wheel DODGE AVENGER 2011 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2011, Model line: AVENGER, Model: DODGE AVENGER 2011 2.GPages: 494, PDF Size: 3.37 MB

Page 380 of 494

NOTE:The jack handle attaches to the side of the jack

with two attachment points. When the jack is partially

expanded, the tension between the two attachment

points holds the jack handle in place. 2. Loosen, but do not remove, the wheel nuts by turning

them to the left one turn while the wheel is still on the

ground.

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in Step 3.

3. There is a front and rear jacking location on each side

of the vehicle.

Removing Jack Handle From Jack

378 WHAT TO DO IN EMERGENCIES

Page 381 of 494

4. Turn the jack screw to the left until the jack can be

placed under the jacking location. Once the jack is

positioned, turn the jack screw to the right until the jack

head is properly engaged with the lift area closest to the

wheel to be changed. Do not raise the vehicle until you

are sure the jack is securely engaged.

Front Jacking LocationRear Jacking Location6

WHAT TO DO IN EMERGENCIES 379

Page 382 of 494

WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

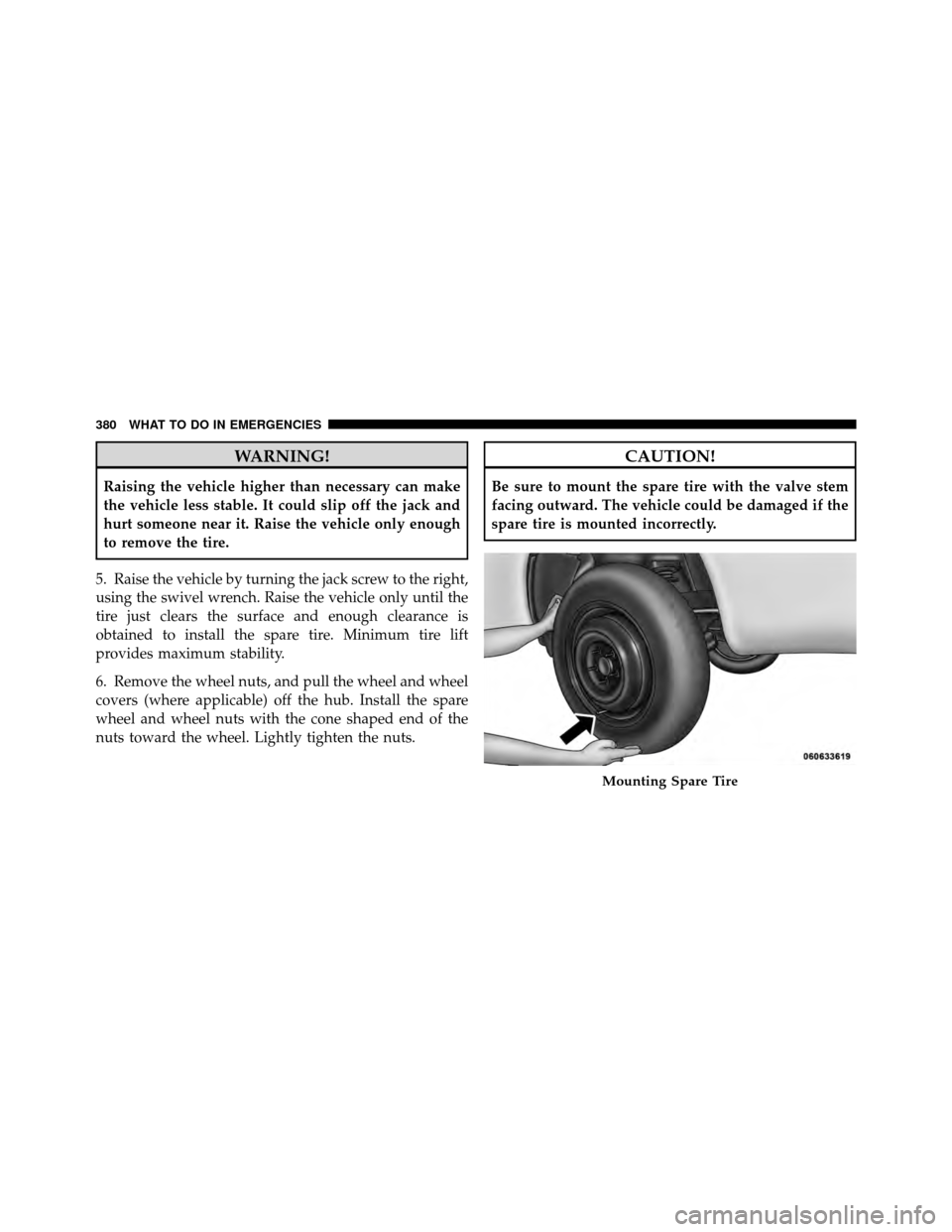

5. Raise the vehicle by turning the jack screw to the right,

using the swivel wrench. Raise the vehicle only until the

tire just clears the surface and enough clearance is

obtained to install the spare tire. Minimum tire lift

provides maximum stability.

6. Remove the wheel nuts, and pull the wheel and wheel

