maintenance schedule DODGE CALIBER 2006 1.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: CALIBER, Model: DODGE CALIBER 2006 1.GPages: 322, PDF Size: 5.99 MB

Page 1 of 322

TABLE OF CONTENTSSECTIONPAGE

1

INTRODUCTION.............................................................3

2

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE...........................7

3

UNDERSTANDING THE FEATURES OF YOUR VEHICLE............................63

4

UNDERSTANDING YOUR INSTRUMENT PANEL.................................105

5

STARTING AND OPERATING................................................171

6

WHAT TO DO IN EMERGENCIES.............................................227

7

MAINTAINING YOUR VEHICLE..............................................239

8

MAINTENANCE SCHEDULES................................................281

9

IF YOU NEED CONSUMER ASSISTANCE.......................................299

10

INDEX...................................................................307

1

2

3

4

5

6

7

8

9

10

Page 210 of 322

Snow tires generally have lower speed ratings than what

was originally equipped with your vehicle and should

not be operated at sustained speeds over 75 mph (120

km/h).

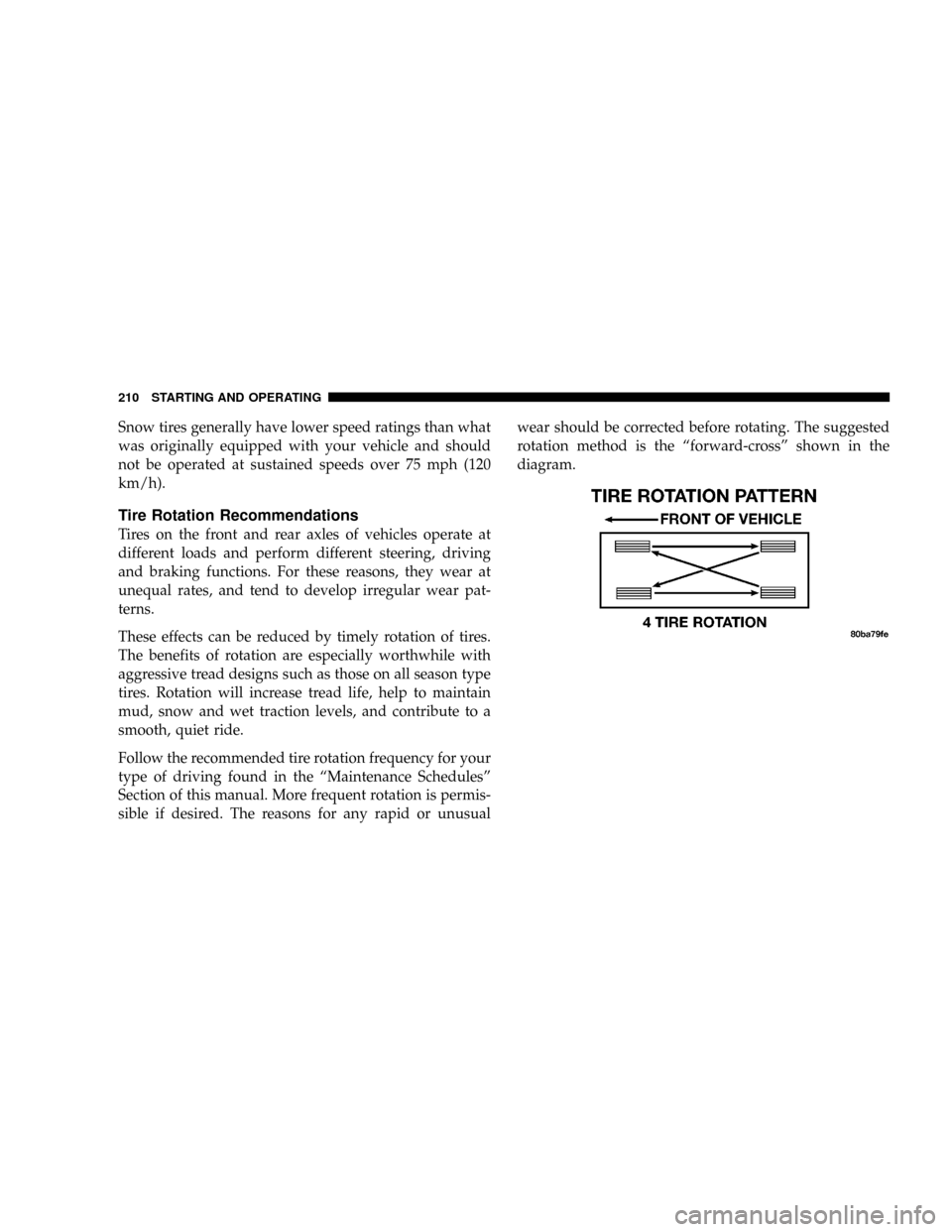

Tire Rotation Recommendations

Tires on the front and rear axles of vehicles operate at

different loads and perform different steering, driving

and braking functions. For these reasons, they wear at

unequal rates, and tend to develop irregular wear pat-

terns.

These effects can be reduced by timely rotation of tires.

The benefits of rotation are especially worthwhile with

aggressive tread designs such as those on all season type

tires. Rotation will increase tread life, help to maintain

mud, snow and wet traction levels, and contribute to a

smooth, quiet ride.

Follow the recommended tire rotation frequency for your

type of driving found in the ªMaintenance Schedulesº

Section of this manual. More frequent rotation is permis-

sible if desired. The reasons for any rapid or unusualwear should be corrected before rotating. The suggested

rotation method is the ªforward-crossº shown in the

diagram.

210 STARTING AND OPERATING

Page 244 of 322

b. The MIL will not flash at all and will remain fully

illuminated until you turn off the ignition key or

start the engine. This means that your vehicle's OBD

system isreadyand you can proceed to the I/M

station.

If your OBD system isnot ready,you should see your

authorized dealer or repair facility. If your vehicle was

recently serviced or had a battery failure or replacement,

