turn signal bulb DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 242 of 513

BODY

ELECTRICAL

Note

8

When

a

fuse

is

blown

off

be

sure

to

correct

the

cause

before

installing

new

fuse

b

Be

sure

to

use

fuse

having

the

rated

capacity

Do

not

use

fuse

having

larger

capacity

i

e

20A

JOA

etc

c

Particularly

when

the

fusible

link

is

fused

replace

with

a

designated

fusible

link

Green

color

link

for

model

8110

In

comparison

with

fuse

much

higher

current

flows

through

the

fusible

link

Moreover

it

is

important

to

eliminate

the

cause

of

blown

off

fusible

link

before

replacing

d

When

fuse

is

connected

incorrectly

and

the

contact

is

loose

voltage

drops

and

heat

are

gener

ated

resulting

abnormally

operated

electrical

equip

ment

Remove

dust

or

when

oxidized

polish

with

a

fine

emery

paper

so

that

the

contact

is

improved

LlGHTING

SYSTEM

CONTENTS

HEAD

LAMP

Descri

ption

Sealed

beam

replacement

Aiming

adjustment

FRONT

PARKING

AND

TURN

SIGNAL

SIDE

FLASHER

IMARKER

LAMP

AN

D

LICENSE

LAMP

REAR

COMBINATION

LAMPS

BULB

SPECIFICATIONS

TURN

SIGNAL

AND

DIMMER

COMBINATION

SWITCH

BE

7

BE

7

BE

7

BE

8

LAMP

BE

8

BE

9

BE10

BE10

HEAD

LAMP

Description

All

weather

type

sealed

beam

2

light

system

