8

Brush

assembly

9

Diode

t

plate

assembly

10

Diode

cover

11

Through

bolt

EE031

Fig

76

Exploded

view

of

alternator

Page 51 of 136

ruel

Sptem

CO

percentage

with

lever

In

D

posltton

15

050

If

necessary

adjust

by

progressively

turmng

throttle

adjustIng

screw

and

Idle

adJusttng

screw

unttl

correct

adjustments

are

made

Notes

a

Do

not

attempt

to

screw

down

the

Idle

adjusting

screw

completely

to

aVOid

damage

to

the

tip

which

will

tend

to

cause

malfunctions

b

After

idle

adjustment

has

been

made

shift

the

lever

to

UN

or

P

position

for

automatic

transmission

c

Remove

wheel

chocks

before

starting

the

car

Idle

Limiter

Cap

Do

not

remove

this

Idle

hmlter

cap

unless

nccesbary

If

this

Unit

IS

removed

It

IS

I

Throttle

adJu

tmg

suew

2

Idle

adJu

t

Ing

rcw

3

Idle

hmlter

p

4

Stopper

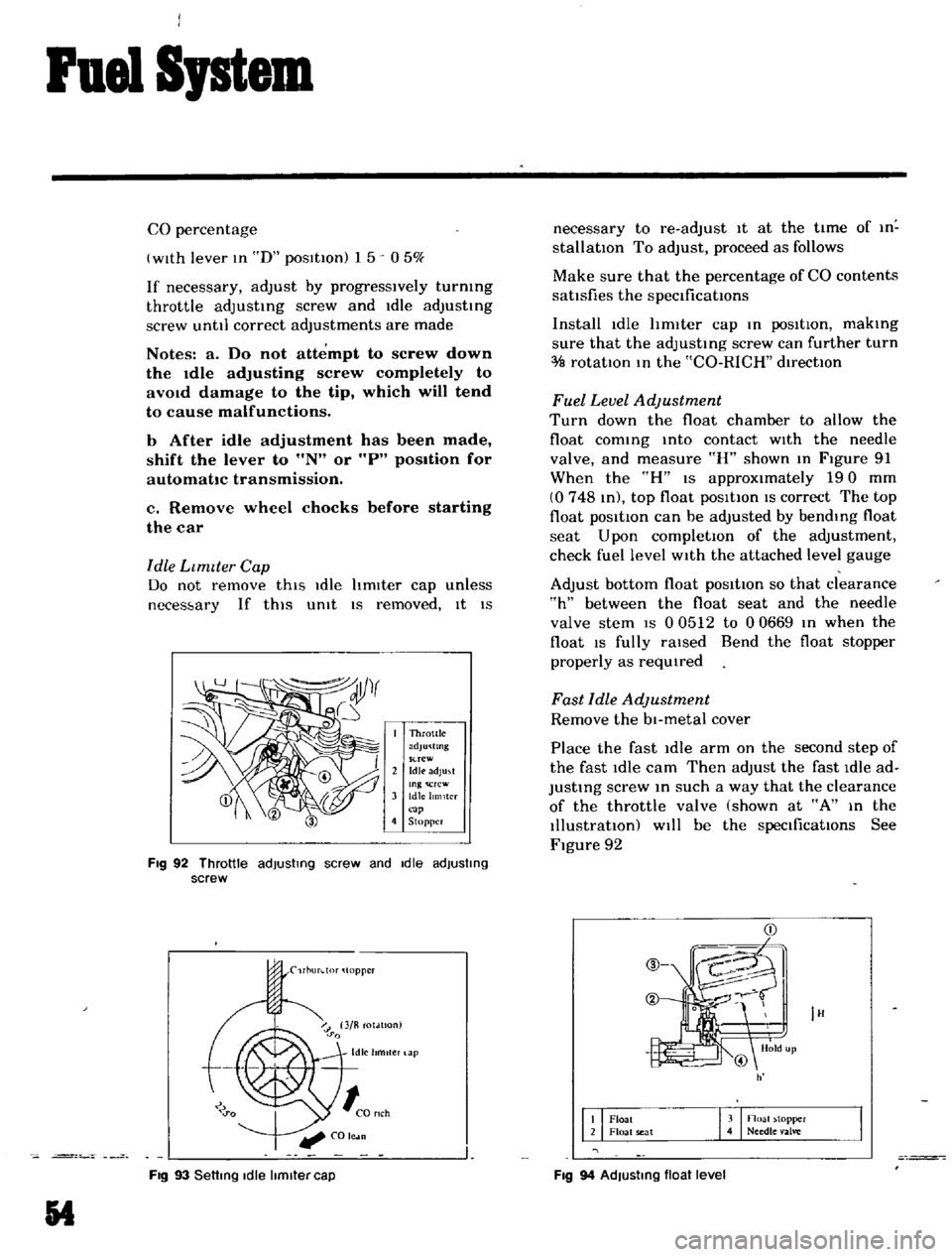

FIg

92

Throttle

adjusting

screw

and

Idle

adjusting

screw

rl1urdor

topper

Fig

93

Setting

Idle

limiter

cap

54

necessary

to

re

adJust

it

at

the

time

of

In

stallatIOn

To

adjust

proceed

as

follows

Make

sure

that

the

percentage

of

CO

contents

sattsfies

the

speClficattons

Install

idle

hmIter

cap

In

poSItIOn

makIng

sure

that

the

adjustIng

screw

can

further

turn

rotatIOn

In

the

CO

RICH

dIrectIOn

Fuel

Level

Adjustment

Turn

down

the

float

chamber

to

allow

the

float

comIng

Into

contact

WIth

the

needle

valve

and

measure

R

shown

In

Figure

91

When

the

H

IS

approximately

190

mm

0748

In

top

float

posltton

IS

correct

The

top

float

