check engine DODGE AVENGER 2008 User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: AVENGER, Model: DODGE AVENGER 2008Pages: 467, PDF Size: 7.16 MB

Page 180 of 467

CAUTION!The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures and

warning have been established for the tire size

equipped on your vehicle. Undesirable system opera-

tion or sensor damage may result when using re-

placement equipment that is not of the same size,

type, and/or style. Aftermarket wheels can cause

sensor damage. Do not use aftermarket tire sealants

or balance beads if your vehicle is equipped with a

TPMS, as damage to the sensors may result.

(Refer to ªTire Inflation Pressuresº under ªTires Ð Gen-

eral Informationº and to ªTire Pressure Monitor System

(TPMS)º in Section 5 of this manual for more informa-

tion). 25. Malfunction Indicator Light

This light is part of an onboard diagnostic system

called OBD that monitors emissions, engine, and

automatic transaxle control systems. The light

will illuminate when the key is in the ON/RUN position

before engine start. If the bulb does not come on when

turning the key from LOCK/OFF to ON/RUN, have the

condition checked promptly.

Certain conditions such as a loose or missing gas cap,

poor fuel quality, etc. may illuminate the light after

engine start. The vehicle should be serviced if the light

stays on through several of your typical driving cycles. In

most situations the vehicle will drive normally and will

not require towing.

If the Malfunction Indicator Light flashes when the

engine is running, serious conditions may exist that178 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 280 of 467

BRAKE SYSTEM

Your vehicle is equipped with power assisted brakes as

standard equipment. In the event power assist is lost for

any reason (i.e., repeated brake applications with the

engine off) the brakes will still function. However, the

effort required to brake the vehicle will be much greater

than that required with the power system operating.

WARNING!Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency. This light monitors various brake functions,

including brake fluid level and parking brake

application. If the brake light turns on, it may

indicate that the parking brake is applied, that

the brake fluid level is low, or that there is a problem with

the anti-lock brake system.

WARNING!Driving a vehicle with the brake light on is danger-

ous. A significant decrease in braking performance or

vehicle stability during braking may occur. It will

take you longer to stop the vehicle or will make your

vehicle harder to control. You could have an accident.

Have the vehicle checked immediately.278 STARTING AND OPERATING

Page 346 of 467

Automatic Transaxle

The DRIVE range can be selected when towing. How-

ever, if frequent shifting occurs while in this range, third

gear for a four-speed automatic and the fifth gear for a

six-speed AutoStick t should be selected.

NOTE: Using third or fifth instead of DRIVE while

operating the vehicle under heavy operating conditions,

will improve performance and extend transaxle life by

reducing excessive shifting and heat build-up. This ac-

tion will also provide better engine braking.

If you REGULARLY TOW a trailer for more than 45

minutes of continuous operation, then change the auto-

matic transaxle fluid and filter according to the interval

specified for ªpolice, taxi, fleet, or frequent trailer tow-

ingº in the ªMaintenance Scheduleº in this manual.

NOTE: Check the four-speed automatic transaxle fluid

level before towing. AutoStick t sixÐspeed transmission is sealed and the fluid level cannot be checked. See your

authorized dealership service center for assistance.

Electronic Speed Control Ð (If Equipped)

² Don't use in hilly terrain or with heavy loads.

² When using the speed control, if you experience speed

drops greater than 10 mph (16 km/h), disengage until

you can get back to cruising speed.

² Use speed control in flat terrain and with light loads to

maximize fuel efficiency.

Cooling System

To reduce potential for engine and transaxle overheating,

take the following actions:

² City Driving

When stopped for short periods of time, put transaxle in

neutral and increase engine idle speed.344 STARTING AND OPERATING

Page 360 of 467

11. Check the tire pressure as soon as possible. Correct

pressure as required.

JUMP-STARTING PROCEDURES DUE TO A LOW

BATTERY

Jump-starting remote battery terminals are located under

the hood.

