check oil DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 41 of 537

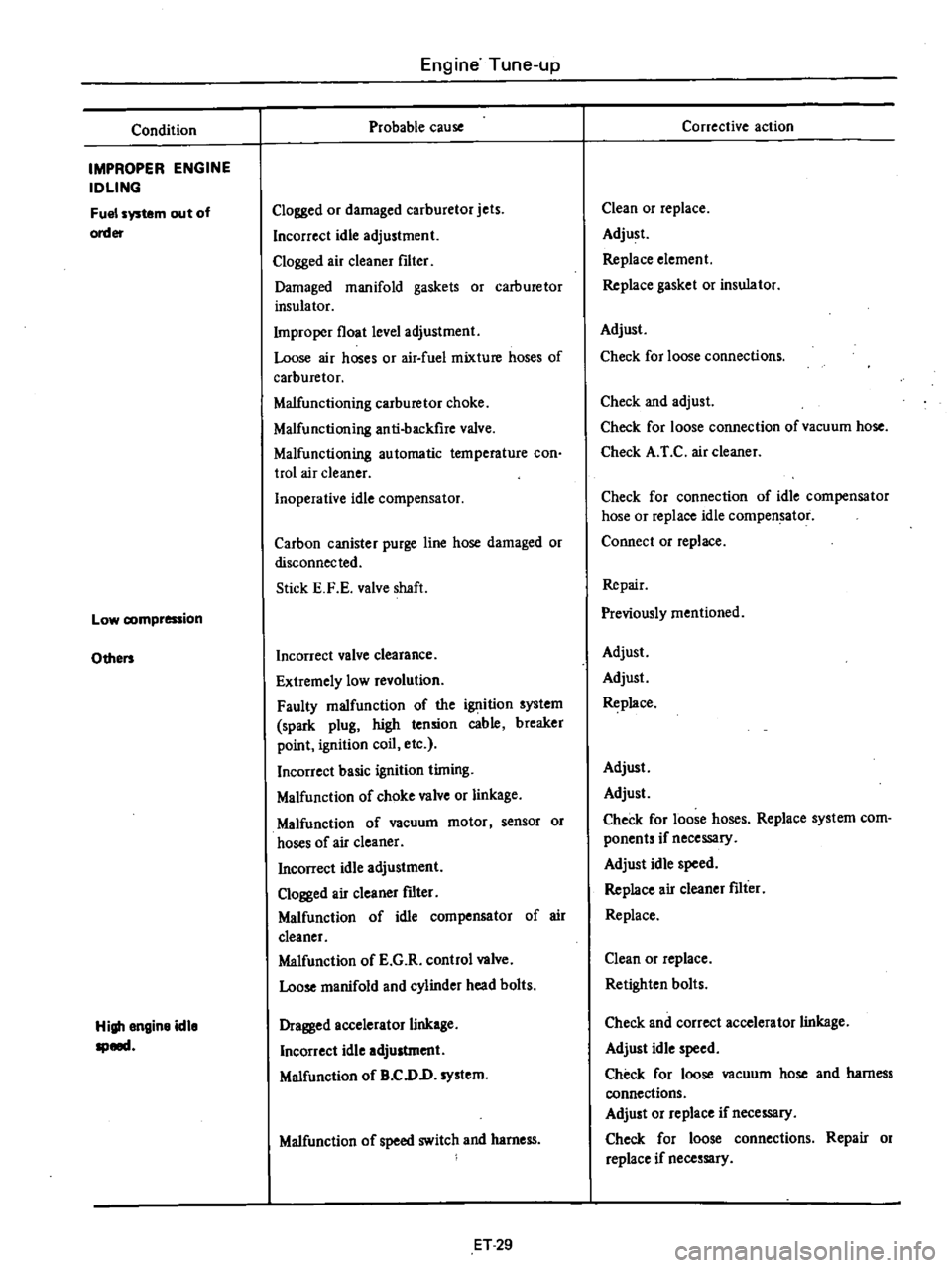

Condition

IMPROPER

ENGINE

IDLING

Fuel

system

out

of

order

Low

compression

Others

High

engine

idle

speed

Engine

Tune

up

Probable

cause

Clogged

or

damaged

carburetor

jets

Incorrect

idle

adjustment

Clogged

air

cleaner

filter

Damaged

manifold

gaskets

or

carburetor

insulator

Improper

float

level

adjustment

Loose

air

hoses

or

air

fuel

mixture

hoses

of

carburetor

Malfunctioning

carburetor

choke

Malfunctioning

anti

backfire

valve

Malfunctioning

automatic

temperature

con

trol

air

cleaner

Inoperative

idle

compensator

Carbon

canister

purge

line

hose

damaged

or

disconnected

Stick

E

F

E

valve

shaft

Incorrect

valve

clearance

Extremely

low

revolution

Faulty

malfunction

of

the

ignition

system

spark

plug

high

tension

cable

breaker

point

ignition

coil

etc

Incorrect

basic

ignition

timing

Malfunction

of

choke

valve

or

linkage

Malfunction

of

vacuum

motor

sensor

or

hoses

of

air

cleaner

Incorrect

idle

adjustment

Clogged

air

cleaner

fdter

Malfunction

of

idle

compensator

of

air

cleaner

Malfunction

of

E

G

R

control

valve

Loose

manifold

and

cylinder

head

bolts

Dragged

accelerator

linkage

Incorrect

idle

adjustment

Malfunction

of

B

CDD

system

Malfunction

of

speed

switch

and

harness

ET

29

Corrective

action

Clean

or

replace

Adjust

Replace

element

Replace

gasket

or

insulator

Adjust

Check

for

loose

connections

Check

and

adjust

Check

for

loose

connection

of

vacuum

hose

Check

A

r

C

air

cleaner

Check

for

connection

of

idle

compensator

hose

or

replace

idle

compen

tor

Connect

or

replace

Repair

Previously

mentioned

Adjust

Adjust

Replace

Adjust

Adjust

Check

for

loose

hoses

Replace

system

com

ponents

if

necessary

Adjust

idle

speed

Replace

air

cleaner

fdter

Replace

Clean

or

replace

Retighten

bolts

Check

and

correct

accelerator

linkage

Adjust

idle

speed

Check

for

loose

vacuum

hose

and

harness

connections

Adjust

or

replace

if

necessary

Check

for

loose

connections

Repair

or

replace

if

necessary

Page 42 of 537

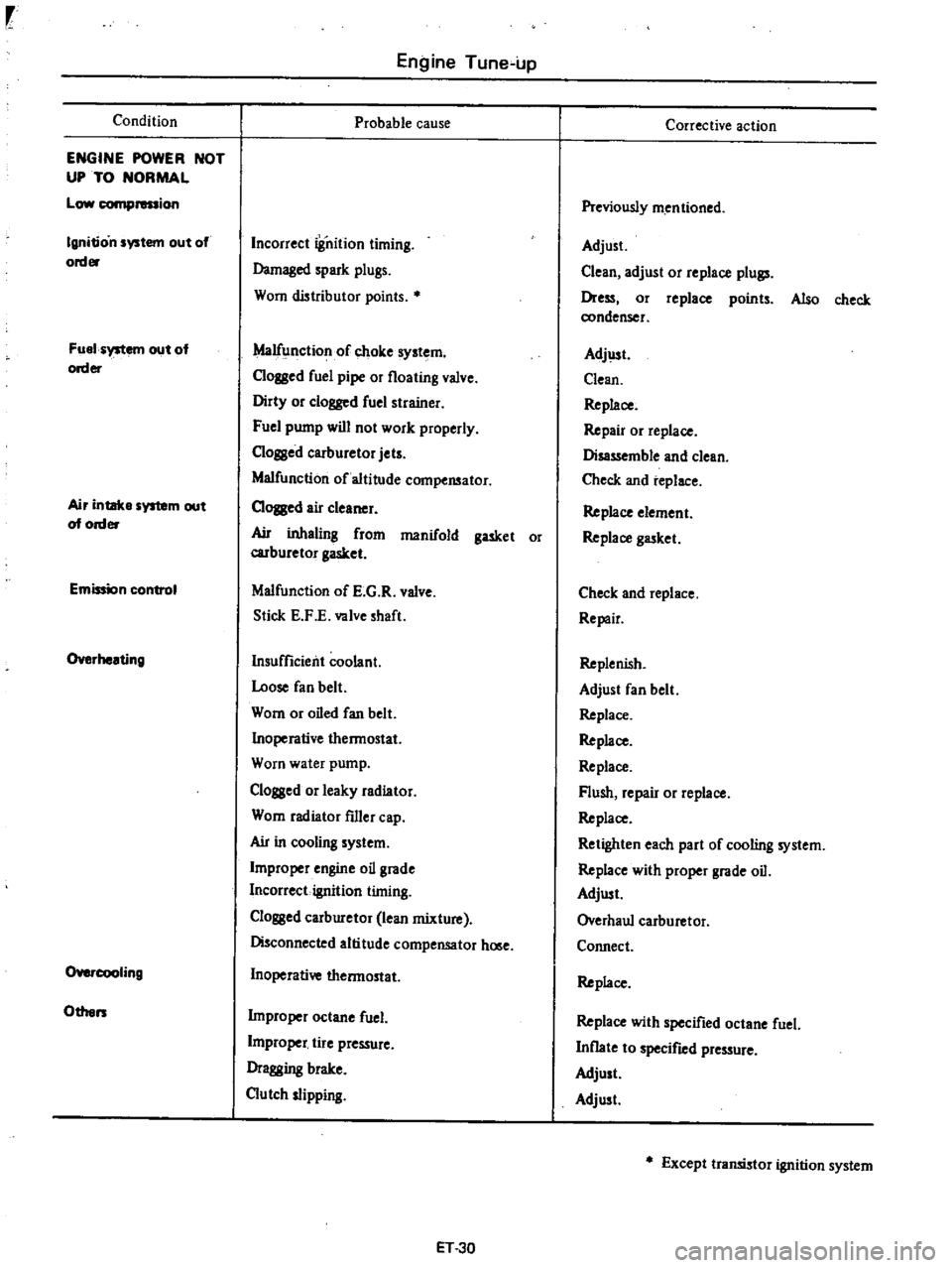

Condition

ENGINE

POWER

NOT

UP

TO

NORMAL

Low

compression

Ignition

system

out

of

order

Fuel

system

out

of

order

Air

intake

system

out

of

order

Emission

control

Overheating

O

cooIing

Others

Engine

Tune

up

Probable

cause

Incorrect

iSnition

timing

Damaged

spark

plugs

Worn

distributor

points

Malfunction

of

choke

system

Clogged

fuel

pipe

or

floating

valve

Dirty

or

clogged

fuel

strainer

Fuel

pump

will

not

work

properly

C10ssed

carburetor

jets

Malfunction

of

altitude

compensator

CIOJBed

air

cleaner

Ail

inhaling

