wiring DATSUN B110 1969 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 6 of 136

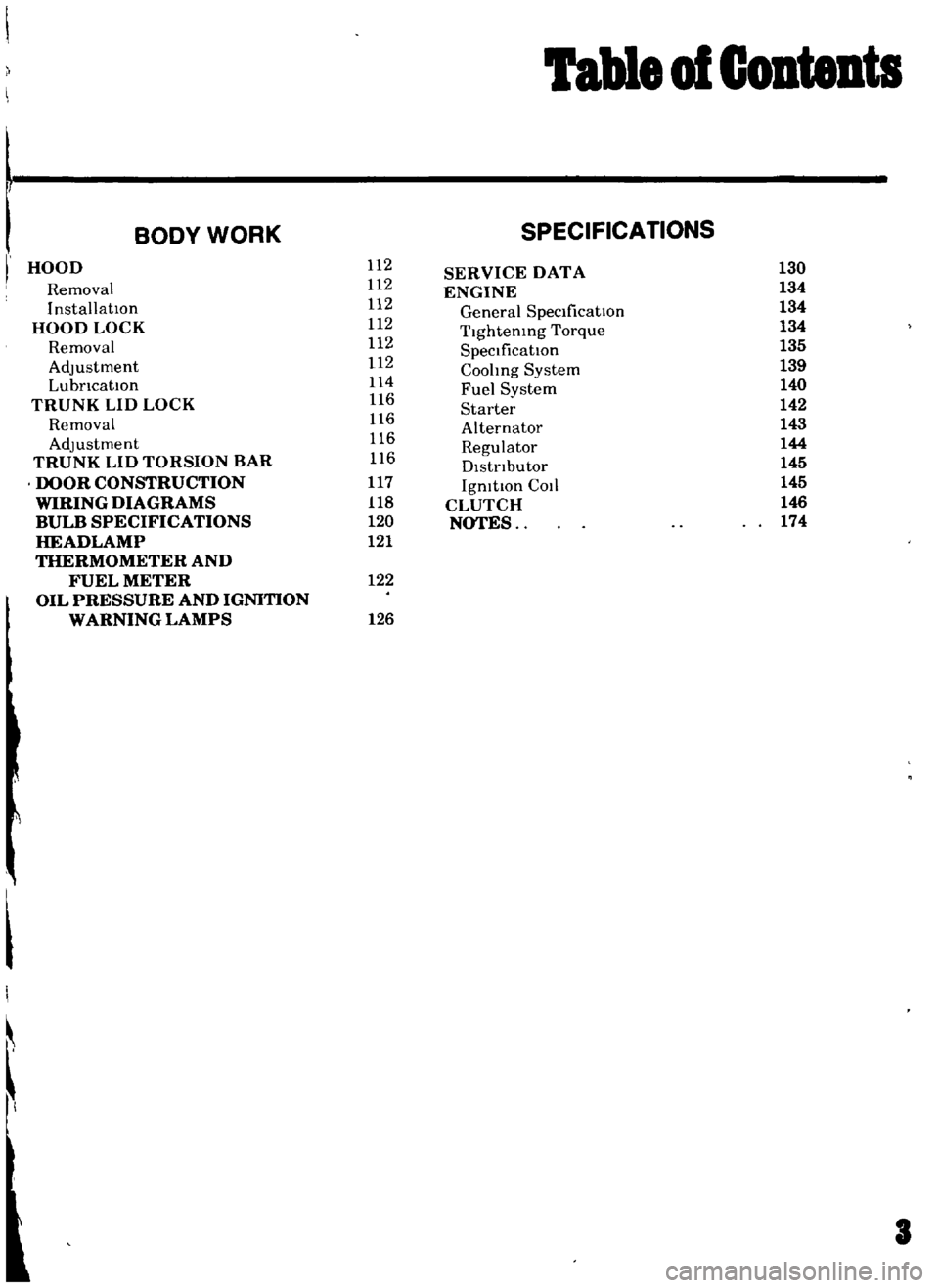

fable

of

Contents

BODY

WORK

SPECIFICATIONS

I

HOOD

112

SERVICE

DATA

130

Removal

112

ENGINE

134

InstallatIOn

112

General

SpeCificatIOn

134

HOOD

LOCK

112

Tlghtemng

Torque

134

Removal

112

SpeCIficatIOn

135

Adjustment

112

Coohng

System

139

LubncatlOn

114

Fuel

System

140

TRUNK

LID

LOCK

116

Starter

142

Removal

116

Alternator

143

Adjustment

116

Regulator

144

TRUNK

LID

TORSION

BAR

116

Dlstnbutor

145

DOOR

CONSTRUCTION

117

IgnItIOn

Cot

145

WIRING

DIAGRAMS

118

CLUTCH

146

BULB

SPECIFICATIONS

120

NOTES

174

HEADLAMP

121

THERMOMETER

AND

FUEL

METER

122

OIL

PRESSURE

AND

IGNITION

WARNING

LAMPS

126

I

I

t

I

3

Page 36 of 136

B1eetrical

Iptem

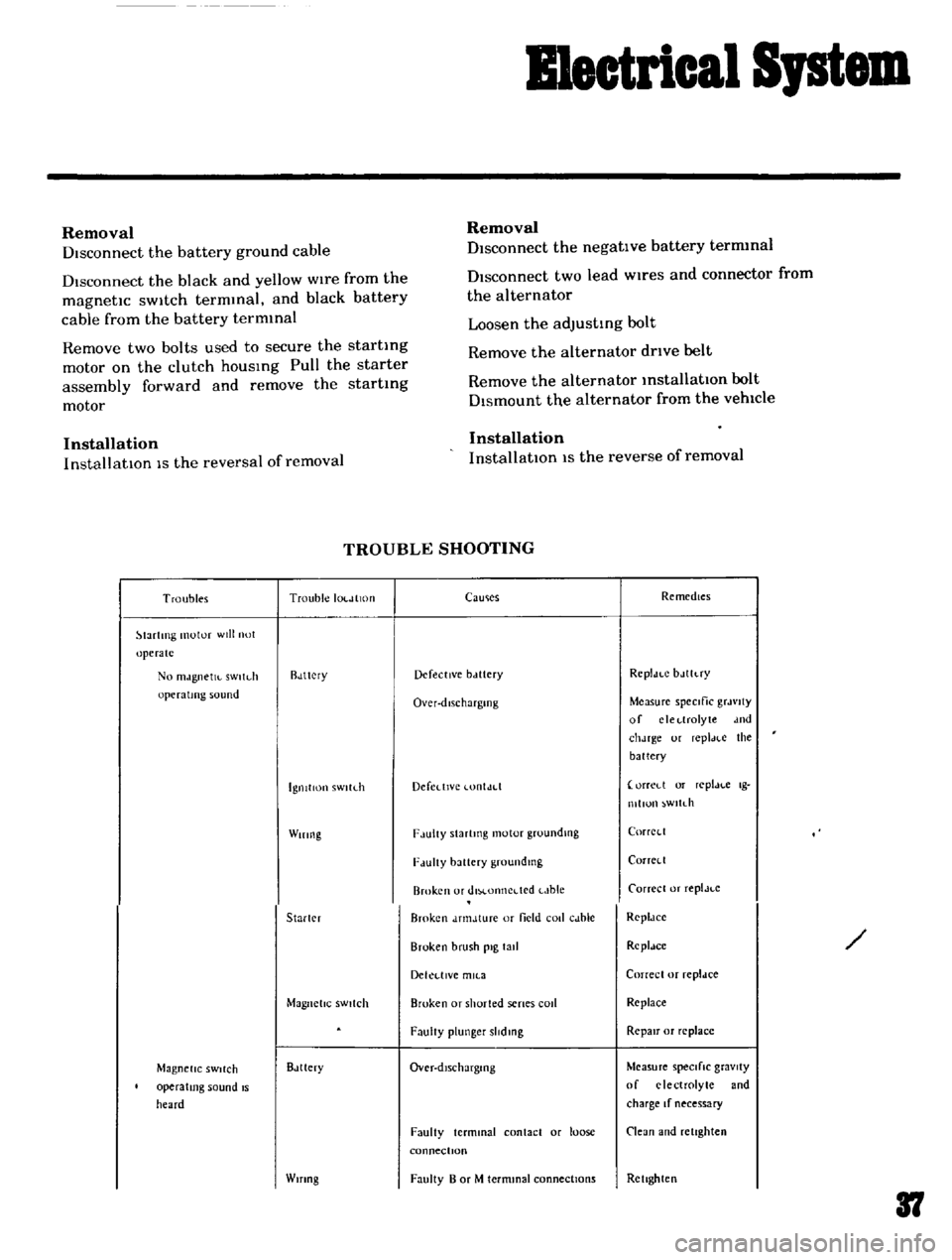

Removal

DIsconnect

the

battery

ground

cable

Disconnect

the

black

and

yellow

wIre

from

the

magnetic

sWitch

termmal

and

black

battery

cable

from

the

battery

termmal

Remove

two

bolts

used

to

secure

the

startmg

motor

on

the

clutch

housing

Pull

the

starter

assembly

forward

and

remove

the

starting

motor

Installation

InstallatlOn

IS

the

reversal

of

removal

Removal

Disconnect

the

negatIve

battery

termmal

DIsconnect

two

lead

wires

and

connector

from

the

alternator

Loosen

the

adjusting

bolt

Remove

the

alternator

drIve

belt

Remove

the

alternator

installation

bolt

Dismount

the

alternator

from

the

vehIcle

Installation

InstallatlOn

1S

the

reverse

of

removal

TROUBLE

SHOOTING

Troubles

Trouble

IOl

JlltHI

lartlTlg

motor

will

not

operate

No

mJgnetJl

sWltdl

operating

sound

Rdttcry

IgnitIon

sWltLh

Wiring

Starler

Magnetic

SWitch

Magnetic

SWitch

operating

sound

IS

heard

Bdttery

Wifing

CaUlies

Remedies

Defective

bclttery

Rcpldt

C

bJlh

ry

Over

dlschargmg

