check engine light DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 315 of 513

ENGINE

Replacing

fuel

filter

Check

for

a

contamination

element

water

deposit

and

defection

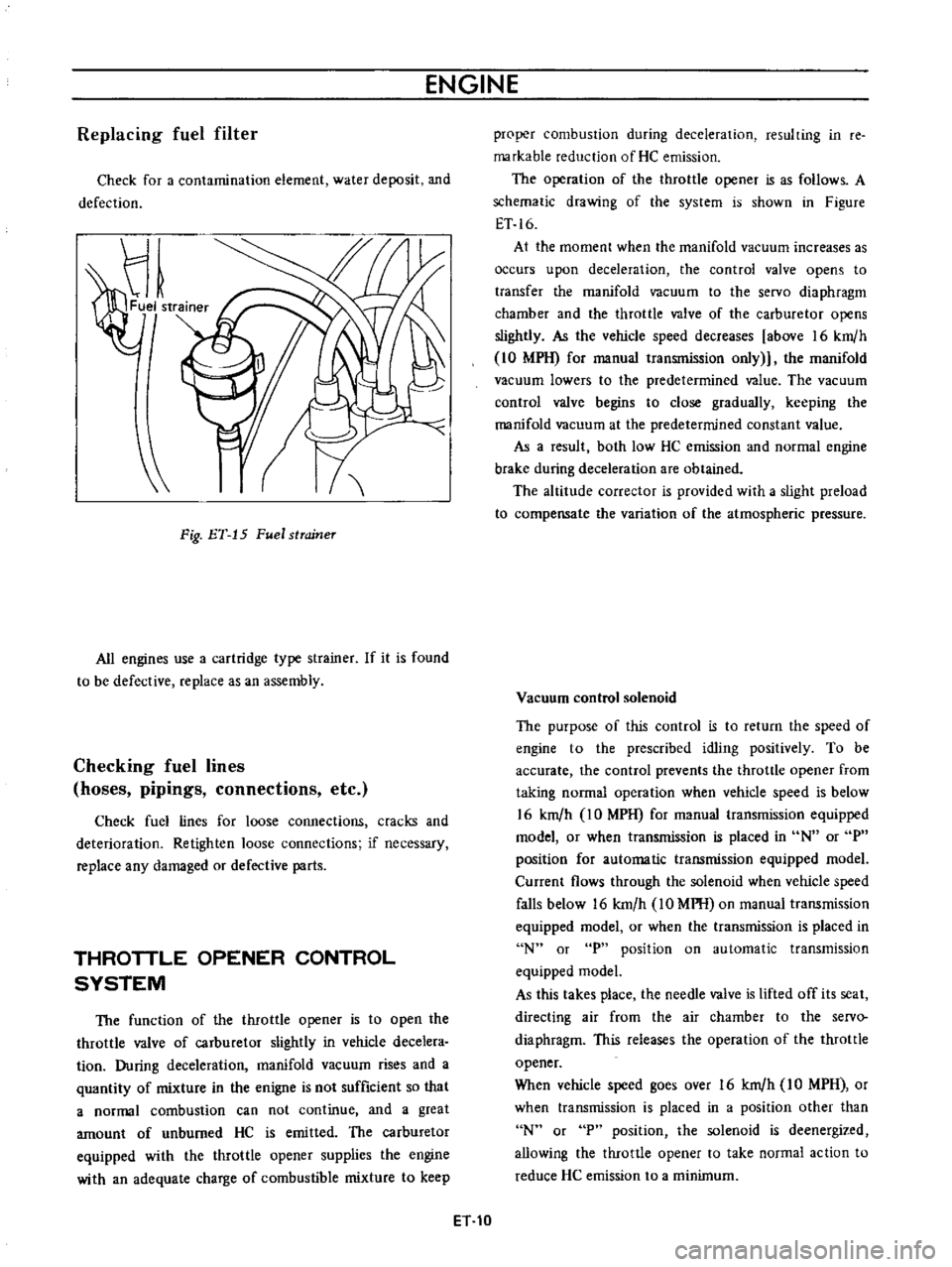

Fig

ET

15

Fuel

strcrineT

All

engines

use

a

cartridge

type

strainer

If

it

is

found

to

be

defective

replace

as

an

assembly

Checking

fuel

lines

hoses

pipings

connections

etc

Check

fuel

lines

for

loose

connections

cracks

and

deterioration

Retighten

loose

connections

if

necessary

replace

any

damaged

or

defective

parts

THROTTLE

OPENER

CONTROL

SYSTEM

The

function

of

the

throttle

opener

is

to

open

the

throttle

valve

of

carburetor

slightly

in

vehicle

decelera

tion

During

deceleration

manifold

vacuum

rises

and

a

quantity

of

mixture

in

the

enigne

is

not

sufficient

so

that

a

normal

combustion

can

not

continue

and

a

great

amount

of

unburned

HC

is

emitted

The

carburetor

equipped

with

the

throttle

opener

supplies

the

engine

with

an

adequate

charge

of

combustible

mixture

to

keep

proper

combustion

during

deceleration

resulting

in

re

markable

reduction

of

He

emission

The

operation

of

the

throttle

opener

is

as

follows

A

schematic

drawing

of

the

system

is

shown

in

Figure

ET

16

At

the

moment

when

the

manifold

vacuum

increases

as

occurs

upon

deceleration

the

control

valve

opens

to

transfer

the

manifold

vacuum

to

the

servo

diaphragm

chamber

and

the

throttle

valve

of

the

carburetor

opens

slightly

As

the

vehicle

speed

decreases

above

16

km

h

10

MPH

for

manual

transmission

only

the

manifold

vacuum

lowers

to

the

predetermined

value

The

vacuum

control

valve

begins

to

close

gradually

keeping

the

manifold

vacuum

at

the

predetermined

constant

value

As

a

result

both

low

HC

emission

and

normal

engine

brake

during

deceleration

are

obtained

The

altitude

corrector

is

provided

with

a

slight

preload

to

compensate

the

variation

of

the

atmospheric

pressure

Vacuum

control

solenoid

The

purpose

of

this

control

is

to

return

the

speed

of

engine

to

the

prescribed

idling

positively

To

be

accurate

the

control

prevents

the

throttle

opener

from

taking

normal

operation

when

vehicle

speed

is

below

16

km

h

IO

MPH

for

manual