front

lamps

are

adopted

Each

lamp

of

both

side

head

lamps

is

provided

with

high

beam

filament

for

long

range

SOW

and

low

beam

filarnent

for

dipping

40W

In

other

words

the

lamp

is

of

a

double

filament

type

Sealed

beam

replacement

I

Rernove

the

wiring

socket

from

back

of

the

head

lamp

2

Remove

the

screws

attaching

the

front

grille

to

the

radiator

core

support

Coupe

only

Remove

three

retaining

screws

and

remove

the

head

lamp

rim

All

other

than

coupe

3

Loosen

three

screws

used

to

install

the

retaining

ring

on

the

sealed

bearn

mounting

ring

and

remove

the

sealed

Removal

LIGHTING

SWITCH

Removal

HAZARD

WARNING

SWITCH

PASSING

LIGHT

SWITCH

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Head

lamp

Turn

signal

lamps

Tail

and

stop

lamp

license

lamp

back

up

lamp

BE

10

BE

11

BE

11

BE

11

BE

12

BE

12

BE

12

BE

13

BE

15

i

Ii

beam

unit

4

When

installing

a

new

unit

be

sure

to

position

the

Top

mark

to

the

top

of

ring

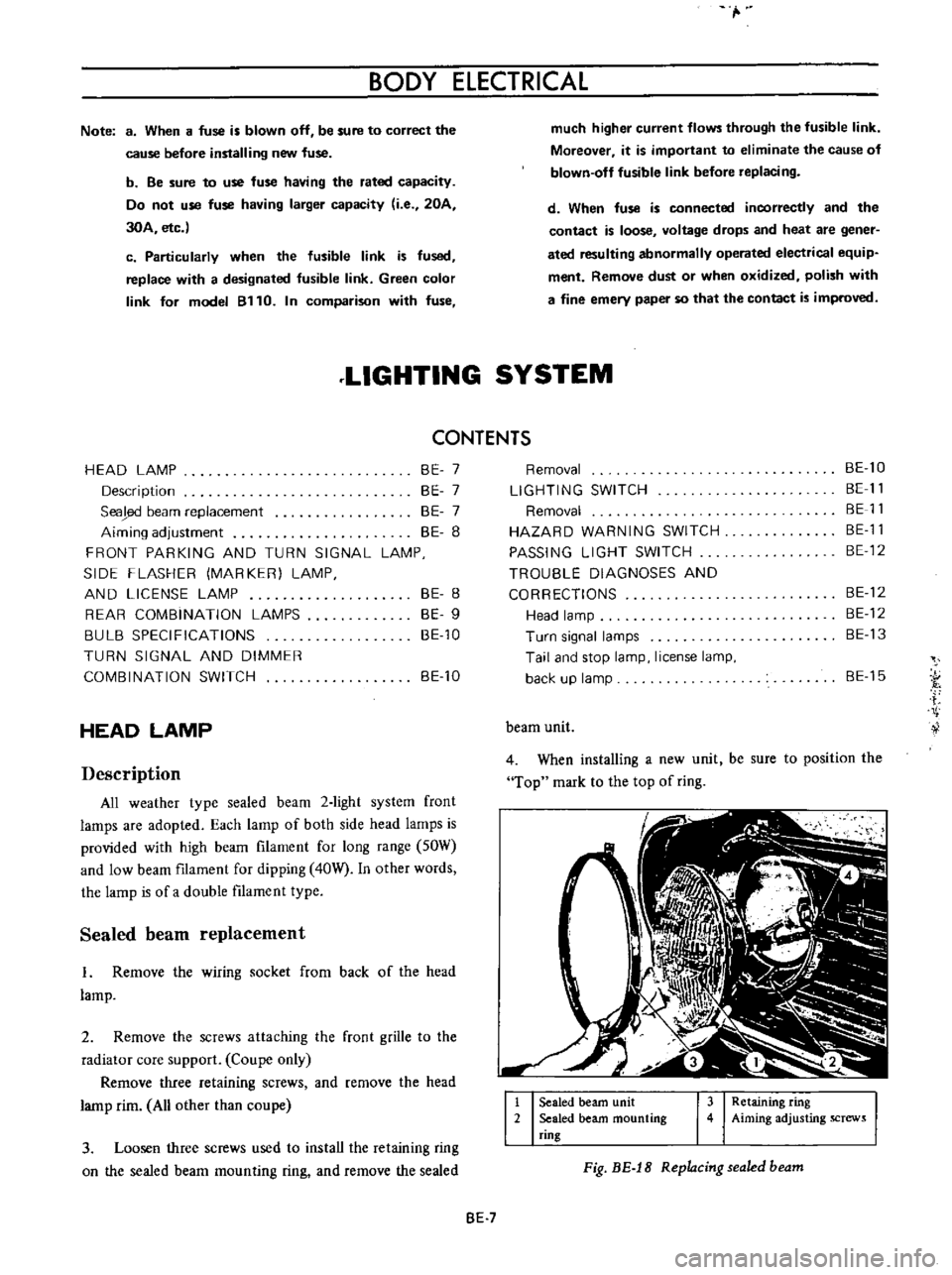

1

2

Sealed

beam

unit

Sealed

beam

mounting

ring

3

Retaining

ring

4

Aiming

adjusting

screws

Fig

BE

18

Replacing

sealed

beam

BE

7

Page 243 of 513

n

YR

f

f1

JC

1

r

8bD

l

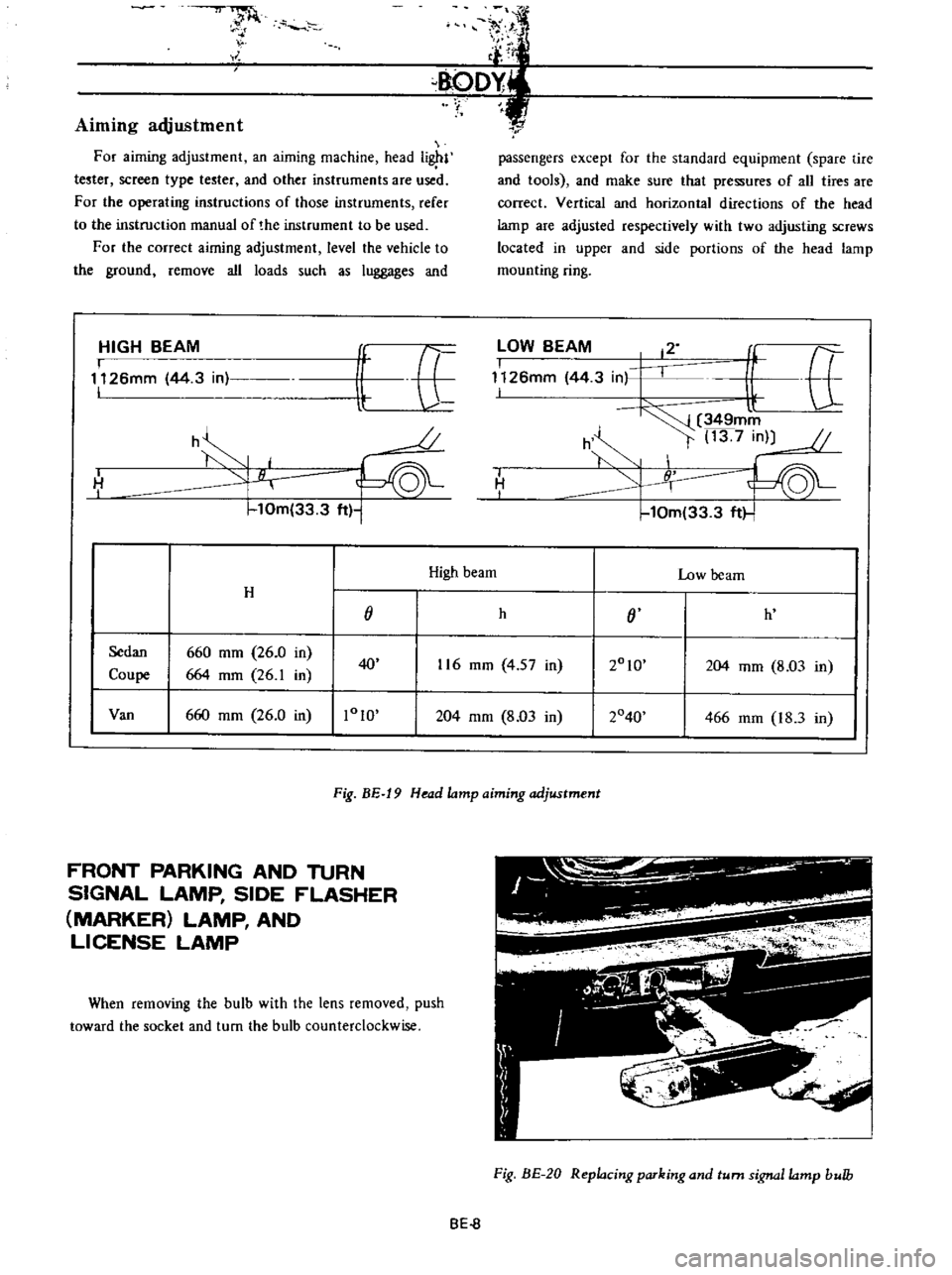