covers (where applicable) off the hub. Install the spare

wheel and wheel nuts with the cone shaped end of the

nuts toward the wheel. Lightly tighten the nuts.

CAUTION!

Be sure to mount the spare tire with the valve stem

facing outward. The vehicle could be damaged if the

spare tire is mounted incorrectly.

Mounting Spare Tire

380 WHAT TO DO IN EMERGENCIES

Page 383 of 494

WARNING!

•To avoid the risk of forcing the vehicle off the jack,

do not tighten the wheel nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in personal injury.

•To avoid possible personal injury, handle the

wheel covers with care to avoid contact with any

sharp edges.

7. Lower the vehicle by turning the jack screw to the left.

8. Finish tightening the nuts. Push down on the wrench

while at the end of the handle for increased leverage.

Tighten the lug nuts in a star pattern until each nut has

been tightened twice. The correct wheel nut torque is

100 ft lbs (135 N·m). If you doubt that you have tightened

the nuts correctly, have them checked with a torque

wrench by your authorized dealer or at a service station. 9. Remove the wheel blocks and lower the jack until it is

free. Reassemble the lug wrench to the jack assembly and

stow it in the spare tire area. Secure the assembly using

the means provided.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided.

10. Place the deflated (flat) tire in the cargo area and have

the tire repaired or replaced as soon as possible.

11. Check the tire pressure as soon as possible. Correct

the tire pressure as required.

