sensor DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 325 of 513

ENGINE

Caution

lock

the

front

and

rear

wheels

by

fully

pulling

the

parking

brake

lever

before

con

ducting

this

test

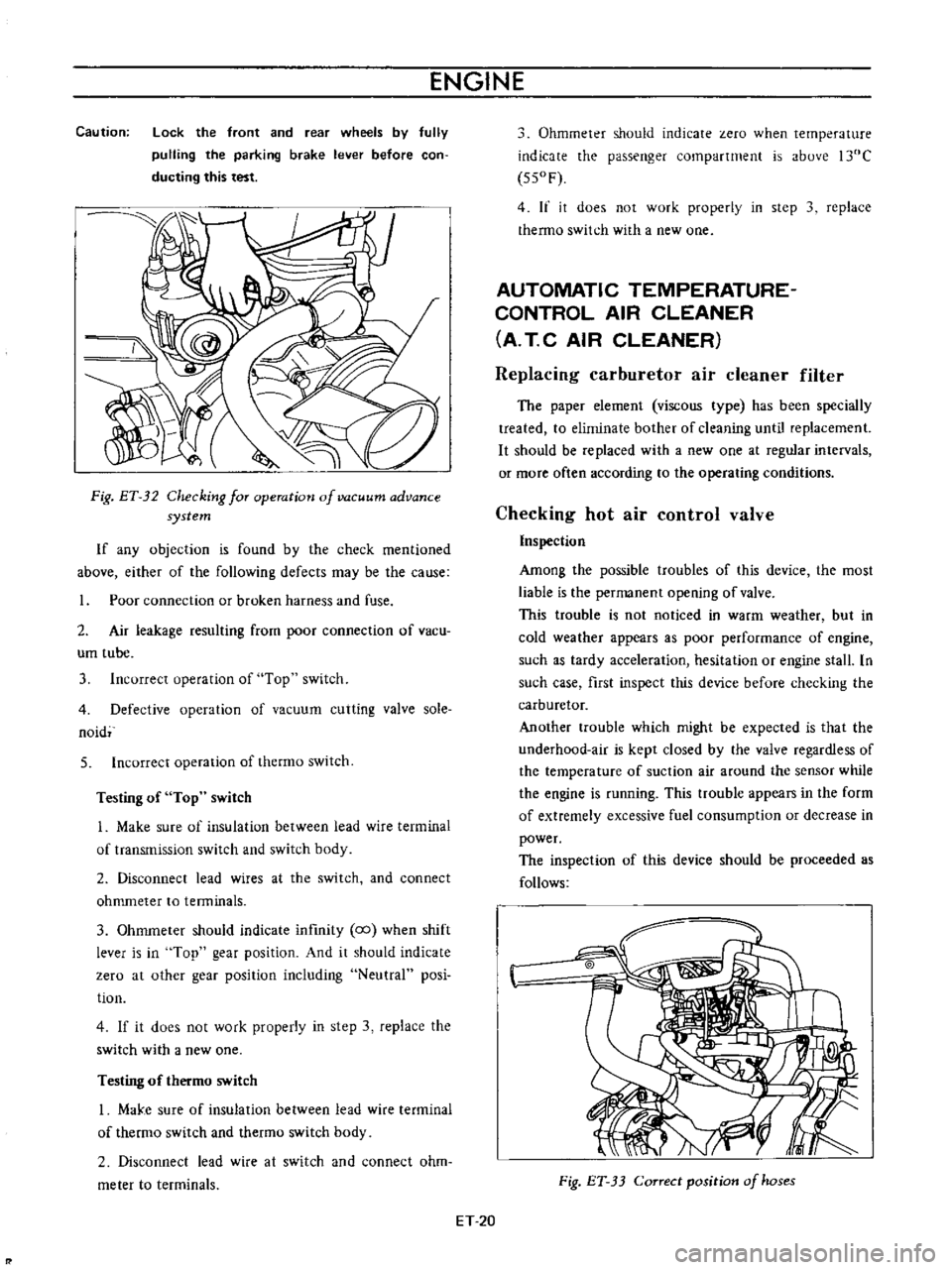

Fig

ET

32

Checking

for

operation

of

vacuum

advance

system

If

any

objection

is

found

by

the

check

mentioned

above

either

of

the

following

defects

may

be

the

cause

Poor

connection

or

broken

harness

and

fuse

2

Air

leakage

resulting

from

poor

connection

of

vacu

um

tube

3

Incorrect

operation

of

Top

switch

4

Defective

operation

of

vacuum

cutting

valve

sole

naid

5

Incorrect

operation

of

thermo

switch

Testing

of

Top

switch

1

Make

sure

of

insulation

between

lead

wire

terminal

of

transmission

switch

and

switch

body

2

Disconnect

lead

wires

at

the

switch

and

connect

ohmmeter

to

tenninals

3

Ohmmeter

should

indicate

infmity

co

when

shift

lever

is

in

Top

gear

position

And

it

should

indicate

zero

at

other

gear

position

including

Neutral

posi

tion

4

If

it

does

not

work

properly

in

step

3

replace

the

switch

with

a

new

one

Testing

of

thermo

switch

I

MaJ

e

sure

of

insulation

between

lead

wire

terminal

of

thermo

switch

and

thetmo

switch

body

2

Disconnect

lead

wire

at

switch

and

connect

ohm

meter

to

terminals

Ohmmeter

should

indicate

zero

when

temperature

indicate

the

passenger

compartment

is

above

l30C

550F

4

If

