service indicator DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 49 of 513

Clearance

between

seal

ring

and

ring

groove

See

Figure

AT

97

Standard

clearance

0

04toO

16mm

0

0016

to

0

0063

in

AT162

Fig

A

T

96

Measuring

clearance

I

earance

I

Seal

rIng

0d

t

AT185

II

Fig

AT

97

Measuring

clearance

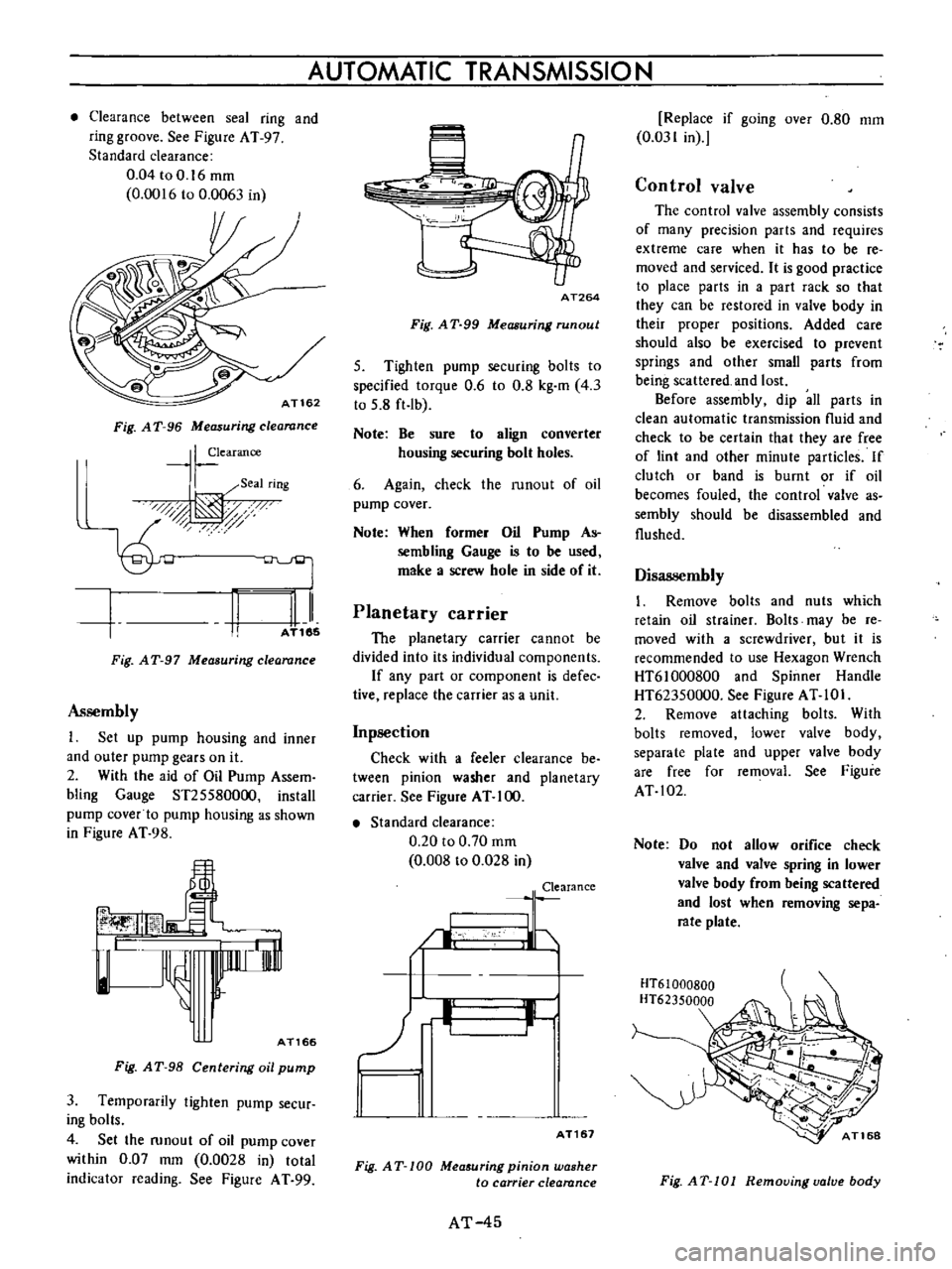

Assembly

1

Set

up

pump

housing

and

inner

and

outer

pump

gears

on

it

2

With

the

aid

of

Oil

Pump

Assem

bling

Gauge

ST255800oo

install

pump

cover

to

pump

housing

as

shown

in

Figure

AT

98

lnnrr

i

rnl

l

AT166

Fig

A

T

98

Centering

oil

pump

3

Temporarily

tighten

pump

secur

ing

bolts

4

Set

the

runout

of

oil

pump

cover

within

0

07

mm

0

0028

in

total

indicator

reading

See

Figure

A

T

99

AUTOMATIC

TRANSMISSION

AT264

Fig

A

T

99

Measuring

run

out

5

Tighten

pump

securing

bolts

to

specified

torque

0

6

to

0

8

kg

m

4

3

to

5

8

ft

Ib

Note

Be

sure

to

align

converter

housing

securing

bolt

holes

6

Again

check

the

runout

of

oil

pump

cover

Note

When

former

Oil

Pump

As

sembling

Gauge

is

to

be

used

make

a

screw

hole

in

side

of

it

Planetary

carrier

The

planetary

carrier

cannot

be

divided

into

its

individual

components

If

any

part

or

component

is

defec

tive

replace

the

carrier

as

a

unit

Inpsection

Check

with

a

feeler

clearance

be

tween

pinion

washer

and

planetary

carrier

See

Figure

AT

100

Standard

clearance

0

20

to

0

70

mm

0

008

to

0

028

in

Clearance

I

LJ

b

II

I

AT161

Fig

AT

100

Mea

uring

pinion

washer

to

carrier

