tow DATSUN B110 1973 Service Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 205 of 513

BODY

Fig

BF

19

R

g

male

side

of

the

hood

lock

Fig

BF

20

Removing

female

side

of

the

hood

lock

3

Remove

three

screws

and

remove

the

hood

lock

control

lever

Fig

BF

21

Removing

hood

lock

control

lever

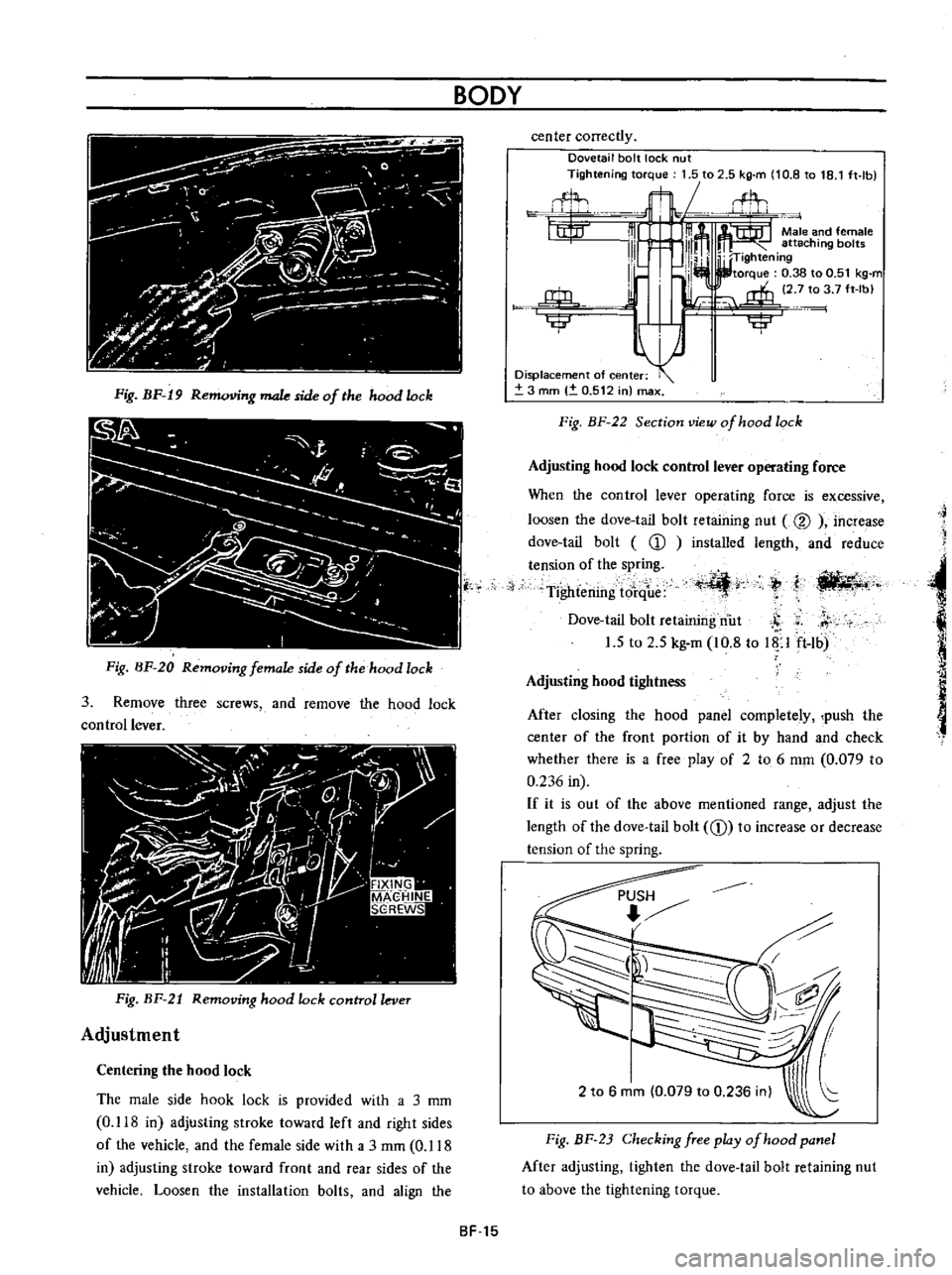

Adjustment

Centering

the

hood

lock

The

male

side

hook

lock

is

provided

with

a

3

mm

0

118

in

adjusting

stroke

toward

left

and

right

sides

of

the

vehicle

and

the

female

side

with

a

3

rnm

0

118

in

adjusting

stroke

toward

front

and

rear

sides

of

the

vehicle

Loosen

the

installation

bolts

and

align

the

center

correctly

Dovetail

bolt

lock

nut

Tightening

torque

1

5

to

2

5

kg

m

10

8

to

18

1

ft

lb

flL

t1t

m

m

Male

and

female

111

l

111m

attaching

bol

W

TIghtening

I

lb

I

I

torque

0

38

to

0

51

kg

m

l

i

2

7

to

3

7

ft

Ibl

j

rffi

u

Ilillr

iji

Displacement

of

center

3

mm

0

512

in

max

Fig

BF

22

Section

view

of

hood

lock

Adjusting

hood

lock

control

lever

operating

force

When

the

control

lever

operating

force

is

excessive

loosen

the

dove

tail

bolt

retaining

nut

@

increase

dove

tail

bolt

CD

installed

length

and

reduce

tension

of

the

spring

Tightening

tore

ue

t

I

ili

4r

ti

llt4

t

j

Dove

tail

bolt

retaining

nut

S

r

1

5

to

2

5

kg

m

10

8

to

Up

ft

lb

Adjusting

hood

tightness

After

closing

the

hood

panel

completely

push

the

center

of

the

front

portion

of

it

by

hand

and

check

whether

there

is

a

free

play

of

2

to

6

mm

0

079

to

0

236

in

