weight DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 362 of 513

ENGINE

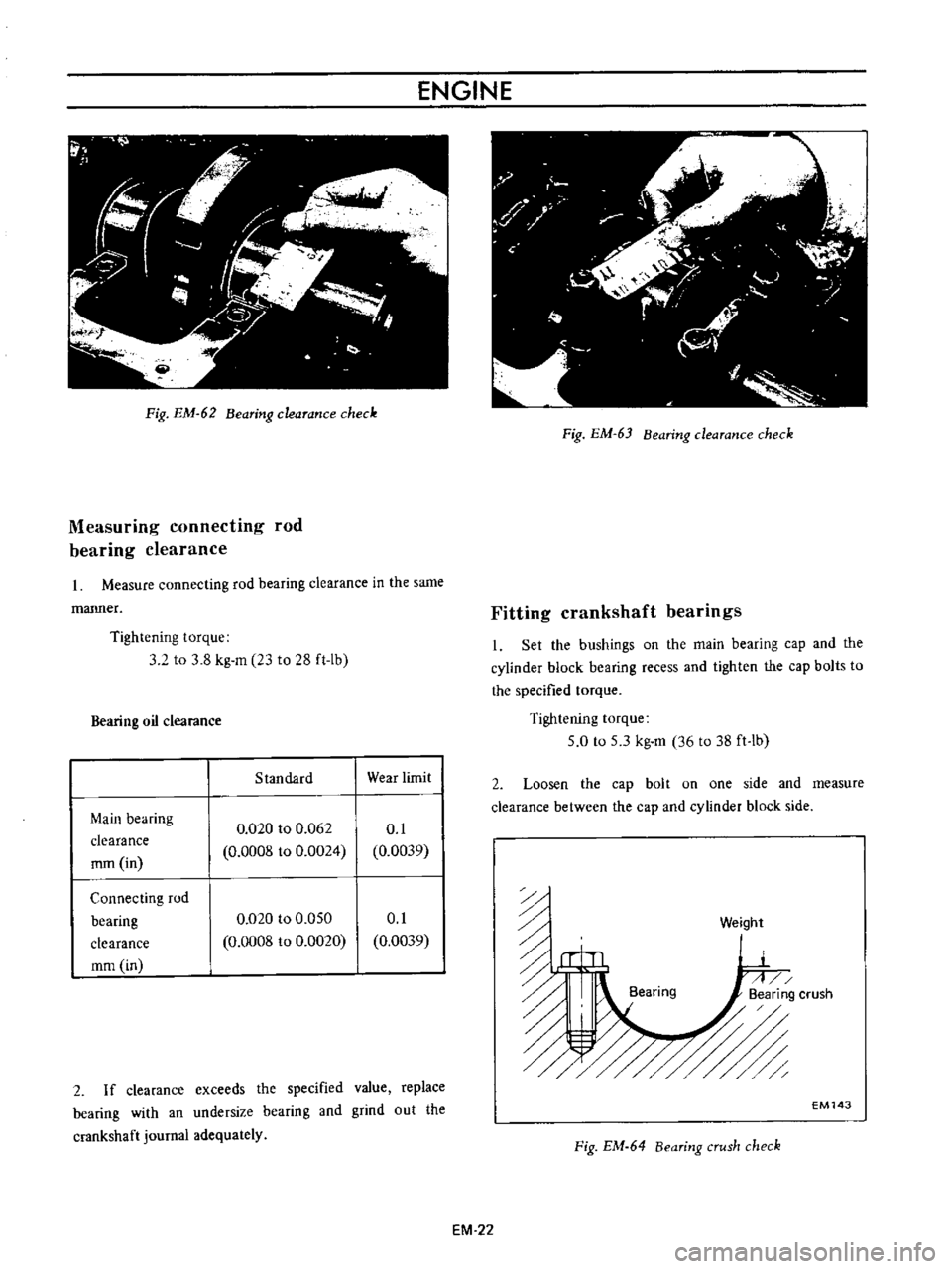

Pig

EM

62

Bearing

clearance

check

Measuring

connecting

rod

bearing

clearance

Measure

connecting

rod

bearing

clearance

in

the

same

manner

Tightening

torque

3

2

to

3

8

kg

m

23

to

28

ft

Ib

Bearing

oil

clearance

Standard

Wear

limit

Main

bearing

clearance

rom

in

0

020

to

0

062

0

0008

to

0

0024

0

1

0

0039

Connecting

rod

bearing

clearance

mm

in

0

020

to

0

050

0

0008

to

0

0020

0

1

0

0039

2

If

clearance

exceeds

the

specified

value

replace

bearing

with

an

undersize

bearing

and

grind

out

the

crankshaft

journal

adequately

Fig

EM

63

Bearing

clearance

check

Fitting

crankshaft

bearings

I

Set

the

bushings

on

the

main

bearing

cap

and

the

cylinder

block

bearing

recess

and

tighten

the

cap

bolts

to

the

specified

torque

Tightening

torque

5

0

to

5

3

kg

m

36

to

38

ft

lb

2

Loosen

the

cap

bolt

on

one

side

and

measure

clearance

between

the

cap

and

cylinder

block

side

n

n

u

ii

Bearing

6

Weight

EM143

Fig

EM

64

Bearing

crush

check

EM

22

Page 402 of 513

FUEl

SYSTEM

Idling

and

slow

system

Passing

through

the

main

jet

the

fuel

passage

is

separated

from

main

line

fuel

flows

through

the

slow

jet

primary

slow

air

bleed

is

ejected

from

the

by

pass

hole

and

idle

nozzle

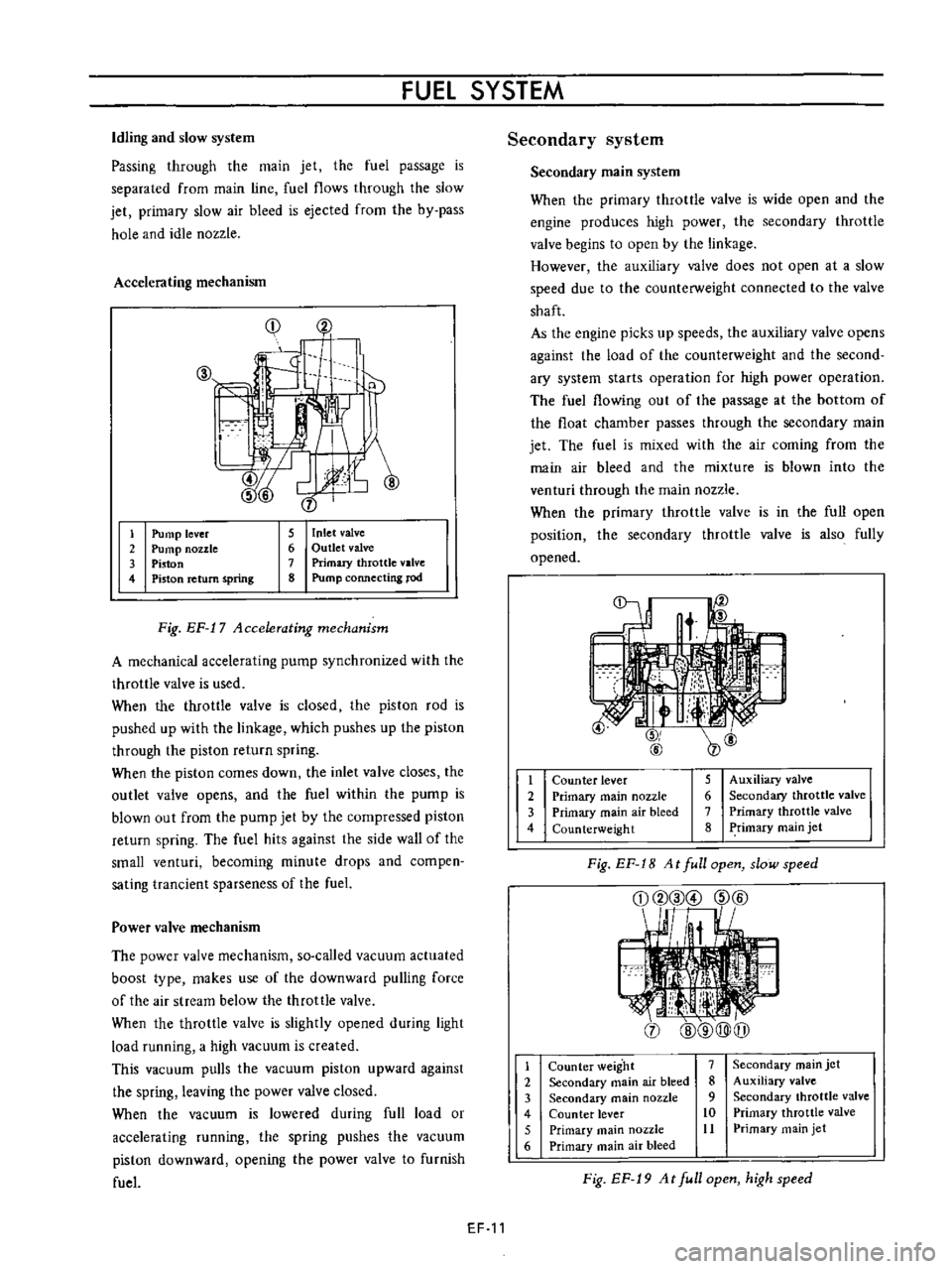

Accelerating

mechanism

Cj

f

li

Ip

j

1

2

3

4

5

Inlet

valve

6

Outlet

valve

7

Primary

throttle

valve

8

Pump

connecting

rod

Pump

lever

Pump

nozzle

Piston

Piston

return

spring

Fig

EF

17

Accelerating

mechanism

A

mechanical

accelerating

pump

synchronized

with

the

throttle

valve

is

used

When

the

throttle

valve

is

closed

the

piston

rod

is

pushed

up

with

the

linkage

which

pushes

up

the

piston

through

the

piston

return

spring

When

the

piston

comes

down

the

inlet

valve

closes

the

outlet

valve

opens

and

the

fuel

within

the

pump

is

blown

out

from

the

pump

jet

by

the

compressed

piston

return

spring

The

fuel

hits

against

the

side

wall

of

the

small

venturi

becoming

minute