transmission

equipped

model

or

when

transmission

is

placed

in

N

or

P

position

for

automatic

transmission

equipped

model

Current

flows

through

the

solenoid

when

vehicle

speed

falls

below

16

km

h

10

MPH

on

manual

transmission

equipped

model

or

when

the

transmission

is

placed

in

N

or

P

position

on

automatic

transmission

equipped

model

As

this

takes

place

the

needle

valve

is

lifted

off

its

seat

directing

air

from

the

air

chamber

to

the

servo

diaphragm

This

releases

the

operation

of

the

throttle

opener

When

vehicle

speed

goes

over

16

km

h

IO

MPH

or

when

transmission

is

placed

in

a

position

other

than

N

or

P

position

the

solenoid

is

deenergized

allowing

the

throttle

opener

to

take

normal

action

to

reduce

He

emission

to

a

minimum

ET

10

Page 329 of 513

ENGINE

3

Connect

a

3

way

connector

a

manometer

and

a

cock

or

an

equivalent

3

way

change

cock

to

the

end

of

the

vent

line

4

Supply

fresh

air

into

the

vapor

vent

line

through

the

cock

little

by

little

until

the

pressure

becomes

368

mm

Aq

14

5

in

Aq

5

Shut

the

cock

completely

and

leave

it

that

way

6

After

2

5

minutes

measure

the

height

of

the

liquid

in

the

manometer

7

Variation

of

height

should

remain

within

254

mmAq

1

0

in

Aq

8

When

the

filler

cap

does

not

close

completely

the

height

should

drop

to

zero

in

a

short

time

9

If

the

height

does

not

drop

to

zero

in

a

short

time

when

the

filler

cap

is

removed

it

is

the

cause

of

the

stuffy

hose

Note

In

case

the

vent

line

is

stuffy

the

breathing

in

fuel

tank

is

not

thoroughly

made

thus

causing

insufficient

delivery

of

fuel

to

engine

or

vapor

lock

It

must

therefore

be

repaired

or

replaced

3

way

connector

Cock

Air

Manometer

Vapor

liquid

seearator

Flow

guide

valve

E

CQ29

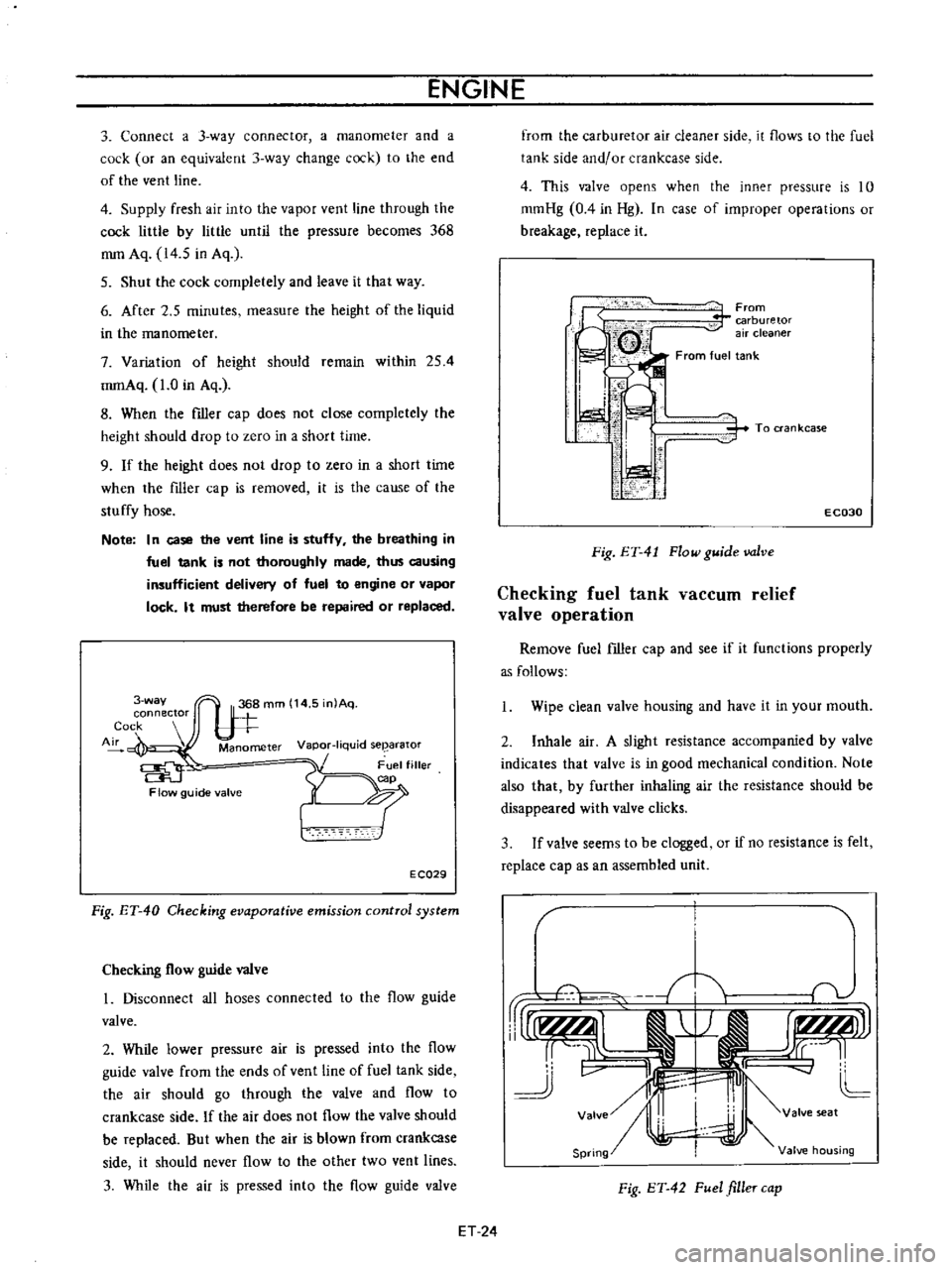

Fig

ET

40

Checking

evaporative

emission

control

system

Checking

flow

guide

valve

I

Disconnect

all

hoses

connected

to

the

flow

guide

valve

2

While

lower

pressure

air

is

pressed

into

the

flow

guide

valve

from

the

ends

of

vent

line

of

fuel

tank

side

the

air

should

go

through

the

valve

and

flow

to

crankcase

side

If

the

air

does

not

flow

the

valve

should

be

replaced