If

it

is

out

of

the

above

mentioned

range

adjust

the

length

of

the

dove

tail

bolt

CD

to

increase

or

decrease

tension

of

the

spring

2

to

6

mm

0

079

to

0

236

inl

Fig

BF

23

Checking

free

play

of

hood

panel

After

adjusting

tighten

the

dove

tail

bolt

retaining

nut

to

above

the

tightening

torque

SF

15

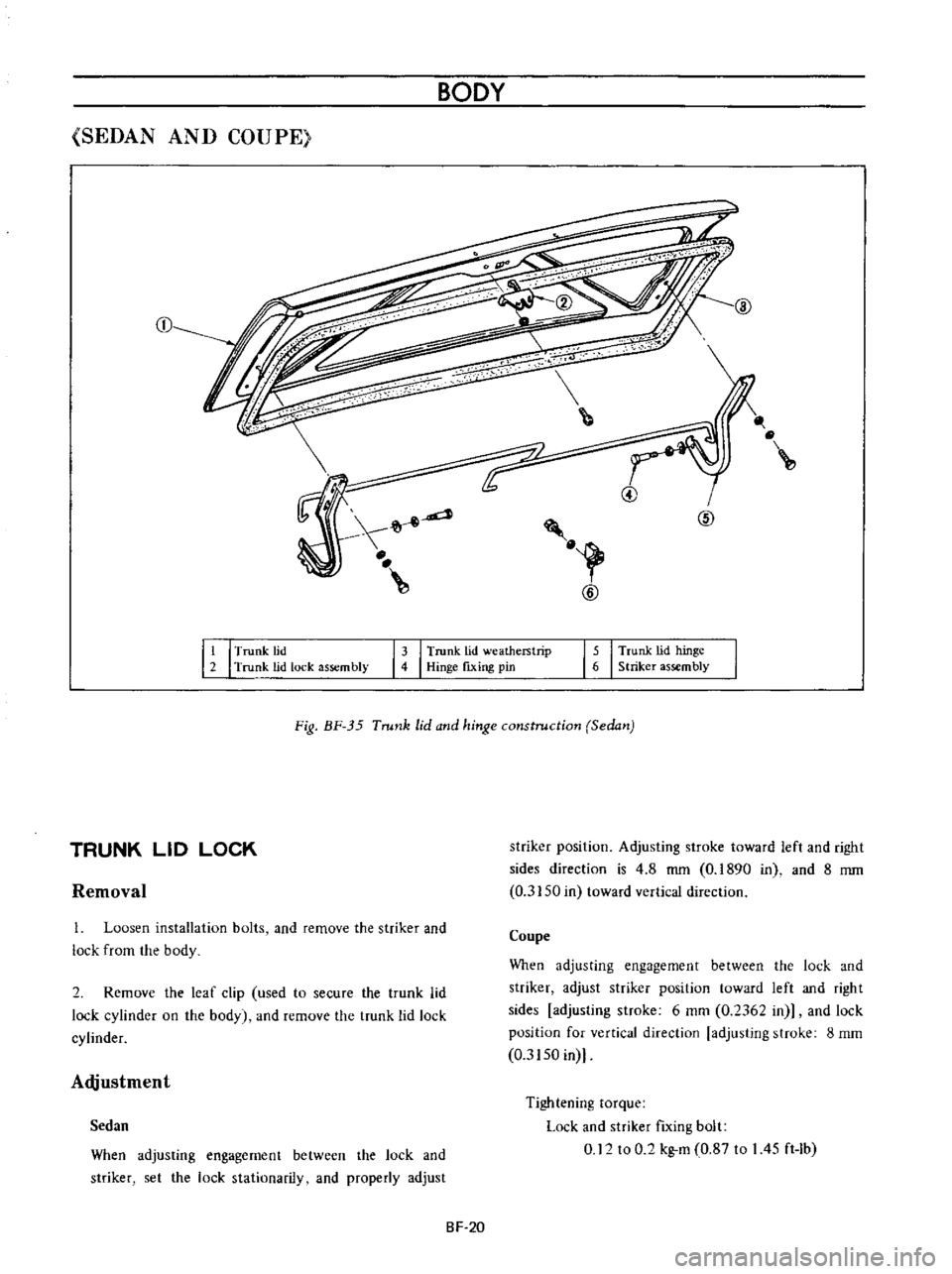

Page 210 of 513

BODY

SEDAN

AND

COUPE

CD

@

h

r

1

@

@

II

I

Trunk

lid

2

Trunk

lid

lock

assembly

13

I

Trunk

lid

weatherstrip

4

Hinge

fixing

pin

15

I

Trunk

lid

hinge

6

Striker

assembly

Fig

BF

35

Trunk

lid

and

hinge

construction

Sedan

Removal

striker

position

Adjusting

stroke

toward

left

and

right

sides

direction

is

4

8

mm

0

1890

in

and

8

mm

0

3150

in

toward

vertical

direction

TRUNK

LID

LOCK

1

Loosen

installation

bolts

and

remove

the

striker

and

lock

from

the

body

Coupe

When

adjusting

engagement

between

the

lock

and

striker

adjust

striker

position

toward

left

and

right

sides

adjusting

stroke

6

mm

0

2362

in

and

lock

position

for

vertical

direction

adjusting

stroke

8

mm

0

3150

in

2

Remove

the

leaf

clip

used

to

secure

the

trunk

lid

lock

cylinder

on

the

body

and

remove

the

trunk

lid

lock

cylinder

Adjustment

When

adjusting

engagement

between

the

lock

and

striker

set

the

lock

stationarily

and

properly

adjust

Tightening

torque

Lock

and

striker

fIxing

bolt

0

12

to

0

2

kg

m

0

87

to

I

45

ft

Ib

Sedan

SF

20

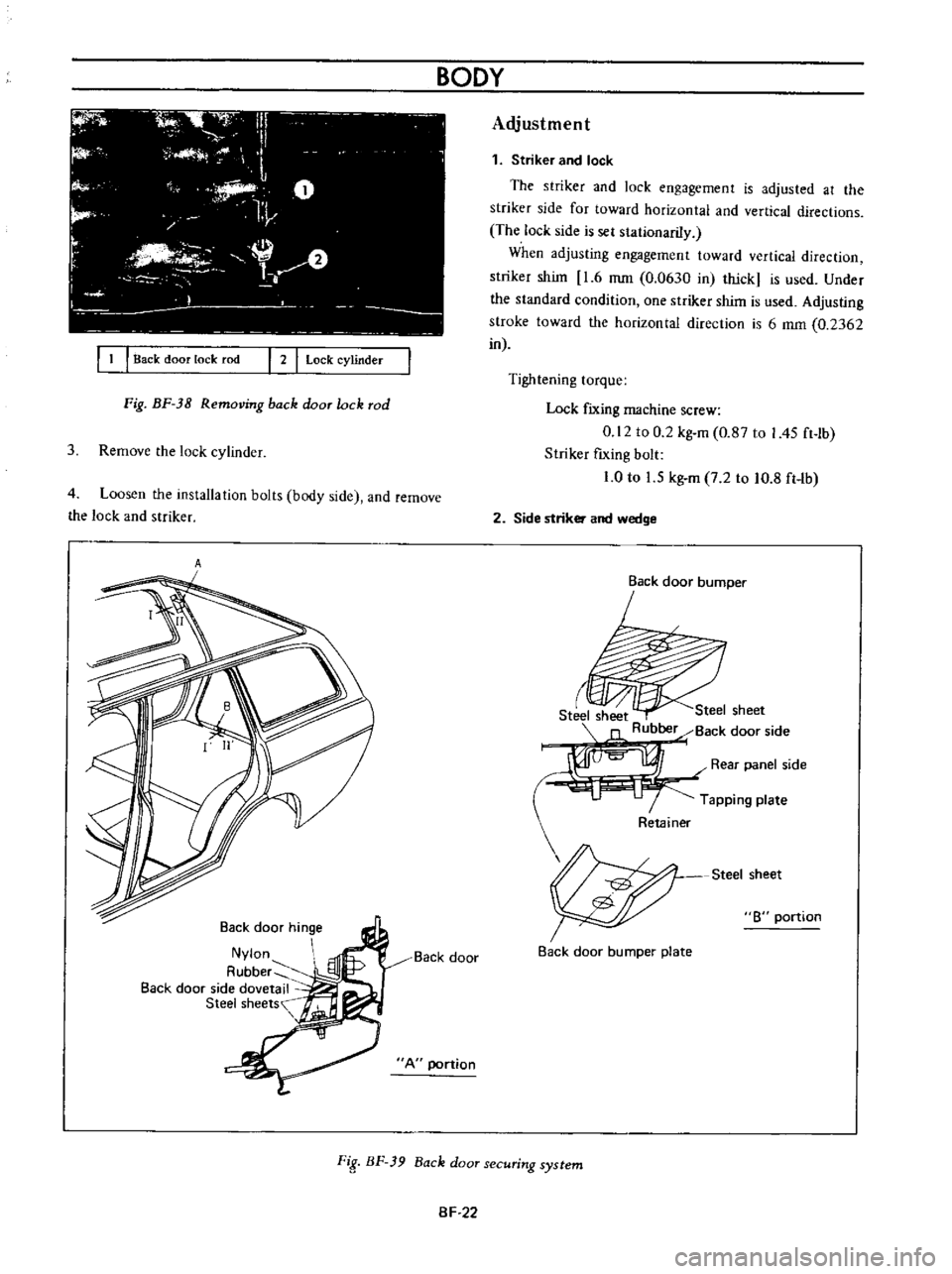

Page 212 of 513

I

1

I

Back

door

lock

rod

I

2

I

Lock

cylinder

Fig

BF

38

Removing

back

