check engine DODGE CALIBER 2008 1.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: CALIBER, Model: DODGE CALIBER 2008 1.GPages: 402, PDF Size: 6.37 MB

Page 334 of 402

Refrigerant Recovery And Recycling

R-134a Air Conditioning Refrigerant is a hydrofluoro-

carbon (HFC) that is endorsed by the Environmental

Protection Agency and is an ozone-saving product. How-

ever, the manufacturer recommends that air conditioning

service be performed by authorized dealers or other

service facilities using recovery and recycling equipment.

NOTE:Use only manufacturer approved A/C system

sealers, stop leak products, seal conditioners, compressor

oil, or refrigerants.

Power Steering — Fluid Check

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises are

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through an autho-

rized DaimlerChrysler Dealership.

WARNING!

Fluid level should be checked on a level surface and

with the engine OFF to prevent injury from moving

parts and to ensure an accurate fluid level reading.

Do not overfill. Use only the manufacturer’s recom-

mended power steering fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to “Fluids, Lubricants, and Genuine

Parts” for correct fluid types.

Front Suspension Ball Joints

There are two front suspension lower ball joints that are

permanently lubricated. Inspect these ball joints when-

ever under-vehicle service is done. Damaged seals and

their corresponding potentially damaged ball joints must

be replaced.

332 MAINTAINING YOUR VEHICLE

Page 336 of 402

2. Push the release tab and slide the wiper blade assem-

bly down along the arm. Gently place the wiper arm on

the windshield.

3. Install the new blade assembly onto the wiper arm tip

until it locks in place.

Windshield Washer Fluid Reservoir

The windshield washer fluid reservoir is located in the

rear of the engine compartment on the right side and

should be checked for fluid level at regular intervals. Fill

the reservoir with windshield washer solvent (not radia-

tor antifreeze).

Exhaust System

The best protection against carbon monoxide entry into

the vehicle body is a properly maintained engine exhaust

system.

If you notice a change in the sound of the exhaust system,

or if exhaust fumes can be detected inside the vehicle orwhen the underside or rear of the vehicle is damaged,

have a competent technician inspect the complete ex-

haust system and adjacent body areas for broken, dam-

aged, deteriorated, or mispositioned parts. Open seams

or loose connections could permit exhaust fumes to seep

into the passenger compartment. In addition, inspect the

exhaust system each time the vehicle is raised for an oil

change or lubrication. Replace as required.

WARNING!

Exhaust gases can injure or kill. They contain carbon

monoxide (CO) which is colorless and odorless.

Breathing it can make you unconscious and can

eventually poison you. To avoid breathing CO, refer

to “Exhaust Gas” in the Safety Tips section of this

manual.

334 MAINTAINING YOUR VEHICLE

Page 337 of 402

Cooling System

WARNING!

•When working near the radiator cooling fan, dis-

connect the fan motor lead or turn the ignition

switch to the OFF position. The fan is temperature

controlled and can start at any time the ignition

switch is in the ON position.

•You or others can be badly burned by hot coolant

or steam from your radiator. If you see or hear

steam coming from under the hood, don’t open the

hood until the radiator has had time to cool. Never

try to open a cooling system pressure cap when the

radiator is hot.

Coolant Checks

Check engine coolant (antifreeze) protection every 12

months (before the onset of freezing weather, where

applicable). If coolant is dirty or rusty in appearance, the

system should be drained, flushed and refilled with fresh

coolant. Check the front of the A/C condenser for any

accumulation of bugs, leaves, etc. If dirty, clean by gently

spraying water from a garden hose vertically down the

face of the condenser.

Check the coolant recovery bottle tubing for brittle rub-

ber, cracking, tears, cuts and tightness of the connection

at the bottle and radiator. Inspect the entire system for

leaks.

MAINTAINING YOUR VEHICLE 335

7

Page 340 of 402

WARNING!