it

does

not

work

properly

in

step

3

replace

thermo

switch

with

a

new

one

AUTOMATIC

TEMPERATURE

CONTROL

AIR

CLEANER

A

T

C

AIR

CLEANER

Replacing

carburetor

air

cleaner

filter

The

paper

element

viscous

type

has

been

specially

treated

to

eliminate

bother

of

cleaning

until

replacement

It

should

be

replaced

with

a

new

one

at

regular

intervals

or

more

often

according

to

the

operating

conditions

Checking

hot

air

control

valve

Inspection

Among

the

possible

troubles

of

this

device

the

most

liable

is

the

permanent

opening

of

valve

This

trouble

is

not

noticed

in

warm

weather

but

in

cold

weather

appears

as

poor

performance

of

engine

such

as

tardy

acceleration

hesitation

or

engine

stall

In

such

case

first

inspect

this

device

before

checking

the

carburetor

Another

trouble

which

might

be

expected

is

that

the

underhood

air

is

kept

closed

by

the

valve

regardless

of

the

temperature

of

suction

air

around

the

sensor

while

the

engine

is

running

This

ttOuble

appears

in

the

form

of

extremely

excessive

fuel

consumption

or

decrease

in

power

The

inspection

of

this

device

should

be

proceeded

as

follows

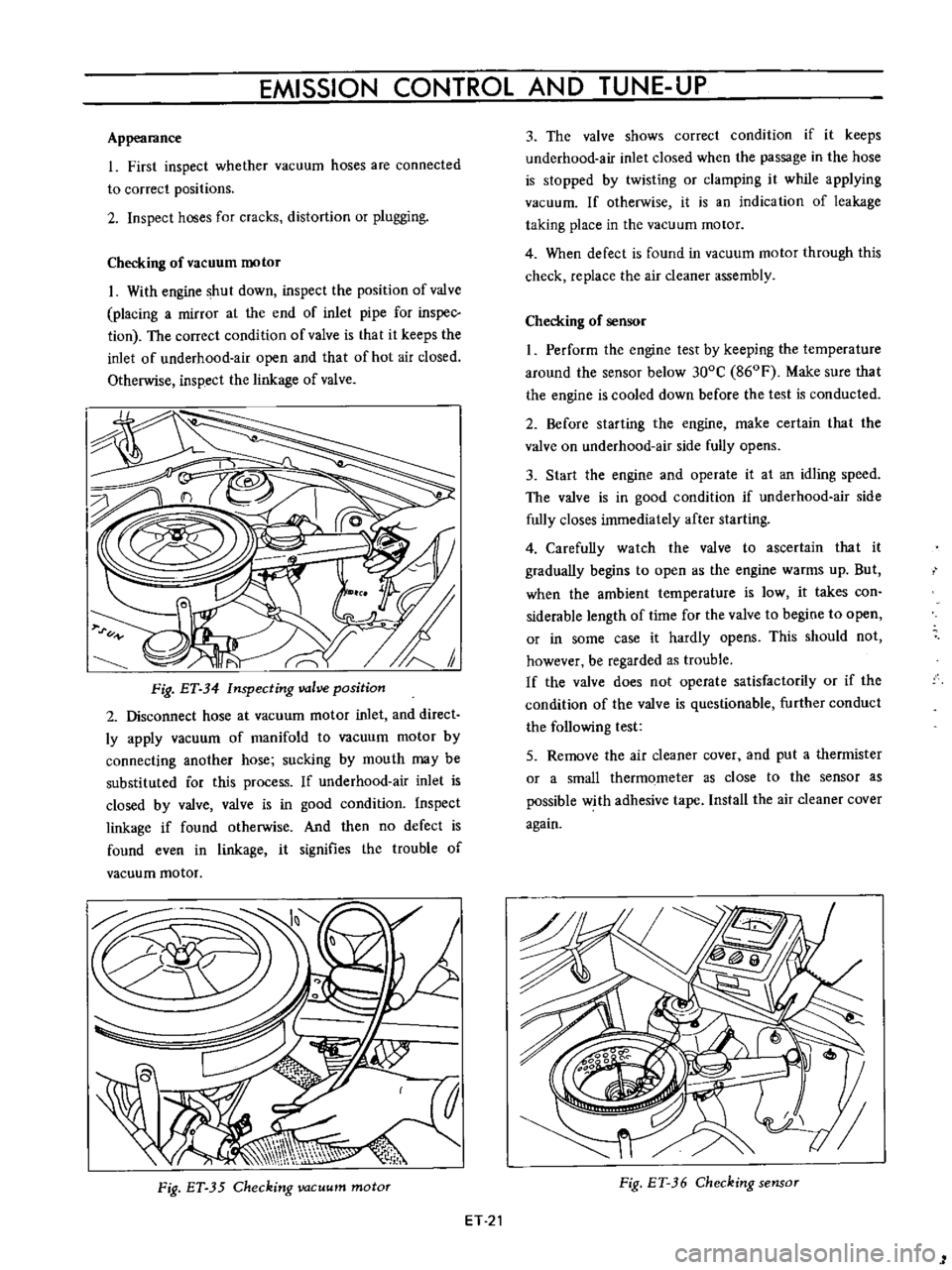

Fig

ET

33

Correct

position

of

hoses

ET

20

Page 326 of 513

EMISSION

CONTROL

AND

TUNE

UP

Appearance

1

First

inspect

whether

vacuum

hoses

are

connected

to

correct

positions

2

Inspect

hoses

for

cracks