But

when

the

air

is

blown

from

crankcase

side

it

should

never

flow

to

the

other

two

vent

lines

3

While

the

air

is

pressed

into

the

flow

guide

valve

from

the

carburetor

air

cleaner

side

it

flows

to

the

fuel

tank

side

and

or

crankcase

side

4

This

valve

opens

when

the

inner

pressure

is

10

mmHg

0

4

in

Hg

In

case

of

improper

operations

or

breakage

replace

it

From

carburetor

air

cleaner

From

fuel

tank

i

I

I

ti

i

i

1

1

i

To

ran

kcase

E

C030

Fig

ET

41

Flow

guide

valve

Checking

fuel

tank

vaCCUID

relief

valve

operation

Remove

fuel

filler

cap

and

see

if

it

functions

properly

as

follows

Wipe

clean

valve

housing

and

have

it

in

your

mouth

2

Inhale

air

A

slight

resistance

accompanied

by

valve

indicates

that

valve

is

in

good

mechanical

condition

Note

also

that

by

further

inhaling

air

the

resistance

should

be

disappeared

with

valve

clicks

3

If

valve

seems

to

be

clogged

or

if

no

resistance

is

felt

replace

cap

as

an

assembled

unit

T

1i

v

rUr1f

AlI

j

r

I

r

tLMJJl

rr

L

cc

11

J

v

II

4J

L

Valve

I

valve

seat

Spring

Valve

housing

Fig

ET

42

Fuel

filler

cap

ET

24

Page 332 of 513

EMISSION

CONTROL

AND

TUNE

UP

Trouble

shooting

procedure

on

starting

circuit

Switch

on

the

starting

motor

with

light

put

on

When

light

goes

off

or

dims

considerably

a

Check

battery

b

Check

cable

for

connection

c

Check

starter

motor

When

light

stays

bright

a

Check

wiring

connection

between

battery

and

starter

motor

b

Check

starter

switch

c

Check

starter

motor

ENGINE

WILL

CRANK

NORMALLY

BUT

WILL

NOT

START

In

this

case

following

trouble

causes

may

exist

In

the

most

causes

ignition

system

or

fuel

system

is

in

trouble

Ignition

system

in

trouble

Fuel

system

in

trouble

Valve

mechanism

does

not

work

properly

Low

compression

Check

spark

plug

first

in

accordance

with

the

following

procedure

Disconnect

high

tension

cable

from

one

spark

plug

and

hold

it

about

10

rom

0

4

in

away

from

the

engine

metal

part

and

crank

the

engine

Good

spark

occurs

a

Check

spark

plug

b

Check

ignition

timing

Check

fuel

system

d

Check

cylinder

compression

No

spark

occurs

Check

the

current

flow

in

primary

circuit

Very

high

