check engine light DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 155 of 537

j

EC231

Thermal

vacuum

valva

o

o

m

Emission

Control

System

0

o

o

o

l

l

@

The

thermal

vacuum

valve

is

mounted

in

the

engine

thermostat

housing

It

detects

engine

coolan

t

tem

perature

by

means

of

a

built

in

bi

metal

and

opensor

closes

the

vacuum

passage

in

the

thermal

vacuum

valve

mt

li

t

00

t

EC232

Fig

EC

54

Thennal

vacuum

valve

To

E

G

R

control

valve

From

carburetor

1

Spring

2

Bi

metal

3

O

ring

E

G

R

warning

system

The

E

G

R

warning

system

install

1

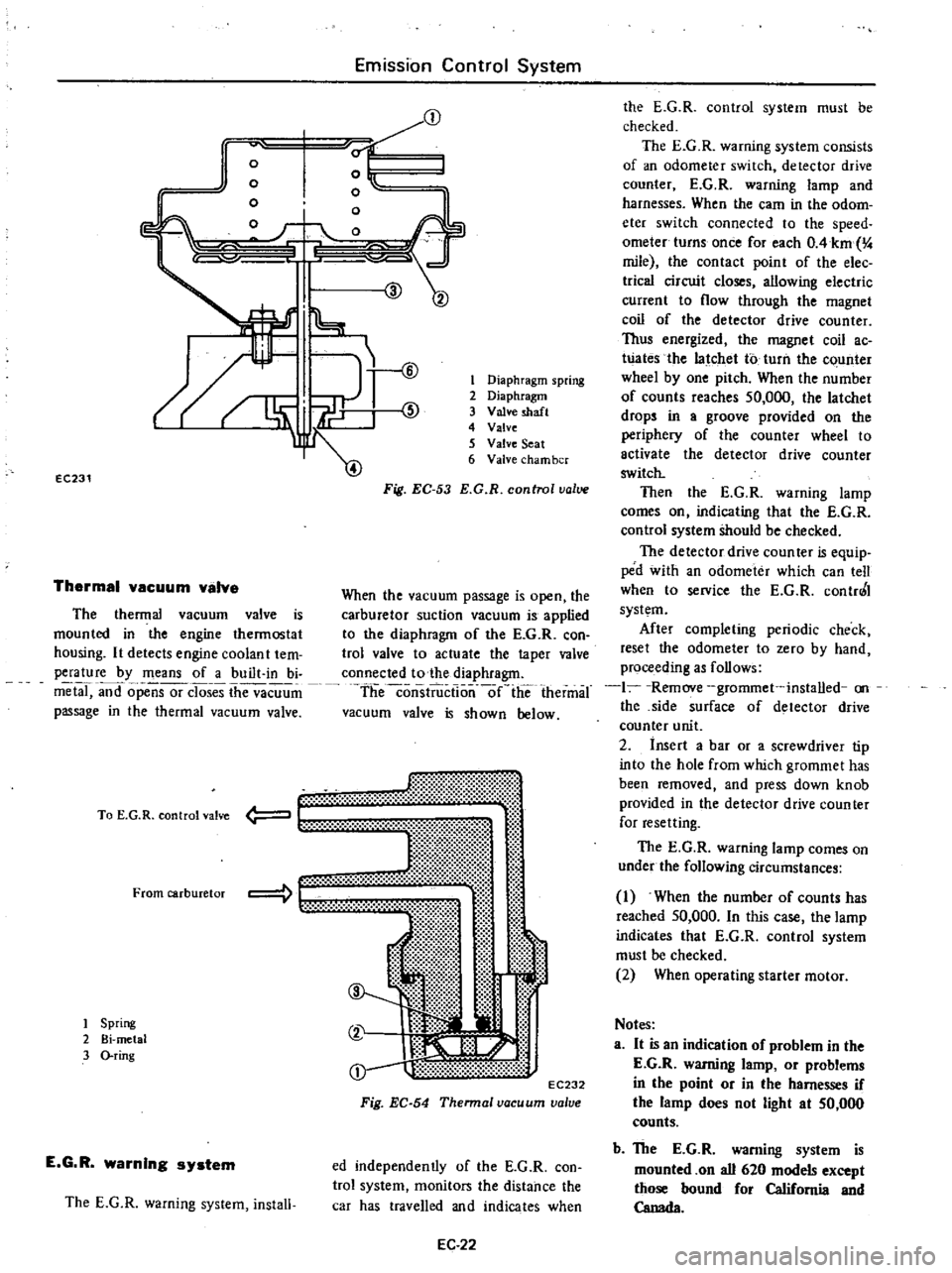

Diaphragm

spring

2

Diaphragm

3

Valve

shaft

4

Valve

5

Valve

Seat

6

Valve

cham

ber

Fig

EC

53

E

G

R

control

value

When

the

vacuum

passage

is

open

the

carburetor

suction

vacuum

is

applied

to

the

diaphragm

of

the

E

G

R

con

trol

valve

to

actuate

the

taper

valve

connected

to

the

diaphragm

theconsiiiictlo

nlie

thermal

vacuum

valve

is

shown

below

ed

independently

of

the

E

G

R

con

trol

system

monitors

the

distance

the

car

has

travelled

and

indicates

when

EC

22

the

E

G

R

control

system

must

be

checked

The

E

G

R

warning

system

consists

of

an

odometer

switch

detector

drive

counter

E

G

R

warning

lamp

and

harnesses

When

the

earn

in

the

odom

eter

switch

connected

to

the

speed

ometer

turns

once

for

each

OAkm

4

mile

the

contact

point

of

the

elec

trica

circuit

closes

allowing

electric

current

to

flow

through

the

magnet

coil

of

the

detector

drive

counter

Thus

energized

the

magnet

coil

ac

Wates

the

latchet

to

turn

the

c

unter

wheel

by

one

pitch

When

the

number

of

counts

reaches

50

000

the

latchet

drops

in

a

groove

provided

on

the

periphery

of

the

counter

wheel

to

activate

the

detector

drive

counter

switch

Then

the

E

G

R

warning

lamp

comes

on

indicating

that

the

E

G

R

control

system

Should

be

checked

The

detector

drive

coun

teT

is

equip

ped

with

an

odometer

which

can

tell

when

to

service

the

E

G

R

contr0

I

system

After

completing

periodic

check

reset

the

odometer

to

zero

by

hand

proceeding

as

follows

1

Remove

grommet

installed

on

the

side

surface

of

detector

drive

counter

unit

2

insert

a

bar

or

a

screwdriver

tip

into

the

hole

from

which

grommet

has

been

removed

and

press

down

knob

provided

in

the

detector

drive

counter

for

resetting

The

E

G

R

warning

lamp

comes

on

under

the

following

circumstances

1

When

the

number

of

counts

has

reached

50

000

In

this

case

the

lamp

indicates

that

E

G

R

control

system

must

be

checked

2

When

operating

starter

motor

Notes

a

It

is

an

indication

of

problem

in

the

E

G

R

warning

lamp

or

problems

in

the

point

or

in

the

harnesses

if

the

lamp

does

not

light

at

50

000

counts

b

The

E

G

R

warning

system

is

mounted

on

all

620

models

except

those

bound

for

California

and

Canada

Page 157 of 537

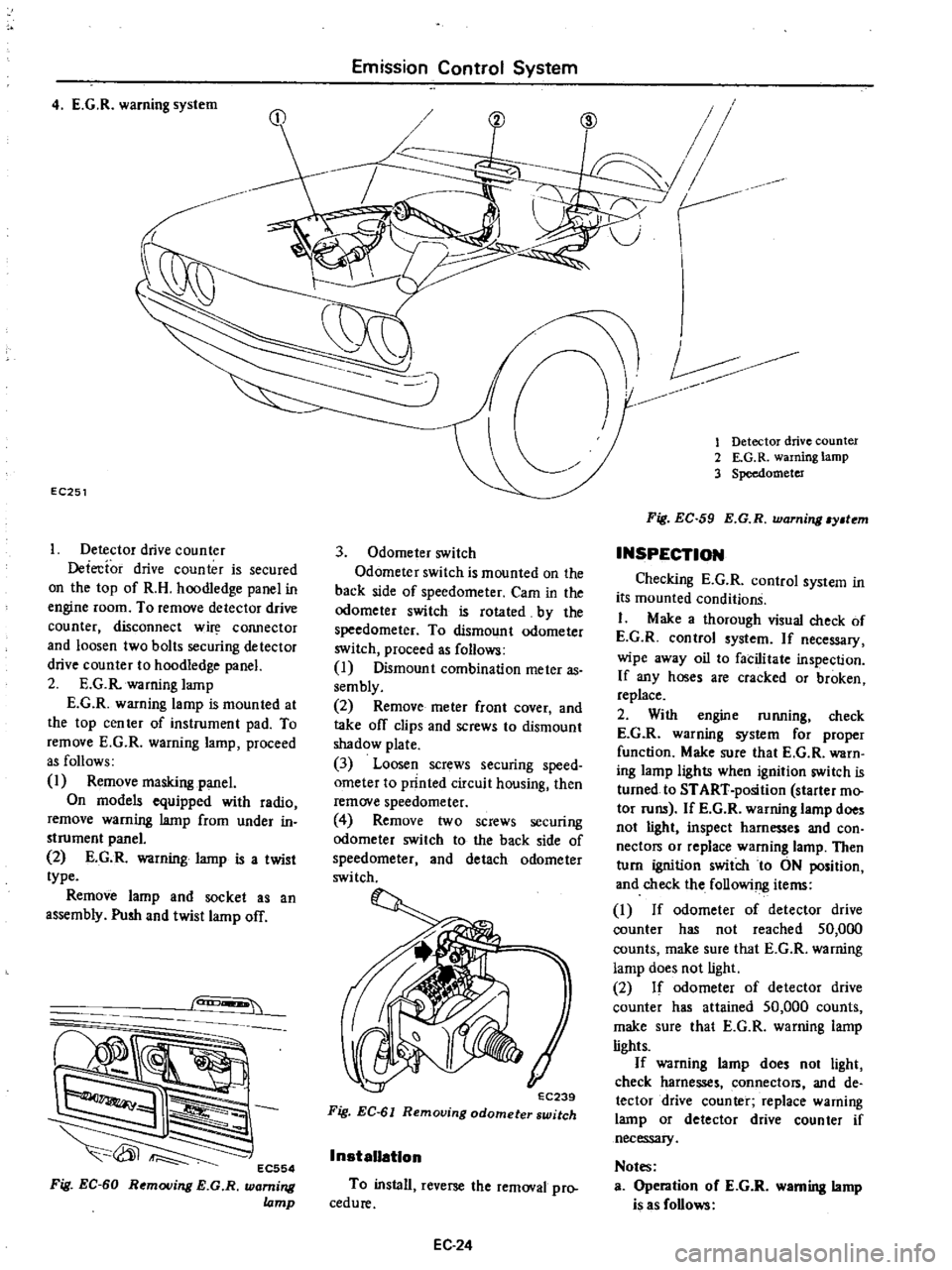

4

E

G

R

warning

system

EC251

Detector

drive

counter

Detecfor

drive

counter

is

secured

on

the

top

of

R

H

hoodledge

panel

in

engine

room

To

remove

detector

drive

counter

disconnect

w

COJUlector

and

loosen

two

bolts

securing

detector

drive

counter

to

hoodledge

panel

2

E

G

R

warning

lamp

E

G

R

warning

lamp

is

mounted

at

the