clearance

AT

45

Replace

if

going

over

0

80

mm

0

031

in

Control

valve

The

control

valve

assembly

consists

of

many

precision

parts

and

requires

extreme

care

when

it

has

to

be

re

moved

and

serviced

It

is

good

practice

to

place

parts

in

a

part

rack

so

that

they

can

be

restored

in

valve

body

in

their

proper

positions

Added

care

should

also

be

exercised

to

prevent

springs

and

other

small

parts

from

being

scattered

and

lost

Before

assembly

dip

all

parts

in

clean

automatic

transmission

nuid

and

check

to

be

certain

that

they

are

free

of

lint

and

other

minute

particles

If

clutch

or

band

is

burnt

or

if

oil

becomes

fouled

the

control

valve

as

sembly

should

be

disassembled

and

flushed

Disassembly

1

Remove

bolts

and

nuts

which

retain

oil

strainer

Bolts

may

be

re

moved

with

a

screwdriver

but

it

is

recommended

to

use

Hexagon

Wrench

HT61000800

and

Spinner

Handle

HT62350000

See

Figure

AT

10

I

2

Remove

attaching

bolts

With

bolts

removed

lower

valve

body

separate

plate

and

upper

valve

body

are

free

for

removal

See

Figure

AT

102

Note

Do

not

allow

orifice

check

valve

and

valve

spring

in

lower

valve

body

from

being

scattered

and

lost

when

removing

sepa

rate

plate

HT61000BOO

HT62350000

Fig

AT

101

Removing

valve

body

Page 253 of 513

BODY

METERS

AND

GAUGES

CONTENTS

CLUSTER

LID

Oescri

ption

Removal

SPEEDOMETER

Replacement

FUEL

GAUGE

AND

TEMPERATURE

GAUGE

Description

Replacement

BE

1B

BE

18

BE

18

BE

19

BE

19

BE

19

BE

19

BE

20

CLUSTER

LID

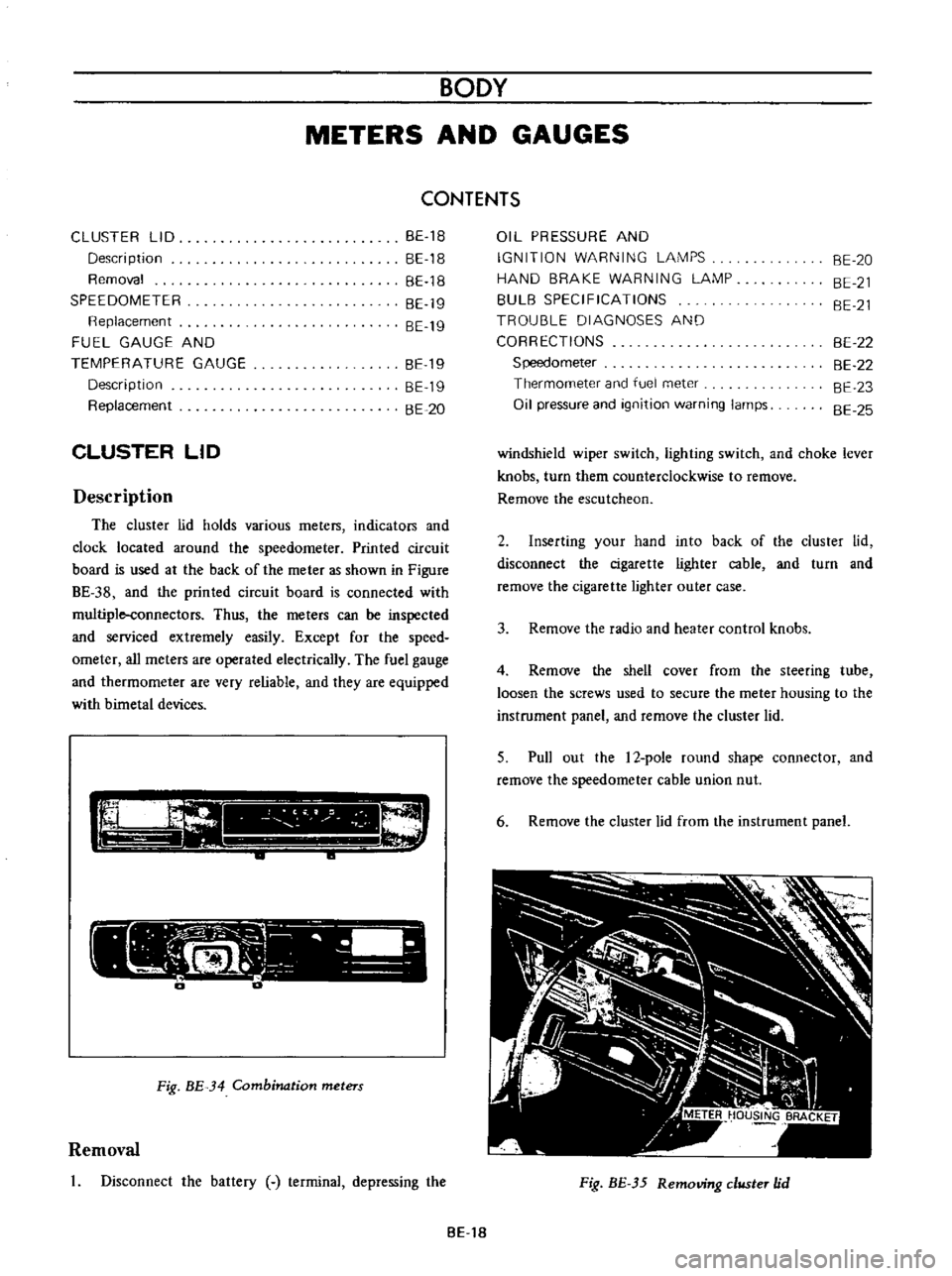