distortion

or

plugging

Checking

of

vacuum

motor

I

With

engine

shut

down

inspect

the

position

of

valve

placing

a

mirror

at

the

end

of

inlet

pipe

for

inspec

tion

The

correct

condition

of

valve

is

that

it

keeps

the

inlet

of

underhood

air

open

and

that

of

hot

air

closed

Otherwise

inspect

the

linkage

of

valve

Fig

ET

34

Inspecting

valve

position

2

Disconnect

hose

at

vacuum

motor

inlet

and

direct

ly

apply

vacuum

of

manifold

to

vacuum

motor

by

connecting

another

hose

sucking

by

mouth

may

be

substituted

for

this

process

If

underhood

air

inlet

is

closed

by

valve

valve

is

in

good

condition

Inspect

linkage

if

found

otherwise

And

then

no

defect

is

found

even

in

linkage

it

signifies

the

trouble

of

vacuum

motor

Fig

ET

35

Checking

vacuum

motor

ET

21

3

The

valve

shows

correct

condition

if

it

keeps

underhood

air

inlet

closed

when

the

passage

in

the

hose

is

stopped

by

twisting

or

clamping

it

while

applying

vacuum

If

otherwise

it

is

an

indication

of

leakage

taking

place

in

the

vacuum

motor

4

When

defect

is

found

in

vacuum

motor

through

this

check

replace

the

air

cleaner

assembly

Checking

of

sensor

I

Perform

the

engine

test

by

keeping

the

temperature

around

the

sensor

below

300C

860F

Make

sure

that

the

engine

is

cooled

down

before

the

test

is

conducted

2

Before

starting

the

engine

make

certain

that

the

valve

on

underhood