top

cen

ter

of

instrument

pad

To

remove

E

G

R

warning

lamp

proceed

as

follows

1

Remove

masking

panel

On

models

equipped

with

radio

remove

warning

lamp

from

under

in

strument

panel

2

E

G

R

warning

lamp

is

a

twist

type

Remove

lamp

and

socket

as

an

assembly

Push

and

twist

lamp

off

can

EC554

Fig

EC

60

Removing

E

G

R

warning

lamp

Emission

Control

System

3

Odometer

switch

Odometer

switch

is

mounted

on

the

back

side

of

speedometer

Cam

in

the

odometer

switch

is

rotated

by

the

speedometer

To

dismount

odometer

switch

proceed

as

follows

I

Dismount

combination

meter

as

sembly

2

Remove

meter

front

cover

and

take

off

clips

and

screws

to

dismount

shadow

plate

3

Loosen

screws

securing

speed

ometer

to

printed

circuit

housing

then

remove

speedometer

4

Remove

two

screws

securing

odomete

switch

to

the

back

side

of

speedometer

and

detach

odometer

switch

EC239

Fig

EC

61

Removing

odometer

switch

InstaUatlon

To

install

reverse

the

removal

pro

cedure

EC24

V

r

CID

1

Detector

drive

counter

2

E

G

R

warning

lamp

3

Speedometer

Fig

EC

59

E

G

R

warning

y

tem

INSPECTION

Checking

E

G

R

control

system

in

its

mounted

conditionS

I

Make

a

thorough

visual

check

of

E

G

R

control

system

If

necessary

wipe

away

oil

to

facilitate

inspection

If

any

hoses

are

cracked

or

broken

replace

2

With

engine

running

check

E

G

R

warning

system

for

proper

function

Make

sure

that

E

G

R

warn

ing

lamp

lights

when

ignition

switch

is

turned

to

START

position

starter

mo

tor

runs

If

E

G

R

wanung

lamp

does

not

light

inspect

harnesses

and

con

nectors

or

replace

warning

lamp

Then

turn

ignition

switch

to

ON

position

and

check

the

following

items

I

If

odometer

of

detector

drive

counter

has

not

reached

50

000

counts

make

sure

that

E

G

R

warning

lamp

does

not

light

2

If

odomete

of

detector

drive

counter

has

attained

50

000

counts

make

sure

that

E

G

R

warning

lamp

lights

If

warning

lamp

does

not

light

check

harnesses

connectors

and

de

tector

drive

counter

replace

warning

lamp

or

detector

drive

counter

if

necessary

Notes

Operation

oC

E

G

R

warning

lamp

is

as

Collows

Page 160 of 537

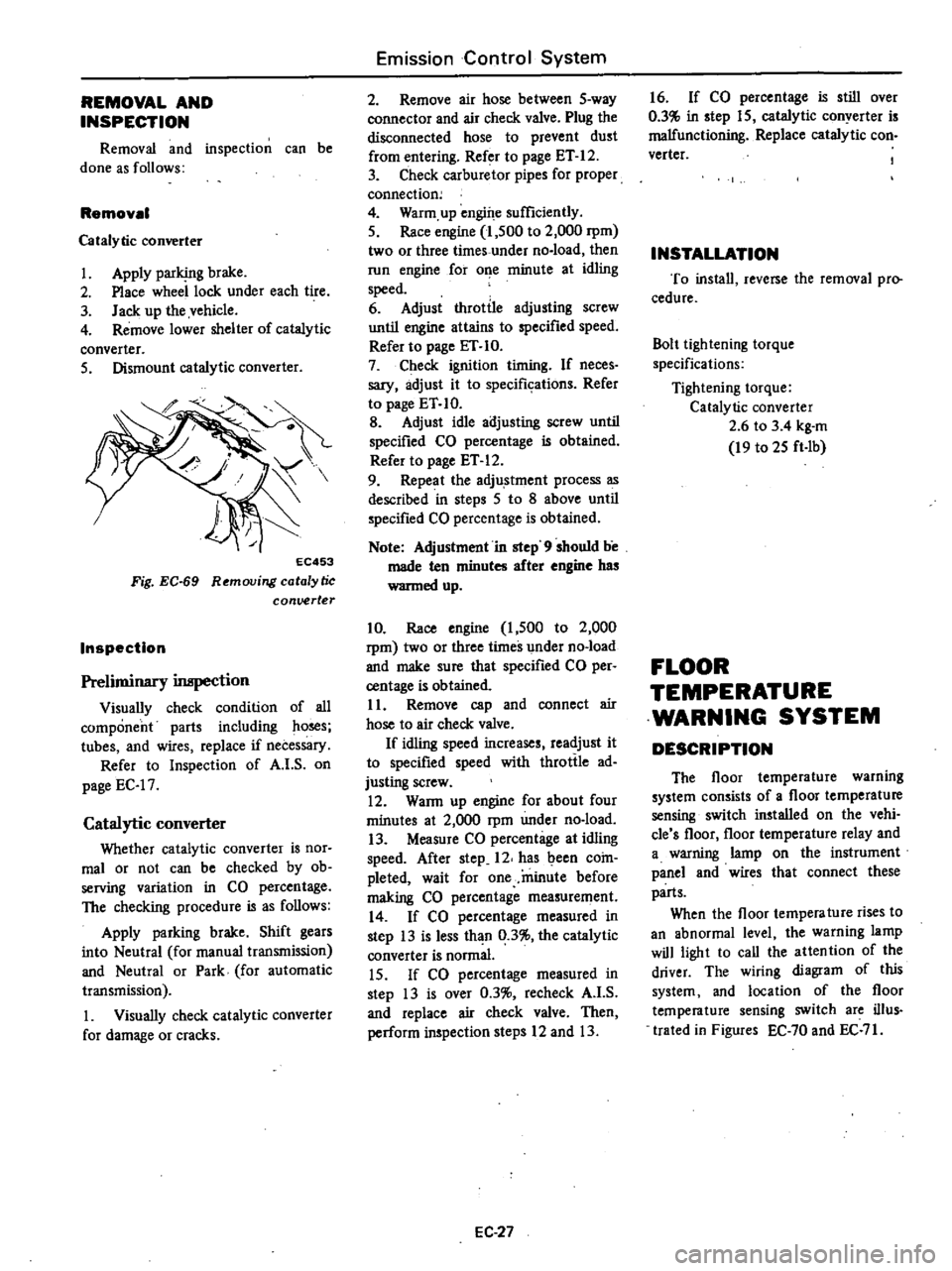

REMOVAL

AND

INSPECTION

Removal

and

inspection

can

be

done

as

follows

Removal

Catalytic

converter

1

Apply

parking

brake

2

Place

wheel

lock

under

each

tire

3

Jack

up

the

vehicle

4

Remove

lower

shelter

of

catalytic

converter

5

Dismount

catalytic

converter

EC453

Fig

EC

69

Removing

catalytic

conuerter

Inspection

Preliminary

inspection

Visually

check

condition

of

all

component

parts

including

ho

s

tubes

and

wires

replace

if

necessary

Refer

to

Inspection

of

A

I

S

on

page

EC

17

Catalytic

converter

Whether

catalytic

converter

is

nor

mal

or

not

can

be

checked

by

ob

serving

variation

in

CO

percentage

The

checking

procedure

is

as

follows

Apply

parking

brake

Shift

gears

into

Neutral

for

manual

transmission

and

Neutral

or

Park

for

automatic

transmission

1

Visually

check

catalytic

converter

for

damage

or

cracks

Emission

Control

System

2

Remove

air

hose

between

5

way

connector

and

air

check

valve

Plug

the

disconnected

hose

to

prevent

dust

from

entering

Refer

to

page

ET

12

3

Check

carburetor

pipes

for

proper