current

Inspect

primary

circuit

for

short

Check

breaker

point

for

operation

Low

or

no

current

Check

for

loose

terminal

or

disconnection

in

primary

circuit

Check

for

burned

points

Ignition

system

in

trouble

Burned

distributor

point

Repair

or

replace

Improper

point

gap

Adjust

Defective

capacitor

Replace

Rotor

cap

and

rotor

leak

Replace

ET

27

ti

Page 336 of 513

EMISSION

CONTROL

AND

TUNE

UP

Mechanical

knocking

Crankshaft

bearing

knocking

Connecting

rod

bearing

knocking

Piston

and

cylinder

noise

Piston

pin

noise

Water

pump

noise

Others

Defect

or

malfunction

of

ignition

system

spark

plug

high

tension

cable

breaker

point

ignition

coil

etc

This

strong

dull

noise

increases

when

the

engine

is

accelerated

To

locate

the

place

calise

a

misfire

on

each

cylinder

If

the

noise

stops

by

the

misfire

this

cylinder

generates

the

noise

This

is

a

little

higher

pitched

noise

than

the

crankshaft

knocking

and

also

increases

when

the

engine

is

accelerated

Cause

a

misfire

on

each

cylinder

and

if

the

noise

diminishes

almost

completely

this

crank

shaft

bearing

generates

the

noise

When

you

hear

an

overlapping

metalic

noise

which

increases

its

magnitude

with

the

revo

lution

of

the

engine

and

which

decreases

as

the

engine

is

warmed

up

this

noise

is

caused

by

the

piston

and

cylinder

To

locate

the

place

cause

a

misfire

on

each

cylinder

This

noise

is

heard

at

each

highest

and

lowest

dead

end

of

the

piston

To

locate

the

place

cause

a

misfire

on

each

cylinder

This

noise

may

be

caused

by

the

worn

or

damaged

bearings

or

by

the

uneven

surface

of

sliding

parts

An

improper

adjustment

of

the

valve

clear

ance

Noise

of

the

timing

chain

An

excessive

end

play

on

the

crankshaft

Remarks

Disengage

the

clutch

slightly

and

this

noise

will

stop

Wear

on

the

clutch

pilot

bushing

Remarks

This

noise

will

be

heard

when

the

clutch

is

disengaged

ET

31

Adjust

or

replace

ignition

syste

m

This

is

caused

by

the

wom

or

damaged

bearings

or

unevenly

worn

crankshaft

Renew

the

bearings

and

adjust

o

change

the

crankshaft

Check

the

lubrication

system

Same

as

the

case

of

crankshaft

bear

ings

This

may

cause

an

abnormal

wearing

of

the