drops

and

compen

sating

trancient

sparseness

of

the

fuel

Power

valve

mechanism

The

power

valve

mechanism

so

called

vacuum

actuated

boost

type

makes

use

of

the

downward

pulling

force

of

the

air

stream

below

the

throttle

valve

When

the

throttle

valve

is

slightly

opened

during

light

load

running

a

high

vacuum

is

created

This

vacuum

pulls

the

vacuum

piston

upward

against

the

spring

leaving

the

power

valve

closed

When

the

vacuum

is

lowered

during

full

load

or

accelerating

running

the

spring

pushes

the

vacuum

piston

downward

opening

the

power

valve

to

furnish

fuel

EF

11

Secondary

system

Secondary

main

system

When

the

primary

throttle

valve

is

wide

open

and

the

engine

produces

high

power

the

secondary

throttle

valve

begins

to

open

by

the

linkage

However

the

auxiliary

Y

J

lve

does

not

open

at

a

slow

speed

due

to

the

counterweight

connected

to

the

valve

shaft

As

the

engine

picks

up

speeds

the

auxiliary

valve

opens

against

the

load

of

the

counterweight

and

the

second

ary

system

starts

operation

for

high

power

operation

The

fuel

flowing

out

of

the

passage

at

the

bottom

of

the

float

chamber

passes

through

the

secondary

main

jet

The

fuel

is

mixed

with

the

air

coming

from

the

main

air

bleed

and

the

mixture

is

blown

into

the

venturi

through

the

main

nozzle

When

the

primary

throttle

valve

is

in

the

full

open

position

the

secondary

throttle

valve

is

also

fully

opened

t

2

3

4

5

Auxiliary

valve

6

Secondary

throttle

valve

7

Primary

throttle

valve

8

Primary

main

jet

Counter

lever

Primary

main

nozzle

Primary

main

air

bleed

Counterweight

Fig

EF

1B

At

full

open

slow

speed

j

1

2

3

4

5

6

Counter

weight

7

Secondary

main

air

bleed

8

Secondary

main

nozzle

9

Counter

lever

10

Primary

main

nozzle

11

Primary

main

air

bleed

Secondary

main

jet

Auxiliary

valve

Secondary

throttle

valve

Primary

throttle

valve

Primary

main

jet

Fig

EF

19

At

full

open

high

speed

Page 410 of 513

FUEl

SYSTEM

MA

JOR

SERVICE

OPERATIONS

A

completely

adjusted

and

serviced

carburetor

will

provide

the