air

side

fully

opens

3

Start

the

engine

and

operate

it

at

an

idling

speed

The

valve

is

in

good

condition

if

underhood

air

side

fully

closes

immediately

after

starting

4

Carefully

watch

the

valve

to

ascertain

that

it

gradually

begins

to

open

as

the

engine

warms

up

But

when

the

ambient

temperature

is

low

it

takes

con

siderable

length

of

time

for

the

valve

to

begine

to

open

or

in

some

case

it

hardly

opens

This

should

not

however

be

regarded

as

trouble

If

the

valve

does

not

operate

satisfactorily

or

if

the

condition

of

the

valve

is

questionable

further

conduct

the

following

test

5

Remove

the

air

cleaner

cover

and

put

a

thermister

or

a

small

thermometer

as

close

to

the

sensor

as

possible

with

adhesive

tape

Install

the

air

cleaner

cover

again

Fig

ET

36

Checking

sensor

1

Page 327 of 513

ENGINE

6

Start

the

engine

and

continue

idling

as

described

under

paragraphs

I

2

and

3

above

When

several

minutes

have

passed

and

the

valve

is

partially

opened

read

the

thermister

indication

It

is

correct

if

the

reading

falls

between

380C

1000

F

and

550C

1300

F

If

the

reading

is

abnormal

replace

the

sensor

7

On

the

engine

equipped

with

an

idle

compensator

as

service

option

do

as

follows

before

replacing

the

sensor

Clog

hose

on

idle

compensator

side

by

twisting

or

clamping

it

and

check

the

temperature

as

given

in

paragraphs