connection

4

Warm

up

engine

sufficiently

5

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

o

e

minute

at

idling

speed

6

Adjust

throttle

adjusting

screw

until

engine

attains

to

specified

speed

Refer

to

page

ET

10

7

Check

ignition

timing

If

neces

sary

adjust

it

to

specifkations

Refer

to

page

ET

10

B

Adjust

idle

adjusting

screw

until

specified

CO

percentage

is

obtained

Refer

to

page

ET

12

9

Repeat

the

adju

stment

process

as

described

in

steps

5

to

8

above

until

specified

CO

percentage

is

obtained

Note

Adjustment

in

step

9

should

be

made

ten

minutes

after

engine

has

wanned

up

10

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

11

Remove

cap

and

connect

air

hose

to

air

check

valve

If

idling

speed

increases

readjust

it

to

specified

speed

with

throttle

ad

justing

screw

12

WaRn

up

engine

for

about

four

minutes

at

2

000

rpm

under

no

load

13

Measure

CO

percentage

at

idling

speed

After

step

12

has

been

coin

pleted

wait

for

one

minute

before

making

CO

percentage

measurement

14

If

CO

percentage

measured

in

step

13

is

less

than

0

3

the

catalytic

converter

is

normal

15

If

CO

percentage

measured

in

step

13

is

over

0

3

recheck

A

I

S

and

replace

air

check

valve

Then

perform

inspection

steps

12

and

13

EC

27

16

If

CO

percentage

is

still

over

0

3

in

step

15

catalytic

conyerter

is

malfunctioning

Replace

catalytic

con

verter

INSTALLATION

To

install

reverse

the

removal

pro

cedure

Bolt

lightening

torque

specifications

Tightening

torque

Catalytic

converter

2

6

to

3

4

kg

m

19

to

25

ft

Ib

FLOOR

TEMPERATURE

WARNING

SYSTEM

DESCRIPTION

The

floor

temperature

warning

system

consists

of

a

floor

temperature

sensing

switch

installed

on

the

vehi

cle

s

floor

floor

temperature

relay

and

a

warning

lamp

on

the

instrument

panel

and

wires

that

connect

these

parts

When

the

floor

tempera

ture

rises

to

an

abnormal

level

the

warning

lamp

will

light

to

call

the

attention

of

the

driver

The

wiring

diagram

of

this

system

and

location

of

the

floor

temperature

sensing

switch

are

ilIus

trated

in

Figures

EC

70

and

EC

71

Page 165 of 537

sufficient

delivery

of

fuel

to

engine

or

vapor

lock

It

must

therefore

be

1

3

connectur

COCk

Air

Manometer

Emission

Control

System

repaired

or

replaced

368

mmH20

14

5

inH20

LL

IPO

liqUid

epo

o

36

r

@

Carbon

canister

EC786

Fig

EC

79

Checking

evaporative

emmion

control

syatem

CARBON

CANISTER

PURGE

CONTROL

VALVE

Check

for

fuel

vapor

leakage

in

the

distributor

vacuum

line

at

diaphragm

of

carbon

canister

purge

control

valve

To

check

for

leakage

proceed

as

follows

I

Disconnect

rubber

hose

in

the

line

between

T

connector

and

carbon

canister

at

T

connector

2

Inhale

air

into

the

opening

of

rubber

hose

running

to

vacuum

hole

in

carbon

canister

and

ensure

that

there

is

no

leak

ET349

Fig

EC

so

Checking

carbon

canuter

purge

control

valve

3

If

there

is

a

leak

remove

top

cover

from

purge

control

valve

and

check

for

dislocated

or

cracked

dia

phragm

If

necessary

replace

dia

phragm

kit

which

is

made

up

of

a

retainer

a

diaphragm

and

a

spring

@

@

1

Cover

2

Diaphragm

3

Retainer

4

Spring

ET350

Fig

EC

81

Carbon

catU

ter

purge

control

valve

CARBON

CANISTER

FILTER

Check

for

a