•The warning words “DO NOT OPEN HOT” on

the cooling system pressure cap are a safety pre-

caution. Never add coolant when the engine is

overheated. Do not loosen or remove the cap to

cool an overheated engine. Heat causes pressure to

build up in the cooling system. To prevent scald-

ing or injury, do not remove the pressure cap while

the system is hot or under pressure.

•Do not use a pressure cap other than the one

specified for your vehicle. Personal injury or en-

gine damage may result.

Disposal Of Used Engine Coolant

Used ethylene glycol-based engine coolant is a regulated

substance requiring proper disposal. Check with your

local authorities to determine the disposal rules for yourcommunity. To prevent ingestion by animals or children

do not store ethylene glycol-based engine coolant in open

containers or allow it to remain in puddles on the

ground. If ingested by a child, contact a physician

immediately. Clean up any ground spills immediately.

Coolant Level

The coolant bottle provides a quick visual method for

determining that the coolant level is adequate. With the

engine idling and warm to normal operating tempera-

ture, the level of the coolant in the bottle should be

between the “ADD” and “FULL” lines shown on the

bottle.

The radiator normally remains completely full, so there is

no need to remove the radiator cap unless checking for

the coolant freeze point or replacing the coolant. Advise

your service attendant of this. As long as the engine

operating temperature is satisfactory, the coolant bottle

need only be checked once a month.

338 MAINTAINING YOUR VEHICLE

Page 341 of 402

When additional coolant is needed to maintain the

proper level, it should be added to the coolant bottle. Do

not overfill.

Points To Remember

NOTE:When the vehicle is stopped after a few miles/

kilometers of operation, you may observe vapor coming

from the front of the engine compartment. This is nor-

mally a result of moisture from rain, snow, or high

humidity accumulating on the radiator and being vapor-

ized when the thermostat opens, allowing hot coolant to

enter the radiator.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

•Do not overfill the coolant recovery bottle.

•Check the coolant freeze point in the radiator and in

the coolant recovery bottle. If antifreeze needs to be

added, the contents of the coolant recovery bottle must

also be protected against freezing.

•If frequent coolant additions are required or if the level

in the coolant recovery bottle does not drop when the

engine cools, the cooling system should be pressure

tested for leaks.

•Maintain coolant concentration at 50% HOAT engine

coolant (minimum) and distilled water for proper

corrosion protection of your engine which contains

aluminum components.

•Make sure that the radiator and coolant recovery

bottle overflow hoses are not kinked or obstructed.

•Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean also.

MAINTAINING YOUR VEHICLE 339

7

Page 344 of 402

NOTE:Inspection of brake hoses should be done when-

ever the brake system is serviced and at every engine oil

change.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Brake Master Cylinder

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the brake system warning light is on.

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the

fluid level up to the requirements described on the brakefluid reservoir. Fluid level can be expected to fall as the

brake pads wear. The brake fluid level should be checked

when the pads are replaced. However, low fluid level

may be caused by a leak and a checkup may be needed.

NOTE:If your vehicle is equipped with amanual

transaxle, the brake fluid reservoir supplies fluid to both

the brake system and the clutch release system. The two

systems are separated in the reservoir, and a leak in one

system will not affect the other system. Themanual

transaxleclutch release system should not require fluid

replacement during the life of the vehicle. If the brake

fluid reservoir is low and the brake system does not

indicate any leaks or other problems, it may be a result of

a leak in the hydraulic clutch release system. See your

local authorized dealer for service.

Use only manufacturer’s recommended brake fluid. Re-

fer to “Fluids, Lubricants, and Genuine Parts” under

Section 8.

342 MAINTAINING YOUR VEHICLE

Page 346 of 402

steel belt traction on the drive and driven pulleys. Refer

to “Fluids, Lubricants and Genuine Parts” for correct

fluid type.

CAUTION!

Using a transmission fluid other than the manufac-

turer’s recommended fluid will cause belt slip and

result in a complete transmission failure! Refer to

“Fluids, Lubricants, and Genuine Parts” for correct

fluid type.