Measure

speCific

grJvlty

of

clcl

lrolyte

dnd

chJrge

ur

repl

H

e

the

battery

Defedlvc

lontJd

orreLl

or

replJl

c

Ig

mllun

wltdl

F

lulty

Slartmg

motor

groundlllg

CorrCl

l

F

lUlty

battery

groundmg

Corrcll

Broken

or

dlM

onncdcd

t

Jble

Carrece

or

replJt

c

Broken

dnnJture

or

field

coli

cJble

RcpldCC

Broken

brush

pig

tall

Rcpldce

Dekl

llVe

mll

3

Correcl

or

repldce

Broken

or

shorted

senes

cod

Replace

FaulIy

plunger

slidmg

RepaIr

or

replace

Over

dlschargmg

Measure

speCifiC

gravity

of

electrolyte

and

charge

If

necessary

Faulty

terminal

contact

or

loose

connectIOn

Clean

and

retighten

Faulty

B

or

M

termmal

connections

Rellghten

37

Page 37 of 136

Bmetrlcal

Spt

The

startmg

motor

rotates

PinIOn

gear

does

not

mtermec

h

with

flOg

gear

Pillion

mtermeshes

with

nng

gc

lT

Startmg

motor

roldles

Jud

pillion

Intermeshes

With

ring

gc

n

but

r

l

IlIan

IS

tou

slow

Startmg

motor

Magnetic

SWitch

Rmg

gear

Startmg

motor

Startmg

motor

Battery

Wiring

IgnitIOn

sWltl

h

Sldelmg

motor

38

Shorted

armature

or

field

cOIl

Worn

brush

or

Improper

spring

pressure

Contaminated

commutator

or

de

fective

mica

Faulty

brush

connection

Seized

metal

Armature

contacted

With

pole

core

Insufficient

plunger

L

dimenSIOn

Faulty

contact

Brok

en

or

shorted

shunt

call

wire

Worn

teeth

Weakened

pinion

sleeve

sprmg

Worn

pm

IOn

teeth

FJulty

plOlOJl

slldmg

Dropped

oft

lever

pill

EXl

hr

plunger

L

dlll1en

IOn

Defel

tlve

over

runnmg

dutch

Over

dlscharglOg

Improper

or

lome

termmdl

con

Lid

Improperly

tightened

connection

Rough

Lontact

urtJce

Shorted

armdture

COil

or

field

cOIl

Worn

brush

or

I11sufficlCnt

spnng

pressure

Conldmmated

Lomrnutator

or

Im

proper

brush

LonldLl

DercLllVe

nllca

Lack

or

metallubneallon

Armature

Lontdcted

With

pole

core

Repair

or