The battery is stored between the left front headlight

assembly and the left front wheel splash shield. Access is

through the splash shield. WARNING! ² Take care to avoid the radiator cooling fan whenever the

hood is raised. It can start anytime the ignition switch is

on. You can be hurt by the fan.

² Do not attempt to push or tow your vehicle to get it

started. Vehicles equipped with an automatic transaxle

cannot be started this way. Unburned fuel could enter

the catalytic converter and once the engine has started,

ignite and damage the converter and vehicle. If the

vehicle has a discharged battery, booster cables may be

used to obtain a start from another vehicle. This type of

start can be dangerous if done improperly, so follow this

procedure carefully.

² Do not use a booster battery or any other booster source

with an output that exceeds 12 volts.

² During cold weather when temperatures are below

freezing point, electrolyte in a discharged battery may

freeze. Do not attempt jump-starting because the battery

could rupture or explode. The battery temperature must

be brought up above freezing point before attempting

jump-start.358 WHAT TO DO IN EMERGENCIES

Page 374 of 467

RESET button to turn off the message. If the problem

persists, the message will appear the next time the

vehicle is started. This might indicate a damaged cap. If

the problem is detected twice in a row, the system will

turn on the MIL. Resolving the problem will turn the MIL

light off.

EMISSIONS INSPECTION AND MAINTENANCE

PROGRAMS

In some localities, it may be a legal requirement to pass

an inspection of this vehicle's emissions control system.

Failure to pass could prevent vehicle registration.

For states that require an Inspection and Mainte-

nance (I/M), this check verifies the Malfunction

Indicator Light (MIL) is functioning and is not on

when the engine is running, and that the OBD II system

is ready for testing. Normally, the OBD II system will be ready. The OBD II

system may not be ready if the vehicle was recently

serviced, recently had a dead battery, or a battery replace-

ment. If the OBD II system should be determined not

ready for the I/M test, the vehicle may fail the test.

This vehicle has a simple ignition key-actuated test,

which you can use prior to going to the test station. To

check if this vehicle's OBD II system is ready, you must

do the following:

1. Insert the ignition key into the ignition switch.

2. Turn the ignition to the ON position, but do not crank

or start the engine.

3. If you crank or start the engine, you will have to start

this test over.

4. As soon as you turn the ignition key to the ON

position, you will see the MIL symbol come on as part of

a normal bulb check.372 MAINTAINING YOUR VEHICLE

Page 375 of 467

5. Approximately 15 seconds later, one of two things will

happen:

a. The MIL will flash for about 10 seconds and then

return to being fully illuminated until you turn OFF

the ignition key or start the engine. This means that the

vehicle's OBD II system is not ready and you should

not proceed to the I/M station.

b. The MIL will not flash at all and will remain fully

illuminated until you turn OFF the ignition key or start

the engine. This means that the vehicle's OBD II

system is ready, and you can proceed to the I/M

station.

If the OBD II system is not ready, you should see an

authorized dealer or repair facility. If this vehicle was

recently serviced or had a battery failure or replacement,

you may need to do nothing more than drive the vehicle as you normally would in order for the OBD II system to

update. A recheck with the above test routine may then

indicate that the system is now ready.

Regardless of whether the vehicle's OBD II system is

ready or not ready, if the MIL is illuminated during

normal vehicle operation, you should have the vehicle

serviced before going to the I/M station. The I/M station

can fail the vehicle because the MIL is on with the engine

running.

REPLACEMENT PARTS

Use of genuine Mopar t parts for normal/scheduled

maintenance and repairs is highly recommended to en-

sure the designed performance. Damage or failures

caused by the use of non-Mopar t parts for maintenance

and repairs will not be covered by the manufacturer's

warranty. MAINTAINING YOUR VEHICLE 373

7

Page 376 of 467

AUTHORIZED DEALER SERVICE

Your authorized dealer has the qualified service person-

nel, special tools, and equipment to perform all service

operations in an expert manner. Service manuals are

available which include detailed service information for

your vehicle. Refer to these service manuals before

attempting any procedure yourself.

