reset DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 107 of 513

FRONT

AXLE

FRONT

SUSPENSION

ADJUSTMENT

CONTENTS

ADJUSTMENT

DATA

ADJUSTMENT

OF

WHEEL

ALIGNMENT

ADJUSTMENT

OF

VEHICLE

LEVEL

FA

21

FA

22

FA

22

1

Carry

out

wheel

alignment

on

a

flat

surface

with

tire

air

pressure

adjusted

to

the

normal

pressure

2

Thoroughly

check

all

component

parts

of

the

steering

and

suspension

systems

and

repair

or

replace

AD

JUSTMENT

DATA

I

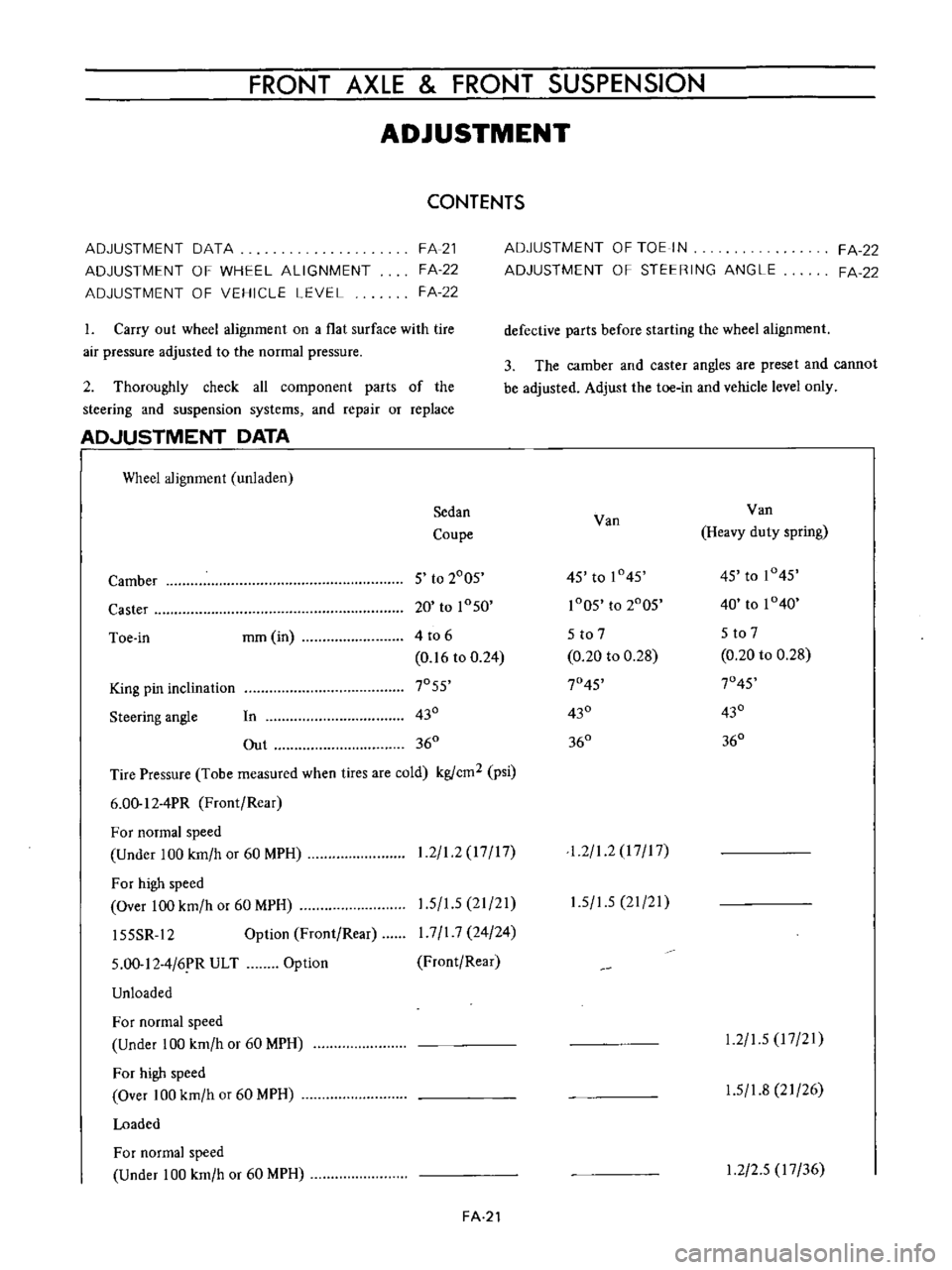

Wheel

alignment

unladen

Sedan

Coupe

Camber

5

to

2005

Caster

20

to

1050

Toe

in

mm

in

4

to

6

0

16

to

0

24

King

pin

inclination

7055

Steering

angle

In

430

Out

360

Tire

Pressure

Tobe

measured

when

tires

are

cold

kgfcm2

psi

6

00

12

4PR

Front

Rear

For

normal

speed

Under

100

km

h

or

60

MPH

For

high

speed

Over

100

km

h

or

60

MPH

15SSR

12

Option

Front

Rear

1

2

1

2

17

17

1

5

1

5

21

21

I

7

I

7

24

24

Front

Rear

5

00

12

4

6

R

ULT

Unloaded

Option

For

normal

speed

Under

100

km

h

or

60

MPH

For

high

speed

Over

100

km

h

or

60

MPH

Loaded

For

normal

speed

Under

100

km

h

or

60

MPH

FA

21

ADJUSTMENT

OF

TOE

IN

ADJUSTMENT

OF

STEERING

ANGLE

FA

22

FA

22

defective

parts

before

starting

the

wheel

alignment

3

The

camber

and

caster

angles

are

preset

and

cannot

be

adjusted

