washer fluid DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 47 of 513

3

Blowout

piston

by

directing

a

jet

of

air

into

hole

in

clutch

drum

See

Figure

AT

S

7

AT155

Fig

AT

87

Blowing

out

piston

Inspection

Refer

to

covering

topic

under

Front

Clutch

Assembly

Assembly

is

reverse

order

of

disas

sembly

Dip

all

parts

in

clean

auto

malic

transmission

fluid

before

as

sembling

Note

that

the

number

of

drive

and

driven

plates

varies

with

types

of

vehicles

For

details

refer

to

Service

Data

Specifications

I

After

rear

clutch

is

assembled

check

to

be

sure

that

clearance

be

tween

snap

ring

CD

and

retaining

plate

CV

is

held

within

prescribed

tolerances

See

Figure

A

T

S8

Specified

clearance

1

0

to

1

5

mm

0

039

to

0

059

in

AT1S6

Fig

A

T

88

Measuring

ring

to

plate

clearance

2

Testing

rear

clutch

Install

rear

clutch

on

oil

pump

cover

Blow

air

under

pressure

into

oil

hole

to

listen

for

definite

clutch

opera

tion

as

shown

in

Figure

AT

S9

AUTOMATIC

TRANSMISSION

AT157

Fig

AT

89

Testing

rear

clutch

Low

reverse

brake

Disassembly

I

Follow

steps

as

per

instructed

on

page

AT

38

2

Blowout

piston

by

directing

a

jet

of

air

into

oil

hole

in

clutch

piston

Inspection

I

Check

drive

plate

facing

for

wear

or

damage

if

necessary

replace

Refer

to

Service

Data

Specifications

for

limits

2

Test

if

piston

return

spring

is

not

weakened

Discard

if

weakened

too

badly

beyond

use

3

Replace

any

defective

parts

with

new