cylinder

and

lower

compression

which

in

turn

will

cause

a

lower

output

power

and

excessive

consump

tion

of

oiL

Overhaul

the

engine

This

may

cause

a

wear

on

the

piston

pin

or

piston

pin

hole

Renew

the

piston

and

piston

pin

as

sembly

Replace

the

water

pump

with

a

new

one

Readjust

Adjust

the

tension

of

the

chain

Disassemble

the

engine

and

renew

the

main

bearing

bushing

Renew

the

bushing

and

adjust

the

drive

shaft

Page 427 of 513

ENGINE

ElECTRICAL

SYSTEM

l

J

r

@

V

I

Fig

EE

14

Inspection

of

brush

spring

pressure

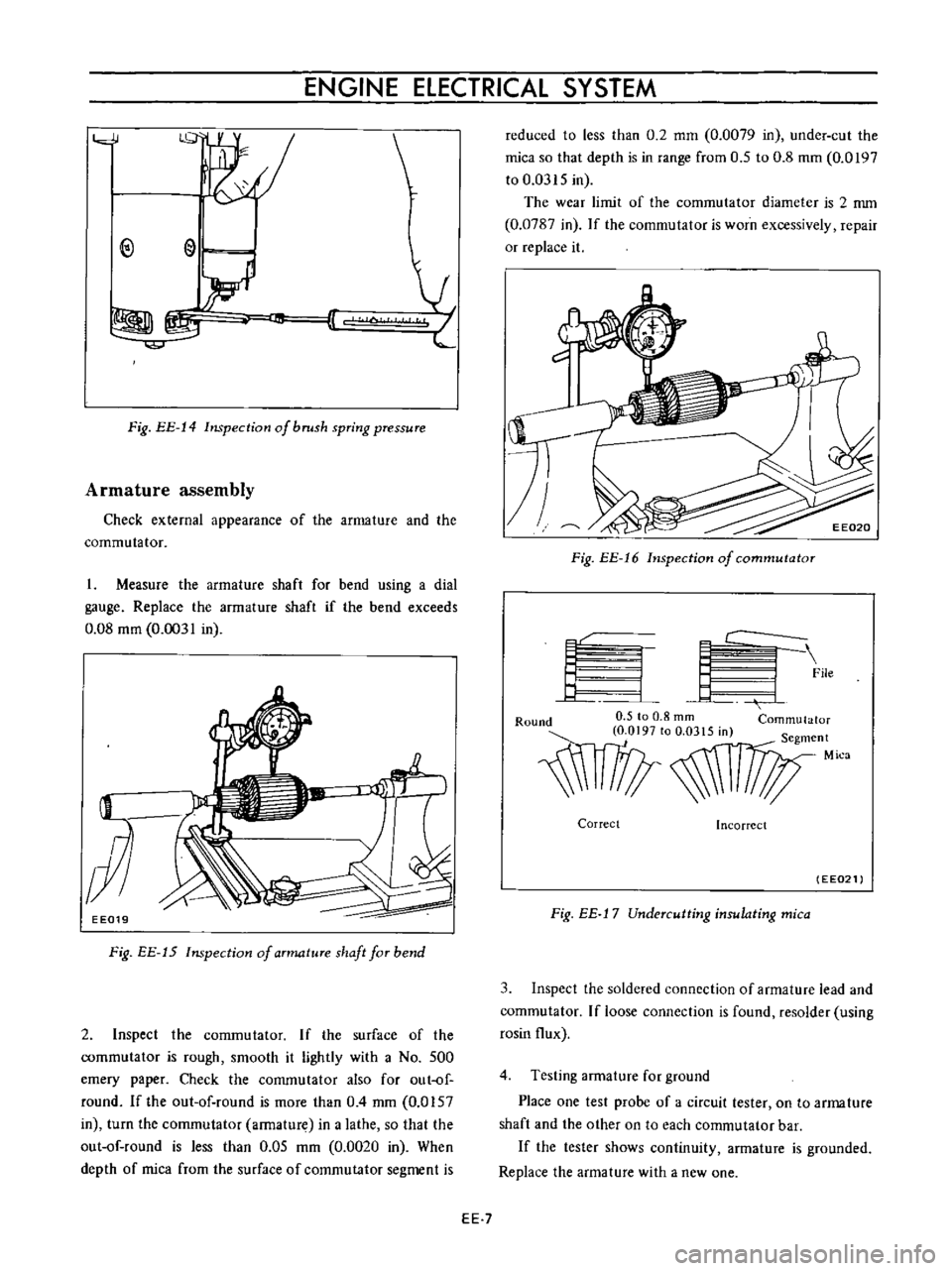

Armature

assembly

Check

external

appearance

of

the

armature

and

the

commutator

I

Measure

the

armature

shaft

for

bend

using

a

dial

gauge

Replace

the

armature

shaft

if

the

bend

exceeds

0

08

mm

0

0031

in

EE019

Fig

EE

15

Inspection

of

aTmatuTe

shaft

faT

bend

2

Inspect

the

commutator

If

the

surface

of

the

commutator

is

rough

smooth

it

lightly

with

a

No

500

emery

paper

Check

the

commutator

also

for

out

of

round

Ifthe

out

of

round

is

more

than

0

4

mm

0

0157

in

turn

the

commutator

armature

in

a

lathe

so

that

the

out

of

round

is

less

than

0

05

mm

0

0020

in

When

depth

of

mica

from

the

surface

of

commutator

segment

is

reduced

to

less

than

0

2

mm

0

0079

in

under

cut

the

mica

so

that

depth

is

in

range

from

0

5

to

0

8

mm

0

0197

to

0

0315

in

The

wear

limit

of

the

commutator

diameter

is

2

nun

0

0787

in

If

the

commutator

is

worn

excessively

repair

or

replace

it

Fig

EE

16

Inspection

of

commutator

f

L

I

C

9

File

4

J

Round

0

5

to

0

8

rom

Commutator

O

OI97tOO

0315m

S

t

egmen

1l1

Mica

Correct

Incorrect

EE021

Fig

EE

j

7

Undercutting

insulating

mica

3

Inspect

the

soldered

connection

of

armature

lead

and

commutator

If

loose

connection

is

found

resolder

using

rosin

flux

4

Testing

armature

for

ground

Place

one

test

probe

of

a

circuit

tester

on

to

arma

ture

shaft

and

the

other

on

to

each

commutator

bar

If

the

tester

shows

continuity

armature

is

grounded

Replace

the

armature

with

a

new

one

EE

7

Page 442 of 513

ENGINE

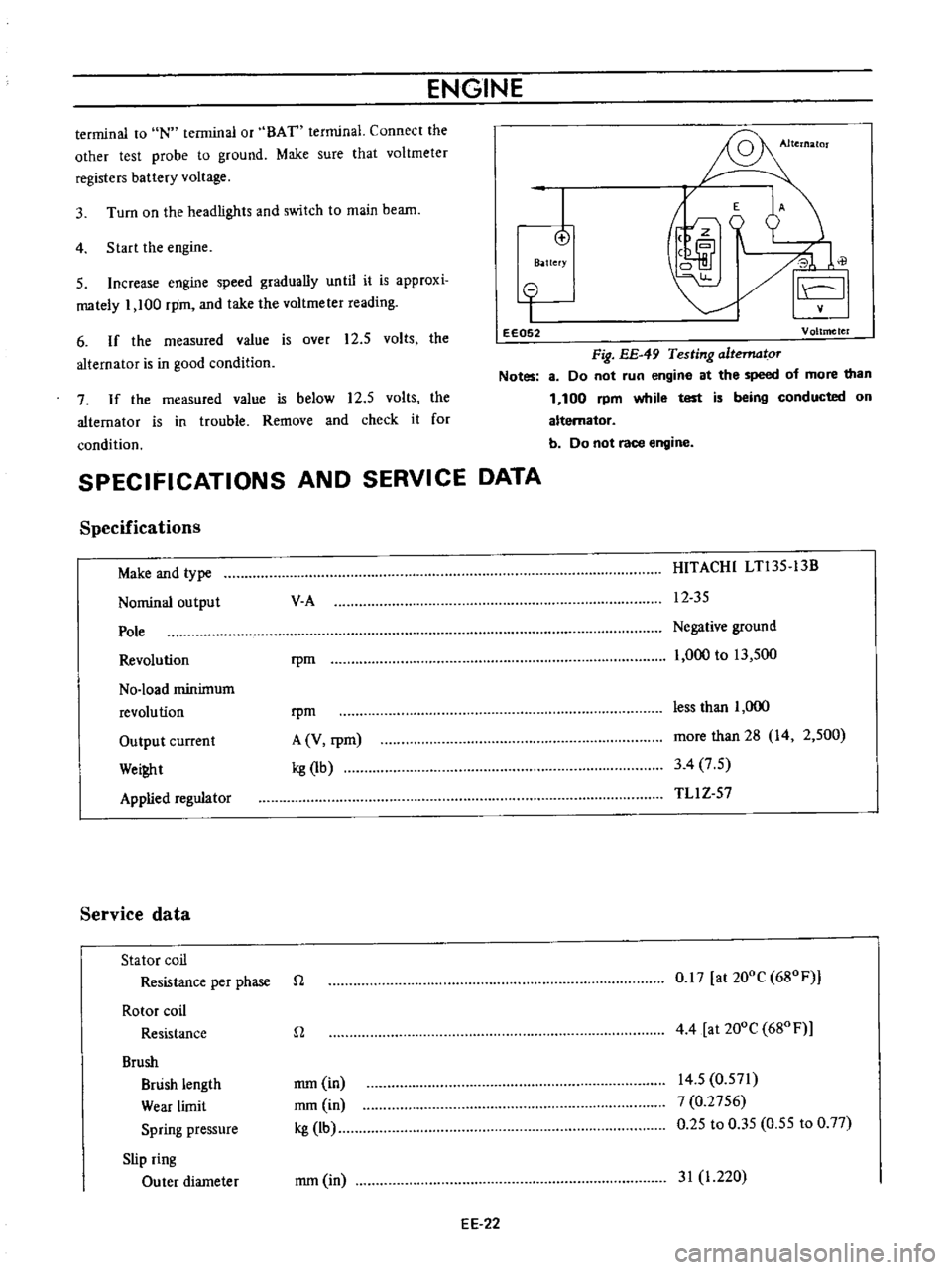

terminal

to

IN

terminal

or

BAT

terminal

Connect

the

other