engine

with

proper

mixture

at

all

speeds

Periodical

overhauling

which

cleans

all

components

and

passages

will

recover

the

originally

designed

performance

producing

the

engine

with

proper

gasoline

and

air

ratio

at

all

speeds

Passages

and

holes

of

the

carburetor

must

be

cleaned

carefully

Use

only

carburetor

solvent

and

com

pressed

air

to

clean

aU

passages

and

discharge

holes

Never

use

wire

or

other

pointed

tool

otherwise

accurately

calibrated

carburetor

will

be

affected

Removal

Remove

the

air

cleaner

2

Disconnect

the

fuel

line

vacuum

line

automatic

choke

harness

and

anti

dieseling

solenoid

harness

from

carburetor

3

Remove

the

throttle

lever

4

Remove

four

nuts

and

washers

retaining

the

carbuTe

tor

to

the

manifold

if

necessary

5

Lift

the

carburetor

and

remove

from

the

manifold

6

Remove

and

discard

the

gasket

used

between

the

carburetor

and

manifold

Disassembly

The

main

jets

and

needle

valves

on

both

primary

and

secondary

sides

are

accessible

from

outside

of

the

carbure

tor

for

disassembly

2

Remove

throttle

return

spring

3

Remove

pump

lever

shaft

take

out

pump

lever

and

pump

connecting

rod

4

Remove

rubber

pipe

from

choke

piston

5

Loosen

off

bolts

securing

servo

diaphragm

in

posi

tion

take

out

diaphragm

6

Back

off

total

of

five

bolts

which

hold

choke

in

position

and

remove

rods

of

starter

system

take

out

choke

chamber

In

removing

chamber

exercise

care

to

avoid

damaging

float

EF

19

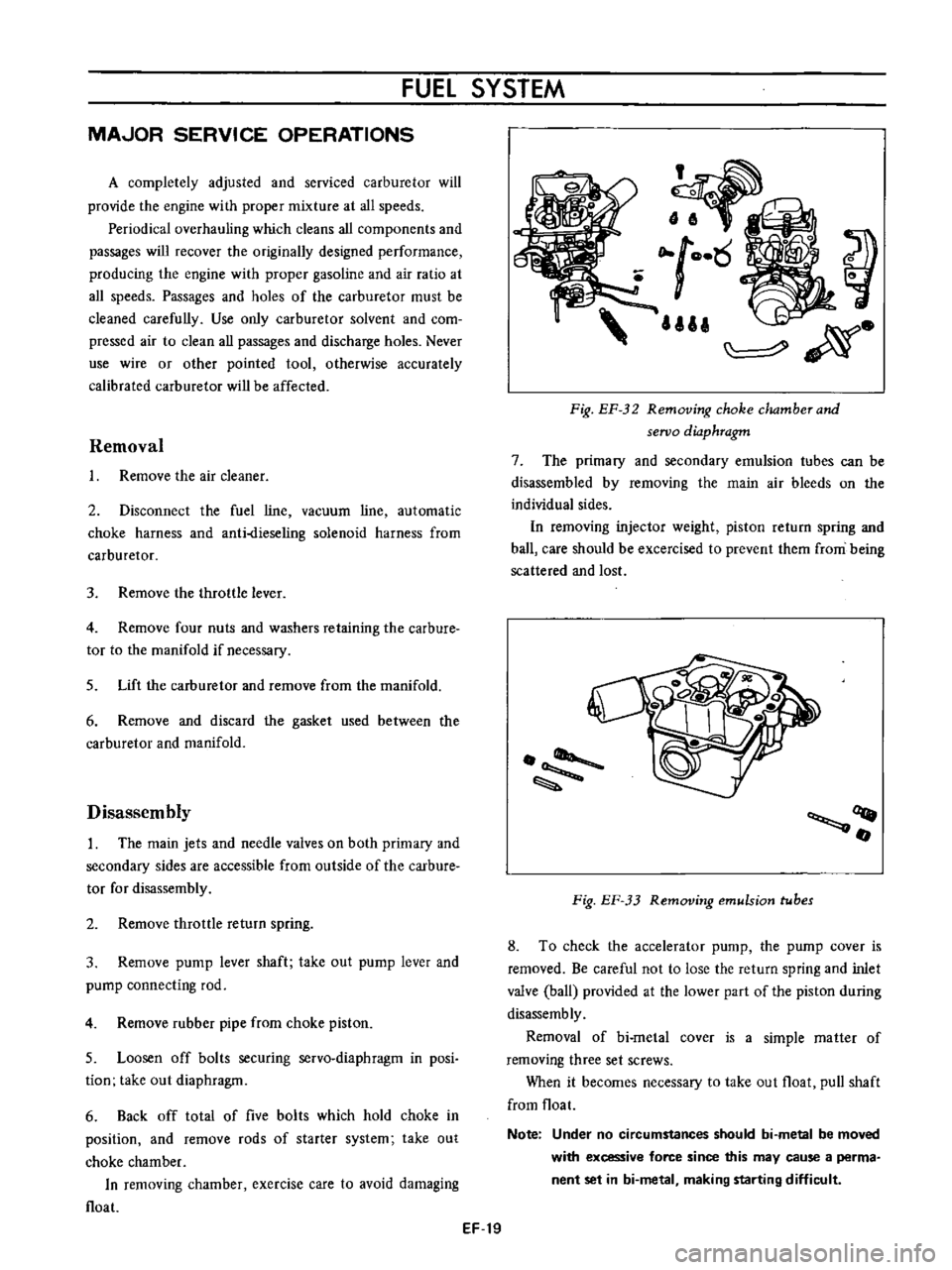

ilia

Fig

EF

32

Removing

choke

dwmherand

seroo

diaphragm

7

The

primary

and

secondary

emulsion

tubes

can

be

disassembled

by

removing

the

main

air

bleeds

on

the

individual

sides

In

removing

injector

weight

piston

return

spring

and

ball

care

should

be

excercised

to

prevent

them

from

being

scattered

and

lost

OQ

fI

Fig

EF

33

Removing

emulsion

tubes

8

To

check

the

accelerator

pump

the

pump

cover

is

removed

Be

careful

not

to

lose

the

return

spring

and

inlet

valve

ball

provided

at

the

lower

part

of

the

piston

during

disassemb

ly

Removal

of

bi

metal

cover

is