Aiming

adjustment

For

aiming

adjustment

an

aiming

machine

head

i

l

tester

screen

type

tester

and

other

instruments

are

used

For

the

operating

instructions

of

those

instruments

refer

to

the

instruction

manual

of

the

instrument

to

be

used

For

the

correct

airning

adjustment

level

the

vehicle

to

the

ground

remove

all

loads

such

as

luggages

and

HIGH

BEAM

I

1126mm

44

3

in

I

it

E

U

o

h

H

I

10m

33

3

ft

1

r

passengers

except

for

the

standard

equipment

spare

tire

and

tools

and

make

sure

that

pressures

of

all

tires

are

correct

Vertical

and

horizontal

directions

of

the

head

lamp

are

adjusted

respectively

with

two

adjusting

screws

located

in

upper

and

side

portions

of

the

head

lamp

mounting

ring

lOW

BEAM

12

I

f

tt

1126mm

44

3

in

I

l

349mm

h

t

13

7

in

10m

33

3

ft

I

H

I

High

beam

Low

beam

H

j

h

j

h

Sedan

660

mm

26

0

in

2010

Coupe

664

mm

26

1

in

40

116

mm

4

57

in

204

mm

8

03

in

Van

660

mm

26

0

in

1010

204

mm

8

03

in

2040

466

mm

18

3

in

Fig

BE

19

Head

lamp

aiming

adjustment

FRONT

PARKING

AND

TURN

SIGNAL

LAMP

SIDE

FLASHER

MARKER

LAMP

AND

LICENSE

LAMP

When

removing

the

bulb

with

the

lens

removed

push

toward

the

socket

and

turn

the

bulb