5

and

6

above

If

the

thermometer

shO

vs

correct

temperature

replace

the

idle

compensa

tOf

if

the

reading

is

abnormal

replace

the

sensor

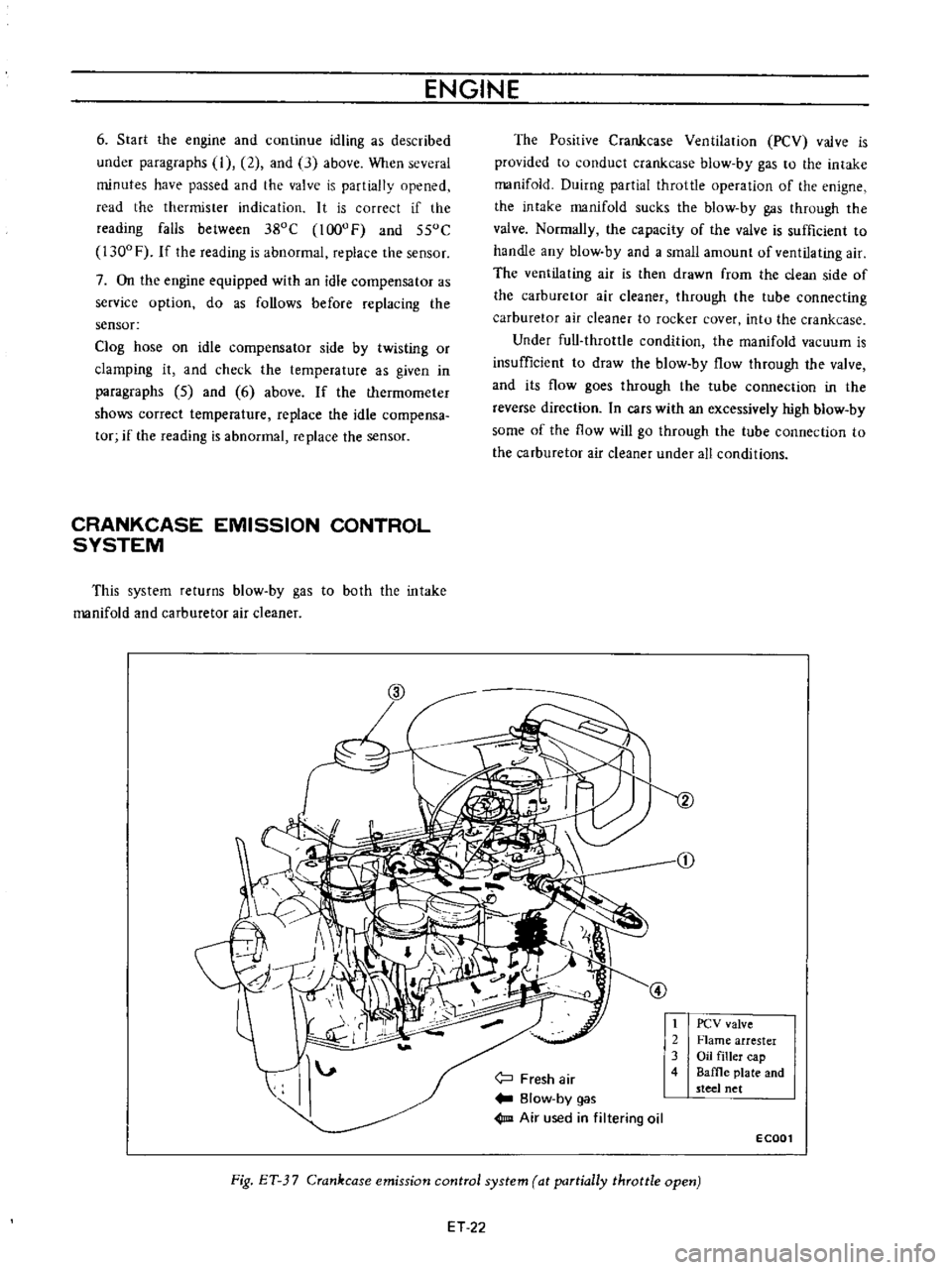

CRANKCASE

EMISSION

CONTROL

SYSTEM

This

system

returns

blow

by

gas

to

both

the

intake

manifold

and

carburetor

air

cleaner

The

Posirive

Crankcase

Ventilation

PCV

valve

is

provided

to

conduct

crankcase

blow

by

gas

to

the

intake

manifold

Duirng

partial

throttle

operation

of

the

enigne

the

intake

manifold

sucks

the

blow

by

gas

through

the

valve

Normally

the

capacity

of

the

valve

is

sufficient

to

handle

any

blow

by

and

a

small

amount

of

ventilating

air

The

ventilating

air

is

then

drawn

from

the

clean

side

of

the

carburetor

air

cleaner

through

the

tube

connecting

carburetor

air

cleaner

to

rocker

cover

intu

the

crankcase

Under

full

throttle

condition

the

manifold

vacuum

is

insufficient

to

draw

the

blow

by

flow

through

the

valve

and

its

flow

goes

through

the

tube

connection

in

the

reverse

direction

In

cars

with

an

excessively

high

blow

by

some

of

the

flow

will

go

through

the

tube

connection

to

the

carburetor

air

cleaner

under

all

conditions

j

Fresh

air

Blow

by

gas

1m

Air

used

in

filtering

oil

t

2

3

4

PCV

valve

Flame

arrester

Oil

filler

cap

Baffle

plate

and

steel

net

ECOOl

Fig

ET

3

7

Crankcase

emission

control

system

at

partially

throttle