Adjust

the

toe

in

and

vehicle

level

only

Van

Van

Heavy

duty

spring

45

to

1045

45

to

1045

1005

to

2005

40

to

1040

5

to

7

5

to

7

0

20

to

0

28

0

20

to

0

28

7045

7045

430

430

360

360

1

2

1

2

I

7

I

7

1

5

1

5

21

21

1

2

1

5

17

21

1

5

1

8

21

26

1

2

2

5

17

36

Page 254 of 513

BODY

ELECTRICAL

SPEEDOMETER

The

speedometer

is

equipped

with

a

total

odometer

which

records

travelled

distance

Replacement

1

When

removing

the

speedometer

remove

the

cluster

lid

first

Separate

the

combination

meter

housing

from

the

cluster

lid

after

removing

four

screws

and

remove

the

trip

recorder

reset

knob

if

any

2

Unscrew

two

screws

and

remove

the

speedometer

from

the

combination

meter

housing

3

Reinstall

a

new

speedometer

in

reverse

sequence

of

removal

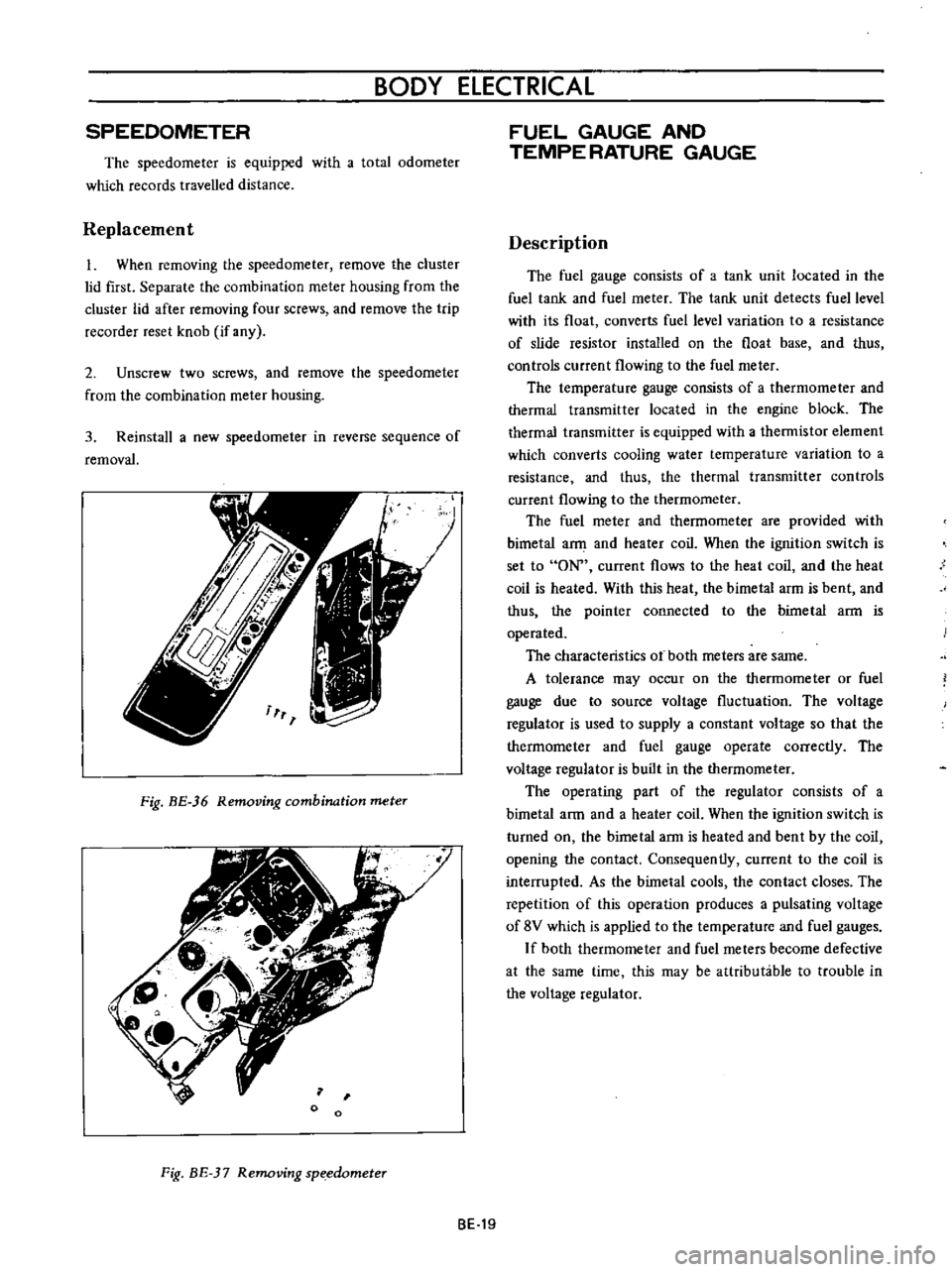

Fig

BE

36

Removing

combination

meter

o

Fig

BE

37

Removing

sp

edometer

FUEL

GAUGE

AND

TEMPE

RATURE

GAUGE

Description

The

fuel

gauge

consists

of

a

tank

unit

located

in

the

fuel

tank

and

fuel

meter

The

tank

unit

detects

fuel

level

with

its

float

converts

fuel

level

variation

to

a

resistance

of

slide

resistor

installed

on

the

float

base

and

thus

controls

current

flowing

to

the

fuel

meter

The

temperature

gauge

consists

of

a

thermorneter

and

thermal