test

probe

to

ground

Make

sure

that

voltmeter

registers

battery

voltage

4

Start

the

engine

3

Turn

on

the

headlights

and

switch

to

main

beam

I

o

B

ttefY

E

A

J

0

il

I

5

Increase

engine

speed

gradually

until

it

is

approxi

mately

1

100

rpm

and

take

the

voltmeter

reading

6

If

the

measured

value

is

over

12

5

volts

the

alternator

is

in

good

condition

o

I

eE052

Voltmeter

Fig

EE

49

Testing

altematoT

Notes

8

Do

not

run

engine

at

the

speed

of

more

than

1

100

rpm

while

test

is

being

conducted

on

alternator

b

Do

not

race

engine

7

If

the

measured

value

is

below

12

5

volts

the

alternator

is

in

trouble

Remove

and

check

it

for

condition

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Make

and

type

Nominal

output

Pole

Revolution

No

load

minimum

revolution

Output

current

Wei

t

Applied

regulator

Service

data

Stator

coil

Resistance

per

phase

Rotor

coil

Resistance

Brush

Brush

length

Wear

limit

Spring

pressure

Slip

ring

Outer

diameter

V

A

HITACHI

LTl35

13B

12

35

rpm

Negative

ground

1

000

to

13

500

rpm

A

V

rpm

kg

1b

less

than

1

000

more

than

28

14

2

500

3

4

7

5

TLl

Z

57

n

0

17

at

200C

680F

n

4

4

at

200e

680

F

mm

in

mm

in

kg

lb

14

5

0

571

7

0

2756

0

25

to

0

35

0

55

to

0

77

mm

in

31

1

220

EE

22

Page 446 of 513

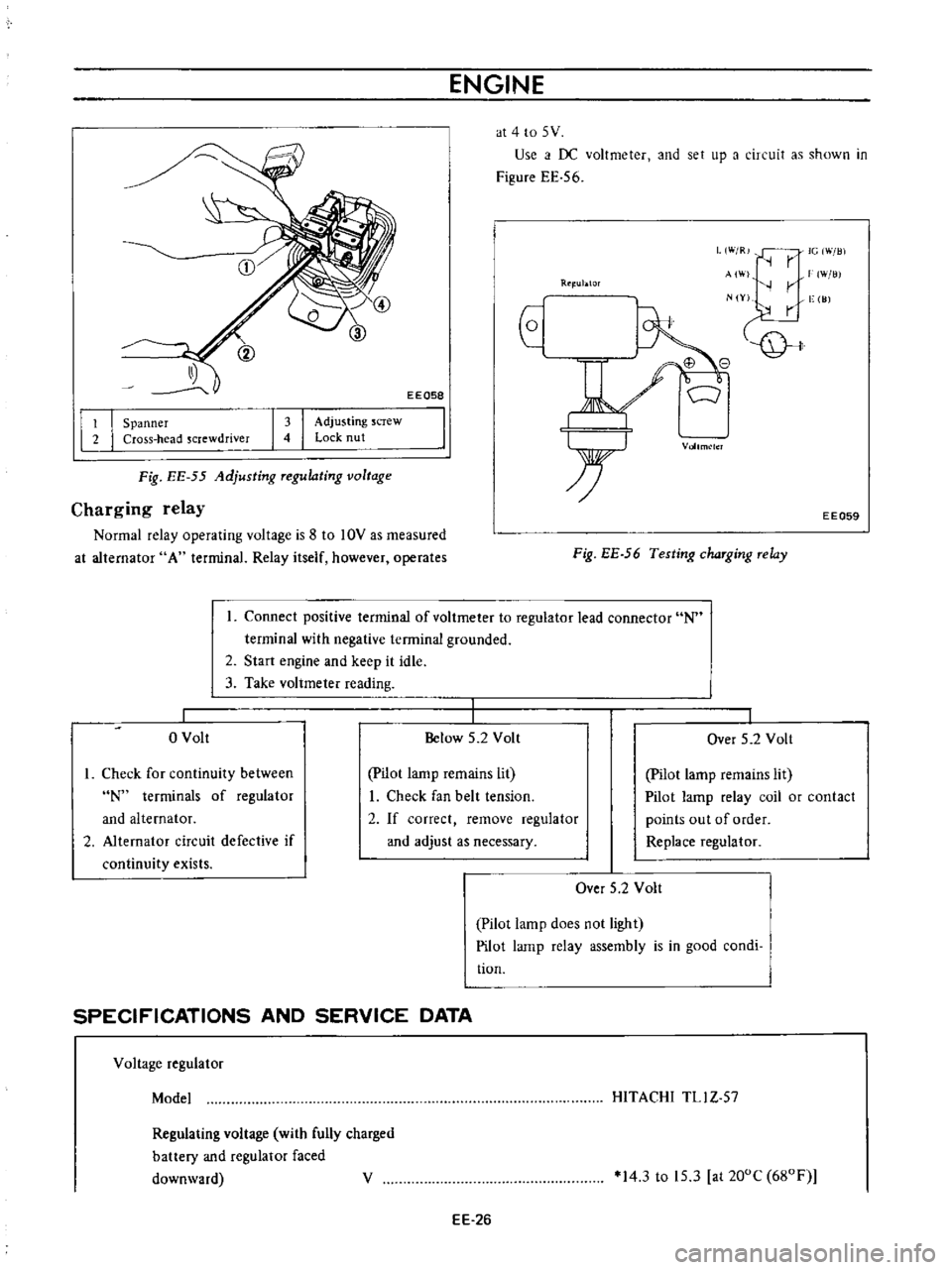

ENGINE

at

4

to

5

V

Use

i

f

DC

voltmeter

and

set

up

a

circuit

as

shown

in

Figure

EE

56

EEQ58

L

W

R

IG

Will

r

AI

W

lli

r

N

Y

vge

I

JJ

Rtl

ublOr

I

I

Spanner

Cross

head

screwdriver

I

I

Adjusting

screw

Lock

nut

Vollm

lcl

Fig

EE

55

Adjusting

Tegulating

voltage

Charging

relay

Normal

relay

operating

voltage

is

8

to

10V

as

measured

at

alternator

A

terminal

Relay

itself

however

operates

EE059

Fig

EE

56

Testing

chaTging

Telay

Connect

positive

terminal

of

voltmeter

to

regulator

lead

connector

N

terminal

with

negative

terminal

grounded

2

Start

engine

and

keep

it

idle

3

Take

voltmeter

reading

o

Volt

Below

5

2

Volt

I

Over

5

2

Volt

I

Check

for

continuity

between

N

terminals

of

regulator

and

alternator

2

Alternator

circuit

defective

if

continuity

exists

pilot

lamp

remains

lit

I

Check

fan

belt

tension

2

If

correct