6

WHAT TO DO IN EMERGENCIES 381

Page 384 of 494

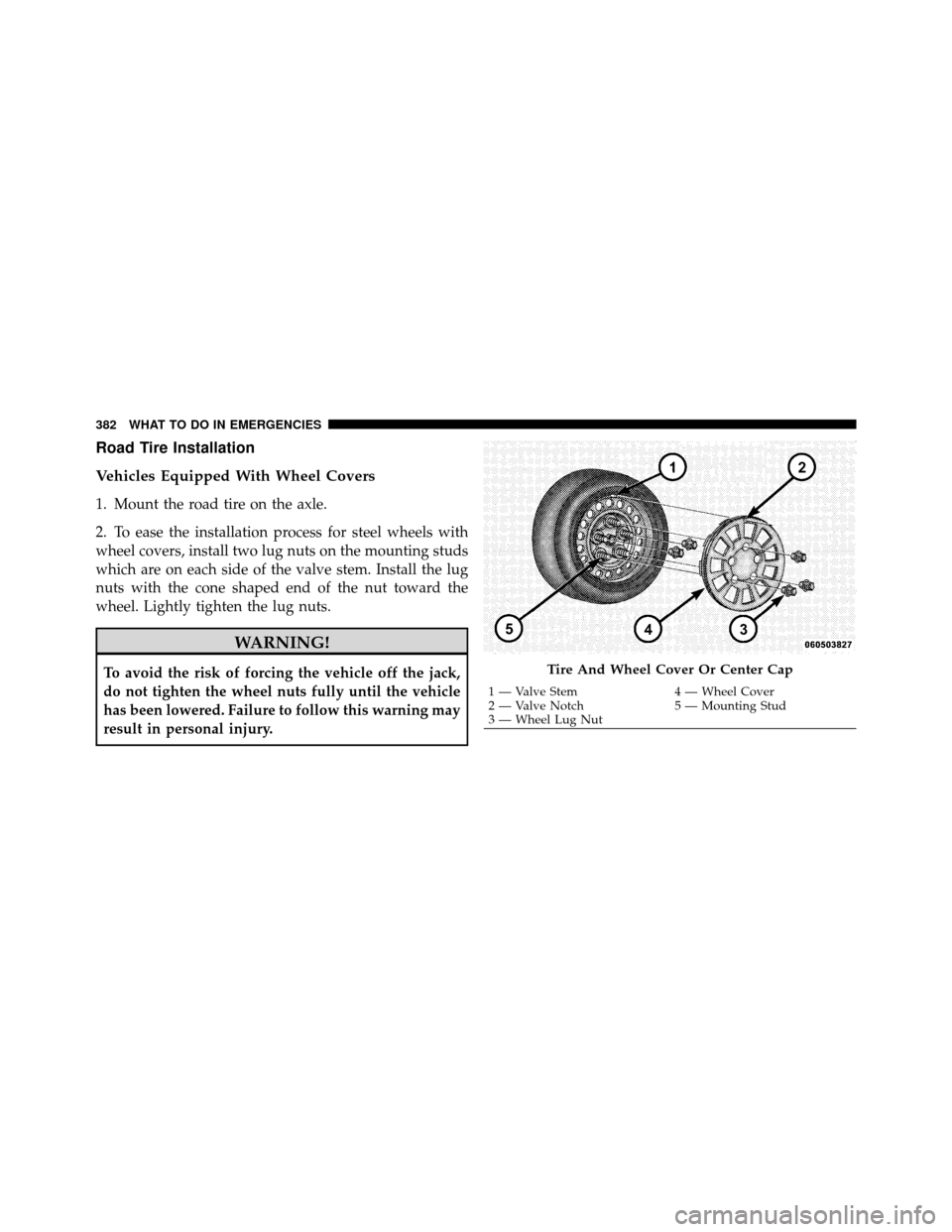

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with

wheel covers, install two lug nuts on the mounting studs

which are on each side of the valve stem. Install the lug

nuts with the cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the wheel nuts fully until the vehicle

has been lowered. Failure to follow this warning may

result in personal injury.Tire And Wheel Cover Or Center Cap

1 — Valve Stem4 — Wheel Cover

2 — Valve Notch 5 — Mounting Stud

3 — Wheel Lug Nut

382 WHAT TO DO IN EMERGENCIES

Page 385 of 494

3. Align the valve notch in the wheel cover with the

valve stem on the wheel. Install the cover by hand,

snapping the cover over the two lug nuts. Do not use a

hammer or excessive force to install the cover.

4. Install the remaining lug nuts with the cone shaped

end of the nut toward the wheel. Lightly tighten the lug

nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the wheel nuts fully until the vehicle

has been lowered. Failure to follow this warning may

result in personal injury.

5. Lower the vehicle to the ground by turning the jack

handle counterclockwise. 6. Finish tightening the lug nuts. Push down on the

wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until each

nut has been tightened twice. The correct tightness of

each lug nut is 100 ft/lbs (135 N·m). If in doubt about the

correct tightness, have them checked with a torque

wrench by your authorized dealer or service station.

7. After 25 miles (40 km) check the lug nut torque with a

torque wrench to ensure that all lug nuts are properly

seated against the wheel.

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped

end of the nut toward the wheel. Lightly tighten the lug

nuts.

6

WHAT TO DO IN EMERGENCIES 383

Page 386 of 494

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the wheel nuts fully until the vehicle

has been lowered. Failure to follow this warning may

result in personal injury.