door

lock

rod

3

Remove

the

lock

cylinder

4

Loosen

the

installation

bolts

body

side

and

remove

the

lock

and

striker

A

Back

door

hinge

Nylon

A

ubber

Back

door

side

dovetail

Steel

sheets

Back

door

A

portion

BODY

Adjustment

1

Striker

and

lock

The

striker

and

lock

engagement

is

adjusted

at

the

striker

side

for

toward

horizontal

and

vertical

directions

The

lock

side

is

sel

stationariIy

When

adjusting

engagement

toward

vertical

direction

striker

shim

1

6

mm

0

0630

in

thick

is

used

Under

the

standard

condition

one

striker

shim

is

used

Adjusting

stroke

toward

the

horizontal

direction

is

6

mm

0

2362

in

Tightening

torque

Lock

fIXing

machine

screw

0

12

to

0

2

kg

m

0

87

to

I

45

ft

lb

Striker

fIxing

bolt

1

0

to

1

5

kg

m

7

2

to

10

8

ft

Ib

2

Side

striker

and

wedge

Back

door

bumper

r

Steel

sheet

Steel

sheet

Rubber

Back

door

side

I

Rear

panel

side

Tapping

plate

Steel

sheet

8

portion

Back

door

bumper

plate

FiS

BF

39

Back

door

securing

system

SF

22

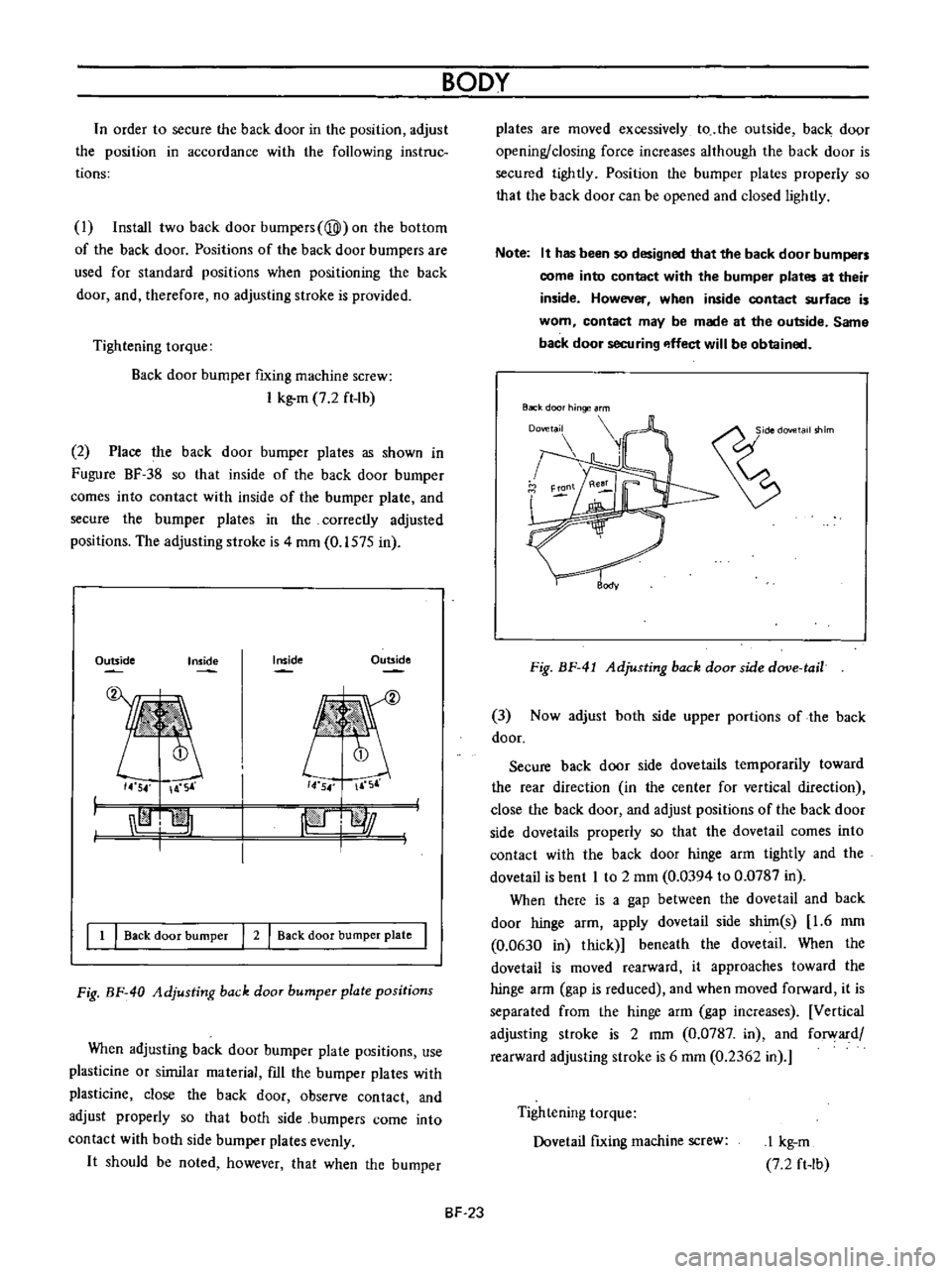

Page 213 of 513

n

order

to

secure

the

back

door

in

the

position

adjust

the

position

in

accordance

with

the

following

instruc

tions

I

Install

two

back

door

bumpers

@

on

the

bottom

of

the

back

door

Positions

of

the

back

door

bumpers

are

used

for

standard

positions

when

positioning

the

back

door

and

therefore

no

adjusting

stroke

is

provided

Tightening

torque

Back

door

bumper

fixing

machine

screw

I

kg

m

7

2

ft

lb

2

Place

the

back

door

bumper

plates

as

shown

in

Fugure

BF

38

so

that

inside