transmitter

located

in

the

engine

block

The

thermal

transmitter

is

equipped

with

a

thermistor

element

which

converts

cooling

water

temperature

variation

to

a

resistance

and

thus

the

thermal

transmitter

controls

current

flowing

to

the

thermometer

The

fuel

rneter

and

thermometer

are

provided

with

bimetal

a

and

heater

coil

When

the

ignition

switch

is

set

to

ON

current

flows

to

the

heat

coil

and

the

heat

coil

is

heated

With

this

heat

the

bimetal

arm

is

bent

and

thus

the

pointer

connected

to

the

bimetal

ann

is

operated

The

characteristics

ot

both

meters

are

same

A

tolerance

may

occur

on

the

thermometer

or

fuel

gauge

due

to

source

voltage

fluctuation

The

voltage

regulator

is

used

to

supply

a

constant

voltage

so

that

the

therrnorneter

and

fuel

gauge

operate

correctly

The

voltage

regulator

is

built

in

the

thermometer

The

operating

part

of

the

regulator

consists

of

a

bimetal

arm

and

a

heater

coil

When

the

ignition

switch

is

turned

on

the

birnetal

arm

is

heated

and

bent

by

the

coil

opening

the

contact

Consequently

current

to

the

coil

is

interrupted

As

the

bimetal

cools

the

contact

closes

The

repetition

of

this

operation

produces

a

pulsating

voltage

of

8V

which

is

applied

to

the

ternperature

and

fuel

gauges

If

both

thermometer

and

fuel