a

simple

matter

of

removing

three

set

screws

When

it

becomes

necessary

to

take

out

float

pull

shaft

from

float

Note

Under

no

circumstances

should

bi

metal

be

moved

with

excessive

force

since

this

may

cause

a

perma

nent

set

in

bi

metal

making

starting

difficult

Page 413 of 513

ENGINE

Choke

unloader

clearance

carburetor

body

C

between

choke

valve

and

mm

in

Bi

metal

resistance

ohms

2

01

0

07911

8

6t09

0

Accelerator

pump

Injector

hole

Return

spring

Fuel

pressure

mm

in

g

mm

Ib

in

kg

cm

2

psi

kg

lb

0

5

0

0197

78

I

I

0

18

2

6

Manual

transmission

Automatic

transmission

Weight

2

8

6

2

2

9

6

39

Example

1

215

represents

215

100

2

15

mm

0

0846

in

diameter

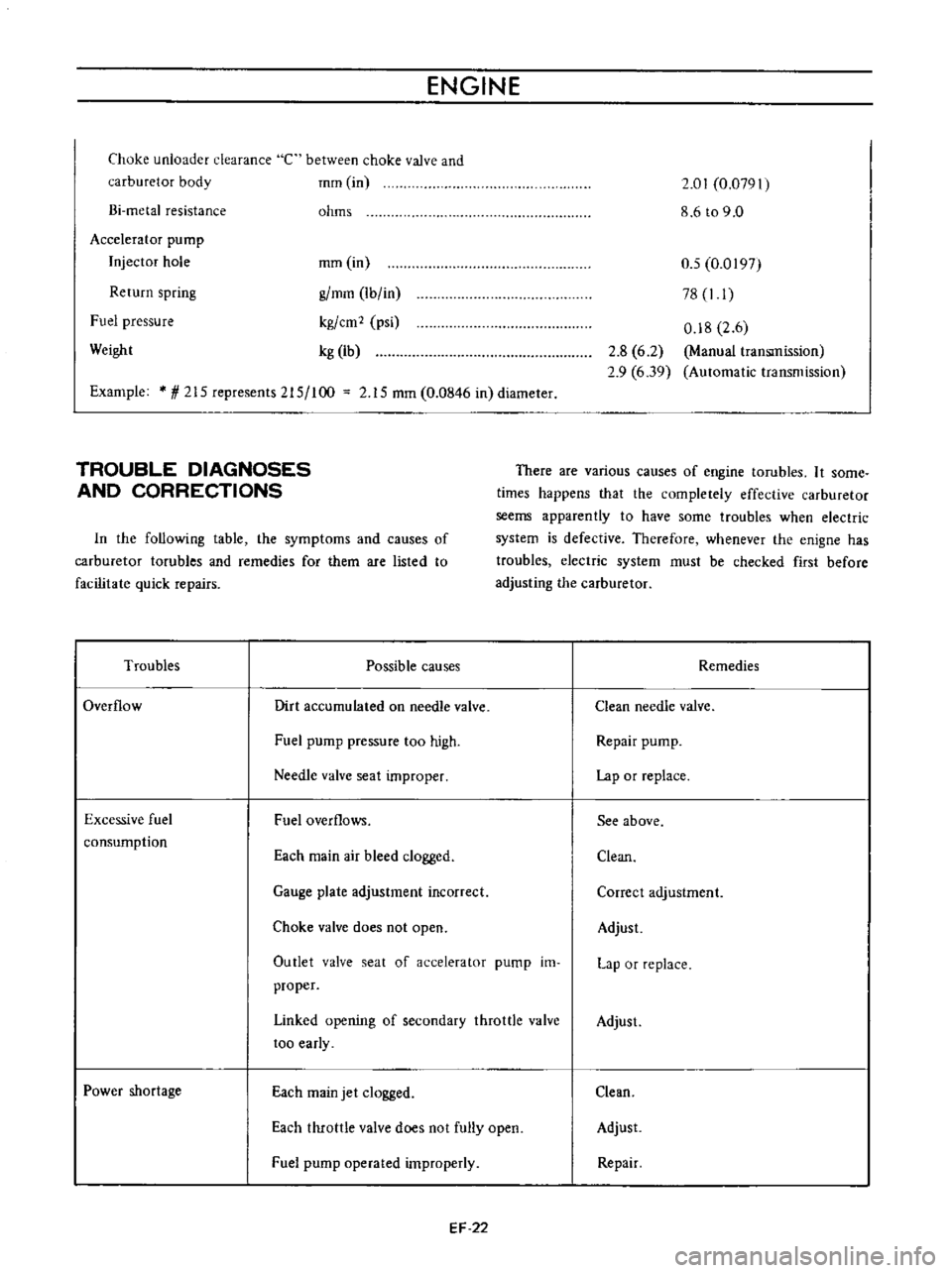

TROUBLE

DIAGNOSES

AND

CORRECTIONS

There

are

various

causes

of

engine

tarubles

It

some

times

happens

that

the

completely

effective

carburetor

seems

apparently

to

have

some

troubles

when

electric

system

is

defective

Therefore

whenever

the

enigne

has

troubles

electric

system

must

be

checked

first

before

adjusting

the

carburetor

In

the

following

table

the

symptoms

and

causes

of

carburetor

tarubles

and

remedies

for

them

are

listed

to

facilitate

quick

repairs

Troubles

Possible

causes

Remedies

Overflow

Dirt

accumulated

on

needle

valve

Clean

needle

valve

Fuel

pump

pressure

too

high

Repair

pump

Needle

valve

seat

improper

Lap

or

replace

Excessive

fuel

consumption

Fuel

overflows

See

above

Each

main

air

bleed

clogged

Clean

Gauge

plate

adjustment

incorrect

Correct

adjustment

Choke

valve

does

not

open

Adjust

Outlet

valve

seat

of

accelerator

pump

im

proper

Lap

or

replace

Linked

opening

of

secondary

throttle

valve

too

early

Adjust

Power

shortage

Each

main

jet

clogged

Clean

Each

throttle

valve

does

not

fully

open

Adjust

Fuel

pump

operated

improperly

Repair

EF

22

Page 431 of 513

ENGINE

ElECTRICAL

SYSTEM

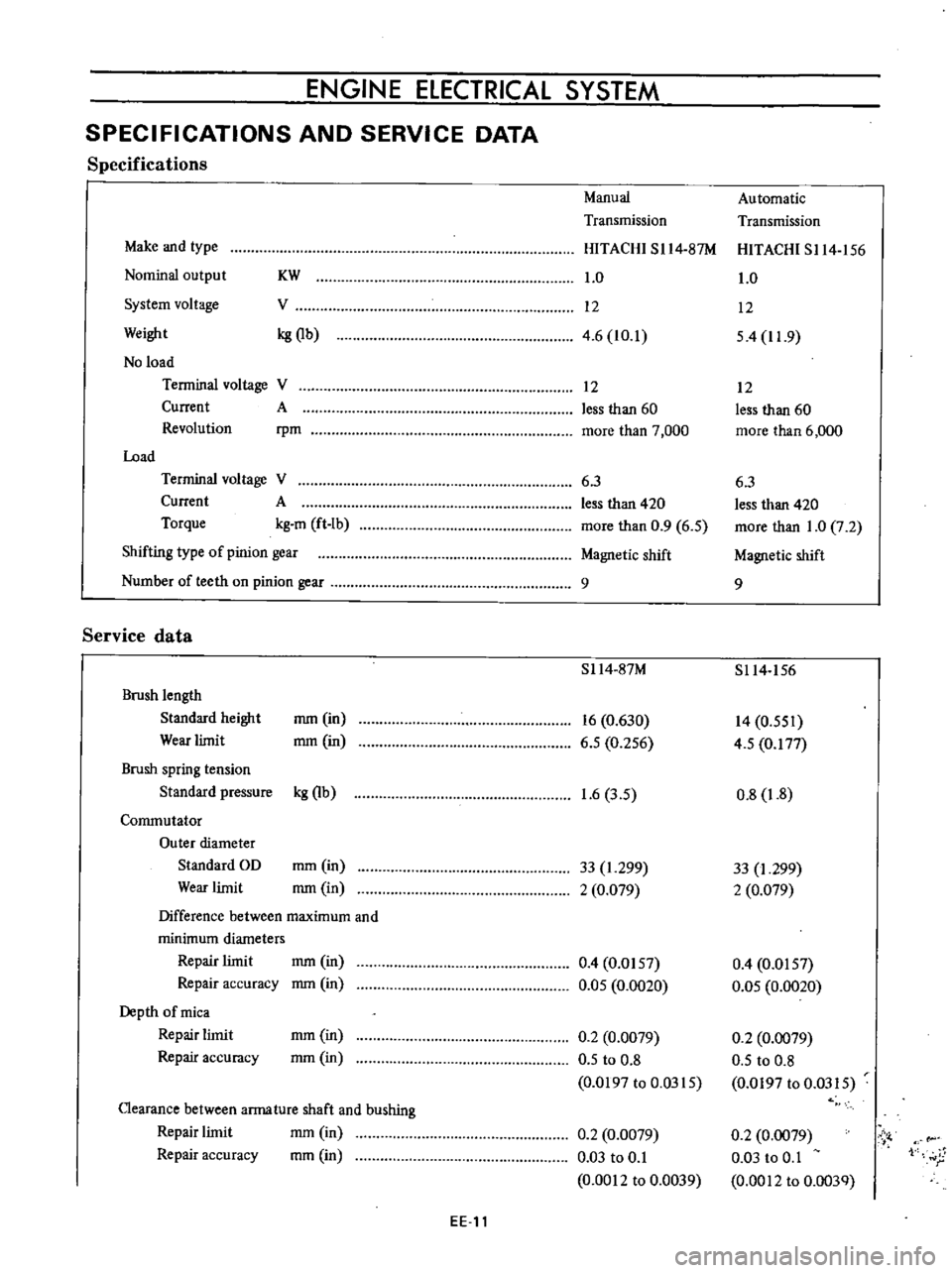

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Manual

Automatic

Transmission

Transmission

Make

and

type

HITACHI

SI14

87M

HITACHI

S114

156

Nominal

output

KW

1

0

1