counterclockwise

Fig

BE

20

Replacing

parking

and

turn

signa

lamp

bulb

BE

8

Page 245 of 513

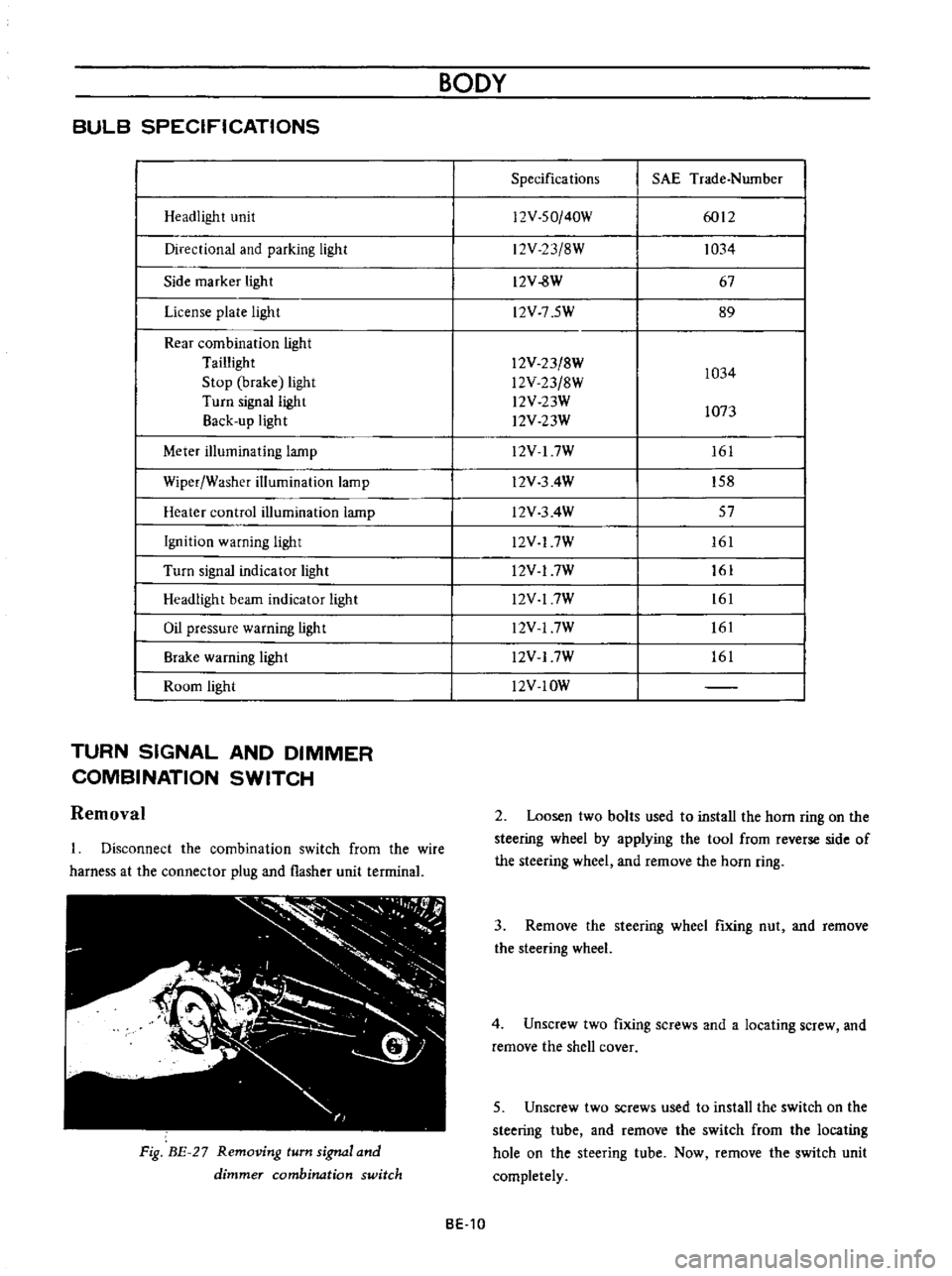

BULB

SPECIFICATIONS

Headlight

unit

Directional

and

parking

light

Side

marker

light

License

plate

light

Rear

combination

light

Taillight

Stop

brake

light

Turn

signal

light

Back

up

light

Meter

illuminating

lamp

Wiper

Washer

illumination

lamp

Heater

control

illumination

lamp

Ignition

warning

light

Turn

signal

indicator

light

Headlight

beam

indicator

light

Oil

pressure

warning

light

Brake

warning

ligh

t

Room

light

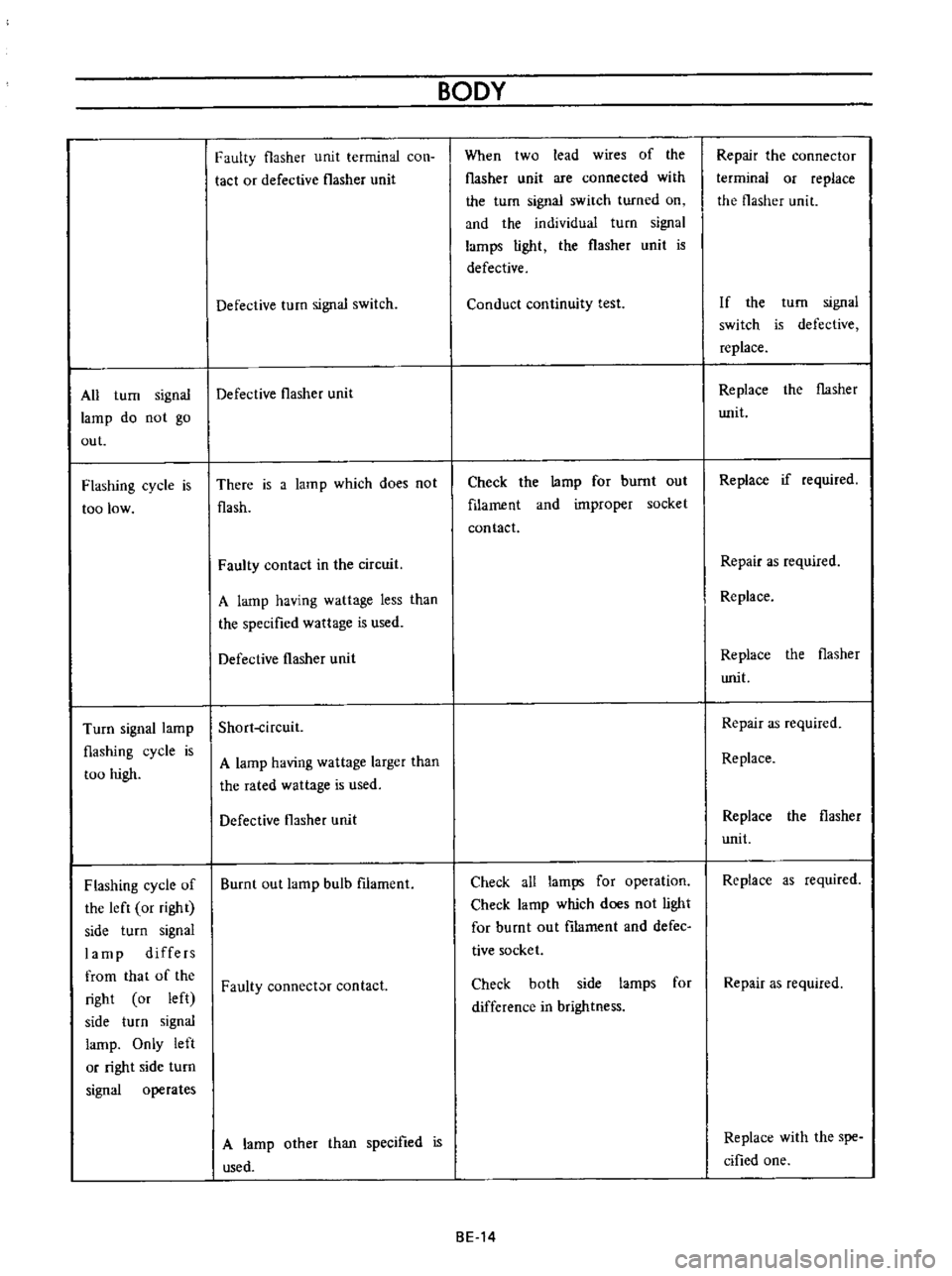

TURN

SIGNAL

AND

DIMMER

COMBINATION

SWITCH

Removal

Disconnect

the

combination

switch

from

the

wire

harness

at

the

connector

plug

and

flasher

unit

terrninal

Fig

BE

27

Removing

turn

signal

and

dimmer

combination

switch

BODY

Specifications

SAE

Trade

Number

12V

SO

40W

6012

12V

23

8W

1034

12V

8W

67

l2V

7

5W

89

12V

23

8W

1034

l2V

23

8W

l2V

23W

1073

l2V

23W

12V

I

7W

161

l2V

3

4W

158

l2V

3

4W

57

l2V

17W

161

l2V

17W

161

l2V

17W

161

l2V

17W

161

l2V

17W

161

l2V

IOW

2

Loosen

two

bolts

used

to

install

the

horn

ring

on

the

steering

wheel

by

applying

the

tool

from

reverse

side

of

the

steering

wheel