NOTE: Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

WARNING!You can be badly injured working on or around a

motor vehicle. Only do service work for which you

have the knowledge and the proper equipment. If you

have any doubt about your ability to perform a service

job, take your vehicle to a competent mechanic. MAINTENANCE PROCEDURES

The pages that follow contain the required maintenance

services determined by the engineers who designed your

vehicle.

Besides the maintenance items for which there are fixed

maintenance intervals, there are other items that should

operate satisfactorily without periodic maintenance.

However, if a malfunction of these items does occur, it

could adversely affect the engine or vehicle performance.

These items should be inspected if a malfunction is

observed or suspected.

ENGINE OIL

Checking Oil Level

To assure proper engine lubrication, the engine oil must

be maintained at the correct level. Check the oil level at

regular intervals, such as every fuel stop.374 MAINTAINING YOUR VEHICLE

Page 377 of 467

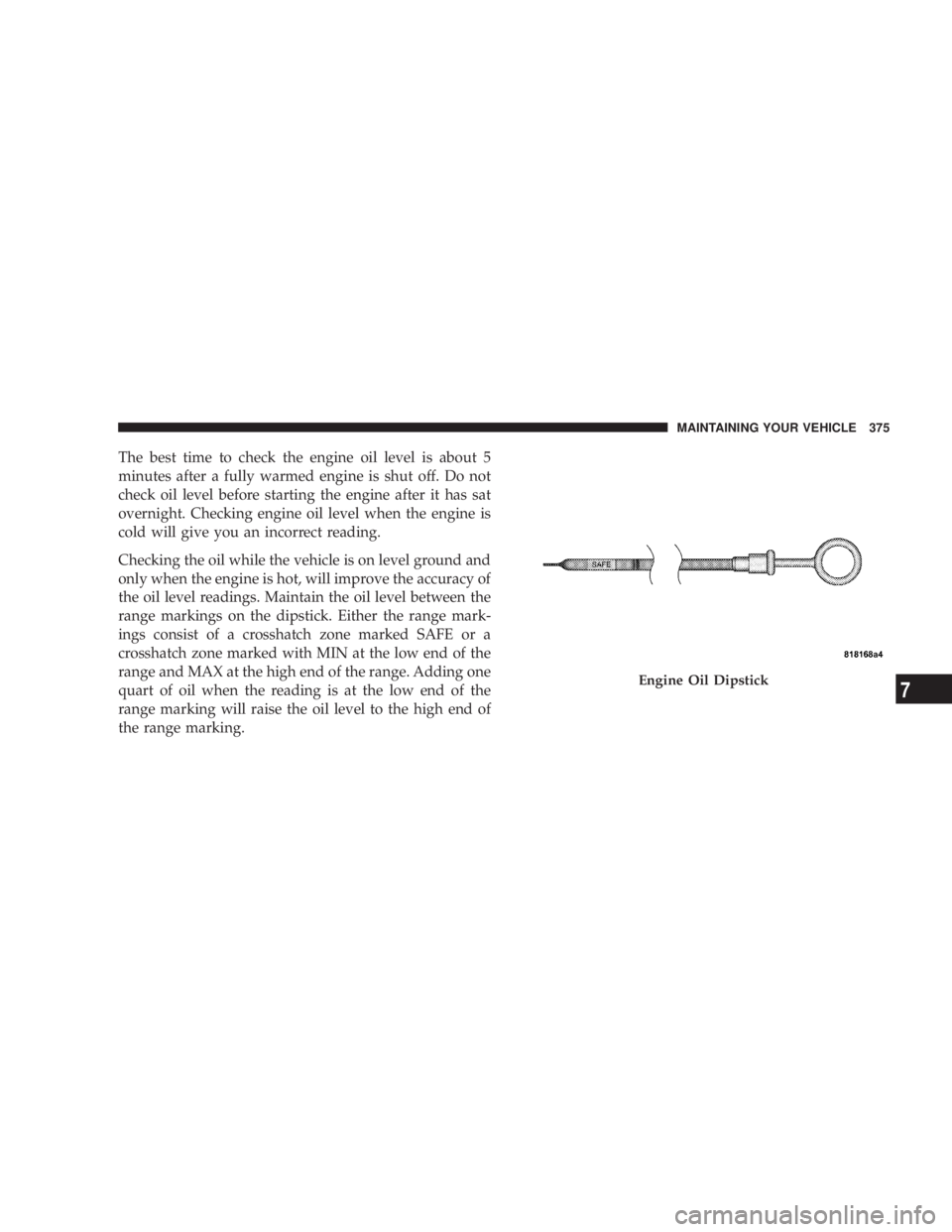

The best time to check the engine oil level is about 5

minutes after a fully warmed engine is shut off. Do not

check oil level before starting the engine after it has sat

overnight. Checking engine oil level when the engine is

cold will give you an incorrect reading.

Checking the oil while the vehicle is on level ground and

only when the engine is hot, will improve the accuracy of

the oil level readings. Maintain the oil level between the

range markings on the dipstick. Either the range mark-

ings consist of a crosshatch zone marked SAFE or a

crosshatch zone marked with MIN at the low end of the

range and MAX at the high end of the range. Adding one

quart of oil when the reading is at the low end of the

range marking will raise the oil level to the high end of

the range marking. Engine Oil Dipstick MAINTAINING YOUR VEHICLE 375

7

Page 387 of 467

CAUTION!The A/C Air Filter is labeled with an arrow to

indicate airflow direction through the filter. Failure

to install the filter properly will result in the need to

replace it more often.

7. Reinstall the glove box door dampener and glove box.

POWER STEERING