of

the

back

door

bumper

comes

into

contact

with

inside

of

the

bumper

plate

and

secure

the

bumper

plates

in

the

correctly

adjusted

positions

The

adjusting

stroke

is

4

mm

0

1575

in

Outside

Inside

Outside

Inside

14

54

A

S

14

54

F

r

I

I

jpiJ

l

l

j

I

1

I

Back

door

bumper

I

2

I

Back

door

bumper

plate

I

Fig

BF

40

Adjusting

back

door

bumper

plate

positions

When

adjusting

back

door

burnper

plate

positions

use

plasticine

or

sirnilar

material

fIll

the

bumper

plates

with

plasticine

close

the

back

door

observe

contact

and

adjust

properly

so

that

both

side

bumpers

come

into

contact

with

both

side

bumper

plates

evenly

It

should

be

noted

however

that

when

the

bumper

BODY

BF

23

plates

are

moved

excessively

to

the

outside

back

door

opening

closing

force

increases

although

the

back

door

is

secured

tightly

Position

the

bumper

plates

properly

so

that

the

back

door

can

be

opened

and

closed

lightly

Note

It

has

been

so

designed

that

the

back

door

bumpers

come

into

contact

with

the

bumper

plates

at

their

inside

However

when

inside

contact

surface

is

worn

contact

may

be

made

at

the

outside

Same

back

door

securing

p

ffect

will

be

obtained

Back

door

hinge

rm

Fig

BF

41

Adjusting

back

door

side

dove

tail

3

Now

adjust

both

side

upper

portions

of

the

back

door

Secure

back

door

side

dovetails

temporarily

toward

the

rear

direction

in

the

center

for

vertical

direction

close

the

back

door

and

adjust

positions

of

the

back

door

side

dovetails

properly

so

that

the

dovetail

comes

into