0

System

voltage

V

12

12

Weight

kg

Qb

4

6

10

1

54

11

9

No

load

Terminal

voltage

V

12

12

Current

A

less

than

60

less

than

60

Revolution

rpm

more

than

7

000

more

than

6

000

Load

Terminal

voltage

V

6

3

6

3

Current

A

less

than

420

less

than

420

Torque

kg

m

ft

Ib

more

than

0

9

6

5

more

than

1

0

7

2

Shifting

type

of

pinion

gear

Magnetic

shift

Magnetic

shift

Number

of

teeth

on

pinion

gear

9

9

Service

data

S114

87M

S114

156

Brush

length

Standard

height

mm

in

16

0

630

14

0

551

Wear

limit

mm

in

6

5

0

256

4

5

0

177

Brush

spring

tension

Standard

pressure

kg

Qb

1

6

3

5

0

8

1

8

Commutator

Outer

diameter

Standard

OD

mm

in

33

1

299

33

I

299

Wear

limit

mm

in

2

0

079

2

0

079

Difference

between

maximum

and

minimum

diameters

Repair

limit

mm

in

0

4

0

0157

0

4

0

0157

Repair

accuracy

mm

in

0

05

0

0020

0

05

0

0020

Depth

of

mica

Repair

limit

mm

in

0

2

0

0079

0

2

0

0079

Repair

accuracy

mm

in

0

5

to

0

8

0

5

to

0

8

0

0197

to

0

0315

0

0197

to

0

0315

Clearance

between

arma

ture

shaft

and

bushing

mm

in

Repair

limit

0

2

0

0079

0

2

0

0079

Vi

Repair

accuracy

mm

in

0

03

to

0

1

0

03

to

0

1

1

r

0

0012

to

0

0039

0

0012

to

0

003Q

EE

11

Page 436 of 513

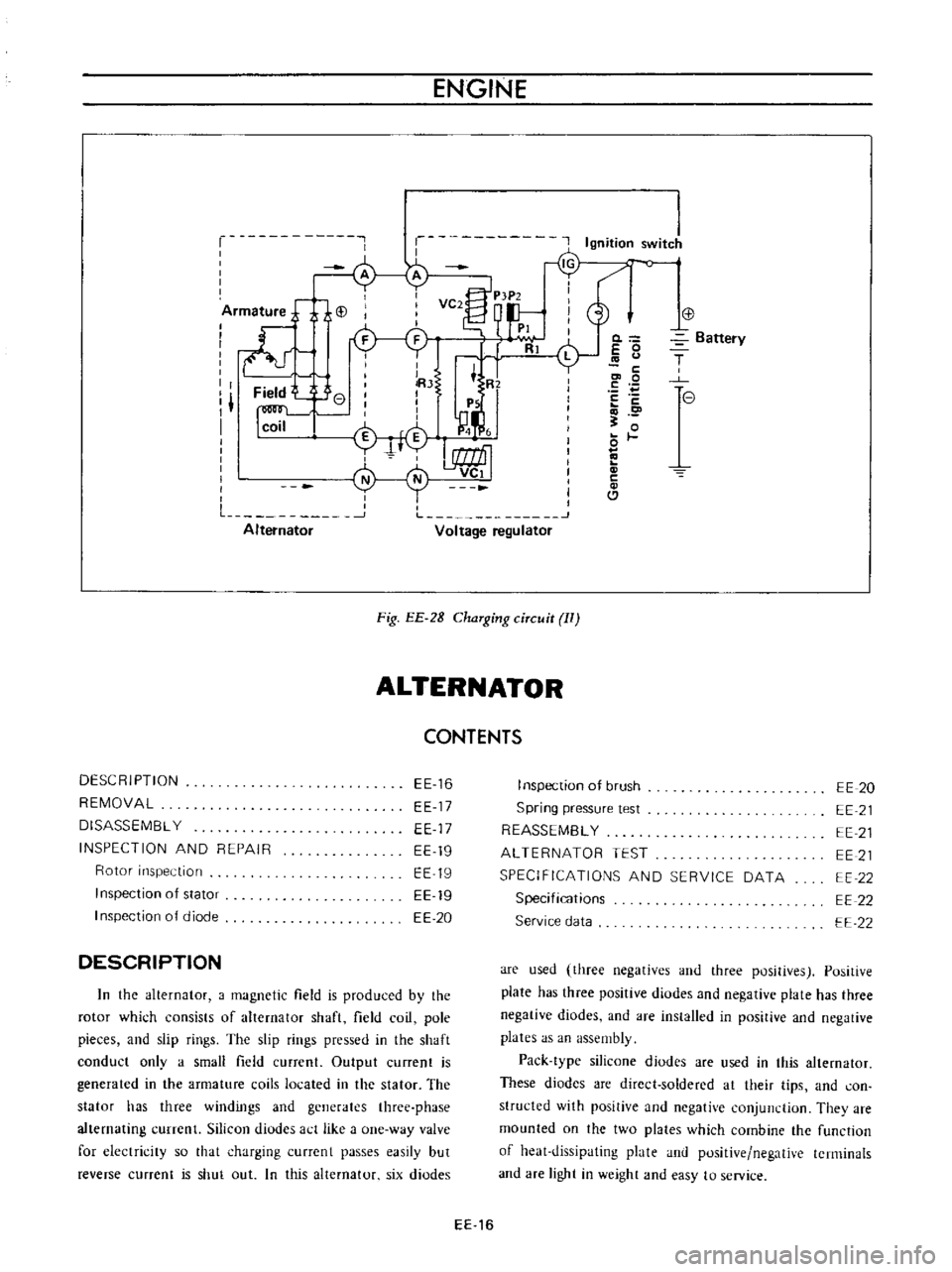

ENGINE

r

Ignition

switJ

c

o

iArm

ture

j

i

i

VC2

P

tP2

d

I

I

I

PI

I

ll

Rl

L

I

I

lRJ

t

R

I

Field

e

I

I

I

I

Ps

I

1

I

I

n

I

coil

M

4

i

f

I

L

1

J

Alternator

Voltage

regulator

Fig

EE

2B

ChaTging

ciTcuit

II

ALTERNATOR

CONTENTS

DESCRIPTION

REMOVAL

DISASSEMBL

Y

INSPECTION

AND

REPAIR

Rotor

inspection

Inspection

of

stator

I

nspection

of

diode

EE

16

EE

17

EE

17

EE

19

EE

19

EE

19

EE

20

DESCRIPTION

In

the

alternator

a

magnetic

field

is

produced

by

the

rotor

which

consists

of

alternator

shaft

field

coil

pole

pieces

and

slip

rings

The

slip

rings

pressed

in

the

shaft

conduct

only

a

small

field

current

Output

current

is

generated

in

the

armature

coils

located

in

the

stator

The

stator

has

three

windings

and

generates

three

phase