and

remove

the

horn

ring

3

Remove

the

steering

wheel

fixing

nut

and

remove

the

steering

wheel

4

Unscrew

two

fixing

screws

and

a

locating

screw

and

remove

the

shell

cover

5

Unscrew

two

screws

used

to

install

the

switch

on

the

steering

tube

and

remove

the

switch

from

the

locating

hole

on

the

steering

tube

Now

remove

the

switch

unit

completely

BE

10

Page 249 of 513

All

turn

signal

lamp

do

not

go

out

Flashing

cycle

is

too

low

Turn

signal

lamp

flashing

cycle

is

too

high

Flashing

cycle

of

the

left

or

right

side

turn

signal

lamp

differs

from

that

of

the

right

or

left

side

turn

signal

lamp

Only

left

or

right

side

turn

signal

operates

Faulty

flasher

unit

terminal

con

tact

or

defective

flasher

unit

Defective

turn

signal

switch

Defective

flasher

unit

There

is

a

lam

p

which

does

no

t

flash

Faulty

contact

in

the

circuit

A

lamp

having

wattage

less

than

the

specified

wattage

is

used

Defective

flasher

unit

Short

ircuit

A

lamp

having

wattage

larger

than

the

rated

wattage

is

used

Defective

flasher

unit

Burnt

out

lamp

bulb

filament

Faulty

connect

contact

A

lamp

other

than

specified

is

used

BODY

When

two

lead

wires

of

the

flasher

unit

are

connected

with

the