open

ET

22

Page 392 of 513

FUEl

SYSTEM

AUTOMATIC

TEMPERATURE

CONTROL

AIR

CLEANER

A

T

C

AIR

CLEANER

CONTENTS

DESCRIPTION

Air

cleaner

element

Automatic

temperature

control

air

cleaner

EF

1

EF

1

EF

2

TEMPERATURE

SENSOR

Removal

and

installation

EF

4

EF

4

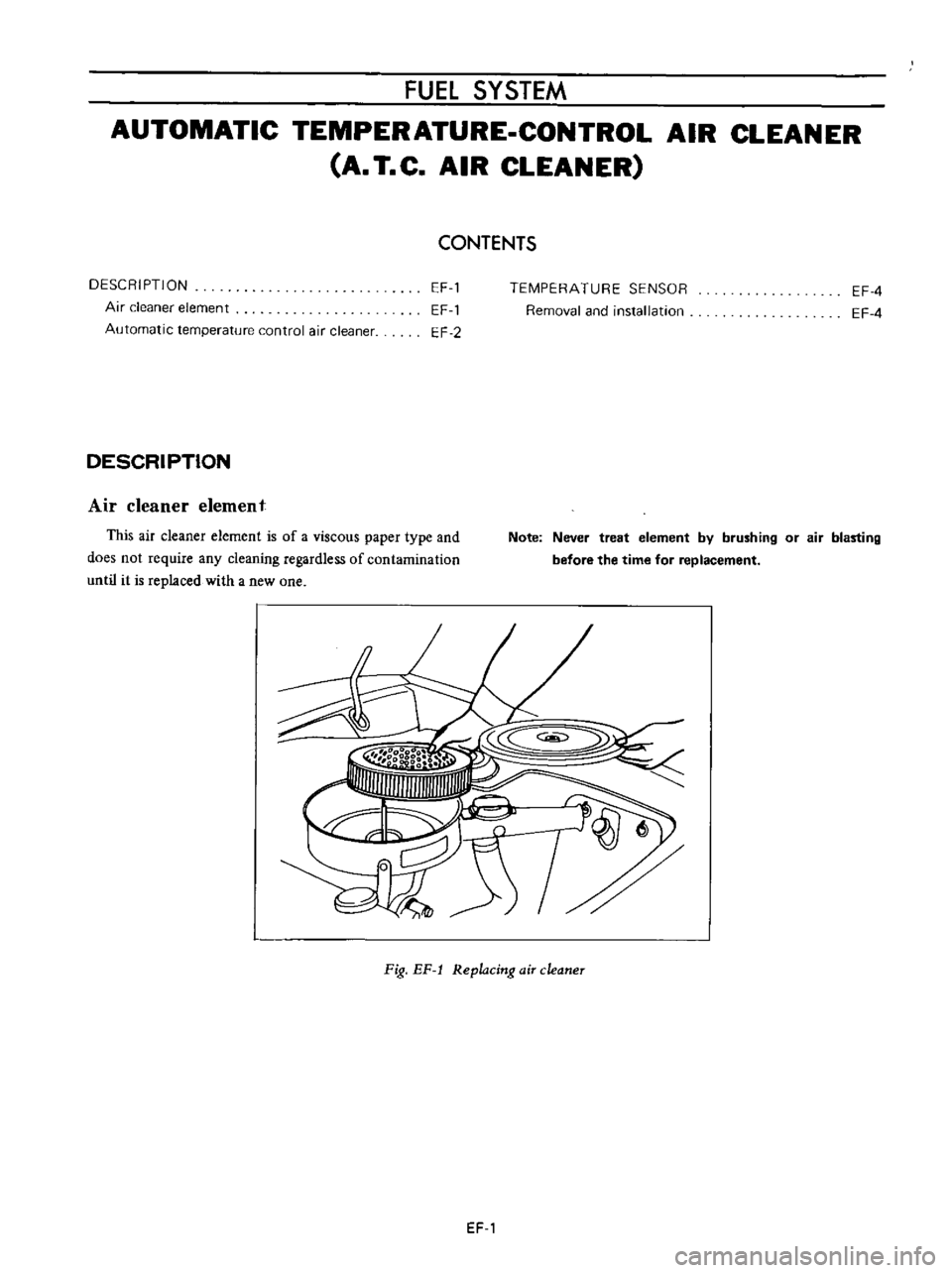

DESCRIPTION

Air

cleaner

element

This

air

cleaner

element

is

of

a

viscous

paper

type

and

does

not

require

any

cleaning

regardless

of

contamination

until

it

is

replaced

with

a

new

one

Note

Never

treat

element

by

brushing

or

air

blasting

before

the

time

for

replacement

Fig

EF

l

Replacing

air

cleaner

EF

1

Page 393 of 513

ENGINf

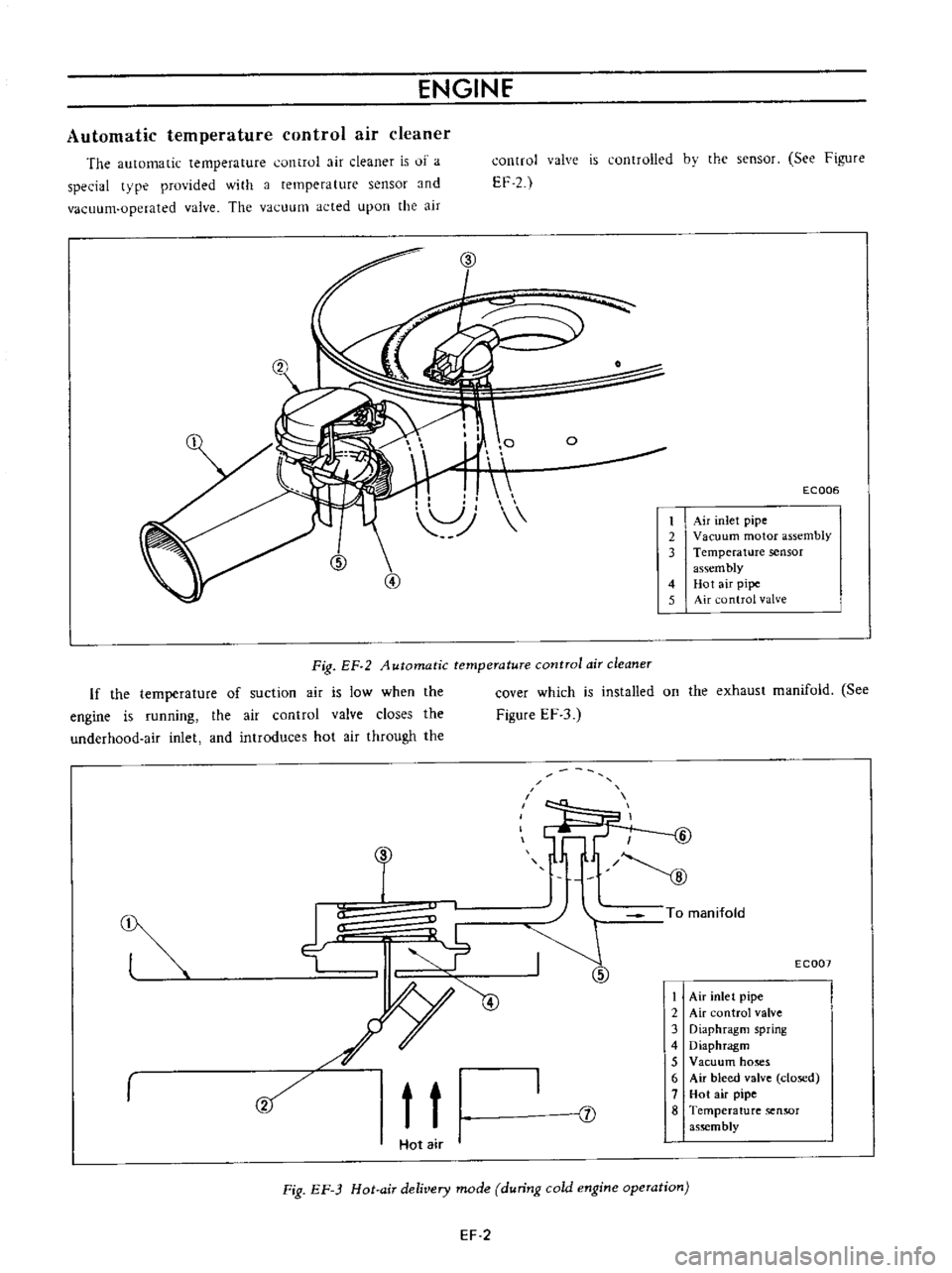

Automatic

temperature

control

air

cleaner

The

automatic

temperature

cuntrol

air

cleaner

is

of

a

special

tvpe

provided

with

a

temperature

sensor

and

vacuum

operated

valve

The

vacuum

acted

upon

the

air

2

I

control

valve

is

controlled

bv

the

sensor

See

Figure

EF

2

J

o

ECQ06

Air

inlet

pipe

2

Vacuum

motor

assembly

3

Temperature

sensor

assem

bly

4

Hot

air

pipe

5

Air

ontrol

valve

Fig

EF

2

Automatic

temperature

control

air

cleaner

If

the

temperature

of

suction

air

is

low

when

the

engine

is

running

the

air

control

valve

closes

the

underhoad

air

inlet

and

introduces

hot

air

through

the

j

I

a

0

Ej

If

f

7

@

t

t

1

Hot

air

I

cover

which

is

installed

on

the

exhaust

manifold