contaminated

element

Element

can

be

removed

at

the

bottom

of

canister

installed

on

vehicle

body

EC

32

ET37Q

Fig

EC

s2

Replacing

carbon

canuter

filter

FUEL

TANK

VACUUM

RELIEF

VALVE

Remove

fuel

filler

cap

and

see

it

functions

properly

I

Wipe

clean

valve

housing

and

have

it

in

your

mouth

2

Inhale

air

A

slight

resistance

ac

companied

by

valve

indicates

that

valve

is

in

good

mechanical

condition

Note

also

that

by

further

inhaling

air

the

resistance

should

be

disappeared

with

valve

clicks

3

If

valve

is

clogged

or

if

no

resist

ance

is

felt

replace

cap

as

an

assem

bled

uni

t

l

u

ET369

Fig

EC

83

Fuel

filler

cap

Page 175 of 537

CLEANING

AND

INSPECTION

Clean

all

disassembled

parts

but

do

not

use

grease

dissolving

solvents

for

cleaning

overrunning

clutch

annature

assembly

magnetic

switch

assembly

and

field

coils

since

such

a

solvent

would

dissolve

grease

packed

in

c1u

tch

mechanism

and

would

damage

coils

or

other

insulators

Check

them

for

excessive

damage

or

wear

and

replace

if

necessary

TERMINAL

Check

terminal

for

damage

and

wear

and

replace

magnetic

switch

assembly

if

necessary

FIELD

COIL

Check

field

coil

for

insulation

If

the

insulation

of

coil

is

damaged

or

worn

it

should

be

replaced

Testing

field

coil

for

continuity

Connect

the

probe

of

a

circuit

tester

or

an

ohmmeter

to

field

coil

positive

terminal

and

positive

brush

holder

If

tester

shows

no

continuity

field

circuit

or

coil

is

open

EE016

Fig

EE

I2

Testing

field

coil

for

continuity

TestIng

field

coD

for

ground

Place

one

probe

of

circuit

tester

onto

yoke

and

the

other

onto

field

coil

lead

positive

tenninal

If

very

little

resistance

is

read

field

coil

is

grounded

Engine

Electrical

System

EE017

Fig

EE

I3

Testing

rU

ld

coil

for

ground

BRUSHES

AND

BRUSH

LEAD

WIRE

Check

the

surface

condition

of

brush

contact

and

wear

of

brush

If

a

loose

contact

is

found

it

should

be

replaced

If

brush

is

worn

so

that

its

length

is

less

than

12

mm

0

472

in

replace

Check

the

connection

of

lead

clip

and

lead

wire

o

@

EE

8

Check

brush

holders

and

spring

cUp

to

see

if

they

are

not

deformed

or

bent

and

will

properly

hold

brushes

against

the

commutator

If

brushes

or

brush

holders

are

dirty

they

should

be

cleaned

BRUSH

SPRING

TENSION

Check

brush

spring

tension

by

a

spring

scale

as

shown

in

Figure

EE

13

The

reading

should

be

1

6

kg

3

5

Ib

Replace

spring

if

tension

is

lower

than

I

4

kg

3

1

Ib

ARMATURE

ASSEMBLY

Check

external

appearance

of

armature

and

commutator

1

Inspect

commutator

If

the

sur

face

of

commutator

is

rough

it

must

be

sanded

lightly

with

a

No

500

emery

cloth

If

the

depth

of

insulating

mica

is

less

than

0

2

mm

0

0079

in

from

commutator

surface

insulating

mica

should

also

be

undercut

so

that

its

depth

is

0

5

to

0

8

mm

0

01

97

to

0

0315

in

The

wear

limit

of

commutator

dia

meter

is

2

mm

0

0787

in

If

the

diameter

of

cammu

tator

is

less

than

31

mm

1

220

in

replace

annature

assembly

EE018

Fig

EE

14

Inspecting

brush

spring

tension

Page 176 of 537

L

0

5

to

0

8

mm

71j

Correct

2

Inspect

soldered

connection

of

armature

lead

and

commutator

If

loose

connection

is

found

solder

it

using

resin

flux

3

Armature