alternating

currenl

Silicon

diudes

act

like

a

one

way

valve

for

electricity

so

that

charging

currcnt

passes

easily

but

reverse

current

is

shut

out

In

this

alternator

six

diodes

0

E

0

c

co

0

E

c

o

0

c

Cl

Battery

T

e

I

nspection

of

brush

Spring

pressure

test

REASSEMBL

Y

ALTERNATOR

TEST

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Service

data

EE

20

EE

21

EE

21

EE

21

EE

22

EE

22

EE

22

are

used

three

negatives

and

three

positives

Positive

plate

has

three

positive

diodes

and

negative

plate

has

three

negative

diodes

and

are

installed

in

positive

and

negative

plates

as

an

assembly

Pack

type

silicone

diodes

are

used

in

this

alternator

These

diodes

are

direct

soldered

at

their

tips

and

con

structed

with

positive

and

negative

conjunction

They

are

mounted

on

the

two

plates

which

combine

the

function

of

heat

dissipating

plate

and

positive

negative

terminals

and

are

light

in

weight

and

easy

to

service

EE

16

Page 450 of 513

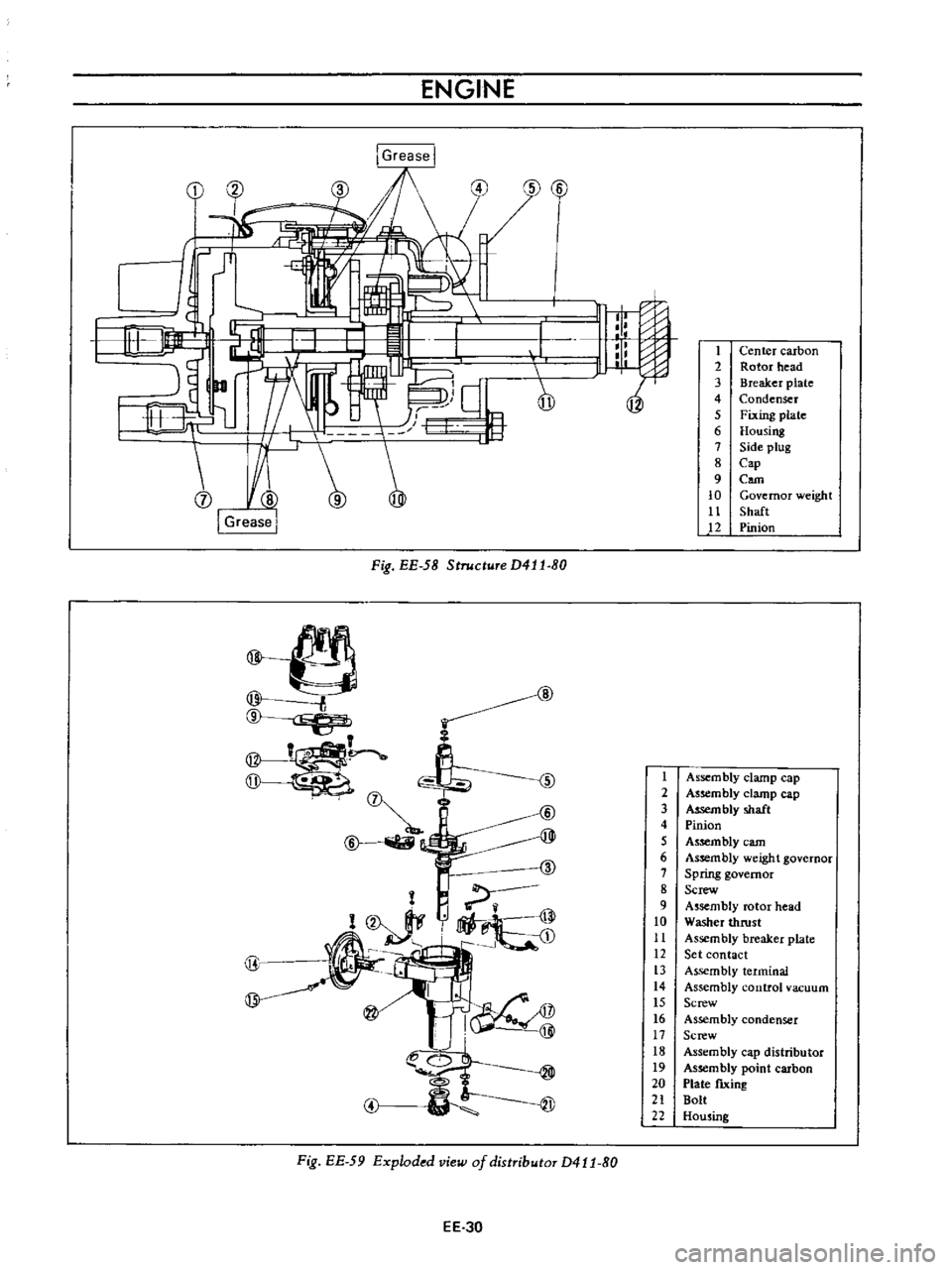

ENGINE

I

Grease

I

I

I

n

r

Y

J

Fig

EE

5B

StructuTe

D4l

l

BO

jj

l1

@

f

1

j

0

i

@r

liiU

ID

r

@l

IlIlJ

e

D

r

J

@

i

i

nL

ft

L

6

Fig

BE

59

Exploded

view

of

distTibutoT

D4Il

BO

EE

30

1

Center

carbon

2

Rotor

bead

3

Breaker

plate

4

Condenser

5

Fixing

plate

6

Housing

7

Side

plug

8

Cap

9

Carn

10

Governor

weight

tl

Shaft

12

Pinion

t

2

3

4

5

6

1

8

9

to

tl

12

13

14

t5

t6

11

18

t9

20

21

22

Assem

bly

clamp

cap

Assembly

clamp

cap

Assembly

shaft

Pinion

Assembly

earn

Assembly

weight

governor

Spring

gO

1emor

Screw

A

sembty

rotor

head

Washer

thrust

Assembly

breaker

plate

Set

contact

Assembly

terminal

Assembly

control

vacuum

Screw

Assembly

condenser

Screw

Assembly

cap

distributor

Assembly

point

carbon

Plate

ftxing

Bolt

HOllSing

Page 452 of 513

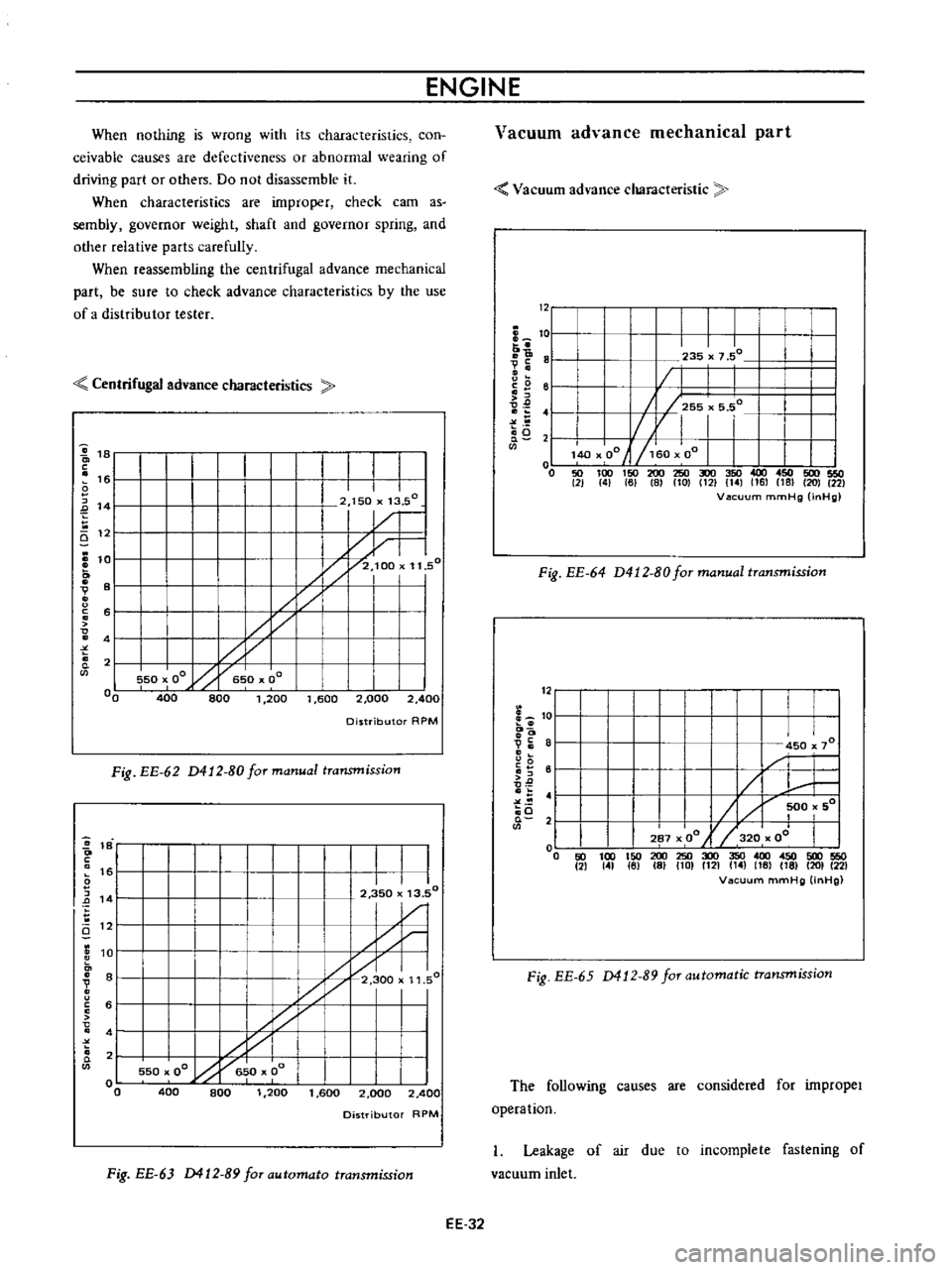

ENGINE

When

nothing

is

wrong

with

its

characteristics

con

ceivable

causes

are

defectiveness

or

abnormal

wearing

of

driving

part

or

others

Do

not

disassemble

it

When

characteristics

are

improper

check

earn

as

sembly

governor