ones

Assembly

1

After

low

reverse

piston

is

installed

assemble

thrust

spring

ring

return

spring

thrust

washer

and

one

way

clutch

inner

race

With

the

aid

of

Hex

head

Extension

ST25570000

tighten

hex

head

slotted

bolt

1

3

to

1

8

kg

m

9

4

to

13

ft

Ib

2

Enter

dished

plate

driven

plate

drive

plate

and

retaining

plate

into

transmission

case

in

this

written

order

Install

snap

ring

to

secure

the

instal

lation

Note

The

number

of

drive

and

driven

plates

varies

with

types

of

vehi

cles

For

detailed

information

refer

to

Service

Data

Specifi

cations

AT

43

3

Without

disturbing

the

above

setting

check

to

be

sure

that

clearance

between

snap

ring

and

retaining

plate

is

held

within

specified

limits

If

nec

essary

try

with

other

plates

having

different

thickness

until

correct

clear

ance

is

obtained

Specified

clearance

O

SO

to

1

05

mm

0

031

to

0

041

in

4

Blow

under

pressure

air

into

oil

hole

in

low

reverse

brake

to

listen

for

definite

brake

operation

as

shown

in

Figure

AT

90

0j

L

J

1

1

I

1

I

Y

1

If

lY

v

A

we

1

a

II

I

7

r

AT158

Fig

AT

90

Testing

low

reverse

brake

Servo

piston

Disassembly

1

Blowout

piston

by

directing

a

jet

of

air

into

hole

in

release

side

of

piston

2

Remove

servo

piston

return

spring

Inspection

Check

piston

for

wear

damage

or

any

other

defects

which

might

inter

fere

with

proper

brake

operation

AT159

Fig

A

T

91

Removing

piston

Page 261 of 513

The

lamp

does

not

go