contact

with

the

back

door

hinge

arm

tightly

and

the

dovetail

is

bent

I

to

2

mm

0

0394

to

0

0787

in

When

there

is

a

gap

between

the

dovetail

and

back

door

hinge

arm

apply

dovetail

side

shim

s

1

6

mm

0

0630

in

thick

beneath

the

dovetail

When

the

dovetail

is

moved

rearward

it

approaches

toward

the

hinge

arm

gap

is

reduced

and

when

moved

forward

it

is

separated

from

the

hinge

arrn

gap

increases

Vertical

adjusting

stroke

is

2

mm

0

0787

in

and

forward

rearward

adjusting

stroke

is

6

mm

0

2362

in

Tightening

torque

Dovetail

fIxing

machine

screw

I

kg

m

7

2

ft

Ib

Page 217 of 513

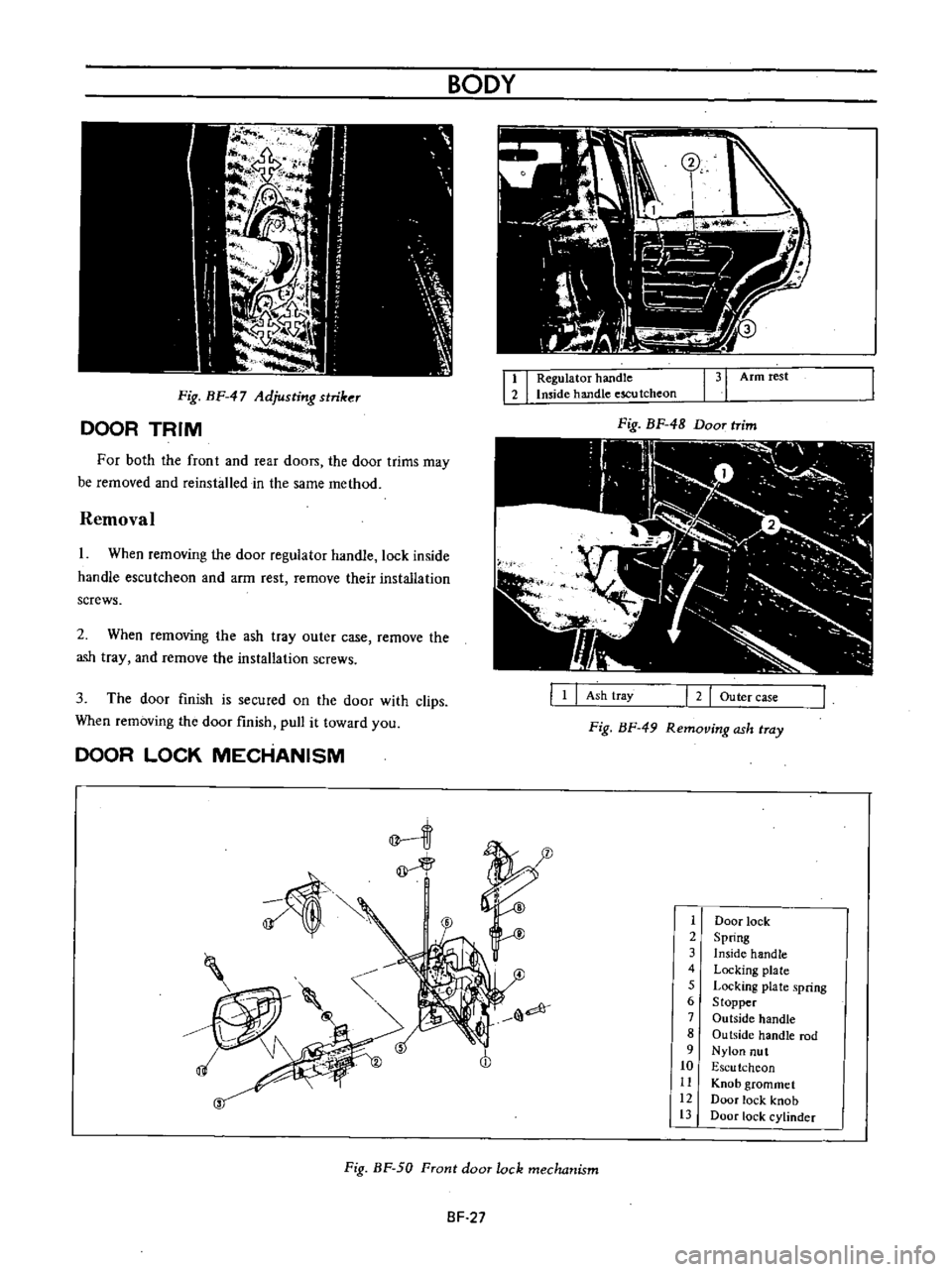

Fig

BF

47

Adjusting

striker

DOOR

TRIM

For

both

the

front

and

rear

doon

the

door

trims

may

be

removed

and

reinsbJled

in

the

same

method

Removal

I

When

removing

the

door

regulator

handle

lock

inside

handle

escutcheon

and

arm

rest

remove

their

installation

screws

2

When

removing

the

ash

tray

outer

case

remove

the

ash

tray

and

remove

the

installation

screws

3

The

door

finish

is

secured

on

the

door

with

clips

When

removing

the

door

finish

pull

it

toward

you

DOOR

LOCK

MECHANISM

BODY

I

I

Regulator

handle

Imide

handle

escu

tcheon

131

Armrest

Fig

BF

48

Door

trim

III

I

2

Outer

case

Ash

tray

Fig

BF

49

Removing

ash

tray

1

1

Door

lock

2

Spring

3

Inside

handle

4

Locking

plate

5

Locking

plate

spring

6

Stopper

7

Outside

handle

8

Ou

tside

handle

rod

9

Nylon

nut

10

Escu

tchcon

11

Knob

grommet

12

Door

lock

knob

13

Door

lock

cylinder

Fig

BF

50

Front

door

lock