Fluid Level Check

The fluid level in the automatic transaxle should be

checked only by a trained technician.

Fluid And Filter Changes

Refer to the “Maintenance Schedule” in Section 8 of this

manual for the correct change interval.

Special Additives

Do not add any materials (other than leak detection dyes)

to Continuously Variable Transaxle (CVT) Fluid

(CVTF+4). CVTF+4 is an engineered product and its

performance may be impaired by supplemental addi-

tives.

Manual Transaxle

Lubricant Selection

Use only the manufacturers recommended transmission

fluid. Refer to “Fluids, Lubricants, and Genuine Parts”

under Section 8.

Fluid Level Check

Check the fluid level by removing the fill plug. The fluid

level should be between the bottom of the fill hole and a

point not more that 3/16 in (4.7 mm) below the bottom of

the hole.

Add fluid, if necessary, to maintain the proper level.

344 MAINTAINING YOUR VEHICLE

Page 367 of 402

if it has been six months since your last oil change and

even if the oil change indicator message is NOT

illuminated.

•Change your engine oil more often if you drive your

vehicle off-road for an extended period of time.

•Under no circumstances should oil change intervals

exceed 6,000 mi (10 000 km) or six months, whichever

comes first.

Your authorized dealer will reset the oil change indicator

message after completing the scheduled oil change. If this

scheduled oil change is performed by someone other

than your authorized dealer, the message can be reset by

referring to the steps described under “Oil Change

Required” in “Use Factory Settings” of the EVIC section

in this manual or under “Odometer/Trip Odometer” in

the Instrument Cluster Descriptions section of this

manual.At Each Stop for Fuel

•Check the engine oil level about five minutes after a

fully warmed engine is shut off. Checking the oil level

while the vehicle is on level ground will improve the

accuracy of the oil level reading. Add oil only when

the level is at or below the ADD or MIN mark.

•Check the windshield washer solvent and add if

required.

Once a Month

•Check the tire pressure and look for unusual wear or

damage.

•Inspect the battery and clean and tighten the terminals

as required.

•Check the fluid levels of coolant reservoir, brake

master cylinder, power steering and transmission and

add as needed.

MAINTENANCE SCHEDULES 365

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 368 of 402

•Check all lights and other electrical items for correct

operation.

At Each Oil Change

•Change the engine oil filter.

•Inspect the brake hoses and lines.

•Check the manual transmission fluid level.

CAUTION!

Failure to perform the required maintenance items

may result in damage to the vehicle.