from

manifold

gasket

or

carburetor

gasket

Malfunction

of

E

G

R

valve

Stick

E

F

E

valve

shaft

Insufficient

coolant

Loose

fan

belt

Worn

or

oiled

fan

belt

Inoperative

thermostat

Worn

water

pump

Clogged

or

leaky

radiator

Worn

radiator

filler

cap

Ail

in

cooling

system

Improper

engine

oil

grade

Incorrect

ignition

timing

Clossed

carburetor

lean

mixture

Disconnected

altitude

compensator

hOlle

Inoperative

thermostat

Improper

octane

fuel

L

j

tire

pressure

Dragging

brake

Clutch

slipping

ET

30

Corrective

action

Previously

mentioned

Adjust

Clean

adjust

or

replace

plull

Dress

or

replace

points

Also

check

condenser

Adj

lst

Clean

Replace

Repair

or

replace

Disassemble

and

clean

Check

and

replace

Replace

element

Replace

gasket

Check

and

replace

Repair

Replenish

Adjust

fan

belt

Replace

Replace

Replace

Flush

repair

or

replace

Replace

Retighten

each

part

of

cooling

system

Replace

with

proper

grade

oil

Adjust

Overhaul

carburetor

Connect

Replace

Replace

with

specified

octane

fuel

Inflate

to

specified

pressure

Adjust

Adjust

Except

transistor

ignition

system

Page 43 of 537

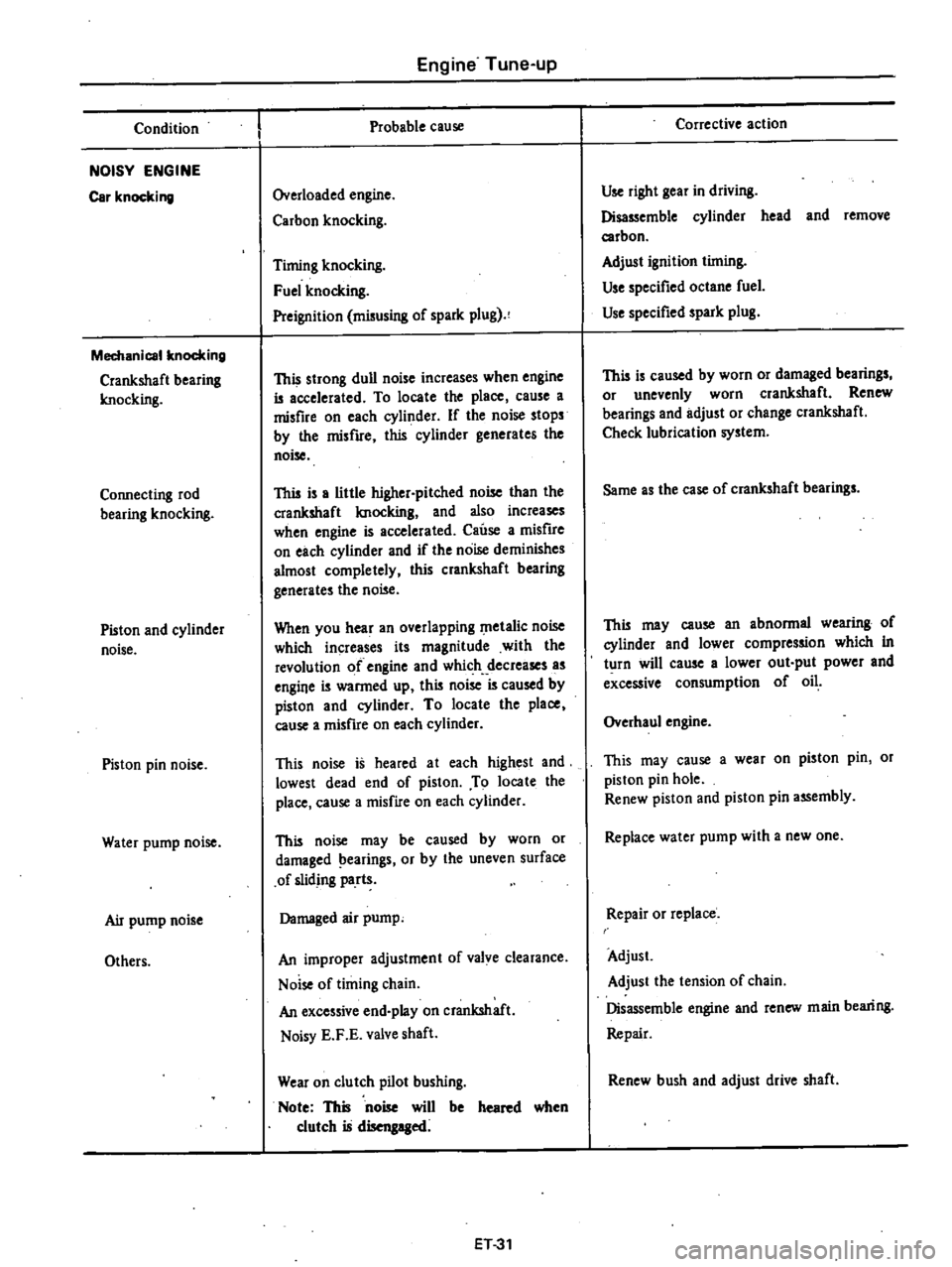

Condition

NOISY

ENGINE

Car

knocking

Mechanical

knocking

Crankshaft

bearing

Imocking

Connecting

rod

bearing

knocking

Piston

and

cylinder

noise

Piston

pin

noise

Water

pump

noise

Air

pump

noise

Others

Engine

Tune

up

Probable

cause

Overloaded

engine

Carbon

knocking

Timing

knocking

Fuel

knocking

Preignition

misusing

of

spark

plug

This

strong

dull

noise

increases

when

engine

is

accelerated

To

locate

the

place

cause

a

misfire

on

each

cylinder

If

the

noise

stops

by

the

misfire

this

cylinder

generates

the

noise

This

is

a

little

higher

pitched

noise

than

the

crankshaft

Imocking

and

also

increases

when

engine

is

accelerated

Cause

a

misfire

on

each

cylinder

and

if

the

noise

deminishes

almost

completely

this

crankshaft

bearing

generates

the

noise

When

you

hear

an

overlapping

metalic

noise

which

increases

its

magnitude

with

the

revolution

of

engine

and

which

decreases

as

engine

is

warmed

up

this

noise

is

caused

by

piston

and

cylinder

To

locate

the

place

cause

a

misfire

on

each

cylinder

This

noise

is

heared

at

each

highest

and

lowest

dead

end

of

piston

To

locate

the

place

cause

a

misfire

on

each

cylinder

This

noise

may

be

caused

by

worn

or

damaged

earings

or

by

the

uneven

surface

of

sliding

parts

Damaged

air

pump

An

improper

adjustment

of

valve

clearance

Noise

of

timing

chain

An

excessive

end

play

on

crankshaft

Noisy

E

F

E

valve

shaft

Wear

on

clutch

pilot

bushing

Note

This

noise

will

be

heared

when

clutch

is

disengaged