out

when

the

engine

is

started

Faulty

charging

system

BODY

Inspect

the

charging

system

WINDSHIELD

WIPER

AND

WASHER

Description

Wiper

motor

replacement

Wiper

blade

operating

range

CONTENTS

BE

26

BE

27

BE

27

Description

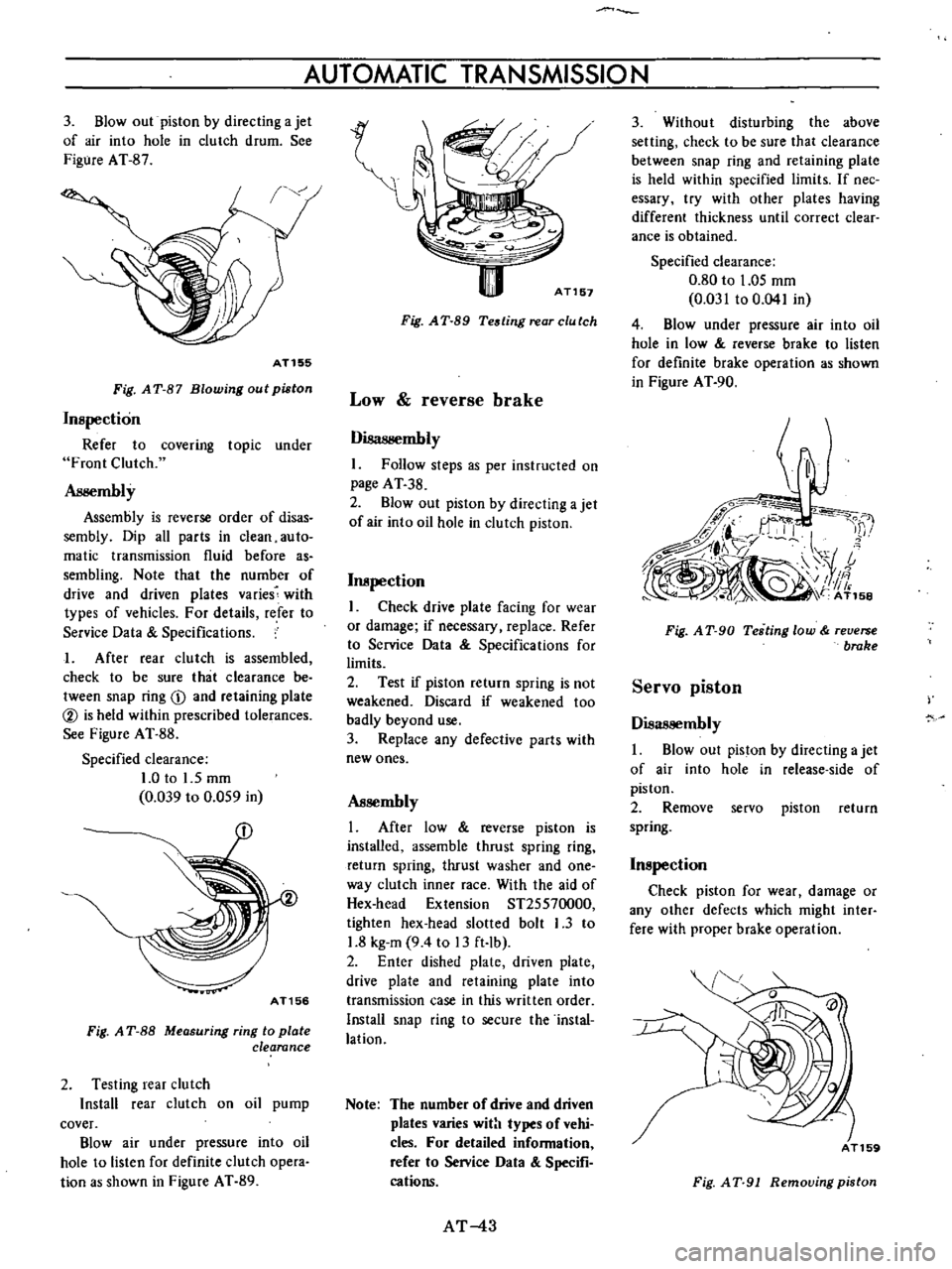

The

windshield

wipers

consist

of

wiper

motor

link

mechanism

wiper

arms

and

blades

The

wiper

motor

unit

consists

of

a

motor

and

auto

stop

mechanism

The

wiper

rnotor

is

of

a

2

speed

type

When

the

wiper

switch

knob

is

pulled

to

the

I

st

step

the

windshield

wipers

operate

at

low

speed

and

when

pulled

to

the

2nd

step

operate

at

high

speed

The

wiper

motor

unit

is

located

on

the

cowl

dash

in

BATTERY

Cl

WIPER

MOTOR

rrQ

J

WASHER

MOTOR

IB

ILRI

L

CJ

LA

t

Y

I

Ll

j

IBI

1

f

I

LW

I

Wiper

washer

switch

replacement

Washer

nozzle

adjustment

TROUBLE

OIAGNOSES

ANO

CORRECTIONS

BE

27

BE

27

BE

28

the

engine

compartment

and

the

link

mechanism

is

located

behind

the

instrument

panel

The

electrically

operated

windshield

washer

consists

of

washing

fluid

lank

with

rnotor

and

pump

washer

nozzles

and

vinyl

tube

used

to

connect

those

compo

nents

The

windshield

washer

switch

is

combined

with

the

windshield

wiper

switch

to

a

single

unit

When

operating

the

washer

twist

the

switch

knob

IG

FUSE

W

v

l

i

f

WIPER

SWITCH

10FFI

I

2

I

TWIST

I

y

ILl

I

b

I

J

6

I

BLII

Fig

BE

43

Circuit

diagram

for

windshield

wiper

washer

system

BE

26

Page 262 of 513

BODY