pOSitIOn

can

be

adjusted

by

bendIng

float

seat

Upon

completIOn

of

the

adjustment

check

fuel

level

WIth

the

attached

level

gauge

Adjust

bottom

float

posItion

so

that

clearance

h

between

the

float

seat

and

the

needle

valve

stem

IS

0

0512

to

00669

In

when

the

float

IS

fully

raIsed

Bend

the

float

stopper

properly

as

reqUIred

Fast

Idle

Adjustment

Remove

the

bl

metal

cover

Place

the

fast

Idle

arm

on

the

second

step

of

the

fast

idle

cam

Then

adjust

the

fast

Idle

ad

JustIng

screw

In

such

a

way

that

the

clearance

of

the

throttle

valve

shown

at

A

In

the

Illustratton

Will

be

the

speCificatIOns

See

Figure

92

IH

Float

Float

seat

3

noall

topper

4

Needle

alve

Fig

94

AdJusting

float

level

Page 55 of 136

ruel

S

stem

Note

When

somewhat

over

choked

set

bl

metal

cover

after

turning

it

clockwise

slightly

Adjustment

oflnterlock

Opelntng

of

Pnmary

and

Secondary

Throttle

Values

Open

the

pnmary

Side

throttle

valve

48

from

the

fully

closed

positIOn

and

measure

clearance

GIn

between

the

throttle

valve

and

throttle

chamber

mSlde

wall

as

shown

m

Figure

99

GIn

0

228

m

WIthout

dlsturbmg

the

above

settmg

bend

connectmg

rod

as

necessary

so

that

secoridary

throttle

valve

IS

about

to

open

Upon

com

pletIOn

of

the

adjustment

make

sure

that

the

hnk

system

operates

smoothly

Dash

Pot

Adjustment

AutomatIC

Trans

mlsszon

car

only

It

IS

necessary

that

the

Idhng

speed

of

engme

and

mIxture

have

been

well

turned

up

and

engme

IS

suffiC1

n

y

warm

1

Turn

throttle