test

for

ground

Using

a

circuit

tester

place

one

test

probe

onto

armature

shaft

and

other

onto

each

commutator

bar

If

tester

shows

continuity

armature

is

grounded

and

must

be

replaced

EE022

Fig

EE

16

Testing

annature

for

ground

4

Check

armature

for

short

by

placing

it

on

armature

tester

growler

with

a

piece

of

iron

over

armature

core

rotating

armature

If

the

plate

vibrates

armature

is

shorted

j

l

EE023

Fig

EE

17

Testing

annature

for

ahort

Engine

Electrical

System

L

File

l

0

Commutator

Segmen

t

IWMica

Incorrect

EE021

Fig

EE

15

Undercutting

i118ulating

mica

5

Check

armature

for

continuity

by

placing

probes

of

tester

on

two

seg

ments

side

by

side

If

tester

shows

no

continuity

the

circuit

is

open

OVERRUNNING

CLUTCH

ASSEMBLY

Inspect

pinion

assembly

and

screw

sleeve

Screw

sleeve

must

slide

freely

along

armature

shaft

splines

If

damage

is

found

or

resistance

is

felt

when

sliding

it

must

be

repaired

Inspect

pinion

teeth

If

excessive

rub

bing

is

found

on

teeth

replace

Flywheel

ring

gear

also

must

be

in

spected

l

EE278

Fig

EE

18

Overrunning

clutch

auem

bly

BRUSH

HOLDER

TEST

FOR

GROUND

Using

a

circuit

tester

place

one

test

probe

onto

negative

side

of

brush

holder

and

another

onto

positive

side

If

tester

shows

continuity

brush

holder

is

shorted

to

ground

Replace

brush

holder

EE

9

Ee026

Fig

EE

19

Testing

brush

for

round

BEARING

METAL

Inspect

bearing

metal

for

wear

or

side

play

If

the

clearance

between

bearing

metal

and

armature

shaft

is

more

than

0

2

mm

0

0079

in

replace

metal

MAGNETIC

SWITCH

ASSEMBLY

1

Using

a

circuit

tester

l

check

con

tinuity

between

S

terminal

of

mag

netic

switch

and

switch

body

metal

If

continuity

does

not

exist

shunt

coit

is

opened

Replace

switch

assembly

2

In

the

same

manner

as

above

check

continuity

between

terminals

S

and

M

If

continuity

does

not

exist

series

coil

is

opened

Replace

switch

assembly

ASSEMBLY

Reassemble

starting

motor

in

re

verse

sequence

of

disassembly

When

assembling

be

sure

to

apply

grease

to

gear

case

and

rear

cover

bearing

metal

and

apply

oil

lightly

to

pinion

TEST

PERFORMANCE

TEST

Starter

motor

should

be

subjected

to

a

no

load

test

whenever

it

has

been

overhauled

to

ensure

that

its

performance

will

be

satisfactory

when

installed

on

engine

Starter

motor

should

also

be

subjected

to

the

test

when

the

cause

of

abnormal

operation

is

to

be

determined

A

brief

outline

of

the

test

is

given

below

Page 186 of 537

Engine

Electrical

System

ALTERNATOR

TEST

Before

conducting

an

alternator

test

make

sure

th

tthe

battery

is

fully

charged

A

30

V

olt

voltmeter

and

suitable

test

probes

3re

necessary

for

the

test

Set

up

a

test

circuit

as

shown

in

Figure

EE45

and

test

auernator

in

the

manner

indica

ted

in

the

flow

chart

below

1

Disconnect

connectors

at

alternator

2

Connect

A

terminal

to

F

terminal

3

Connect

one

test

probe

from

voltmeter

positive

terminal

to

A

terminal

Connect

the

other

test

probe

to

ground

Make

sure

that

voltmeter

registers

battery

voltage

4

Turn

on

headlights

and

switch

to

High

Beam

5

Start

engine

6

Increase

engine

speed

gradually

until

it

is

approximately

1

100

rpm

and

take

the

voltmeter

reading

Measured

value