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises are

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through a certified

DaimlerChrysler dealership. WARNING!Fluid level should be checked on a level surface and

with the engine off to prevent injury from moving

parts and to ensure accurate fluid level reading. Do

not overfill. Use only manufacturers recommended

power steering fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to ªFluids, Lubricants, and Genuine

Partsº in this section for the correct fluid type.

FRONT SUSPENSION

There are two front suspension lower ball joints that are

permanently lubricated. Inspect these ball joints when

other maintenance is performed. A damaged seal and the

corresponding potentially damaged ball joint must be

replaced. MAINTAINING YOUR VEHICLE 385

7

Page 389 of 467

Keep the blade rubber out of contact with petroleum

products such as engine oil, gasoline, etc.

NOTE: Always refer to the wiper blade packaging for

specific installation instructions. Many wiper blade re-

placements fit multiple vehicles.

WINDSHIELD WASHERS

NOTE: Refer to the appropriate ªEngine Compartmentº

diagram in Section 7 for the location of the windshield

washer fluid reservoir.

The fluid reservoir for the windshield washers is located

in the engine compartment. Be sure to check the fluid

level in the reservoir at regular intervals. Fill the reservoir

with windshield washer solvent (not radiator antifreeze)

and operate the system for a few seconds to flush out the

residual water. WARNING!Commercially available windshield washer solvents

are flammable. They could ignite and burn you. Care

must be exercised when filling or working around

the washer solution.

EXHAUST SYSTEM

The best protection against carbon monoxide entry into

the vehicle body is a properly maintained engine exhaust

system.

If you notice a change in the sound of the exhaust system

or if exhaust fumes can be detected inside the vehicle or

when the underside or rear of the vehicle is damaged,

have a competent technician inspect the complete ex-

haust system and adjacent body areas for broken, dam-

aged, deteriorated, or mispositioned parts. Open seams

or loose connections could permit exhaust fumes to seep MAINTAINING YOUR VEHICLE 387

7