turn

signal

switch

turned

on

and

the

individual

turn

signal

larnps

light

the

flasher

unit

is

defective

Conduct

continuity

test

Check

the

lamp

for

burnt

out

filament

and

improper

socket

contact

Check

all

lamps

for

operation

Check

lamp

which

does

not

light

for

burnt

out

filarnent

and

defec

tive

socket

Check

both

side

larnps

for

difference

in

brightness

BE

14

Repair

the

connector

terminal

or

replace

the

flasher

unit

If

the

turn

signal

switch

is

defective

replace

Replace

the

flasher

Wlit

Replace

if

required

Repair

as

required

Replace

Replace

the

flasher

writ

Repair

as

required

Replace

Replace

the

flasher

unit

Replace

as

required

Repair

as

required

Replace

with

the

spe

cified

one

Page 256 of 513

BODY

ElECTRICAL

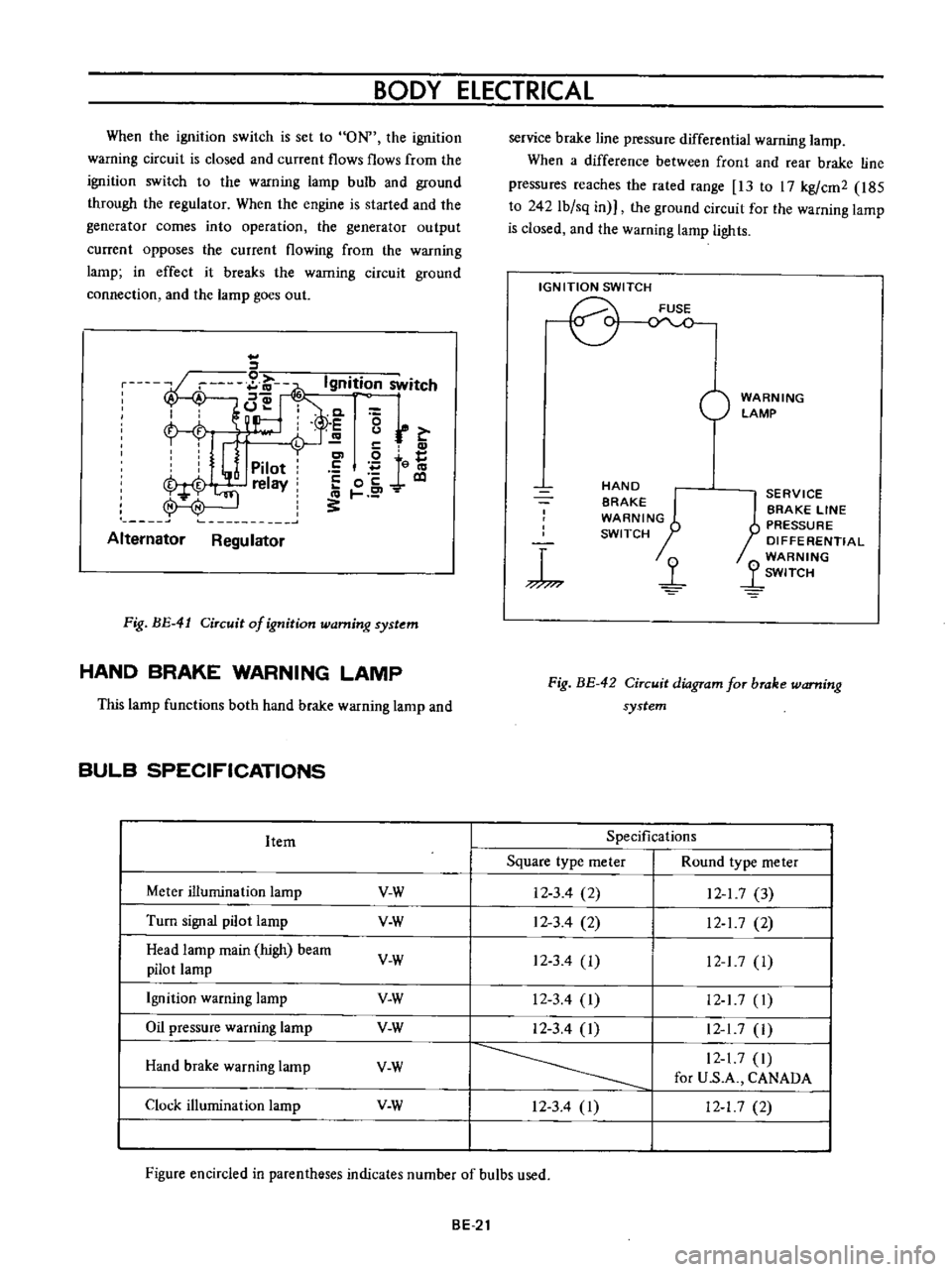

When

the

ignition

switch

is

set

to

ON

the

ignition

wa

rning

circuit

is

closed

and

current

flows

flows

from

the

ignition

switch

to

the

warning

lamp

bulb

and

ground

through

the

regulator

When

the

engine

is

started

and

the

generator

comes

into

operation

the

generator

output

current

opposes

the

current

flowing

from

the

warning

lamp

in

effect

it

breaks

the

warning

circuit

ground

connection

and

the

lamp

goes

out

l

r

hffi

u

z