Below

12

5

Volts

Alternator

is

in

trouble

remove

and

check

it

for

condition

Measured

value

Over

12

5

Volts

Alternator

is

in

good

condition

Notes

a

Do

Dot

run

engine

at

the

speed

of

more

than

1

100

rpm

while

test

is

being

conducted

on

alternator

b

Do

not

race

engine

i

9

l

IV

I

Battery

EE052

Voltmeter

Fig

EE

45

Testing

alternator

SERVICE

DATA

AND

SPECIFICATIONS

Nominal

rating

V

A

LT138

IB

LTl35

36B

For

air

conditioner

1235

12

38

Negative

Negative

1

000

1

000

28

2

500

30

2

500

35

5

000

38

5

000

2

25

2

25

More

than

7

5

0

295

More

than

7

5

0

295

255

to

345

255

to

345

9

0

to

12

2

9

0

to

12

2

More

than

30

1

181

More

than

30

1

181

EE

19

Type

Ground

polarity

Minimum

revolution

when

generating

14V

with

no

load

rpm

Hot

output

current

Nrpm

Pulley

ratio

Brush

Length

Spring

pressure

mm

in

gr

oz

Slip

ring

outer

diameter

mm

in

Page 190 of 537

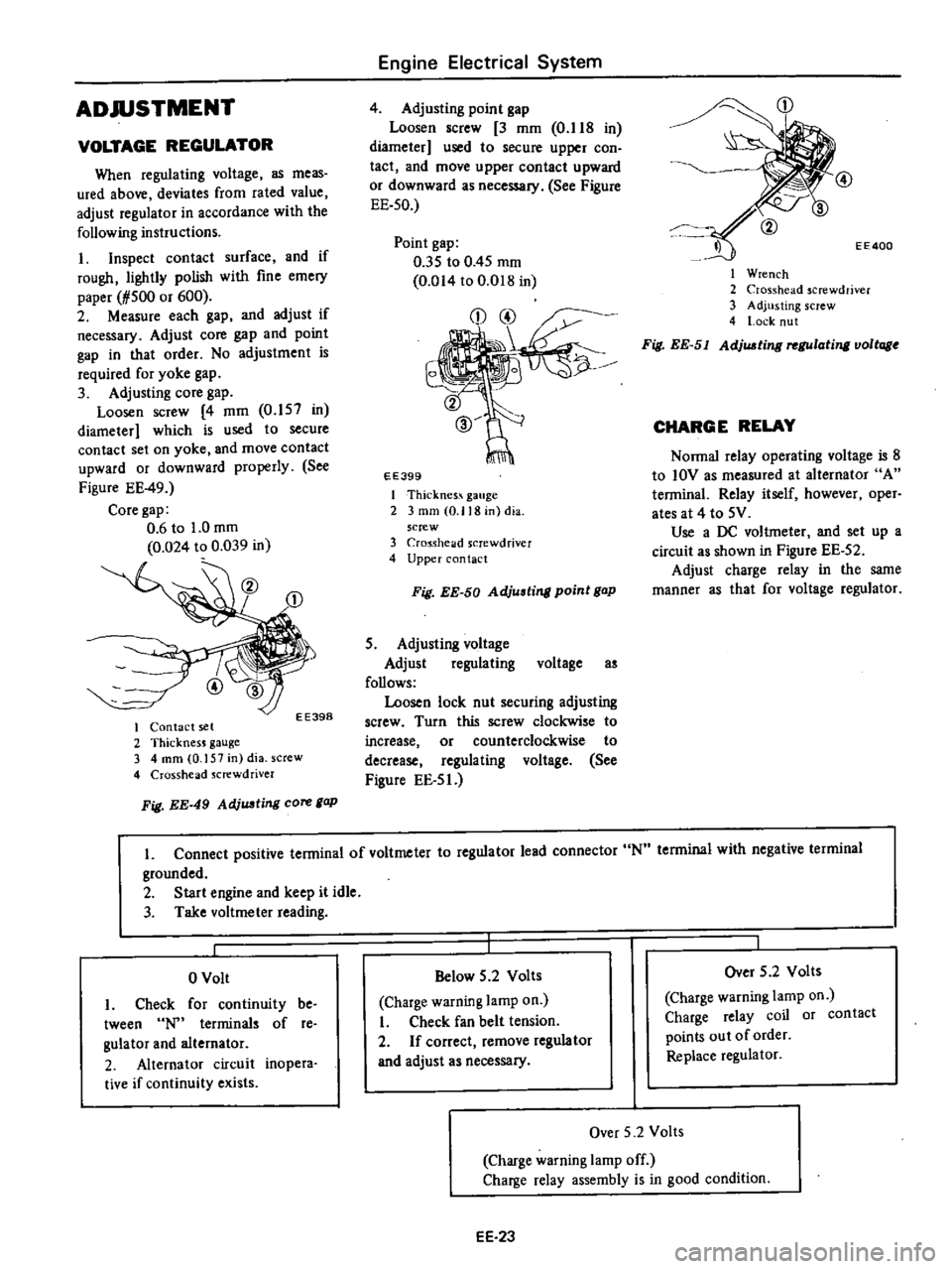

ADJUSTMENT

VOLTAGE

REGULATOR

When

regulating

voltage

as

meas

ured

above

deviates

from

rated

value

adjust

regulator

in

accordance

with

the

following

instructions

I

Inspect

contact

surface

and

if

rough

lightly

polish

with

fine

emery

paper

1

500

or

600

2

Measure

each

gap

and

adjust

if

necessary

Adjust

core

gap

and

point

gap

in

that

order

No

adjustment

is

required

for

yoke

gap

3

Adjusting

core

gap

Loosen

screw

4

mm

0

157

in

diameter

which

is

used

to

secure

contact

set

on

yoke

and

move

contact

upward

or

downward

properly

See

Figure

EE

49

Core

gap

0

6

to

1

0

mm

0

024

to

0

039

in

EE398

I

Contact

set

2

ThicknesJ

gauge

3

4

mm

0

157

in

dia

screw

4

Crosshead

Jcrewdriver

Fig

EE

49

AdjUJJting

core

gap

Engine

Electrical

System

4

Adjusting

point

gap

Loosen

screw

3

mm

O

lIS

in

diameter

used

to

secure

upper

con

tact

and

move

upper

contact

upward

or

downward

as

necessary

See

Figure

EE

50

Point

gap

035

to

0

45

mm

0

014

to

O

D1S

in

EE399

I

Thicknes

gauge

2

3

mm

0

118

in

dia

screw

3

Cro

Sshelld

screwdriver

4

Upper

contact

Fig

EE

50

Adjusting

point

gap

5

Adjusting

voltage

Adjust

regulating

voltage

as

follows

Loosen

lock

nut

securing

adjusting

screw

Turn

this

screw

clockwise

to

increase

or

counterclockwise

to

decrease

regulating

voltage

See

Figure

EE

5

J

CD

EE400

I

Wrench

2

Crosshead

screwdriver

3

Adjusting

screw

4

l

ock

nut

Fig

EE

51

AdjUJJting

rel

Ulating

voltage

CHARGE

RELAY

Nonna

relay

operating

voltage

is

S

to

IOV

as

measured

at

alternator

A

tenninal

Relay

itself

however

oper

ates

at

4

to

5V

Use

a

DC

voltmeter

and

set

up

a

circuit

as

shown

in

Figure

EE

52

Adjust

charge

relay

in

the

same

manner

as

that

for

voltage

regulator

L

Connect

positive

tenninal

of

voltmeter

to

regulator

lead

connector

N

tenninal

with

negative

terminal

grounded

2

Start

engine

and

keep

it

idle

3

Take

voltmeter

reading

o

Volt

I

Check

for

continuity

be

tween

terminals

of

re

gulator

and

alternator

2

Alternator

circuit

inopera

tive

if

continuity

exists

Below

5

2

Volts

Charge

warning

lamp

on

I

Check

fan

belt

tension

2

If

correct

remove

regulator

and

adjust

as

necessary

Over

5

2

Volts

Charge

warning

lamp

on

Charge

relay

coil

or

contact

points

out

of

order

Replace

regulator

Over

5

2