See

Figure

EF

3

I

@

To

manifold

EC007

J

I

Air

inlet

pipe

2

Air

control

valve

3

Diaphragm

spring

4

Diaphragm

5

Vacuum

ho

s

6

Air

bleed

valve

closed

7

Hot

air

pipe

8

Temperature

sensor

as

mbly

Fig

EF

3

Hot

air

delivery

mode

during

cold

engine

operation

EF

2

Page 394 of 513

FUEL

SYSTEM

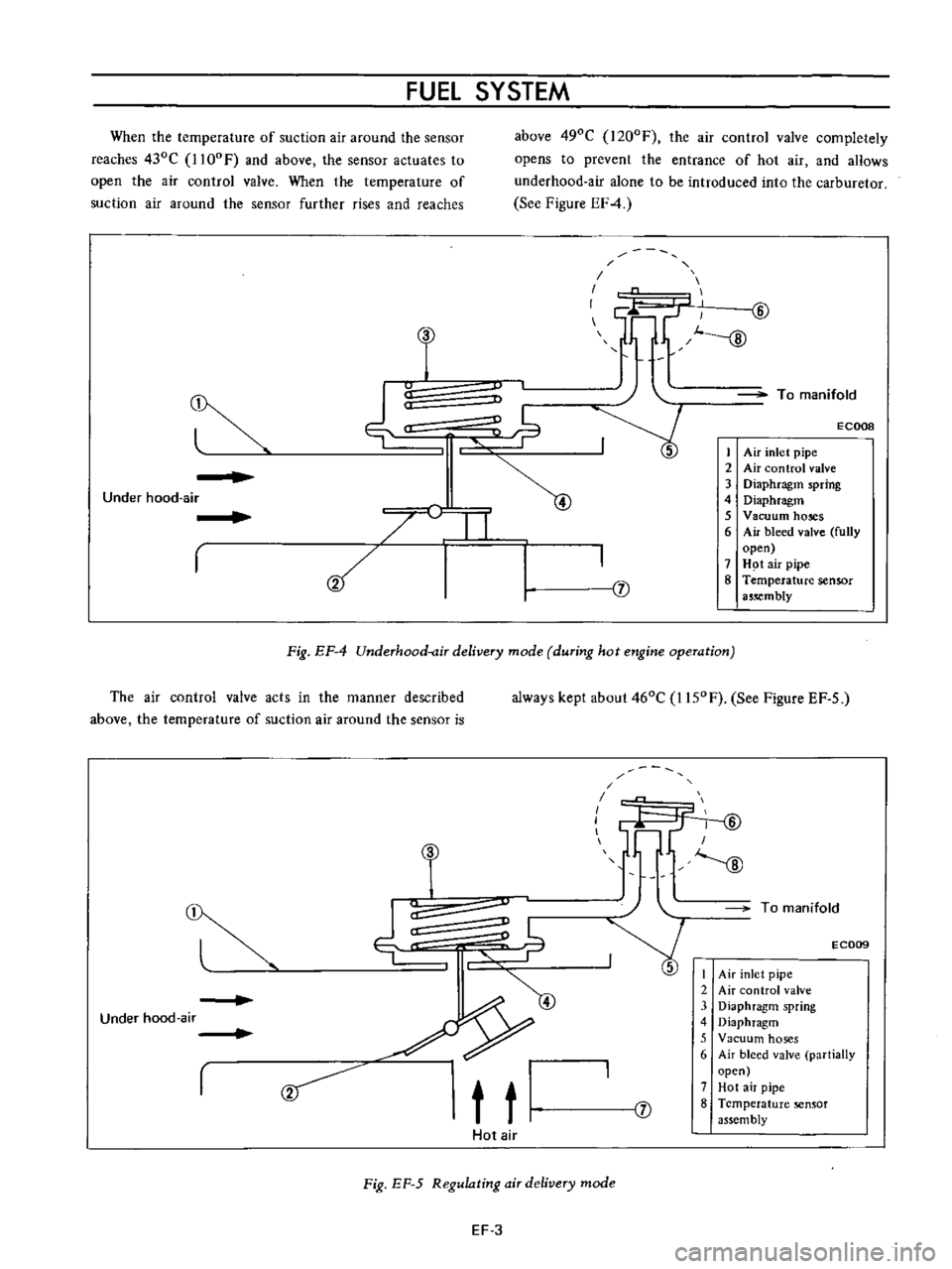

When

the

temperature

of

suction

air

around

the

sensor

reaches

430C

1l00F

and

above

the

sensor

actuates

to

open

the

air

control

valve

When

the

temperature

of

suction

air

around

the

sensor

further

rises

and

reaches

above

490C

I200F

the

air

control

valve

completely

opens

to

prevent

the

entrance

of

hot

air

and

aHows

underhood

air

alone

to

be

introduced

into

the

carburetor

See

Figure

EF4

u

C

I

1f1

lL

GJ

J

To

manifold

ECOOB

j

1

Air

inlet

pipe

2

Air

control

valve

3

Diaphragm

spring

4

Diaphragm

5

Vacuum

hoses

6

Air

bleed

valve

fully

open

7

H

t

air

pipe

8

Temperature

sensor

a5

mbly

Under

hood

air

I

I

Fig

EF

4

Underhood

air

delivery

mode

during

hot

engine

operation

The

air

control

valve

acts

in

the

manner

described

above

the

temperature

of

suction

air

around

the

sensor

is

always

kept

about

460C

I150F

See

Figure

EF

5

r

9

t

t

T

I

I

I

fY

ID

I

J

To

manifold

E

C009

I

Air

inlet

pipe

2

Air

control

valve

3

Diaphragm

spring

4

Diaphragm

5

Vacuum

hoses

6

Air

bleed

valve

partially

open