ET31

Corrective

action

Use

right

gear

in

driving

Disassemble

cylinder

head

and

remove

carbon

Adjust

ignition

timing

Use

specified

octane

fuel

Use

specified

spark

plug

This

is

caused

by

worn

or

damaged

bearings

or

unevenly

worn

crankshaft

Renew

bearings

and

adjust

or

change

crankshaft

Check

lubrication

system

Same

as

the

case

of

crankshaft

bearings

This

may

cause

an

abnormal

wearing

of

cylinder

and

lower

compression

which

in

turn

will

cause

a

lower

out

put

power

and

excessive

consumption

of

oil

Overhaul

engine

This

may

cause

a

wear

on

piston

pin

or

piston

pin

hole

Renew

piston

and

piston

pin

assembly

Replace

water

pump

with

a

new

one

Repair

or

replace

Adjust

Adjust

the

tension

of

chain

Disassemble

engine

and

renew

main

bearing

Repair

Renew

bush

and

adjust

drive

shaft

Page 44 of 537

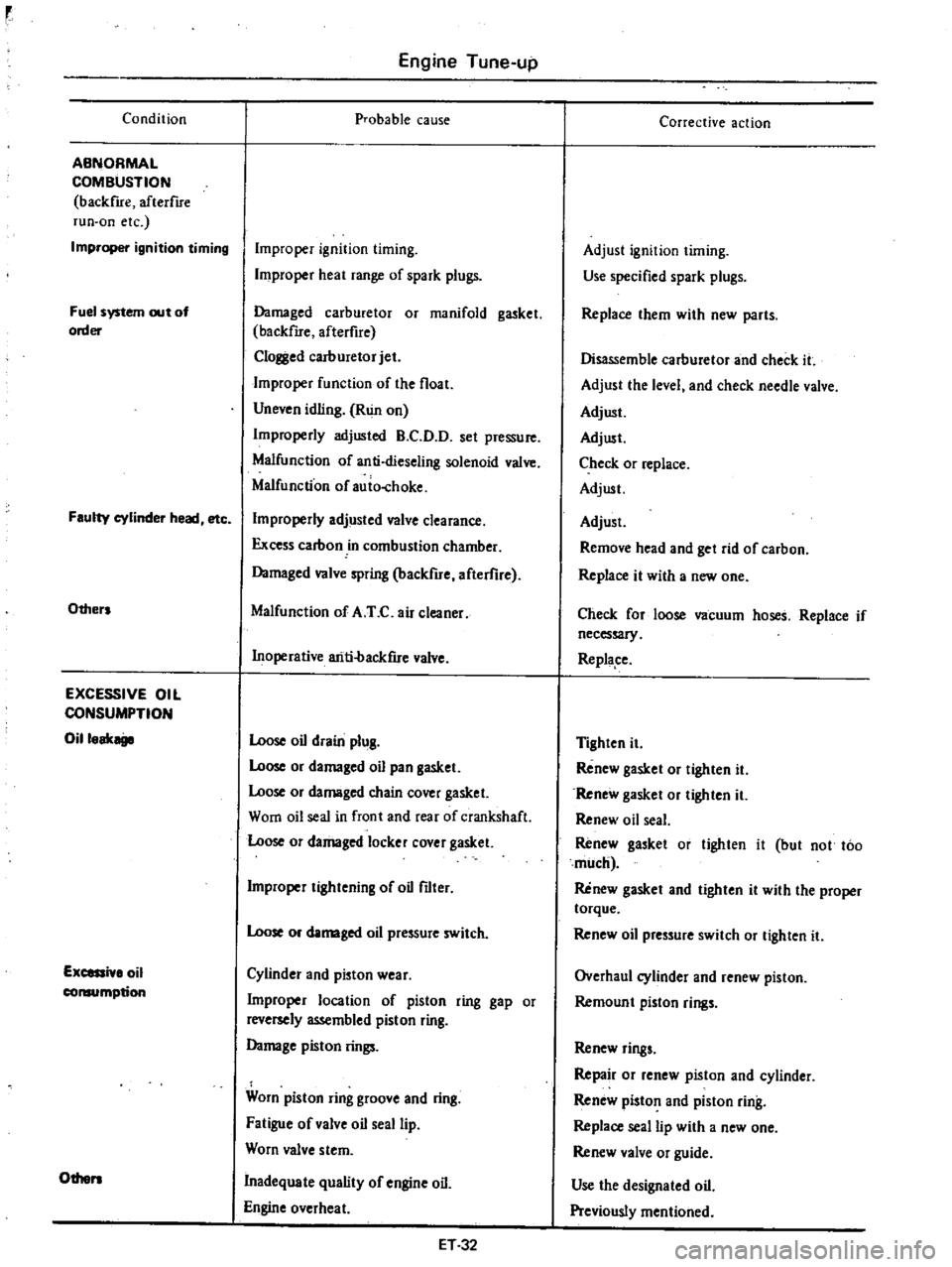

Condition

ABNORMAL

COMBUSTION

backfue

afterflre

run

on

etc

Improper

ignition

timing

Fuel

system

out

of

order

Faulty

cylinder

head

etc

Others

EXCESSIVE

OIL

CONSUMPTION

Oilloak

Excessi

lo

oil

consumption

Others

Engine

Tune

up

probable

cause

Improper

ignition

timing

Improper

heat

range

of

spark

plugs

Damaged

carburetor

or

manifold

gasket

backfue

afterfire

Clol

l

ed

carburetor

jet

Improper

function

of

the

float

Uneven

idling

Run

on

Improperly

adjusted

B

C

D

D

set

pressure

Malfunction

of

anti

dieseling

solenoid

valve

Malfunction

of

auio

choke

Improperly

adjusted

valve

clearance

Excess

carbon

in

combustion

chamber

Damaged

valve

spring

backfire

afterflre

Malfunction

of

A

T

C

air

cleaner

Inoperative

ariti

backfue

valve

Loose

oil

drain

plug

Loose

or

damaged

oil

pan

gasket

Loose

or

damaged

chain

cover

gasket

Worn

oil

seal

in

front

and

rear

of

crankshaft

Loose

or

damaged

locker

cover

gasket

Improper

tightening

of

oil

filter

Loose

or

damaged

oil

pressure

switch

Cylinder

and

pioton

wear

Improper

location

of

piston

ring

gap

or

reversely

assembled

piston

ring

Damage

piston

rings

Worn

piston

ring

groove

and

ring

Fatigue

of

valve

oil

seal

lip

Worn

valve

stem

Inadequate

quality

of

engine

oil

Engine

overheat

ET32

Corrective

action

Adjust

ignition

timing

Use

specified

spark

plugs

Replace

them

with

new

parts

Disassemble

carburetor

and

check

it

Adjust

the

level

and

check

needle

valve

Adjust

Adjust

Check

or

replace

Adjust

Adjust

Remove

head

and

get

rid

of

carbon

Replace

it

with

a

new

one

Check

for

loose

vacuum

hoses

Replace

if

necessary

Replape

Tighten

it

Renew

gasket

or

tighten

it

Renew

gasket

or

tighten

it

Renew

oil

seal

Renew

gasket

or

tighten

it

but

not

too

much

Renew

gasket

and