Ignition

switch

I

Q

6

I

0

c

M

1

E

8

ca

i

L

g

PI

lot

c

P

I

j

co

rt

0

relay

E

0

5

y

y

1

N

N

3

Alternator

Regulator

Fig

BE

41

Circuit

of

ignition

warning

system

HAND

BRAKE

WARNING

LAMP

This

lamp

functions

both

hand

brake

warning

larnp

and

BULB

SPECIFICATIONS

service

brake

line

pressure

differential

warning

lamp

When

a

difference

between

front

and

rear

brake

line

pressures

reaches

the

rated

range

13

to

17

kgfcm2

185

to

242

lb

sq

in

the

ground

circuit

for

the

warning

lamp

is

closed

and

the

warning

lamp

lights

IGNITION

SWITCH

WARNING

LAMP

L

E

WARNING

SWITCH

1

SERVICE

BRAKE

LINE

PRESSU

R

E

DIFFERENTIAL

WARNING

J

SWITCH

Fig

BE

42

Circuit

diagram

for

brake

warning

system

tern

Specifications

Square

type

meter

Round

type

meter

Meter

illumination

larnp

VoW

12

3

4

2

12

1

7

3

Turn

signal

pilot

lamp

VoW

12

3

4

2

12

1

7

2

Head

lamp

main

high

beam

VoW

12

3

4

I

12

17

1

pilot

lamp

Ignition

warning

lamp

VoW

123

4

I

12

17

1

Oil

pressure

warning

lamp

VoW

12

3

4

1

12

1

7

1

Hand

brake

warning

lamp

VoW

12

1

7

1

for

U

S

A

CANADA

Clock

illumination

lamp

VoW

123

4

I

12

17

2

Figure

encircled

in

parentheses

indicates

number

of

bulbs

used

BE

21