mechanism

SF

27

Page 229 of 513

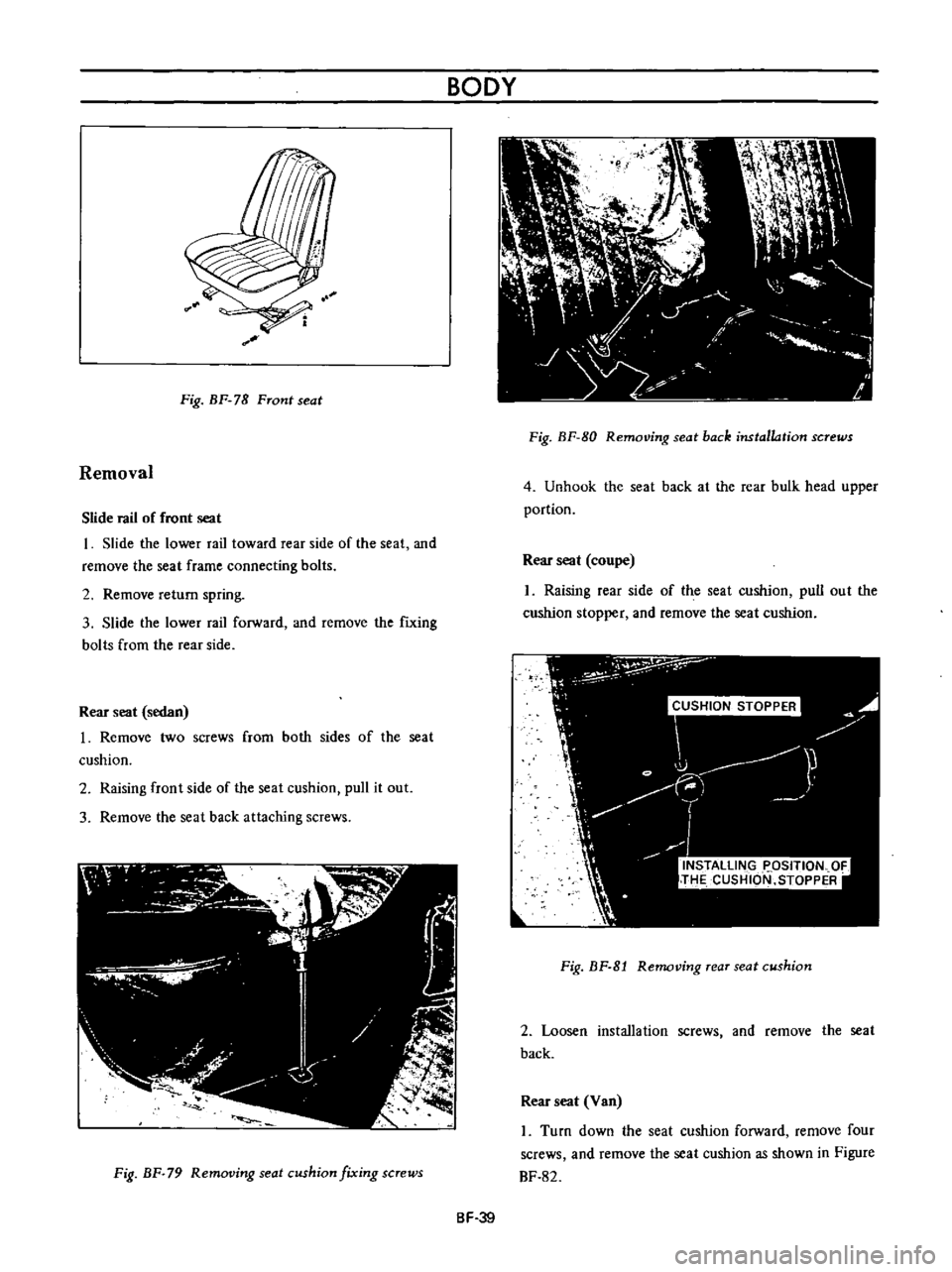

Fig

BF

78

Front

seat

Removal

Slide

rail

of

front

seat

I

Slide

the

lower

rail

toward

rear

side

of

the

seat

and

remove

the

seat

frame

connecting

bolts

2

Remove

return

spring

3

Slide

the

lower

rail

forward

and

remove

the

fIxing

bolts

from

the

rear

side

Rear

seat

sedan

1

Remove

two

screws

from

both

sides

of

the

seat

cushion

2

Raising

front

side

of

the

seat

cushion

pull

it

out

3

Remove

the

seat

back

attaching

screws

Fig

BF

79

Removing

seat

cushion

fixing

screws

BODY

Fig

BF

80

Removing

seat

back

installation

screws

4

Unhook

the

seat

back

at

the

rear

bulk

head

upper

portion

Rear

seat

coupe

Raising

rear

side

of

the

seat

cushion

pull

out

the

cushion

stopper

and

remove

the

seat

cushion

Fig

BF

81

Removing

Tear

seat

cushion

2

Loosen

installation

screws

and

remove

the

seat

back

Rear

seat

Van

I

Turn

down

the

seat

cushion

forward

remove

four

screws

and

remove

the

seat

cushion

as

shown

in

Figure

BF

82

8F

39

Page 231 of 513

j

L

CD

1

II

r

1

P

r

4vc

V

4

I

o

@

@

c

ID

I

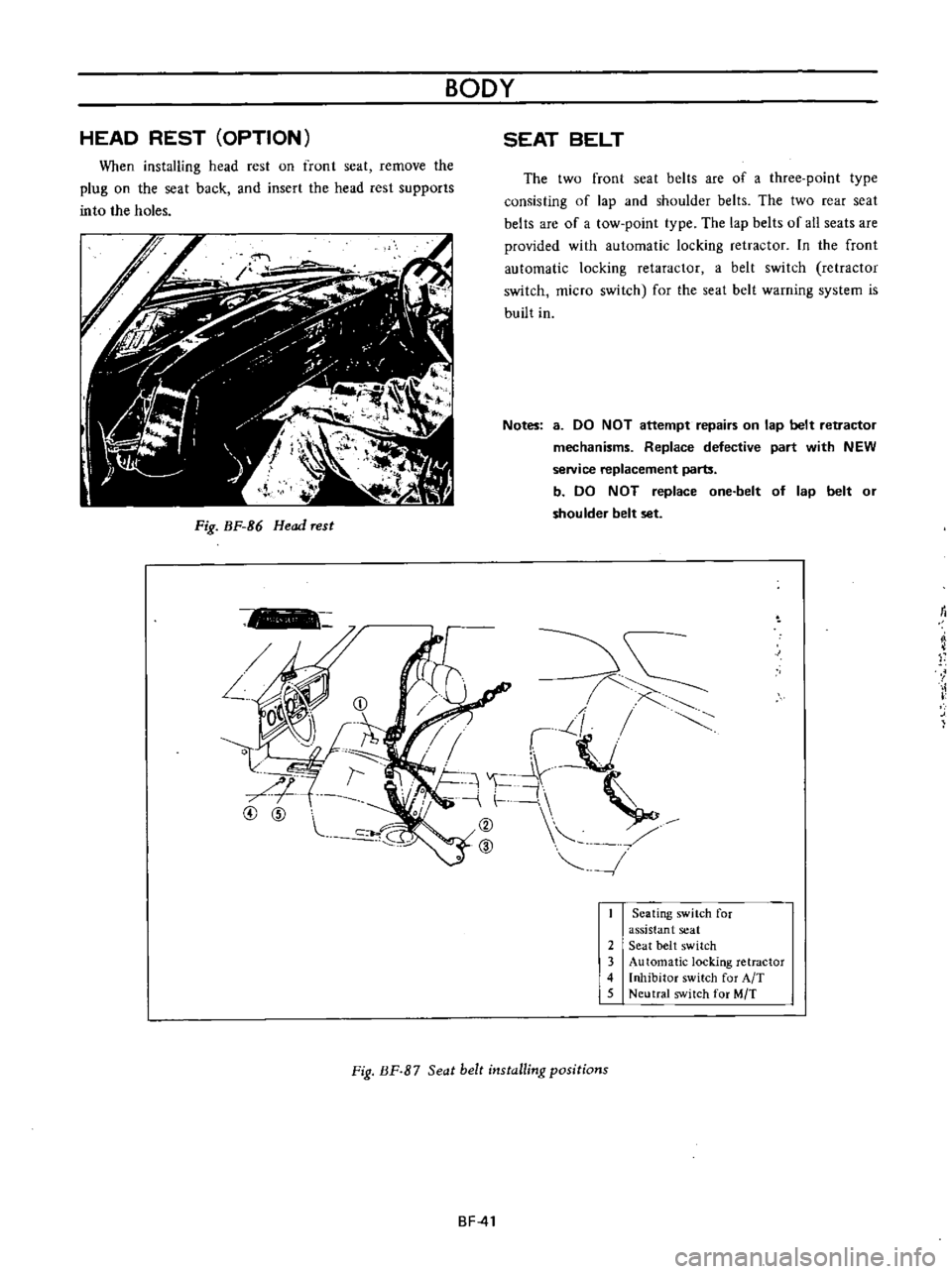

HEAD

REST

OPTION

When

installing

head

rest

on

front

seat

remove

the

plug

on

the

seat

back

and

insert

the

head

rest

supports

into

the

holes

Fig

BF

86

Head

rest

BODY

SEAT

BELT

The

two

front

seat

belts

are

of

a

three

point

type

consisting

of

lap

and

shoulder

belts

The

two

rear

seat

belts

are

of

a

tow

point

type

The

lap

belts

of

all

seats

are

provided

with

automatic

locking

retractor

In

the