tighten

it

with

the

proper

torque

Renew

oil

pressure

switch

or

tighten

it

Overhaul

cylinder

and

renew

piston

Remoun

t

piston

rings

Renew

rings

Repair

or

renew

piston

and

cylinder

Renew

piston

and

piston

ring

Replace

seal

lip

with

a

new

one

Renew

valve

or

guide

Use

the

designated

oil

Previously

mentioned

Page 45 of 537

Condition

POOR

FUEL

ECONOMY

Se

the

xplanation

of

the

pow

r

dec

Oth

n

PROBLEM

IN

OTHER

FUNCTIONS

D

cr

d

oil

p

ssure

Excessive

wear

on

the

sliding

parts

Scuffing

of

sliding

parts

Floor

temperature

too

high

California

only

Engine

Tune

up

Probable

cause

Exceeding

idling

revolution

Inoperative

acceleration

recovery

Fuel

leakage

Malfunction

of

B

C

D

D

Malfunction

of

A

r

C

air

cleaner

Inadequate

oil

quality

Overheat

Worn

oil

pump

regulator

valve

Functional

deterioration

of

oil

pump

Blocked

oil

f1lter

Increased

clearance

in

various

sliding

parts

Blocked

oil

strainer

Inoperative

oil

gauge

pressure

switch

Oil

pressure

decreases

Improper

quality

or

contamination

of

oil

Damaged

air

cleaner

Overheat

or

overcoal

Improper

fuel

mixture

Decrease

of

oil

pressure

Insufficient

clearances

Overhea

t

Improper

fuel

mixture

Problem

in

fuel

system

Refer

to

Inspec

tion

of

Fuel

System

Problem

in

ignition

system

Refer

to

In

spection

of

Ignition

System

ET33

Corrective

action

Adjust

it

to

the

designated

rpm

Adjust

it

Repair

or

tighten

the

connection

of

fuel

pipes

Adjust

Check

and

replace

Use

the

designated

oil

Previously

mentioned

Disassemble

oil

pump

and

repair

or

renew

it

Repair

or

replace

it

with

a

new

one

Renew

it

Disassemble

and

replace

the

worn

parts

with

new

ones

Oeanit

Replace

it

with

a

new

one

Previousiy

mentioned

Exchange

the

oil

with

proper

one

and

change

element

Change

elemen

t

Previously

mentioned

Check

the

fuel

system

Previously

mentioned

Readjust

to

the

designated

clearances

Previously

mentioned

Check

the

fuel

system

Check

and

repair

Check

and

repair

Page 49 of 537

r

I

I

PRELIMINARY

CLEANING

AND

INSPECTION

DISASSEMBL

Y

PRELIMINARY

CLEANING

AND

INSt

ECTION

Before

disassembling

engine

note

the

following

I

Fuel

oil

or

water

may

leak

past

cylinder

head

and

block

Prior

to

disassembling

check

cylinder

head

1

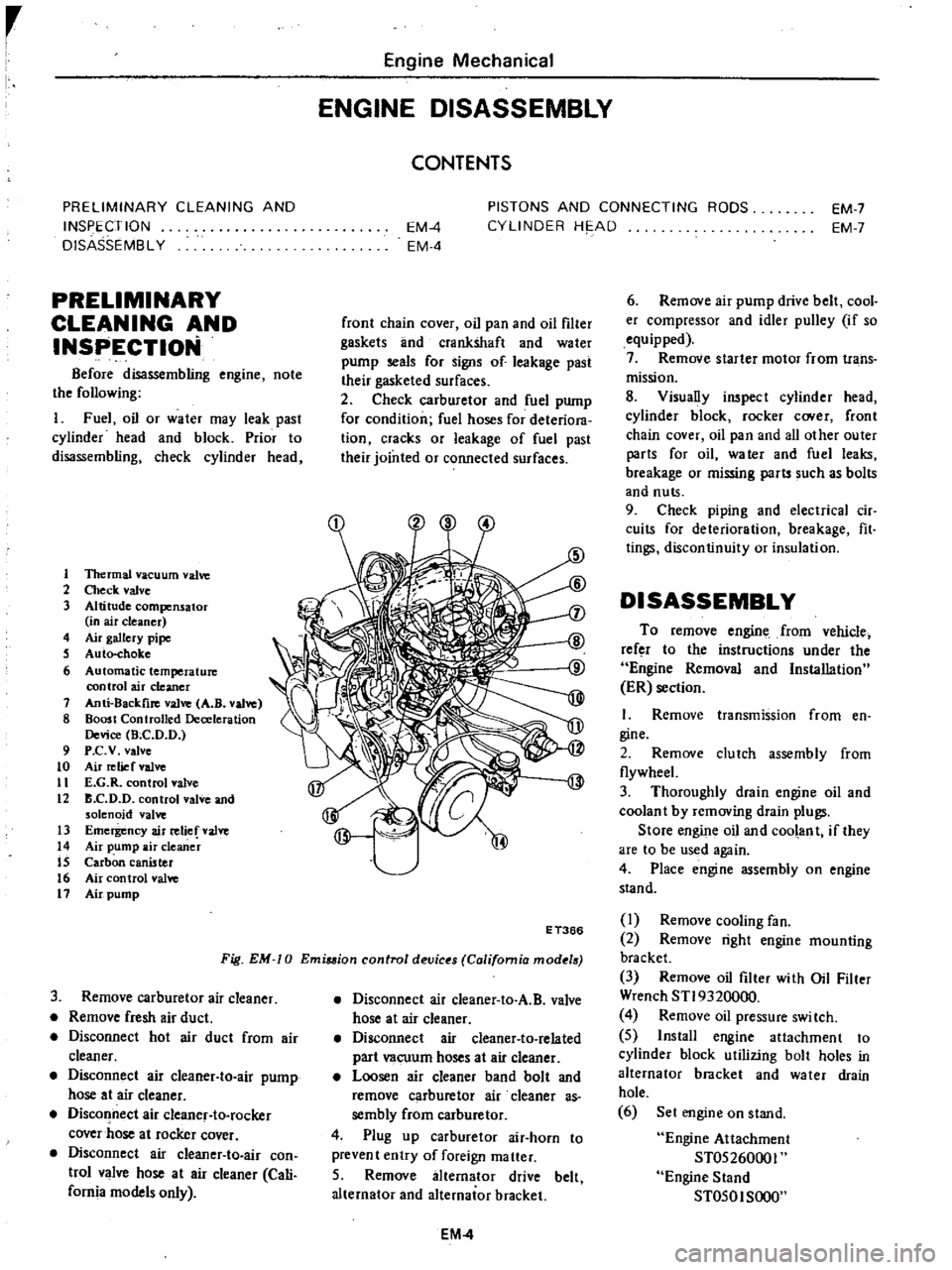

1ltermal

vacuum

valve

2

Check

valve

3

Altitude

compensator

in

air

cleaner

4

Air

gallery

pipe

S

Auto

choke

6

Automatic

temperature

control

air

cleaner

7

Anti

8ackfire

valve

A

B

valve

8

Boost

Controlled

Deceleration

Device

Bee

D

D

9

P

c

v

valve

to

Air

relief

valve

11

E

G

R

control

valve

12

B

C

D

D

control

valve

and

solenoid

valve

13

Emergency