remove

regulator

and

adjust

as

necessary

Pilot

lamp

remains

lit

Pilot

lamp

relay

coil

or

contact

points

out

of

order

Replace

regulator

Over

5

2

Volt

Pilot

lamp

does

not

light

Pilot

lamp

relay

assembly

is

in

good

condi

tion

SPECIFICATIONS

AND

SERVICE

DATA

Voltage

regulator

Model

HITACHI

TLl

Z

57

Regulating

voltage

with

fully

charged

battery

and

regulator

faced

downward

V

14

3

to

15

3

at

200C

680F

EE

26

Page 457 of 513

ENGINE

ElECTRICAL

SYSTEM

SPECIFICATIONS

Make

and

type

Primary

voltage

v

Spark

gap

mm

in

Primary

resistance

at

200C

680

F

n

Secondary

resistance

at

200C

680F

Kn

External

resistor

at

200C

680

F

n

Applied

resistor

HANSHIN

HITACHI

H5

15

2

C6R

601

12

12

more

than

7

more

than

7

0

28

0

28

1

17

to

I

43

l

l

7

to

I

43

11

2

to

16

8

11

2

to

16

8

l

3tol7

l

3tol7

RC

15

5560R

151O

SPARK

PLUG

CONTENTS

DESCRIPTION

INSPECTION

CLEANING

AND

REGAP

EE

37

EE

37

EE

38

DESCRIPTION

The

spark

plugs

are

of

the

resister

type

having

14

mm

0

551

in

threads

and

0

8

to

0

9

mm

0

031

to

0

Q35

in

gap

Note

All

spark

plugs

installed

on

an

engine

must

be

of

the

same

brand

and

number

of

heat

range

INSPECTION

1

Remove

spark

plug

wire

by

pulling

on

boot

not

on

wire

itself

2

Remove

spark

plugs

3

Check

electrodes

and

inner

and

outer

porcelains

of

plugs

noting

the

type

of

deposits

and

the

degree

of

electrode

erosion

Refer

to

Figure

EE

74

Normal

Brown

to

grayish

tan

deposits

and

slight

elec

trode

wear

indicate

correct

spark

plug

heat

range

SPECIFICATIONS

AND

SERVICE

DATA

TROUBLE

DIAGNOSES

AND

CORRECTIONS

EE

38

EE

39

Carbon

fouled

Dry

fluffy

carbon

deposits

on

the

insula

tor

and

electrode

were

mostly

caused

by

slow

speed

driving

in

city

weak

ignition

too

rich

fuel

mixture

dirty

air

cleaner

etc

H

is

advisable

to

replace

with

plugs

having

hotter

heat

range

Oil

fouled

Wet

black

deposits

show

excessive

oil

en

trance

into

combustion

chamber

through

worn

rings

and

pistons

or

excessive

clearance

between

valve

guides

and

stems

If

the

same

condition

remains

after

repair

use

a

hotter

plug

Overheating

White

or

light

gray

insulator

with

black

or

gray

brown

spots

and

bluish