Description

The

cluster

lid

holds

various

rneters

indicators

and

clock

located

around

the

speedorneter

Printed

circuit

board

is

used

at

the

back

of

the

meter

as

shown

in

Figure

BE

38

and

the

printed

circuit

board

is

connected

with

multiple

connectors

Thus

the

meters

Can

be

inspected

and

serviced

extremely

easily

Except

for

the

speed

ometer

all

rneters

are

operated

electrically

The

fuel

gauge

and

therrnometer

are

very

reliable

and

they

are

equipped

with

bimetal

devices

F

a

o

ill

I

1

a

a

Fig

BE

34

Combination

meters

Removal

Disconnect

the

battery

terminal

depressing

the

OIL

PRESSURE

AND

IGNITION

WARNING

LAMPS

HAND

BRAKE

WARNING

LAMP

BULB

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Speedometer

Thermometer

and

fuel

meter

Oil

pressure

and

ignition

warning

lamps

BE

20

BE

21

BE

21

BE

22

BE

22

BE

23

BE

25

windshield

wiper

switch

lighting

switch

and

choke

lever

knobs

turn

them

counterclockwise

to

remove

Remove

the

escutcheon

2

Inserting

your

hand

into

back

of

the

cluster

lid

disconnect

the

cigarette

lighter

cable

and

turn

and

remove

the

cigarette

lighter

outer

case

3

Remove

the

radio

and

heater

control

knobs

4

Remove

the

shell

cover

from

the

steering

tube

loosen

the

screws

used

to

secure

the

meter

housing

to

the

instrument

panel

and

remove

the

cluster

lid

5

Pull

out

the

l2

pole

round

shape

connector

and

remove

the

speedometer

cable

union

nut

6

Remove

the

cluster

lid

from

the

instrument

panel

Fig

BE

35

Removing

clllSter

jd

BE

18