air

relief

valve

14

Air

pump

air

cleaner

IS

Carbon

canister

16

Air

control

valve

11

Air

pump

Engine

Mechanical

ENGINE

DISASSEMBLY

CONTENTS

EM

4

EM

4

PISTONS

AND

CONNECTING

RODS

CYLINDER

HE

AD

EM

7

EM

7

front

chain

cover

oil

pan

and

oil

filter

gaskets

lInd

crankshaft

and

water

pump

seals

for

signs

of

leakage

past

their

gasketed

surfaces

2

Check

carburetor

and

fuel

pump

for

condition

fuel

hoses

for

deteriora

tion

cracks

or

leakage

of

fuel

past

their

jointed

or

connected

surfaces

Fig

EM

0

Emiuion

control

devic

s

California

mod

18

E

T366

3

Remove

carburetor

air

cleaner

Remove

fresh

air

duct

Disconnect

hot

air

duct

from

air

cleaner

Disconnect

air

cleaner

to

air

pump

hose

at

air

cleaner

Disconnect

air

cleanef

to

rocker

cover

hose

at

rocker

cover

Disconnect

air

cIeaner

to

air

con

trol

valve

hose

at

air

cleaner

Cali

fornia

models

only

Disconnect

air

cleaner

to

A

B

valve

hose

at

air

cleaner

Disconnect

air

cleaner

to

related

part

vacuum

hoses

at

air

cleaner

Loosen

air

cleaner

band

bolt

and

remove

carburetor

air

cleaner

as

sembly

from

carburetor

4

Plug

up

carburetor

air

horn

to

prevent

entry

of

foreign

matter

5

Remove

alternator

drive

belt

alternator

and

alternator

bracket

EM

4

6

Remove

air

pump

drive

belt

cool

er

compressor

and

idler

pulley

if

so

equipped

7

Remove

starter

motor

from

trans

mission

8

Visually

inspect

cylinder

head

cylinder

block

rocker

C

Ner

front

chain

cover

oil

pan

and

all

other

outer

parts

for

oil

water

and

fuel

leaks

breakage

or

missing

parts

such

as

bolts

and

nuts

9

Check

piping

and

electrical

cir

cuits

for

deterioration

breakage

fit

tings

discontinuity

or

insulation

DISASSEMBLY

To

remove

engine

from

vehicle

refer

to

the

instructions

under

the

Engine

Removal

and

Installation

ER

section

I

Remove

transmission

from

en

gine

2

Remove

clutch

assembly

from

flywheeL

3

Thoroughly

drain

engine

oil

and

coolan

t

by

removing

drain

plugs

Store

engine

oil

and

coolant

if

they

are

to

be

used

again

4

Place

engine

assembly

on

engine

stand

I

Remove

cooling

fan

2

Remove

right

engine

mounting

bracket

3

Remove

oil

filter

with

Oil

Filter

Wrench

STI9320000

4

Remove

oil

pressure

swi

tch

5

Install

engine

attachment

to

cylinder

block

utilizing

bolt

holes

in

alternator

bracket

and

water

drain

hole

6

Set

engine

on

stand

Engine

Attachment

ST05260001

Engine

Stand

ST050I

SOOO

Page 50 of 537

EM410

Fig

EM

II

Engine

on

engine

land

Remove

oil

level

gauge

6

Remove

carburetor

from

intake

manifold

1

Disconnect

cylinder

block

to

P

C

V

valve

hose

at

P

C

V

valve

2

Disconnect

A

B