weight

shaft

and

governor

spring

and

other

relative

parts

carefully

When

reassembling

the

centrifugal

advance

mechanical

part

be

sure

to

check

advance

characteristics

by

the

use

of

a

distributor

tester

Centrifugal

advance

characteristics

1

c

1

Ei

12

L

o

V

o

u

c

o

o

t

D

c

s

151

14

e

101

0

81

V

0

u

c

51

0

41

t

0

Q

2

01

0

I

I

I

1

rj

11

50

I

J

2

100

50

oQ

5

00

400

800

1

200

1

600

2

00

Distributor

RPM

Fig

EE

62

D412

80formanual

transmission

I

I

I

2

350

13

50

1

1

1

300

1

1

550

00

h

6

0

0

I

400

800

1

200

1

600

2

000

Distributor

RPM

Fig

EE

63

D412

B9

faT

automata

transmission

2

400

I

11

50

2

400

EE

32

Vacuum

advance

mechanical

part

Vacuum

ad

ance

characteristic

12

I

I

I

I

I

II1

5515

5Q

i

01

40

00

i1j

50

00

1

I

o

50

100

150

200

250

300

350

400

450

500

550

21

41

6

8

101

C121

141

161

181

201

22

V2Icuum

mmHg

inHg

I

I

I

I

7

50

1

1Q

Ii

V

I

o

0

u

i

e

6

tI

2

o

i5

0

235

Fig

EE

64

D412

80

for

manual

transmission

c

1

0

I

o

9i

8

o

u

0

i

61

0

0

0

4

o

Q

2

I

I

I

450

x

70

L

H

1

500

501

287

00

l

320

oJ

I

I

200250300350400450500550

IS

101

1121

t4

16

16

1201

22

Vacuum

mmHg

OnHg

o

50

100

150

2

141

161

Fig

EE

65

0412

89

for

automatic

transmission

The

following

causes

are

considered

for

impropeI

opera

tion

I

Leakage

of

air

due

to

incomplete

fastening

of

vacuum

inlet

Page 454 of 513

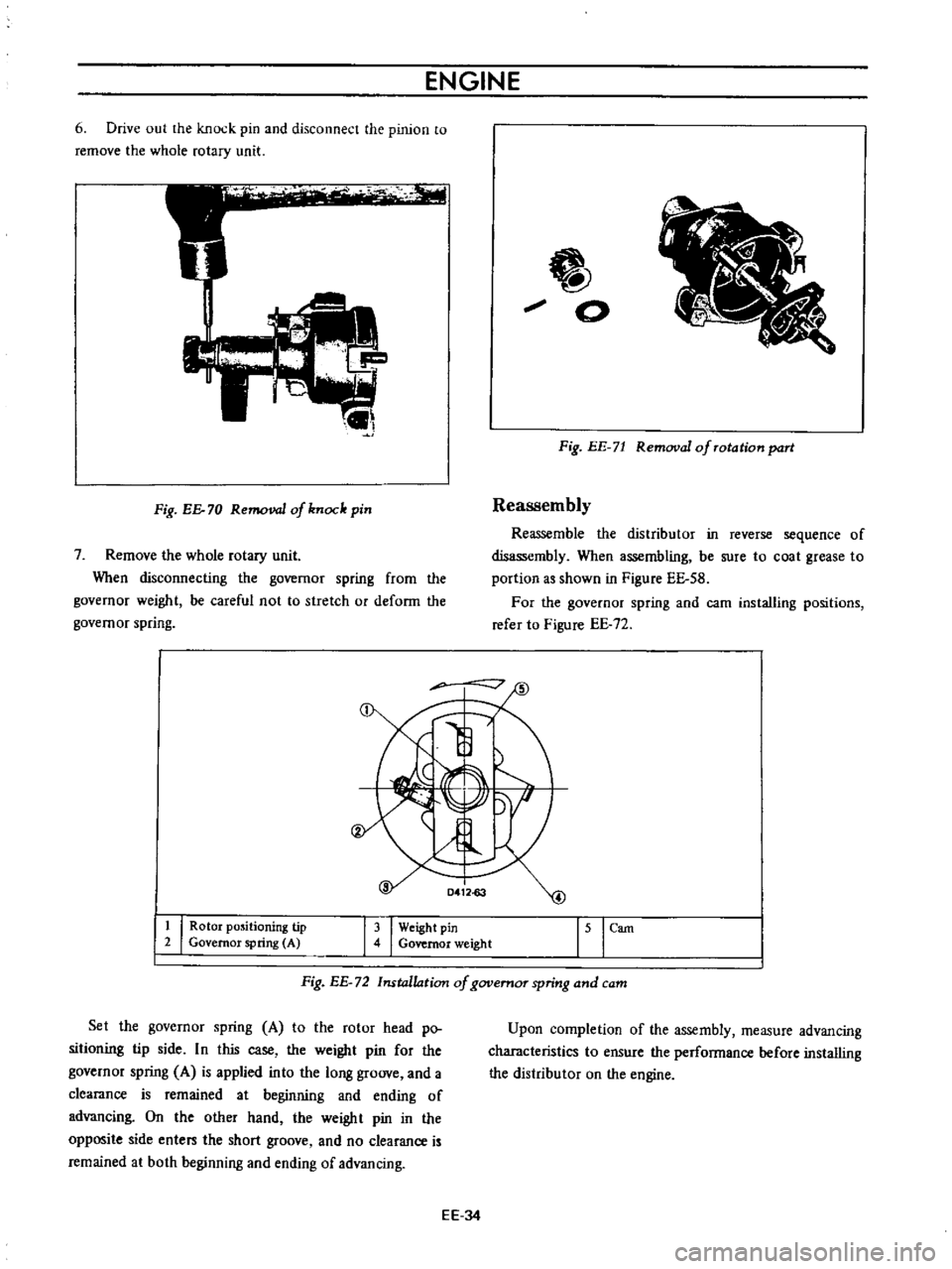

ENGINE

6

Drive

out

the

knock

pin

and

disconnect

the

pinion

to

remove

the

whole

rotary

unit

Fig

EE

70

Removal

of

knock

pin

7

Remove

the

whole

rotary

unit

When

disconnecting

the

governor

spring

from

the

governor

weight

be

careful

not

to

stretch

or

deform

the

governor

spring

tJ

0

Fig

EE

71

Removal

of

Totation

pari

Reassembly

Reassemble

the

distributor

in

reverse

sequence

of

disassembly

When

assembling

be

sure

to

coat

grease

to

portion

as

shown

in

Figure

EE

58

For

the

governor

spring

and

earn

installing

positions

refer

to

Figure

EE

72

1

I

Rotor

positioning

tip

2

Governor

spring