Volts

Charge

warning

lamp

off

Charge

relay

assembly

is

in

good

condition

EE

23

Page 198 of 537

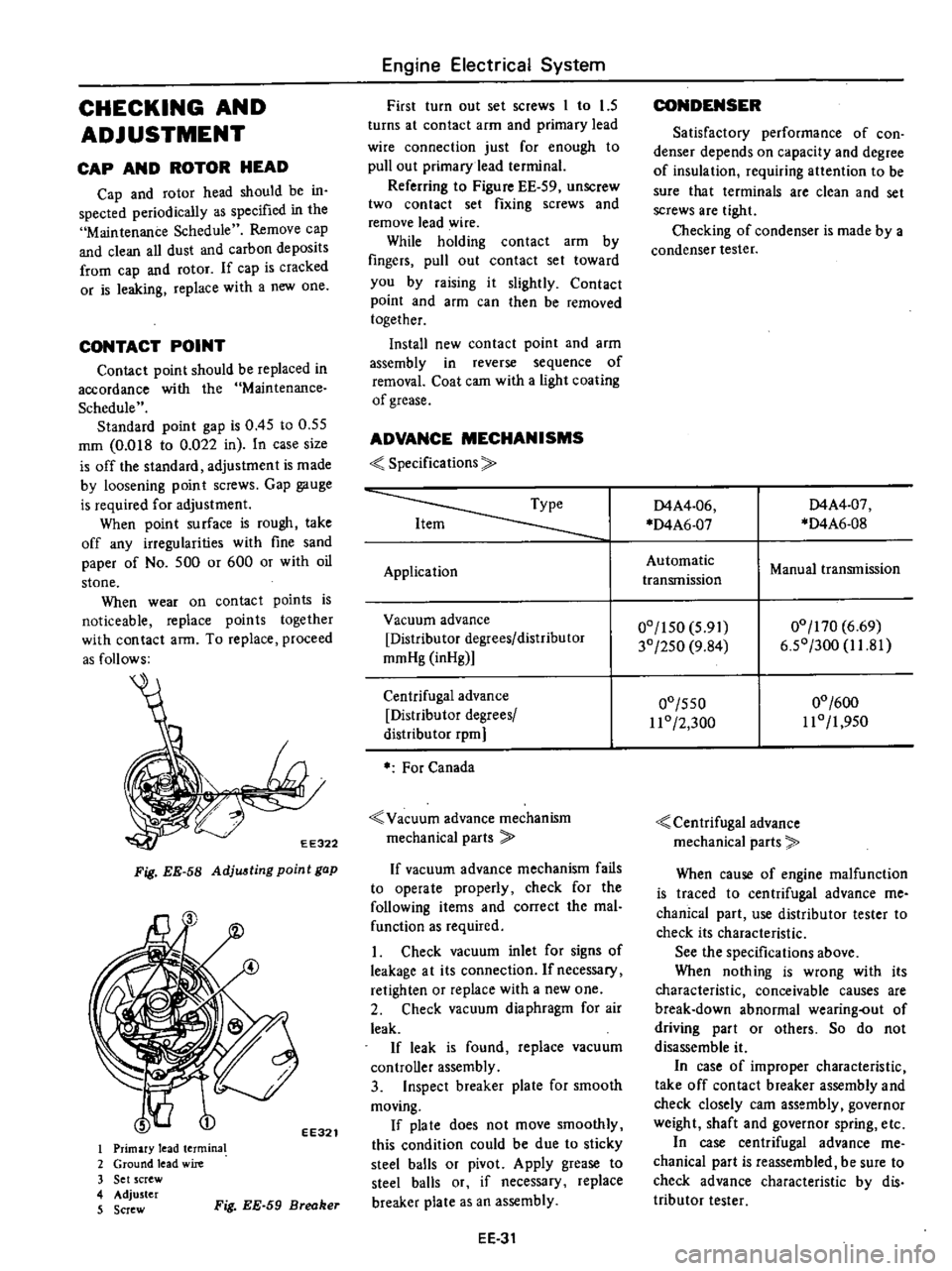

CHECKING

AND

ADJUSTMENT

CAP

AND

ROTOR

HEAD

Cap

and

rotor

head

should

be

in

spected

periodically

as

specified

in

the

Maintenance

Schedule

Remove

cap

and

clean

all

dust

and

carbon

deposits

from

cap

and

rotor

If

cap

is

cracked

or

is

leaking

replace

with

a

De

one

CONTACT

POINT

Contact

point

should

be

replaced

in

accordance

with

the

Maintenance

Schedule

Standard

point

gap

is

0

45

to

0

55

mm

O

OIS

to

0

022

in

In

case

size

is

off

the

standard

adjustment

is

made

by

loosening

point

screws

Gap

gauge

is

required

for

adjustment

When

point

surface

is

rough

take

off

any

irregularities

with

fine

sand

paper

of

No

500

or

600

or

with

oil

stone

When

wear

on

contact

points

is

noticeable

replace

points

together

with

contact

arm

To

replace

proceed

as

follows

EE322

Fig

EE

58

Adju

ting

point

gap

EE321

I

Primary

lead

termina

2

Ground

lead

wire

3

Set

screw

4

Adjuster

5

Screw

Fig

EE

59

Breaker

Engine

Electrical

System

First

turn

out

set

screws

1

to

1

5

turns

at

contact

arm

and

primary

lead

wire

connection

just

for

enough

to

pull

out

primary

lead

terminal

Referring

to

Figure

EE

59

unSCrew

two

contact

set

fixing

screws

and

remove

lead

wire

While

holding

contact

arm

by

fingers

pull

out

contact

set

toward

you

by

raising

it

slightly

Contact

point

and

afm

can

then

be

removed

together

Install

new

contact

point

and

arm

assembly

in

reverse

sequence

of

removal

Coat

cam

with

a

light

coating

of

grease

ADVANCE

MECHANISMS

Specifications

Application

Vacuum

advance

Distributor

degrees

distributor

mmHg

inHg

Centrifugal

advance

Distributor

degrees

distribu

tor

rpm

For

Canada

Vacuum

advance

mechanism

mechanical

parts

If

vacuum

advance

mechanism

fails

to

operate

properly

check

for

the

following

items

and

correct

the

mal

function

as

required

1

Check

vacuum

inlet

for

signs

of

leakage

at

its

connection

Ifnecessacy

retighten

or

replace

with

a

new

one

2

Check

vacuum

diaphragm

for

air

leak

If

leak

is

found

replace

vacuum

controller

assembly

3

Inspect

breaker

plate

for

smooth

moving

If

pia

te

does

not

move

smoothly

this

condition

could

be

due

to

sticky

steel

balls

or

pivot

Apply

grease

to

steel

balls

or

if

necessary

replace

breaker

plate

as

an

assembly

EE

31

CONDENSER

Satisfactory

performance

of

con

denser

depends

on

capacity

and

degree

of

insulation

requiring

attention

to

be

sure

that

terminals

are

clean

and

set

screws

are

tight

Checking

of

condenser

is

made

by

a

condenser

tester

D4A4

06

D4A6

07

D4A4

07

D4A6

0S

Automatic

transmission

Manual

transmission

00

150

5

91

30

250

9

S4

00

170

6

69

6

50

300

1I

S1

00

550

11

0

2

300

00

600

110

1

950

Centrifugal

advance

mechanical

parts

When

cause

of

engine

malfunction

is

traced

to

centrifugal

advance

me

chanical

part

use

distributor

tester

to

check

its

characteristic

See

the

specifications

above

When

nothing

is

wrong

with

its

characteristic

conceivable

causes

are

break

down

abnormal

wearing

out

of

driving

part

or

others

So

do

not

disassemble

it

In

case

of

improper

characteristic

take

off

contact

breaker

assembly

and

check

closely