valve

to

E

G

R

passage

hose

at

E

G

R

passage

3

Disconnect

vacuum

tube

to

carburetor

hoses

white

and

yellow

at

vacuum

tube

4

Disconnect

fuel

hose

from

carburetor

5

Remove

dash

pot

bracket

from

intake

manifold

6

Remov

carburetor

attaching

bolts

and

remove

carburetor

assembly

and

gasket

7

Disconnect

distributor

high

ten

sion

cables

from

sparkplugs

8

Disconnect

vacuum

hose

from

distributor

and

remove

distributor

as

sembly

9

Disconnect

fuel

hose

from

fuel

pump

and

remove

fuel

and

vacuum

hoses

combined

from

cylinder

head

10

Remove

fuel

pump

assembly

from

cylinder

head

EM412

Fig

EM

12

Removing

fuel

pump

IJ

Remove

in

take

and

exhaust

manifold

assembly

from

cylinder

head

1

Disconnect

vacuum

hose

from

air

control

valve

and

remove

air

con

trol

valve

for

California

and

a

r

hoses

as

an

assembly

Engine

Mechanical

1

Air

control

valve

2

Distributor

EM531

Fig

EM

13

Removing

air

control

valve

Californio

model

2

Remove

carburetor

air

cleaner

bracket

3

Disconnect

vacuum

hose

from

E

G

R

valve

4

Remove

check

valve

from

air

gallery

pipe

5

Disconnect

E

G

R

tube

from

E

G

R

passage

and

exhaust

manifold

6

Remove

E

G

R

passage

and

E

G

R

valve

from

intake

manifold

I

E

G

R

passage

2

E

G

R

tube

Fig

EM

14

EM532

Removing

E

G

R

tube

and

passage

7

Remove

F

l

C

D

bracket

from

cylinder

head

if

so

equipped

8

Disconnect

vacuum

hoses

from

thermal

vacuum

valve

and

remove

thermostat

housing

and

gasket

from

cylinder

head

EM089

Fig

EM

15

Removing

thermostat

housing

EM

5

9

Remove

cylinder

block

to

P

C

V

valve

hose

blow

by

gas

hose

from

cylinder

block

10

Remove

manifold

attaching

bolts

and

remove

intake

and

exhaust

manifold

assembly

and

gasket

from

cylinder

head

Fig

EM

16

Removing

intake

and

exhaust

manifold

assembly

11

Remove

intake

and

exhaust

manifold

attaching

bolts

and

separate

intake

manifold

from

exhaust

mani

fold

12

Remove

air

gallery

pipes

from

exhaust

manifold

12

Remove

left

engi

e

mounting

bra

et

from

cylinder

blopk

13

Remove

air

pump

and

cooler

compressor

bracket

14

Remove

crankshaft

pulley

in

stalling

bolt

and

washer

and

then

remove

pulley

with

a

two

jaw

puller

15

Remove

water

pump

assembly

16

Remove

rocker

cover

17

R

emove

spark

plugs

18

Remove

fuel

pump

drive

earn

19

Remove

camshaft

sprocket

Refer

to

the

following

note

during

operation

when

removing

camshaft

sprocket

from

engine

installed

on

car

EM091

Fig

EM

17

Removing

cammaf

sprocket

Page 53 of 537

r

Engine

Mechanical

INSPECTION

AND

REPAIR

PREPARATION

FOR

INSPECTION

CYLINDER

HEAD

AND

VALVE

CHECKING

CYLINDER

HEAD

MATING

FACE