you may need to do nothing more than drive your

vehicle as you normally would in order for your OBD

system to update. A recheck with the above test routine

may then indicate that the system is now ready.

Regardless of whether your vehicle's OBD system is

ready or not ready, if the MIL symbol is illuminated

during normal vehicle operation, you should have your

vehicle serviced before going to the I/M station. The I/M

station can fail your vehicle because the MIL symbol is on

with the engine running.

REPLACEMENT PARTS

Use of genuine Mopartparts for normal/scheduled

maintenance and repairs is highly recommended to in-

sure the designed performance. Damage or failures

caused by the use of non-Mopartparts for maintenance

and repairs will not be covered by the manufacturer's

warranty.

DEALER SERVICE

Your dealer has the qualified service personnel, special

tools and equipment to perform all service operations in

an expert manner. Service Manuals are available which

include detailed service information for your vehicle.

Refer to these manuals before attempting any procedure

yourself.

NOTE:Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

244 MAINTAINING YOUR VEHICLE

Page 246 of 322

Checking the oil while the vehicle is on level ground and

only when the engine is hot, will improve the accuracy of

the oil level readings. Maintain the oil level between the

range markings on the dipstick. The range markings will

consist of a crosshatch zone that says SAFE or a cross-

hatch zone that says MIN at the low end of the range and

MAX at the high end of the range. Adding one quart of

oil when the reading is at the low end of the indicated

range will result in the oil level at the full end of the

indicator range.

CAUTION!

Do not overfill the engine. Overfilling the engine as

indicated by the range markings, as described above,

on the engine oil dipstick will cause oil aeration,

which can lead to loss of oil pressure and an increase

in oil temperature. This could damage your engine.

Change Engine Oil

Road conditions and your kind of driving affects the

interval at which your oil should be changed. Check the

following list to decide if any apply to you.

²Day and night temperatures are below 32ÉF (0ÉC).

²Stop and Go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 10 miles (16 km).

²More than 50% of your driving is at sustained high

speeds during hot weather, above 90ÉF (32ÉC).

²Trailer towing.

²Taxi, Police or delivery service (commercial service).

²Off-Road or desert operation.