burnt

electrodes

indicate

engine

overheating

Moreover

the

appearance

results

from

incorrect

ignition

timing

loose

spark

plugs

low

fuel

pump

pressure

wrong

selection

of

fuel

a

hotter

plug

etc

H

is

advisable

to

replace

with

plugs

having

colder

heat

range

EE

37

Page 483 of 513

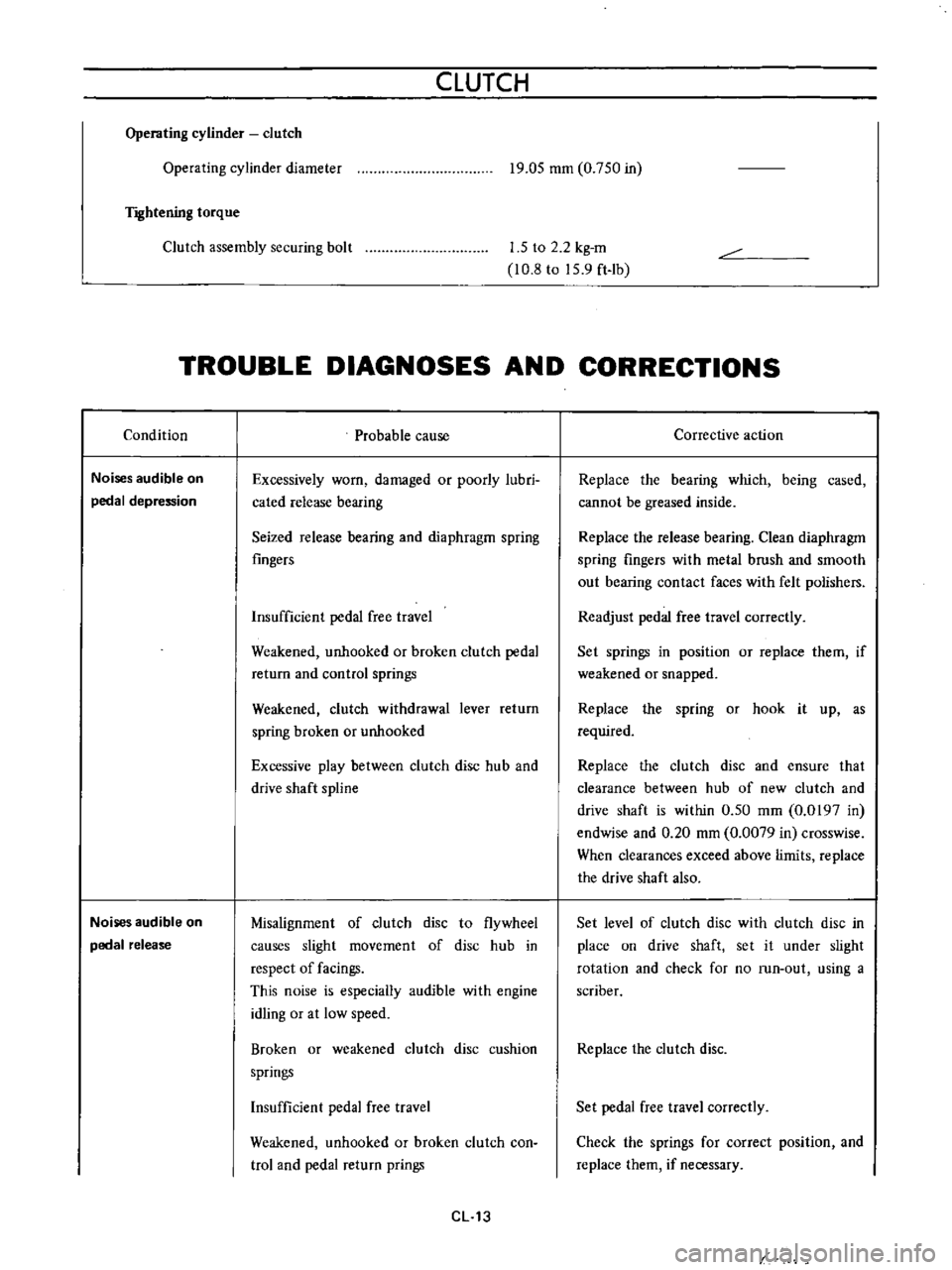

CLUTCH

Operating

cylinder

clutch

Operating

cylinder

diameter

T

Ilhtening

torque

19

05

mm

0

750

in

Clutch

assembly

securing

bolt

1

5

to

2

2

kg

m

10

8

to

15

9

ft

Ib

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Noises

audible

on

pedal

depression

Noises

audible

on

pedal

release

Probable

cause

Excessively

worn

damaged

or

poorly

lubri

cated

release

bearing

Seized

release

bearing

and

diaphragm

spring

fingers

Insufficient

pedal

free

travel

Weakened

unhooked

or

broken

clutch

pedal

return

and

control

springs

Weakened

clutch

withdrawal

lever

return

spring

broken

or

unhooked

Excessive

play

between

clutch

disc

hub

and

drive

shaft

spline

Misalignment

of

clutch

disc

to

flywheel

causes

slight

movement

of

disc

hub

in

respect

of

facings

This

noise

is

especially

audible

with

engine

idling

or

at

low

speed

Broken

or

weakened

clutch

disc

cushion

springs

Insufficient

pedal

free

travel

Weakened

unhooked

or

broken

clutch

con

trol

and

pedal

return

prings

CL

13

Corrective

action

Replace

the

bearing

which

being

cased

cannot

be

greased

inside

Replace

the

release

bearing

Clean

diaphragm

spring

fingers

with

metal

brush

and

smooth

out

bearing

contact

faces

with

felt

polishers

Readjust

pedal

free

travel

correctly

Set

springs

in

position

or

replace

them

if

weakened

or

snapped

Replace

the

spring

or

hook

it

up

as

required

Replace

the

clutch

disc

and

ensure

that

clearance

between

hub

of

new

clutch

and

drive

shaft

is

within

0

50

mm

0

0197

in

endwise

and

0

20

mm

0

0079

in

crosswise

When

clearances

exceed

above

limits

replace

the

drive

shaft

also

Set

level

of

clutch

disc

with

clutch

disc

in

place

on

drive

shaft

set

it

under

slight

rotation

and

check

for

no

run

out

using

a

scriber

Replace

the

clutch

disc

Set

pedal

free

travel

correctly

Check

the

springs

for

correct

position

and

replace

them

if

necessary