VALVE

ASSEMBLY

VALVE

SPRING

ROCKER

ARM

AND

VALVE

ROCKER

PIVOT

VALVE

GUIDE

VALVE

SEAT

INSERTS

CAMSHAFT

AND

CAMSHAFT

BEARING

CAMSHAFT

BEARING

CLEARANCE

VALVE

TIMING

CAMSHAFT

ALIGNMENT

CYLINDER

BLOCK

HOW

TO

MEASURE

CYLINDER

BORE

CYLINDER

BORING

PREPARATION

FOR

INSPECTI

N

I

Before

cleaning

check

for

signs

of

water

and

oil

leaks

in

cylinder

block

and

head

2

Clean

oil

carbon

deposits

and

sealant

from

an

parts

Remove

gasket

3

Clean

all

oil

holes

with

solvent

and

dry

with

compressed

air

Make

sure

that

they

are

not

restricted

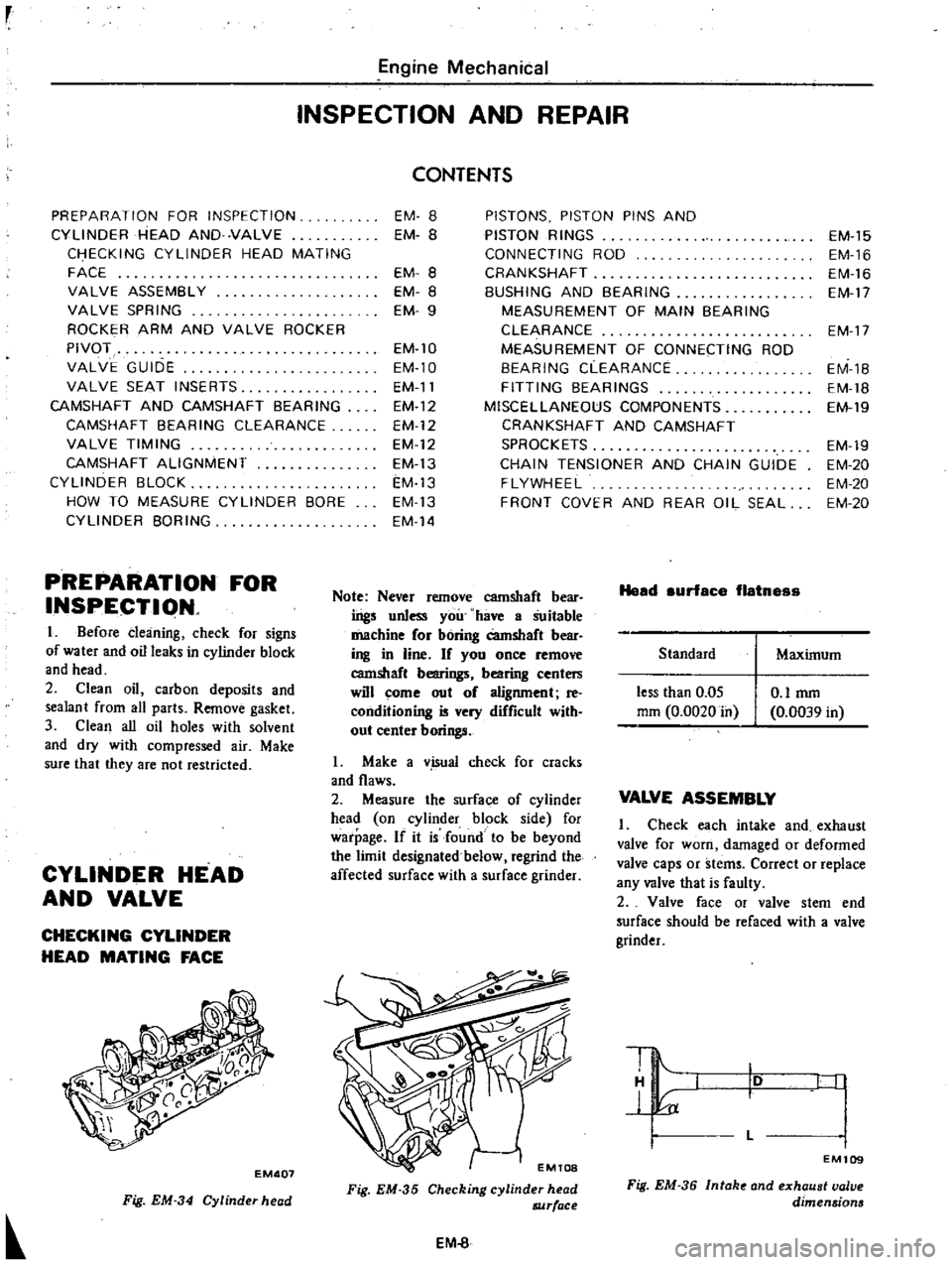

CYLINDER

HEAD

AND

VALVE

CHECKING

CYLINDER

HEAD

MATING

FACE

EM407

Fig

EM

34

Cylinder

head

CONTENTS

EM

8

EM

B

EM

8

EM

8

EM

9

EM

lO

EM

l0

EM

11

EM

12

EM

12

EM

12

EM

13

EM

13

EM

13

EM

14

PISTONS

PISTON

PINS

AND

PISTON

RINGS

CONNECTING

ROD

CRANKSHAFT

BUSHING

AND

BEARING

MEASUREMENT

OF

MAIN

BEARING

CLEARANCE

MEASUREMENT

OF

CONNECTING

ROD

BEARING

CLEARANCE

FITTING

BEARINGS

MISCELLANEOUS

COMPONENTS

CRANKSHAFT

AND

CAMSHAFT

SPROCKETS

CHAIN

TENSIONER

AND

CHAIN

GUIDE

FLYWHEEL

FRONT

COVER

AND

REAR

OIL

SEAL

Note

Never

remove

camshaft

bear

ings

unless

you

have

a

Suitable

machine

or

boring

Camshaft

bear

ing

in

line

If

you

once

remove

camshaft

bearings

bearing

centers

will

come

out

o

alignment

reo

conditioning

is

very

difficult

with

out

center

borings

L

Make

a

v

isual

check

for

cracks

and

flaws

2

Measure

the

surface

of

cylinder

head

on

cylinder

block

side

for

warpage

If

it

is

found

to

be

beyond

the

limit

designated

below

regrind

the

affected

surface

with

a

surface

grinder

Fig

EM

35

Checking

cylinder

head

8JJrface

EM

8

Head

surface

flatnes

Standard

less

than

0

05

mm

0

0020

in

O

lmm

0

0039

in

EM

15

EM

16

EM

16

EM

17

EM

17

EM

1B

EM

18

EM

19

EM

19

EM

20

EM

20

EM

20

Maximum

VALVE

ASSEMBLY

Check

each

intake

and

exhaust

valve

for

worn

damaged

or

deformed

valve

caps

or

stems

Correct

or

replace

any

valve

that

is

faulty

2

Valve

face

or

valve

stem

end

surface

should

be

refaced

with

a

valve

grinder

10

L

I

I

I

EM109

Fig

EM

36

Intak

and

exhaust

valve

dimensions

Page 57 of 537

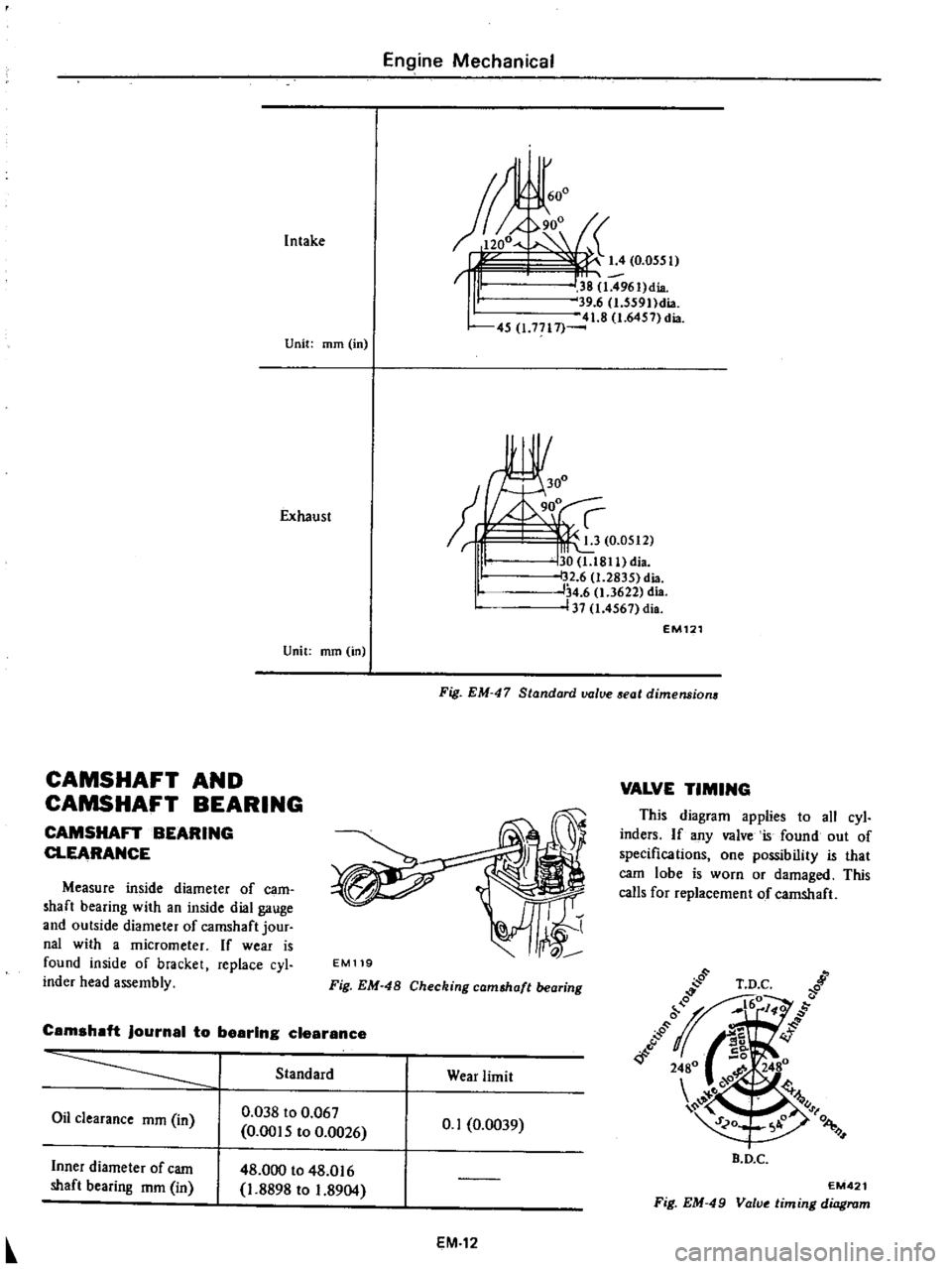

Intake

Engine

Mechanical

I

600

38

1

496I

dia

W

39

6

I

559Ildia

1

8

1

6457

dia

45

1

71l1

Unit

mm

in

Exhaust

30

30

1

l811

di

I

32

6

2835

dia

34

6

1

3622

dia

137

1

4567

dia

Unit

mm

m

CAMSHAFT

AND

CAMSHAFT

BEARING

CAMSHAnBEARING

CLEARANCE

Measure

inside

diameter

of

earn

haft

beating

with

an

inside

dial

gauge

and

outside

diameter

of

camshaft

jour

nal

with

a

micrometer

If

wear

is

found

inside

of

bracket

replace