3. Lower the vehicle to the ground by turning the jack

handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the

wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until each

nut has been tightened twice. The correct tightness of

each lug nut is 100 ft/lbs (135 N·m). If in doubt about the

correct tightness, have them checked with a torque

wrench by your authorized dealer or service station. 5. After 25 miles (40 km) check the lug nut torque with a

torque wrench to ensure that all lug nuts are properly

seated against the wheel.

JUMP-STARTING

If your vehicle has a discharged battery it can be jump-

started using a set of jumper cables and a battery in

another vehicle or by using a portable battery booster

pack. Jump-starting can be dangerous if done improperly

so please follow the procedures in this section carefully.

NOTE:

When using a portable battery booster pack

follow the manufacturer’s operating instructions and

precautions.

384 WHAT TO DO IN EMERGENCIES

Page 387 of 494

CAUTION!

Do not use a portable battery booster pack or any

other booster source with a system voltage greater

than 12 Volts or damage to the battery, starter motor,

alternator or electrical system may occur.

WARNING!

Do not attempt jump-starting if the battery is frozen.

It could rupture or explode and cause personal injury.

Preparations For Jump-Start

The battery in your vehicle is located between the left

front headlight assembly and the left front wheel splash

shield. To allow jump-starting there are remote battery

posts located on the left side of the engine compartment.

Remote Battery Posts

1 — Remote Positive(+) Post (covered with protective cap)

2 — Remote Negative (-) Post

6

WHAT TO DO IN EMERGENCIES 385

Page 391 of 494

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or snow, it

can often be moved by a rocking motion. Turn your

steering wheel right and left to clear the area around the

front wheels. Then shift back and forth between DRIVE

and REVERSE. Using minimal accelerator pedal pressure

to maintain the rocking motion, without spinning the

wheels, is most effective.

CAUTION!

Racing the engine or spinning the wheels may lead to

transmission overheating and failure. Allow the en-

gine to idle with the shift lever in NEUTRAL for at

least one minute after every five rocking-motion

cycles. This will minimize overheating and reduce

the risk of transmission failure during prolonged

efforts to free a stuck vehicle.NOTE:

If your vehicle is equipped with Electronic

Stability Control (ESC), turn the system to Partial OFF

before attempting to “rock” the vehicle. Refer to “Elec-

tronic Brake Control” in “Starting and Operating” for

further information.

CAUTION!

•When “rocking” a stuck vehicle by moving be-

tween DRIVE and REVERSE, do not spin the

wheels faster than 15 mph (24 km/h), or drivetrain

damage may result.

•Revving the engine or spinning the wheels too fast

may lead to transmission overheating and failure.

It can also damage the tires. Do not spin the

wheels above 30 mph (48 km/h) while in gear (no

transmission shifting occurring).6

WHAT TO DO IN EMERGENCIES 389

Page 392 of 494

WARNING!

Fast spinning tires can be dangerous. Forces gener-

ated by excessive wheel speeds may cause damage, or

even failure, of the axle and tires. A tire could

explode and injure someone. Do not spin your vehi-

cle’s wheels faster than 30 mph (48 km/h) or for

longer than 30 seconds continuously without stop-

ping when you are stuck and do not let anyone near

a spinning wheel, no matter what the speed.

SHIFT LEVER OVERRIDE

If a malfunction occurs and the shift lever cannot be

moved out of the PARK position, you can use the

following procedure to temporarily move the shift lever:

1. Firmly apply the parking brake.

2. Remove the cupholder liner.

3. Turn the ignition switch to the ON/RUN position

without starting the engine.

4. Press and maintain firm pressure on the brake pedal.

5. Insert a screwdriver or similar tool into the hole at the

front of the cupholder and push and hold the override

release lever forward.

6. Move the shift lever into the NEUTRAL position.

7. The vehicle may then be started in NEUTRAL.

8. Reinstall the cupholder liner.

390 WHAT TO DO IN EMERGENCIES