7

Hot

air

pipe

8

Temperature

sensor

assembly

Under

hood

air

J

Hot

air

Fig

EF

5

Regulating

air

delivery

mode

EF

3

Page 395 of 513

ENGINE

When

the

engine

is

operating

under

heavy

load

the

air

control

valve

fully

opens

the

underhood

air

inlet

to

obtain

full

power

regardless

of

the

temperature

around

sensor

TEMPERATURE

SENSOR

Removal

and

installation

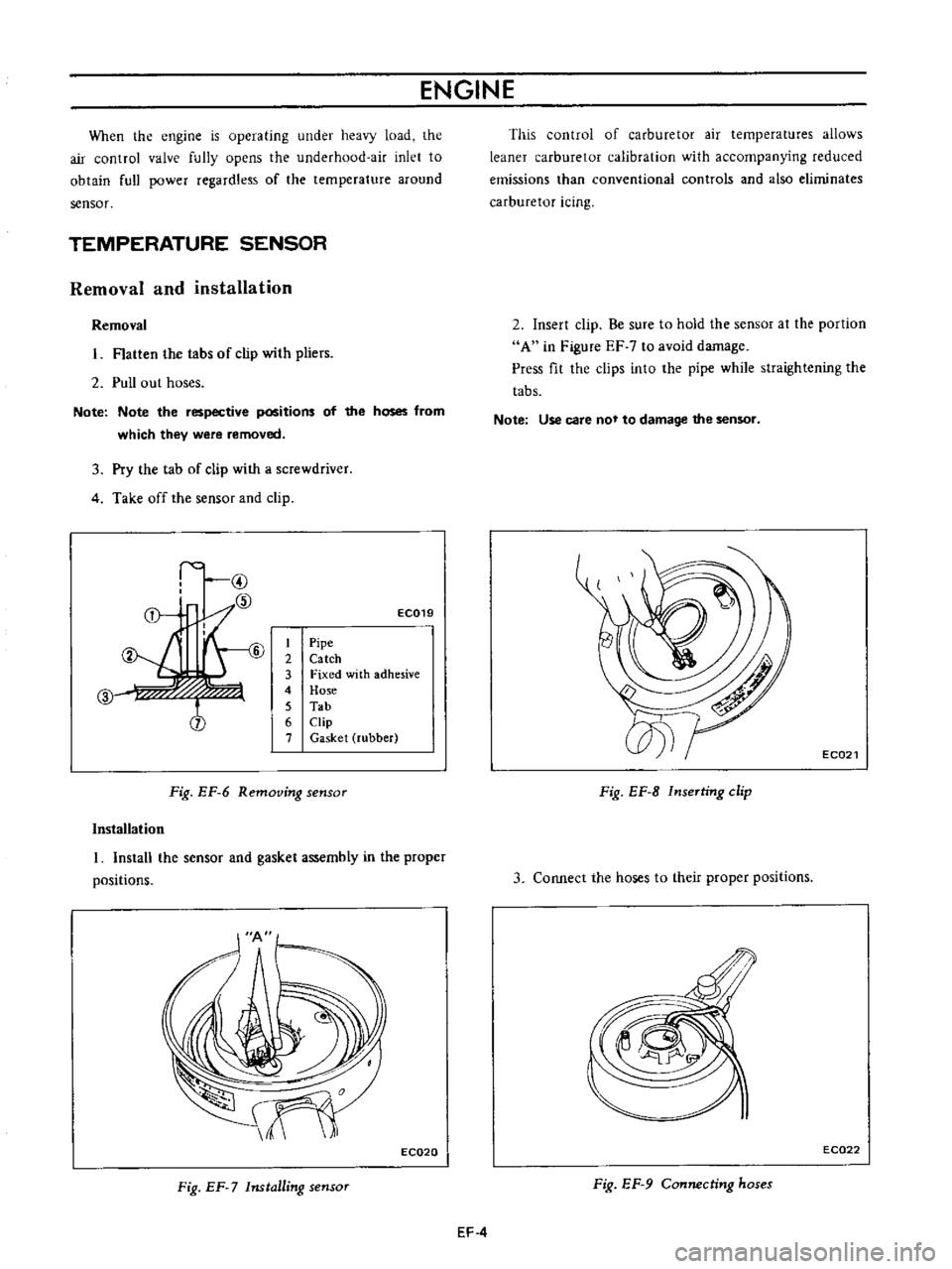

Removal

Hatten

the

tabs

of

clip

with

pliers

2

Pull

out

hoses

Note

Note

the

respective

positions

of

the

hoses

from

which

they

were

removed

3

Pry

the

tab

of

clip

with

a

screwdriver

4

Take

off

the

sensor

and

clip

I

@

f

6

7

CID

f

j

EC019

1

Pipe

2

Catch

3

Fixed

with

adhesive

4

Hose

5

Tab

6

Clip

7

Gasket

rubber

Fig

EF

6

Removing

sensor

Installation

I

Install

the

sensor

and

gasket

assembly

in

the

proper

positions

EC020

Fig

EF

7

Installing

sensor

This

control

of

carburetor

air

temperatures

allows

leaner

carburetor

calibration

with

accompanying

reduced

emissions

than

conventional

controls

and

also

eliminates

carburetor

icing

2

Insert

clip

Be

sure

to

hold

the

sensor

at

the

portion

A

in

Figure

EF

7

to

avoid

damage

Press

fit

the

clips

into

the

pipe

while

straightening

the

tabs

Note

Use

care

not

to

damage

the

sensor

EC021

Fig

EF

B

InseTting

clip

3

COIUlect

the

hoses

to

their

proper

positions

EC022

Fig

EF

9

Connecting

hoses

EF

4