front

automatic

locking

retaractor

a

belt

switch

retractor

switch

micro

switch

for

the

seat

belt

warning

system

is

built

in

Notes

a

DO

NOT

attempt

repairs

on

lap

belt

retractor

mechanisms

Replace

defective

part

with

NEW

service

replacement

parts

b

DO

NOT

replace

one

belt

of

lap

belt

or

shou

Ider

belt

set

r

l

Scating

switch

for

assistant

seat

2

Seat

belt

switch

3

Automatic

locking

retractor

4

Inhibitor

switch

for

AfT

5

Neutral

switch

for

M

T

Fig

BF

87

Seat

belt

installing

positions

BF

41

Page 233 of 513

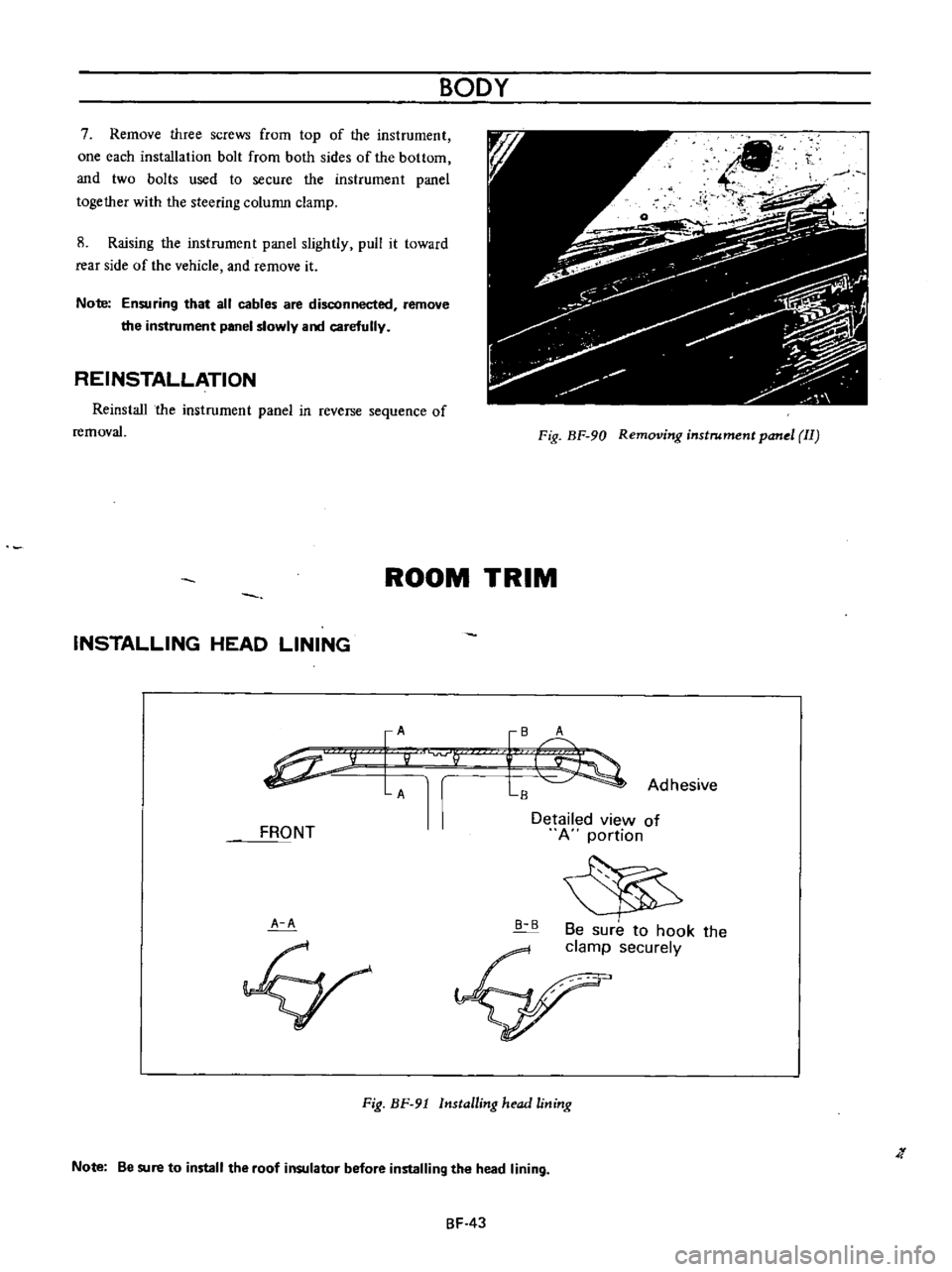

7

Remmre

three

screws

from

top

of

the

instrument

one

each

installation

bolt

frorn

both

sides

of

the

bottorn

and

two

bolts

used

to

secure

the

instrument

panel

together

with

the

steering

column

clamp

8

Raising

the

instrument

panel

slightly

pull

it

toward

rear

side

of

the

vehicle

and

remove

it

Note

Ensuring

that

all

cables

are

disconnected

remove

the

instrument

panel

slowly

aoo

carefully

REINSTALLATION

Reinstall

the

instrument

panel

in

reverse

sequence

of

removal

BODY

Fig

BF

90

Removing

instrument

panel

II

ROOM

TRIM

INSTALLING

HEAD

LINING

IA

P

AV

FRONT

A

A

IB

A

L

Adhesive

Detailed

view

of

A

portion

B

B

Be

sure

to

hook

the

clamp

securely

Fig

BF

91

Installing

head

lining

Note

Be

sure

to

install

the

roof

insulator

before

installing

the

head

lining

J

BF

43

Page 243 of 513

n

YR

f

f1

JC

1

r

8bD

l

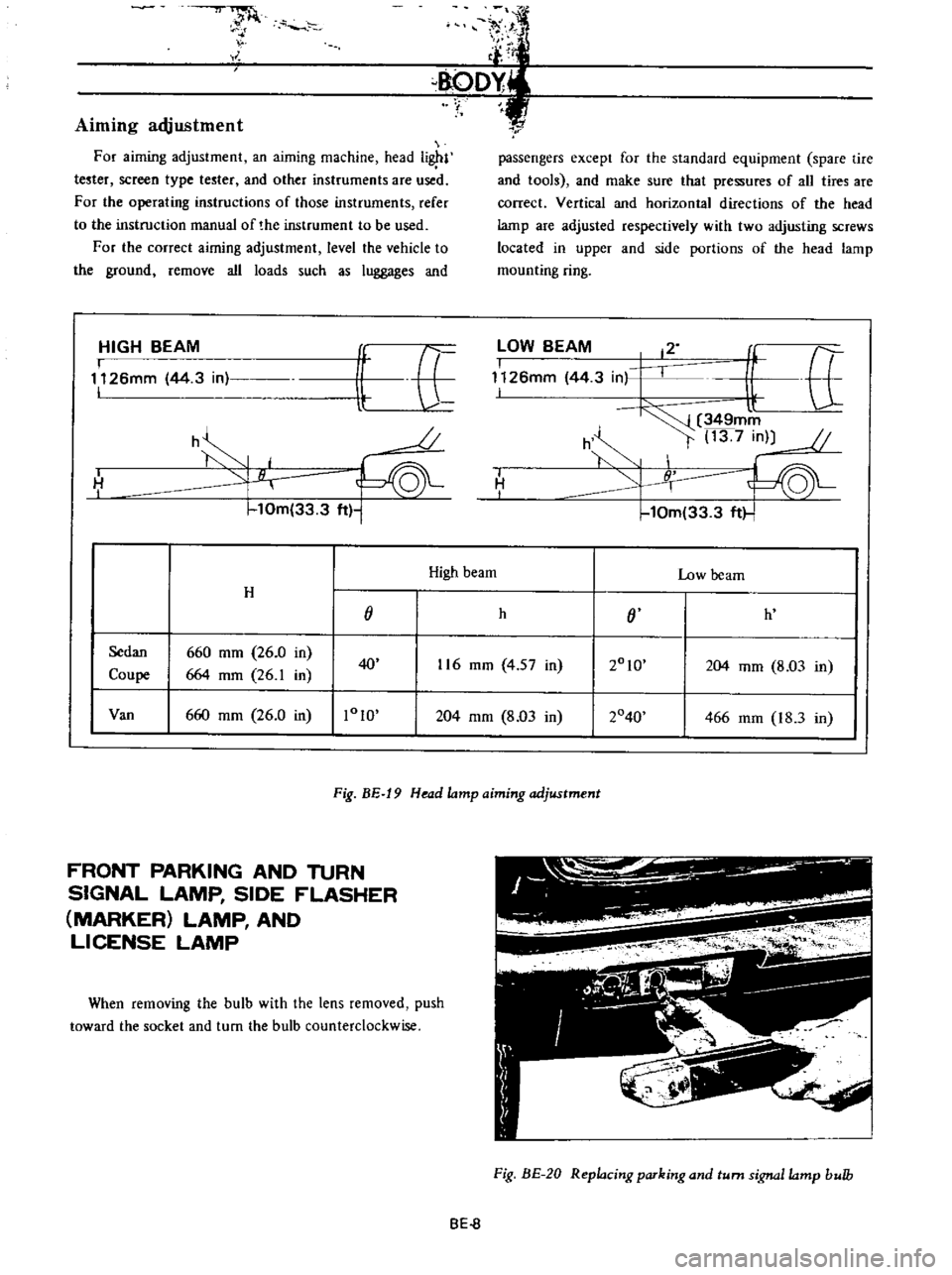

Aiming

adjustment

For

aiming

adjustment

an

aiming

machine

head

i

l

tester

screen

type

tester

and

other