ELECTRICAL

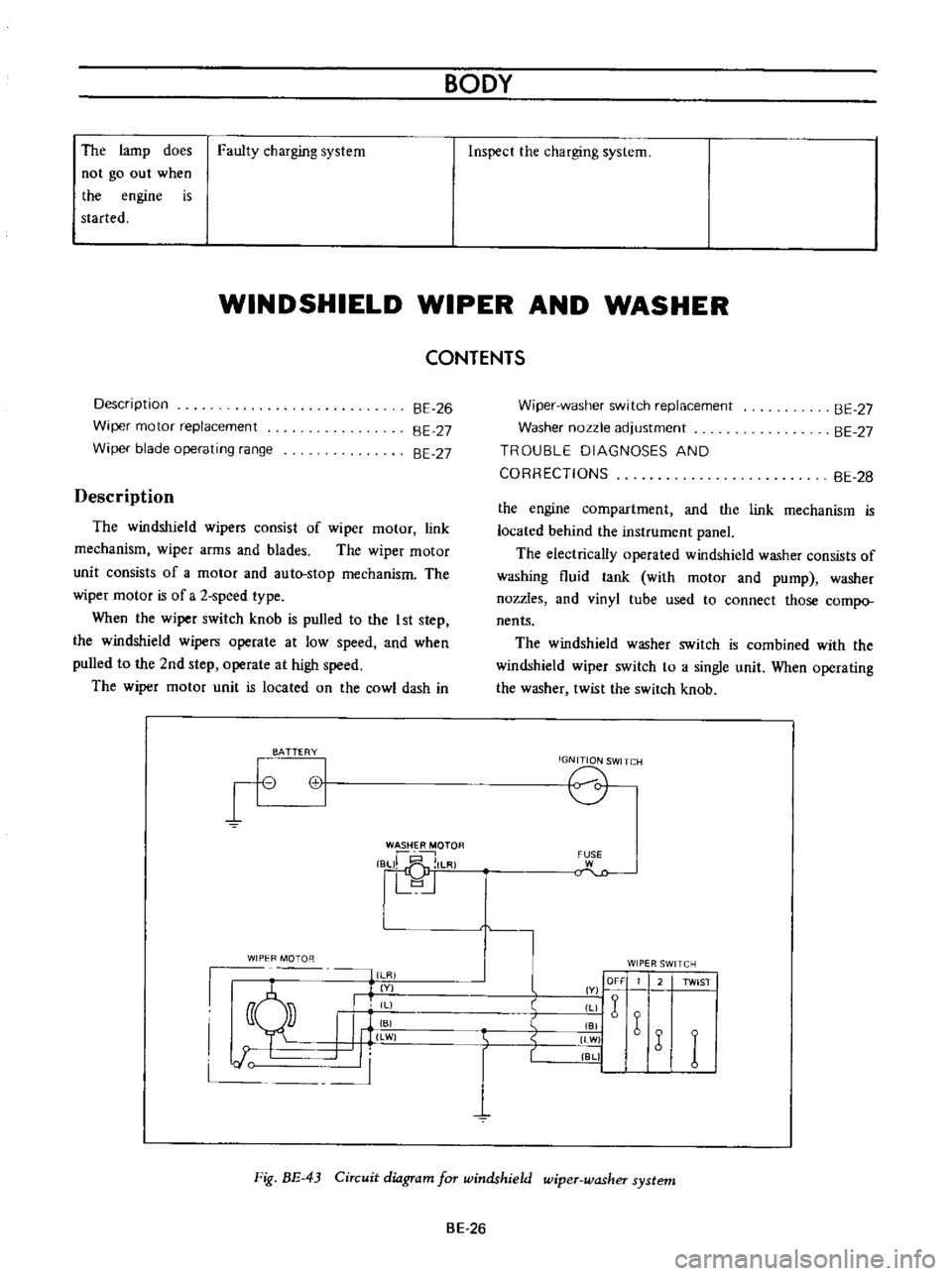

Wiper

motor

replacement

First

of

all

remove

the

connector

plug

from

the

wiper

motoI

2

Remove

a

nut

used

to

connect

wiper

motor

worm

wheel

shaft

to

the

connecting

rod

from

passenger

compartment

side

dash

panel

3

Loosen

three

bolts

used

to

install

the

wiper

motor

on

the

cowl

dash

remove

the

wiper

motor

4

Reinstall

a

new

wiper

motor

in

reverse

sequence

of

removal

Fig

BE

44

Wiper

motor

Q

V

rt

ir

o

y

At

Jllif

Fig

BE

45

Wiper

motor

linkage

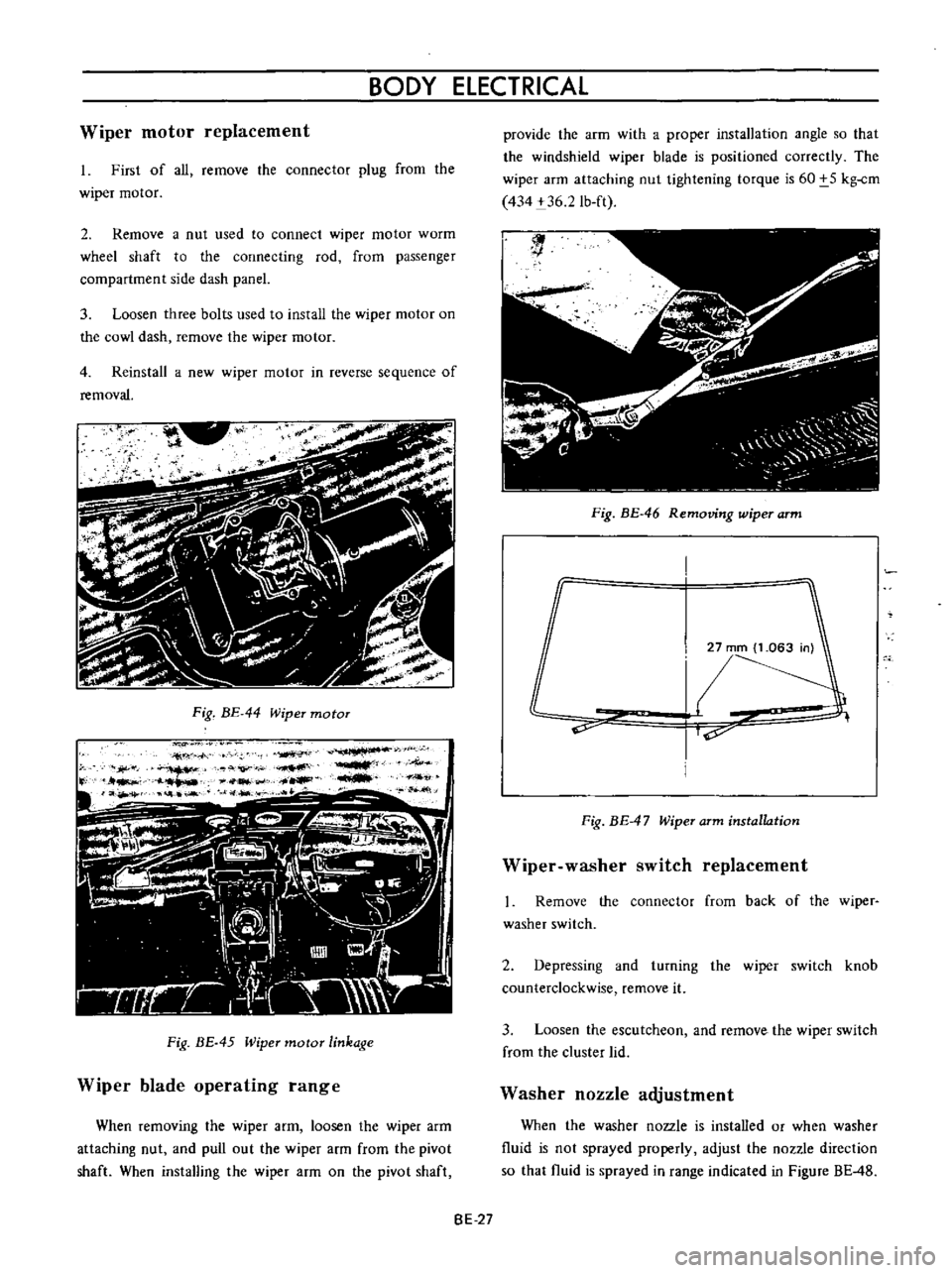

Wiper

blade

operating

range

When

removing

the

wiper

arm

loosen

the

wiper

arm

attaching

nut

and

pull

out

the

wiper

arm

from

the

pivot

shaft

When

installing

the

wiper

arm

on

the

pivot

shaft

provide

the

arm

with

a

proper

installation

angle

so

that

the

windshield

wiper

blade

is

positioned

correctly

The

wiper

arm

attaching

nut

tightening

torque

is

60

5

kg

m

434

36

2lb

ft

Fig

BE

46

Removing

wiper

arm

00

I

i

Fig

BE

47

Wiper

arm

installation

Wiper

washer

switch

replacement

Remove

the

connector

from

back

of

the

wiper

washer

switch

2

Depressing

and

turning

the

wiper

switch

knob

counterclockwise

remove

it

3

Loosen

the

escutcheon

and

remove

the

wiper

switch

from

the

cluster

lid

Washer

nozzle

adjustment

When

the

washer

nozzle

is

installed

or

when

washer

fluid

is

not

sprayed

properly

adjust

the

nozzle

direction

so

that

fluid

is

sprayed

in

range

indicated

in

Figure

BE

48

BE

27