cyl

inder

head

assembly

EM121

Fig

EM

47

Standard

value

aeat

dimensions

EM119

Fig

EM

48

Checking

cam

haft

bearing

Camshaft

journal

to

bearing

clearance

Standard

Wear

limit

Oil

clearance

mm

in

0

038

to

0

067

0

0015

to

0

0026

0

1

0

0039

Inner

diameter

of

earn

shaft

bearing

mm

in

48

000

to

48

016

1

8898

to

1

8904

EM

12

VALVE

TIMING

This

diagram

applies

to

all

cyl

inders

If

any

valve

is

found

out

of

specifications

one

possibility

that

carn

lobe

is

worn

or

damaged

This

calls

for

replacement

of

camshaft

B

D

C

EM421

Fig

EM

49

Value

timing

diagram

Page 60 of 537

Engine

Mechanical

Notes

a

When

measuring

clearance

slowly

pull

feeier

gaUge

siraight

upward

b

It

Is

reConUnended

that

piston

and

cylinder

be

hel

ted

to

200C

680F

PISTONS

PISTON

PINS

AND

PISTON

RINGS

I

Remove

carbon

from

piston

and

ring

grooves

with

a

ca

bon

scraper

and

a

curved

steel

wire

Clean

out

oil

slots

in

bottom

land

of

oil

ring

groove

2

Check

for

damage

scratches

and

wear

Replace

if

necessary

3

Meas1

1re

side

clearance

of

rings

in

ring

grooves

as

each

ring

is

installed

Side

clearance

should

be

as

follows

00

I

EM542

Fig

EM

58

Measuring

ring

gap

Notes

a

When

piston

ring

only

is

to

be

replaced

without

cylinder

bore

being

corrected

measure

gap

at

bottom

of

cylinder

where

wear

is

minor

b

Oversize

piston

rings

are

available

for

serv

ce

Oversize

0

5

mm

0

0197

in

and

1

0

mm

0

0394

in

5

Measure

piston

pin

hole

in

rela

tion

to

outer

diameter

of

pin

If

wear

exceeds

limit

replace

each

piston

pin

together

with

the

piston

on

which

it

is

installed

6

Determine

the

fitting

of

piston

pin

into

piston

pin

hole

to

such

an

extent

that

it

can

be

finger

pressed

at

room

temperature

This

piston

pin

must

be

a

tight

pre

s

fit

into

connect

ing

rod

t

J

f

rr

11

1

I

EM541

Fig

EM

56

Measuring

piaton

fit

in

cylinder

Fig

EM

57

Measuring

piston

ring

side

clearance

Side

clearance

Unit

mm

in

I

Second

ring

I

I

Wear

limit

Standard

0

040

to

0

073

0

0016

to

0

0029

0

030

to

0

070

I

0

0012

to

0

0028

I

Top

ring

0

1

0

0039

Oil

ring

f

feeler

gauge

Ring

should

be

placed

to

diameter

at

upper

or

lower

limit

of

ring

travel

4

Push

ring

into

cylinder

with

pis

ton

so

as

to

place

it

squarely

in

cylinder

measure

ring

gap

with

a

EM131

Ring

gap

Fig

EM

59

Piston

pin

fitting

Unit

rom

in

Standard

Wear

limit

0

25

to

0

40

0

0098

to

0

0157

0

30

to

0

50

0

0

II

8

to

0

0197

Top

ring

Second

ring

1

0

0

0394

EM132

0

30

to

0

90

0

0118

to

0

0354

Oil

ring

Fig

EM

60

Measuring

pi

ton

pin

diamet

EM

15