replace

Repair

or

replace

Cledn

or

repair

Repair

Replace

RepJlr

or

replace

AdjUst

ReplJee

Replace

ReplJee

Replnee

Rcpldce

RepJlr

Rep

m

Adjust

Re

place

Charge

battery

Repall

l11d

retIghten

Rellghten

RepJIr

or

replaLc

Repair

or

replace

Repair

or

replace

Repair

Repau

Repdlf

or

replace

Repair

or

replace

Page 39 of 136

Blectrical

Sptem

Troubles

Trouble

locatIon

Not

output

Alternator

Regulator

WIring

Low

output

Alterndtor

Regulator

Wifing

TROUBLE

SHOOTING

Causes

Sl1ckmg

brushes

Duty

brushes

and

slIp

nngs

Loose

connections

or

broken

leads

Open

stator

coLI

Open

rotor

cotl

DefectIVe

dJodes

Shorted

rotor

Shorted

stator

Grounded

A

ternunal

Broken

fan

belt

FJulty

voltage

regulator

pomt

con

tact

Broken

cable

or

disconnectIOn

of

chargIng

CIH

UIt

StIcking

brushes

Low

brush

spring

tenSion

Duty

slIp

nngs

Partially

shorted

ground

or

open

stator

cod

Partially

shorted

or

grounded

rotor

c01l

DefectIVe

dIOde

Loose

or

worn

fan

belt

Improper

voltage

regulator

adlust

Pl

n

I

Faulty

voltage

regulator

pomt

con

t

ct

Defective

operation

Faulty

chargmg

CUI

Ult

lead

WIn

connection

Remedies

Correct

or

replace

brush

and

brush

spnng

aean

RetIghten

or

solder

connection

Replace

leads

If

necessary

6

RepaIr

or

replace

the

stator

coLi

Replace

the

rotor

Replace

the

dIOde

assembly

Replace

the

rotor

RepaIr

or

replace

the

stator

Replace

the

Insulator

Replace

the

belt

RepdU

01

replace

the

regulator

Repdtr

or

replace

Correct

or

replace

brushes

If

neces

sary

Correct

or

replace

brush

Clean

Replace

the

stator

Replace

the

rotor

Replace

the

dIode

assembly

Rettghlen

or

replace

the

belt

Check

the

voltage

regulalor

op

eratIOn

no

rep

Jr

r

J

j

required

Repair

or

replace

the

regulator

Re

olf

or

rpla

e

t

J

Loose

baltery

leririmaJ

Rettghten

1