NOTE:IfANYof these apply to you then change your

engine oil every 3,000 miles (5 000 km) or 3 months,

whichever comes first, and follow schedule ªBÐAll

Enginesº of the9Maintenance Schedules9section of this

manual.

246 MAINTAINING YOUR VEHICLE

Page 247 of 322

If none of these apply to you, then change your engine

oil at every interval shown on schedule ªAº in the

maintenance schedule section of this manual.

NOTE:

Under no circumstances should oil change

intervals exceed 6000 miles (10 000 km) or 6 months

whichever comes first.

Engine Oil Selection - Non ACEA Categories

For best performance and maxi-

mum protection under all types of

operating conditions, the manu-

facturer only recommends engine

oils that are API certified and

meet the requirements of

DaimlerChrysler Material Stan-

dard MS-6395. Use Mopar or an

equivalent oil meeting the specifi-

cation MS-6395. These Certified Oils exhibit the Ameri-

can Petroleum Institute (API) Engine Oil Certification

Symbol on the front of the oil container. This symbol

means that the oil has been tested, certified and licensed

by the American Petroleum Institute (API) to meet the oil

standards required by the manufacturers.

Engine Oil Selection - ACEA Categories

For countries that use the ACEA European Oil Categories

for Service Fill Oils, use engine oils that meet the require-

ments of ACEA A1/B1, A3/B4 or A3/B3.

Engine Oil Viscosity (SAE Grade)

SAE 5W-20 engine oil is recommended for all operating

temperatures. This engine oil improves low tempera-

ture starting and vehicle fuel economy. Your engine oil

filler cap also states the recommended engine oil vis-

cosity grade for your engine.

Lubricants which do not have both, the engine oil certi-

fication mark and the correct SAE viscosity grade num-

ber should not be used.

Synthetic Engine Oils

There are a number of engine oils being promoted as

either synthetic or semi-synthetic. If you chose to use

such a product, use only those oils that are certified by

the American Petroleum Institute (API) to display the

symbol on the front of the container or the proper ACEA

category and show the recommended SAE viscosity

grade. Follow the maintenance schedule that describes

your driving type.

MAINTAINING YOUR VEHICLE 247

7

Page 249 of 322

Selecting Engine Oil

Viscosity:Grade 5W-40 is recommended.

Oil Quality:Use only Synthetic Diesel engine oils con-

forming to the most current version of ACEA A3/B4 or

A3/B4/C3.

Drive Belt Ð Check Condition

At the mileage shown in the maintenance schedules,

check the drive belt for condition.

Inspect the drive belt for evidence of cuts, cracks, or

glazing and replace belt if any sign of damage which

could result in belt failure.

The belt is self-tensioning and will not need adjustment.

Spark Plugs

Spark plugs must fire properly to assure engine perfor-

mance and emission control. New plugs should be in-

stalled at the specified mileage. The entire set should be

replaced if there is any malfunction due to a faulty spark

plug. Refer to the Engine data Label located under the

hood for the proper type of spark plug for use in your

vehicle.

Ignition Wiring System

The ignition cables should be kept clean and properly

connected. Terminals should be fully seated. Cracked,

damaged, or faulty cables should be replaced.

Catalytic Converter

The catalytic converter requires the use of unleaded fuel

only. Leaded gasoline will destroy the effectiveness of the

catalyst as an emission control device.

Under normal operating conditions, the catalytic con-

verter will not require maintenance. However, it is im-

portant to keep the engine properly tuned to assure

proper catalyst operation and prevent possible catalyst

damage.

MAINTAINING YOUR VEHICLE 249

7

Page 251 of 322

Check ventilation hose for indication of damage or

plugging deposits. Replace if necessary.

Fuel Filter

A plugged fuel filter can cause hard starting or limit the

speed at which a vehicle can be driven. Should an

excessive amount of dirt accumulate in the fuel tank,

frequent filter replacement may be necessary. The fuel

filters are located inside the fuel tank. See your dealer for

service.

Air Cleaner Element (Filter)

Under normal driving conditions, replace the filter at the

intervals shown on Schedule ªAº. If, however, you drive

the vehicle frequently under dusty or severe conditions,

the filter element should be inspected periodically and

replaced if necessary at the intervals shown on Schedule

ªBº.