366 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 384 of 402

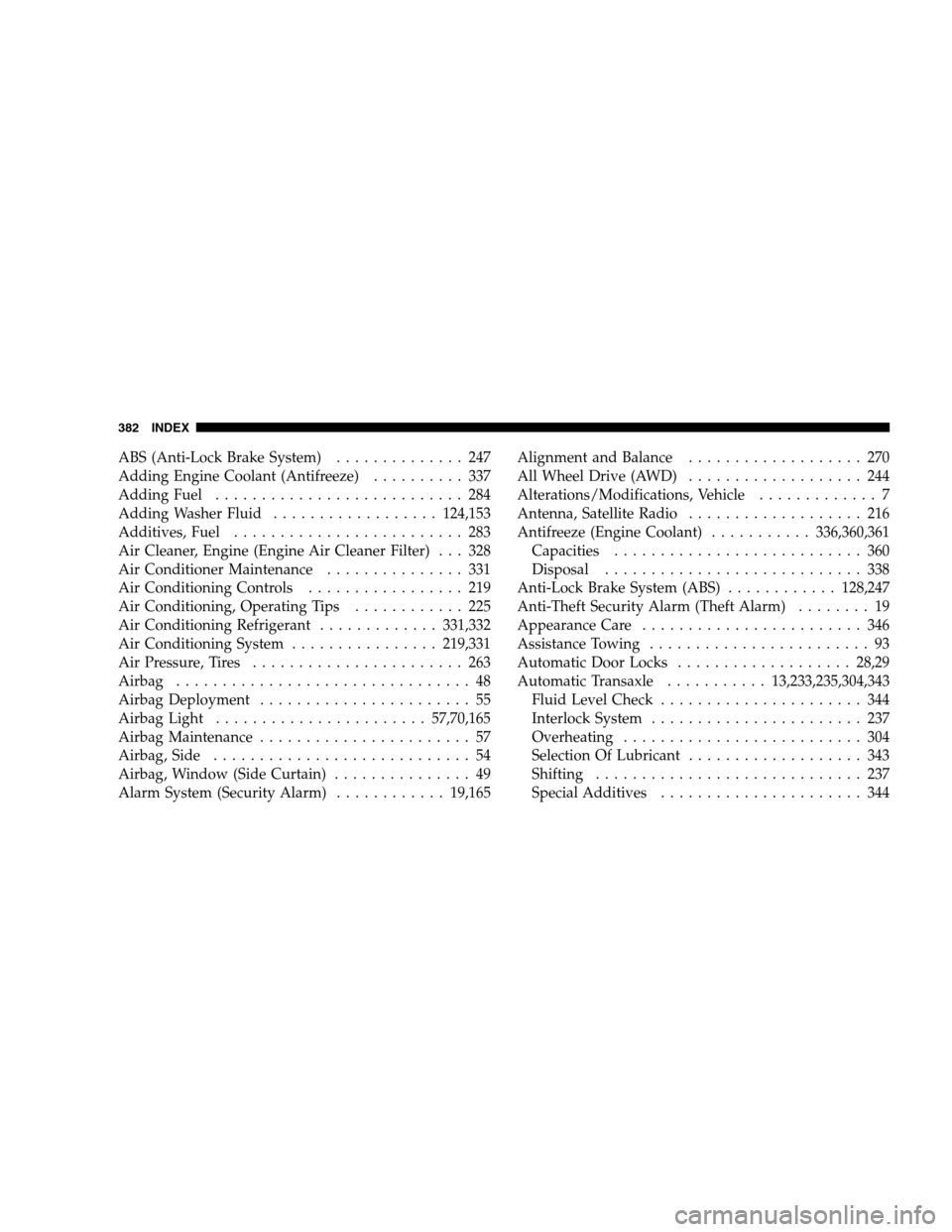

ABS (Anti-Lock Brake System).............. 247

Adding Engine Coolant (Antifreeze).......... 337

Adding Fuel........................... 284

Adding Washer Fluid..................124,153

Additives, Fuel......................... 283

Air Cleaner, Engine (Engine Air Cleaner Filter) . . . 328

Air Conditioner Maintenance............... 331

Air Conditioning Controls................. 219

Air Conditioning, Operating Tips............ 225

Air Conditioning Refrigerant.............331,332

Air Conditioning System................219,331

Air Pressure, Tires....................... 263

Airbag................................ 48

Airbag Deployment....................... 55

Airbag Light....................... 57,70,165

Airbag Maintenance....................... 57

Airbag, Side............................ 54

Airbag, Window (Side Curtain)............... 49

Alarm System (Security Alarm)............ 19,165Alignment and Balance................... 270

All Wheel Drive (AWD)................... 244

Alterations/Modifications, Vehicle............. 7

Antenna, Satellite Radio................... 216

Antifreeze (Engine Coolant)...........336,360,361

Capacities........................... 360

Disposal............................ 338

Anti-Lock Brake System (ABS)............128,247

Anti-Theft Security Alarm (Theft Alarm)........ 19

Appearance Care........................ 346

Assistance Towing........................ 93

Automatic Door Locks................... 28,29

Automatic Transaxle........... 13,233,235,304,343

Fluid Level Check...................... 344

Interlock System....................... 237

Overheating.......................... 304

Selection Of Lubricant................... 343

Shifting ............................. 237

Special Additives...................... 344

382 INDEX