A

13

I

Weight

pin

4

Governor

weight

15

I

earn

Fig

EE

72

Installation

of

governor

spring

and

cam

Set

the

governor

spring

A

to

the

rotor

head

po

sitioning

tip

side

In

this

case

the

weight

pin

for

the

governor

spring

A

is

applied

into

the

long

groove

and

a

clearance

is

remained

at

beginning

and

ending

of

advancing

On

the

other

hand

the

weight

pin

in

the

opposite

side

enters

the

short

groove

and

no

clearance

is

remained

at

both

beginning

and

ending

of

advancing

Upon

completion

of

the

assembly

measure

advancing

characteristics

to

ensure

the

performance

before

installing

the

distributor

on

the

engine

EE

34

Page 456 of 513

ENGINE

Weight

pivot

diameter

mm

in

Weight

hole

diameter

mm

in

Clearance

between

pivot

and

hole

mmOn

5

0

028

0

9

9

1

0011

1

005

1

6

1

0002

5

1

018

0

1969

0

0007

o

0

0

005

to

0

046

0

0002

to

0

0018

IGNITION

COIL

CONTENTS

DESCRIPTION

EE

36

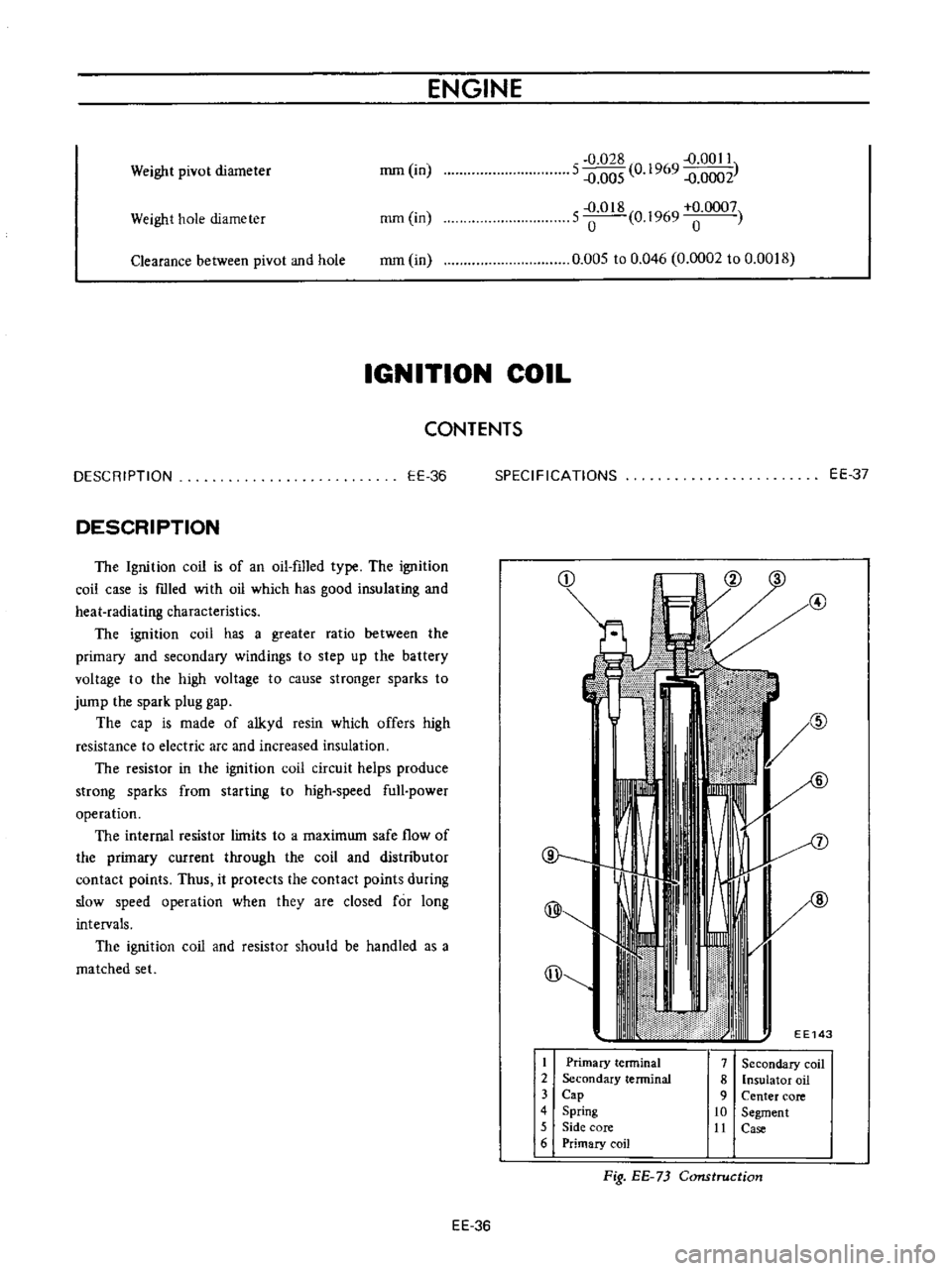

DESCRIPTION

The

Ignition

coil

is

of

an

oil

filled

type

The

ignition

coil

case

is

mted

with

oil

which

has

good

insulating

and

heat

radiating

characteristics

The

ignition

coil

has

a

greater

ratio

between

the

primary

and

secondary

windings

to

step

up

the

battery

voltage

to

the

high

voltage

to

cause

stronger

sparks

to

jump

the

spark

plug

gap

The

cap

is

made

of

alkyd

resin

which

offers

high

resistance

to

electric

arc

and

increased

insulation

The

resistor

in

the

ignition

coil

circuit

helps

produce

strong

sparks

from

starting

to

high

speed

full

power

operation

The

internal

resistor

limits

to

a

maximum

safe

flow

of

the

primary

current

through

the

coil

and

distributor

contact

points

Thus

it

protects

the

contact

points

during

slow

speed

operation

when

they

are

closed

for

long

intervals

The

ignition

coil

and

resistor

should

be

handled

as

a

matched

set

EE

36

SPECIFICATIONS

EE

37

@

@

@l

@

EE143

I

Primary

terminal

2

Secondary

terminal

3

Cap

4

Spring

5

Side

core

6

Primary

coil

7

Secondary

coil

8

insulator

oil

9

Center

core

10

Segment

tt

Case

Fig

EE

73

Construction