WARNING!

The air cleaner can provide a measure of protection

in the case of engine backfire. Do not remove the air

cleaner unless such removal is necessary for repair or

maintenance. Make sure that no one is near the

engine compartment before starting the vehicle with

the air cleaner removed. Failure to do so can result in

serious personal injury.

Maintenance-Free Battery

You will never have to add water, nor is periodic main-

tenance required.

CAUTION!

When servicing the battery, always reinstall the

battery thermowrap. The thermowrap provides bat-

tery heat protection and will extend overall battery

life. Failure to reinstall the thermowrap can result in

evaporative loss of the battery fluid.

MAINTAINING YOUR VEHICLE 251

7

Page 256 of 322

Cooling System

WARNING!

²When working near the radiator cooling fan, dis-

connect the fan motor lead or turn the ignition

switch to the OFF position. The fan is temperature

controlled and can start at any time the ignition

switch is in the ON position.

²You or others can be badly burned by hot coolant

or steam from your radiator. If you see or hear

steam coming from under the hood, don't open

the hood until the radiator has had time to cool.

Never try to open a cooling system pressure cap

when the radiator is hot.

Coolant Checks

Check engine coolant (antifreeze) protection every 12

months (before the onset of freezing weather, where

applicable). If coolant is dirty or rusty in appearance, the

system should be drained, flushed and refilled with fresh

coolant. Check the front of the A/C condenser for anyaccumulation of bugs, leaves, etc. If dirty, clean by gently

spraying water from a garden hose vertically down the

face of the condenser.

Check the coolant recovery bottle tubing for brittle rub-

ber, cracking, tears, cuts and tightness of the connection

at the bottle and radiator. Inspect the entire system for

leaks.

Cooling System Ð Drain, Flush and Refill

At the intervals shown on the Maintenance Schedules,

the system should be drained, flushed and refilled.

If the solution is dirty or contains a considerable amount

of sediment, clean and flush with a reliable cooling

system cleaner. Follow with a thorough rinsing to remove

all deposits and chemicals. Properly dispose of old

antifreeze solution.

Selection Of Coolant

Use only the manufacturers recommended coolant, refer

to Fluids, Lubricants and Genuine Parts for correct

coolant type.

256 MAINTAINING YOUR VEHICLE

Page 261 of 322

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake And Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect the surface of the hoses and nylon tubing for

evidence of heat and mechanical damage. Hard and

brittle rubber, cracking, tears, cuts, abrasions, and exces-

sive swelling suggest deterioration of the rubber. Particu-

lar attention should be made to examining those hose

surfaces nearest to high heat sources, such as the exhaust

manifold.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

Insure nylon tubing in these areas has not melted or

collapsed.

NOTE:Often, fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before a hose is replaced

based on leakage.

NOTE:Inspection of brake hoses should be done

whenever the brake system is serviced and at every

engine oil change.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

MAINTAINING YOUR VEHICLE 261

7

Page 263 of 322

WARNING!

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching fire.

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter.

Do not allow petroleum based fluid to contaminate the

brake fluid as seal damage will result!

Automatic Transaxle

All front wheel drive vehicles have a transmission and

differential assembly contained within a single housing.

Selection Of Lubricant

It is important that the proper lubricant is used in the

transaxle to assure optimum transaxle performance. Use

only the manufacturer's recommended transmission

fluid which has been formulated with special metal to

metal friction coefficient additives to provide the propersteel belt traction on the drive and driven pulleys. Refer

to Fluids, Lubricants and Genuine Parts for correct fluid

type.

CAUTION!

Using a transmission fluid other than the manufac-

turers recommended fluid will cause belt slip and

result in a complete transmission failure! Refer to

Fluids, Lubricants and Genuine Parts for correct

fluid type.

Fluid Level Check

The fluid level in the automatic transaxle should be

checked only by a trained technician.

Fluid and Filter Changes

Refer to the ªMaintenance Schedule located if section 8 of

this manual for the correct change interval for your type

of driving.

MAINTAINING YOUR VEHICLE 263

7