valve

by

hand

and

read

engme

speed

when

the

da

h

pot

Just

touches

the

stop

per

lever

Adjust

the

pOSitIOn

of

the

dash

pot

by

turnmg

the

nut

until

the

engine

speed

IS

In

the

range

from

1

900

to

2

000

rpm

Make

sure

that

the

engine

speed

IS

smoothly

leduced

from

3

000

to

1

000

rpm

within

a

few

econds

Removal

Remove

the

aIr

cleaner

DIsconnect

the

fuel

line

vacuum

line

automatic

choke

harness

and

antl

dlesehng

solenOId

harness

from

carburetor

Remove

the

throttle

lever

Remove

four

nuts

and

washers

retaining

the

carburetor

to

the

mamfold

If

necessary

LIft

the

carburetor

and

remove

from

the

mamfold

Remove

and

dlscard

the

gasketcused

between

the

carburetor

and

mamfold

8

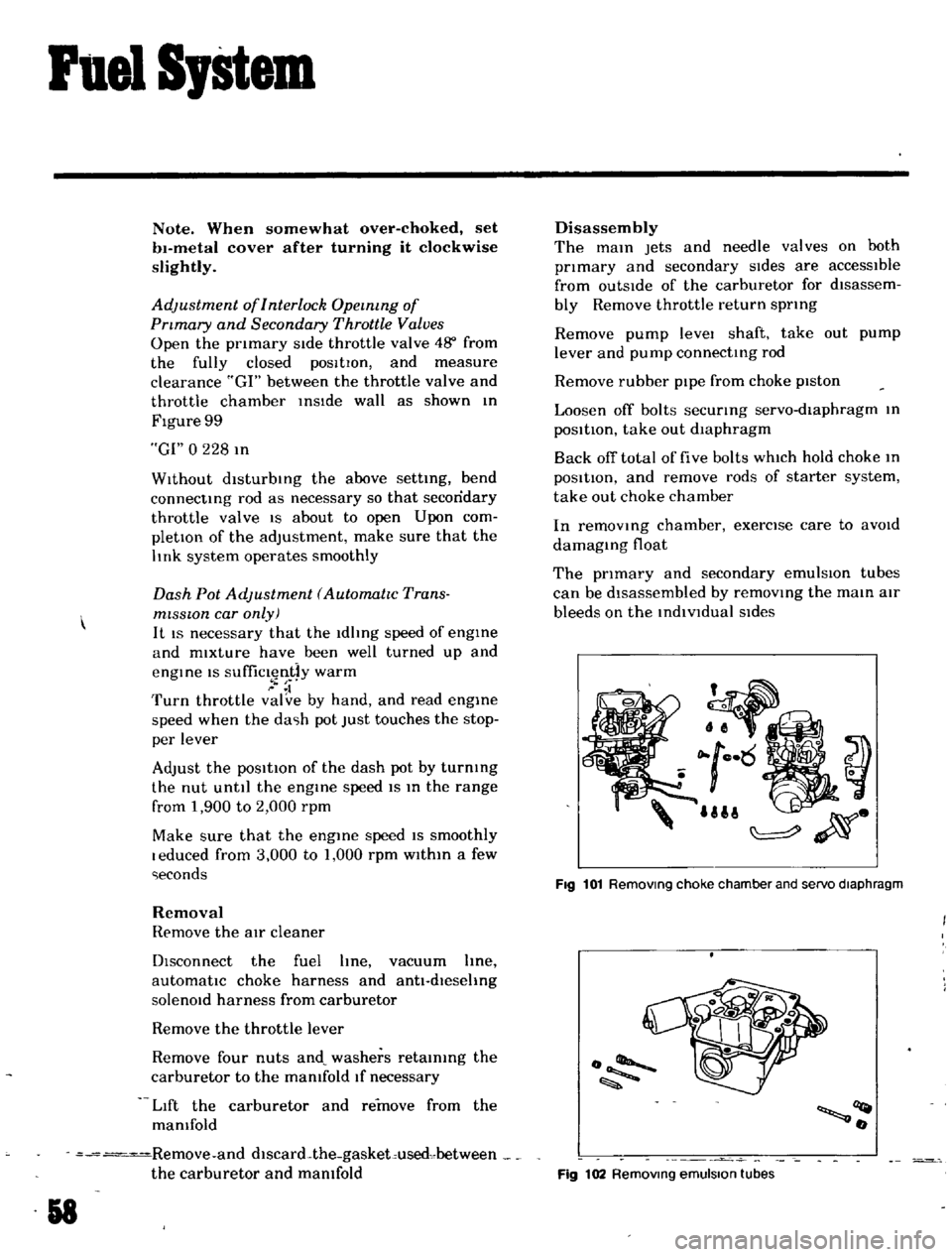

Disassembly

The

main

Jets

and

needle

valves

on

both

primary

and

secondary

Sides

are

accessible

from

outSIde

of

the

carburetor

for

disassem

bly

Remove

throttle

return

sprmg

Remove

pump

level

shaft

take

out

pump

lever

and

pump

connectmg

rod

Remove

rubber

pipe

from

choke

piston

Loosen

off

bolts

secutlng

servo

diaphragm

In

positIOn

take

out

dIaphragm

Back

off

total

of

five

bolts

which

hold

choke

In

posItion

and

remove

rods

of

starter

system

take

out

choke

chamber

In

removmg

chamber

exercise

care

to

aVOId

damaging

float

The

pnmary

and

secondary

emulsIOn

tubes

can

be

disassembled

by

removmg

the

main

air

bleeds

on

the

indiVidual

SIdes

UII

ij

Fig

101

Removmg

choke

chamber

and

servo

diaphragm

o

llQt

o

Fig

102

Removmg

emulsion

tubes