cam

assembly

governor

weight

shaft

and

governor

spring

etc

In

case

centrifugal

advance

me

chanical

part

is

reassembled

be

sure

to

check

advance

characteristic

by

dis

tributor

tester

Page 204 of 537

Engine

Electrical

System

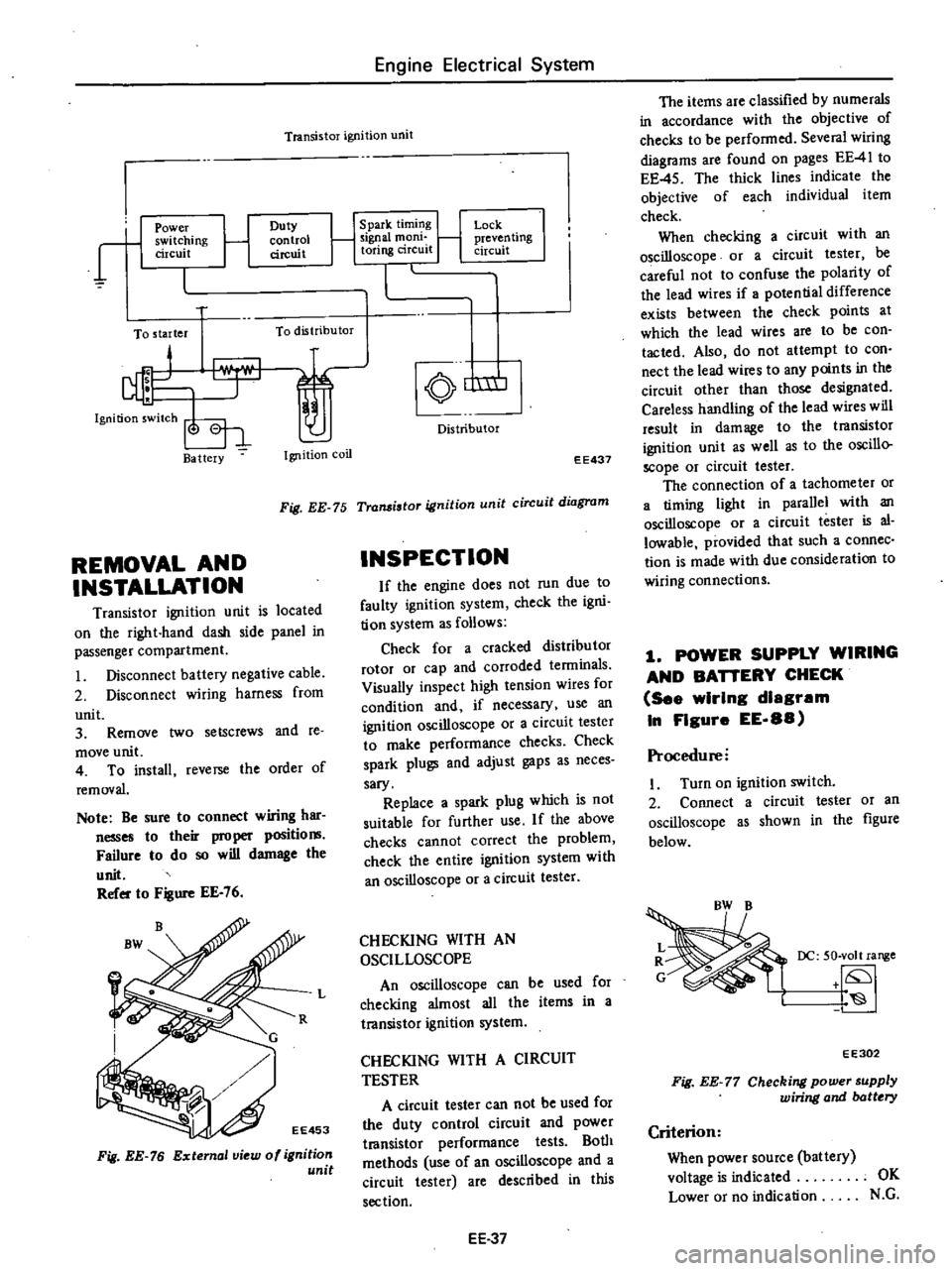

Transistor

ignition

unit

r

1

Power

switching

circuit

Duty

control

circuit

To

starter

To

distributor

Ba

ttery

Ignition

coil

1

Spark

timing

1

Signal

mom

toring

circuit

Lock

j

preven

ling

circuit

nm

Distributor

EE437

Fig

EE

75

Transistor

ignition

unit

circuit

diagram

REMOVAL

AND

INSTALLATION

Transistor

ignition

unit

is

located

on

the

right

hand

dash

side

panel

in

passenger

compartment

Disconnect

battery

negative

cable

2

Disconnect

wiring

harness

from

unit

3

Remove

two

setscrews

and

te

move

unit

4

To

install

reverse

the

order

of

removal

Note

Be

sure

to

connect

wiring

har

nesses

to

their

proper

positio

Failure

to

do

so

will

damage

the

unit

Refer

to

Figure

EE

76

Fig

EE

76

External

view

of

ignition

unit

INSPECTION

If

the

engine

does

not

run

due

to

faulty

ignition

system

check

the

igni

tion

system

as

follows

Check

for

a

cracked

distributor

rotor

or

cap

and

corroded

tenninals

Visually

inspect

high

tension

wires

for

condition

and

if

necessary

use

an

ignition

oscilloscope

or

a

circuit

tester

to

make

performance

checks

Check

spark

plugs

and

adjust

gaps

as

neces

sary

Replace

a

spark

plug

which

is

not

suitable

for

further

use

If

the

above

checks

cannot

correct

the

problem

check

the

entire

ignition

system

with

an

oscilloscope

or

a

circuit

tester

L

CHECKING

WITH

AN

OSCILLOSCOPE

An

oscilloscope

can

be

used

for

checking

almost

all

the

items

in

a

transistor

ignition

system

CHECKING

WITH

A

CIRCUIT

TESTER

A

circuit

tester

can

not

be

used

for

the

duty

control

circuit

and

power

t18nsistor

performance

tests

Both

methods

use

of

an

oscilloscope

and

a

circuit

tester

are

described

in

this

section

EE

37

The

items

are

classified

by

numerals

in

accordance

with

the

objective

of

checks

to

be

performed

Several

wiring

diagrams

are

found

on

pages

EE

41

to

EE

45

The

thick

lines

indicate

the

objective

of

each

individual

item

check

When

checking

a

circuit

with

an

oscilloscope

or

a

circuit

tester

be

careful

not

to

confuse

the

polarity

of

the

lead

wires

if

potential

difference

exists

between

the

check

points

at

which

the

lead

wires

are

to

be

con

tacted

Also

do

not

attempt

to

con

nect

the

lead

wires

to

any

points

in

the

circuit

other

than

those

designated

Careless

handling

of

the

lead

wires

will

result

in

damage

to

the

transistor

ignition

unit

as

well

as

to

the

oscillo

scope

or

circuit

tester

The

connection

of

a

tachometer

or

a

timing

light

in

parallel

with

an

oscilloscope

or

a

circuit

tester

is

al

lowable

provided

that

such

a

connec

tion

is

made

with

due

consideration

to

wiring

connections

1

POWER

SUPPLY

WIRING

AND

BAnERY

CHECK

See

wIrIng

diagram

In

FIgure

EE

88

Procedure

I

Turn

on

ignition

switch

2

Connect

a

circuit

tester

or

an

oscilloscope

as

shown

in

the

figure

below

DC

50

volt

range

EE302

Fig

EE

77

Checking

power

supply

wiring

and

batt

ry

Criterion

When

power

source

battery

voltage

is

indicated

OK

Lower

or

no

indication

N

G