meters

become

defective

at

the

same

time

this

may

be

attributable

to

trouble

in

the

voltage

regulator

BE

19

Page 458 of 513

ENGINE

Overheating

Normal

Carbon

fould

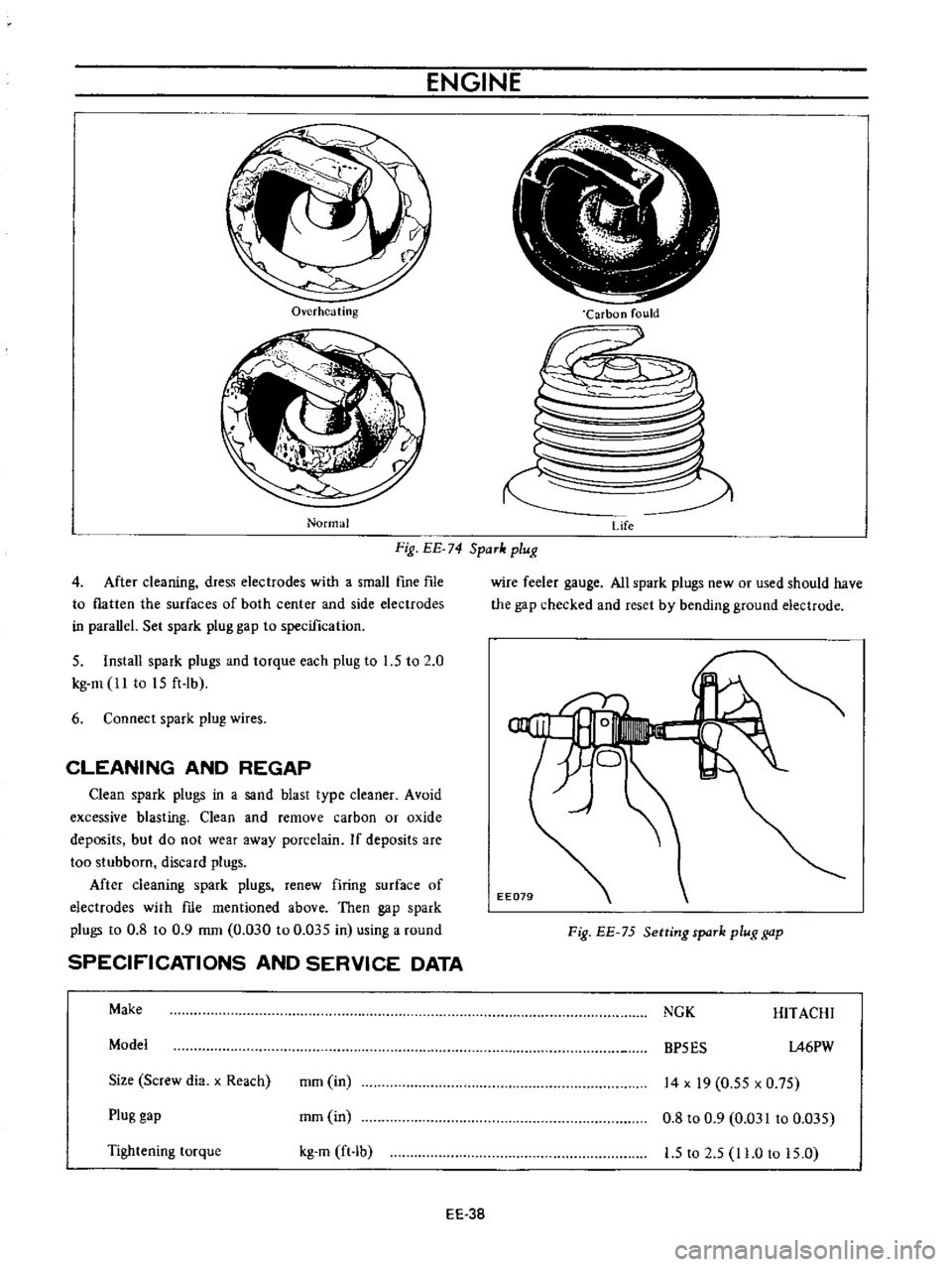

Fig

EE

74

SpaTk

plug

Life

4

After

cleaning

dress

electrodes

with

a

small

fine

fIle

to

flatten

the

surfaces

of

both

center

and

side

electrodes

in

parallel

Set

spark

plug

gap

to

specification

5

Install

spark

plugs

and

torque

each

plug

to

1

5

to

2

0

kg

m

ll

to

15

ft

lb

6

Connect

spark

plug

wires

CLEANING

AND

REGAP

Clean

spark

plugs

in

a

sand

blast

type

cleaner

Avoid

excessive

blasting

Clean

and

remove

carbon

or

oxide

deposits

but

do

not

wear

away

porcelain

If

deposits

are

too

stubborn

discard

plugs

Mter

cleaning

spark

plugs

renew

firing

surface

of

electrodes

with

me

mentioned

above

Then

gap

spark

plugs

to

0

8

to

0

9

mm

0

030

to

0

035

in

using

a

round

SPECIFICATIONS

AND

SERVICE

DATA

Make

Model

Size

Screw

dia

x

Reach

mm

in

Plug

gap

mm

in

Tightening

torque

kg

m

ft

b

EE

38

wire

feeler

gauge

All

spark

plugs

new

or

used

should

have

the

gap

checked

and

reset

by

bending

ground

electrode

Fig

EE

75

Setting

spaTk

plug

gap

NGK

HITACHI

BP5ES

1A6PW

14

x

19

0

55

x

0

75

0

8

to

0

9

0

031

to

0

035

1

5

to

2

5

11

0

to

15

0