instruments

are

used

For

the

operating

instructions

of

those

instruments

refer

to

the

instruction

manual

of

the

instrument

to

be

used

For

the

correct

airning

adjustment

level

the

vehicle

to

the

ground

remove

all

loads

such

as

luggages

and

HIGH

BEAM

I

1126mm

44

3

in

I

it

E

U

o

h

H

I

10m

33

3

ft

1

r

passengers

except

for

the

standard

equipment

spare

tire

and

tools

and

make

sure

that

pressures

of

all

tires

are

correct

Vertical

and

horizontal

directions

of

the

head

lamp

are

adjusted

respectively

with

two

adjusting

screws

located

in

upper

and

side

portions

of

the

head

lamp

mounting

ring

lOW

BEAM

12

I

f

tt

1126mm

44

3

in

I

l

349mm

h

t

13

7

in

10m

33

3

ft

I

H

I

High

beam

Low

beam

H

j

h

j

h

Sedan

660

mm

26

0

in

2010

Coupe

664

mm

26

1

in

40

116

mm

4

57

in

204

mm

8

03

in

Van

660

mm

26

0

in

1010

204

mm

8

03

in

2040

466

mm

18

3

in

Fig

BE

19

Head

lamp

aiming

adjustment

FRONT

PARKING

AND

TURN

SIGNAL

LAMP

SIDE

FLASHER

MARKER

LAMP

AND

LICENSE

LAMP

When

removing

the

bulb

with

the

lens

removed

push

toward

the

socket

and

turn

the

bulb

counterclockwise

Fig

BE

20

Replacing

parking

and

turn

signa

lamp

bulb

BE

8

Page 296 of 513

@

wWD@R

l

u

DJlliJ

1

SECTION

GI

DATSUN

1200

MODEL

B

11

0

SERIES

GENERAL

INFORMATION

I

NISSA

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

MODEL

VARIATION

GI

I

IDENTIFICATION

NUMBER

GI

I

JACKING

UP

AND

TOWING

GI

3

THE

CAR

APPROXIMATE

REFILL

GI

5

CAPACITY

RECOMMENDED

LUBRICANTS

GI

5

NISSAN

LONG

LIFE

GI

7

COOLANT

L

L

C

r

em