check oil DODGE CARAVAN 2004 4.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: CARAVAN, Model: DODGE CARAVAN 2004 4.GPages: 397, PDF Size: 6.83 MB

Page 72 of 397

Airbag Light

The light should come on and remain on for 6 to 8

seconds as a bulb check when the ignition switch is first

turned ON. If the LED is not lit during starting, have it

checked. If the light stays on or comes on while driving,

have the system checked by an authorized dealer.

Defroster

Check operation by selecting the defrost mode and place

the blower control on high speed. You should be able to

feel the air directed against the windshield.

Periodic Safety Checks You Should Make Outside

The Vehicle

Tires

Examine tires for excessive tread wear or uneven wear

patterns. Check for stones, nails, glass, or other objects

lodged in the tread. Inspect tread and sidewall for cuts or

cracks. Check wheel nuts for tightness, and tires (includ-

ing spare) for proper pressure.

Lights

Have someone observe the operation of exterior lights

while you work the controls. Check turn signal and high

beam indicator lights on the instrument panel.

Fluid Leaks

Check area under vehicle after overnight parking for fuel,

engine coolant, oil or other fluid leaks. Also, if gasoline

fumes are detected or fuel, power steering fluid or brake

fluid leaks are suspected, the cause should be located and

corrected immediately.

72 THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

Page 155 of 397

WARNING!

A hot engine cooling system is dangerous. You or

others could be badly burned by steam or boiling

coolant. You may want to call a service center if your

vehicle overheats. If you decide to look under the

hood yourself, see Section 7 of this manual. Follow

the warnings under the Cooling System Pressure

Cap paragraph.

15. Washer Fluid Light

This light turns on when the washer fluid level

falls below approximately 1/4 filled. The light will

remain on until fluid is added.

16. Transmission Range Indicator

This vacuum fluorescent display indicator shows the

automatic transaxle gear selection.17. Oil Pressure Warning Light

This light shows low engine oil pressure. The light

should turn on momentarily when the engine is

started. If the light turns on while driving, stop the

vehicle and shut off the engine as soon as possible. A

chime will sound for 4 minutes when this light turns on.

Do not operate the vehicle until the cause is corrected.

This light does not show how much oil is in the engine.

The engine oil level must be checked under the hood.

18. Malfunction Indicator Light

This light is part of an onboard diagnostic system

called OBD that monitors engine and automatic

transmission control systems. The light will illu-

minate when the key is in the ON position before engine

start. If the bulb does not come when turning the key

from OFF to ON, have the condition checked promptly.

Certain conditions such as a loose or missing gas cap,

poor fuel quality, etc. may illuminate the light after

UNDERSTANDING YOUR INSTRUMENT PANEL 155

4

Page 295 of 397

MAINTAINING YOUR VEHICLE

CONTENTS

m2.4L Engine...........................298

m3.3L/3.8L Engines......................299

mOnboard Diagnostic System Ð OBD II........300

mEmissions Inspection And Maintenance

Programs............................301

mReplacement Parts......................302

mDealer Service.........................302

mMaintenance Procedures..................303

NEngine Oil..........................303NEngine Oil Filter......................307

NDrive Belts Ð Check Condition And Tension . . 307

NSpark Plugs.........................308

NEngine Air Cleaner Filter................308

NEngine Fuel Filter.....................309

NCatalytic Converter....................309

NMaintenance-Free Battery................311

NAir Conditioner......................312

NPower Steering Ð Fluid Check............314

7

Page 303 of 397

NOTE:Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

WARNING!

You can be badly injured working on or around a

motor vehicle. Do only that service work for which

you have the knowledge and the proper equipment.

If you have any doubt about your ability to perform

a service job, take your vehicle to a competent

mechanic.

MAINTENANCE PROCEDURES

The pages that follow contain therequiredmaintenance

services determined by the engineers who designed your

vehicle.

Besides the maintenance items for which there are fixed

maintenance intervals, there are other items that should

operate satisfactorily without periodic maintenance.

However, if a malfunction of these items does occur, it

could adversely affect the engine or vehicle performance.

These items should be inspected if a malfunction is

observed or suspected.

Engine Oil

Checking Oil Level

To assure proper engine lubrication, the engine oil must

be maintained at the correct level. Check the oil level at

regular intervals, such as every fuel stop.

MAINTAINING YOUR VEHICLE 303

7

Page 304 of 397

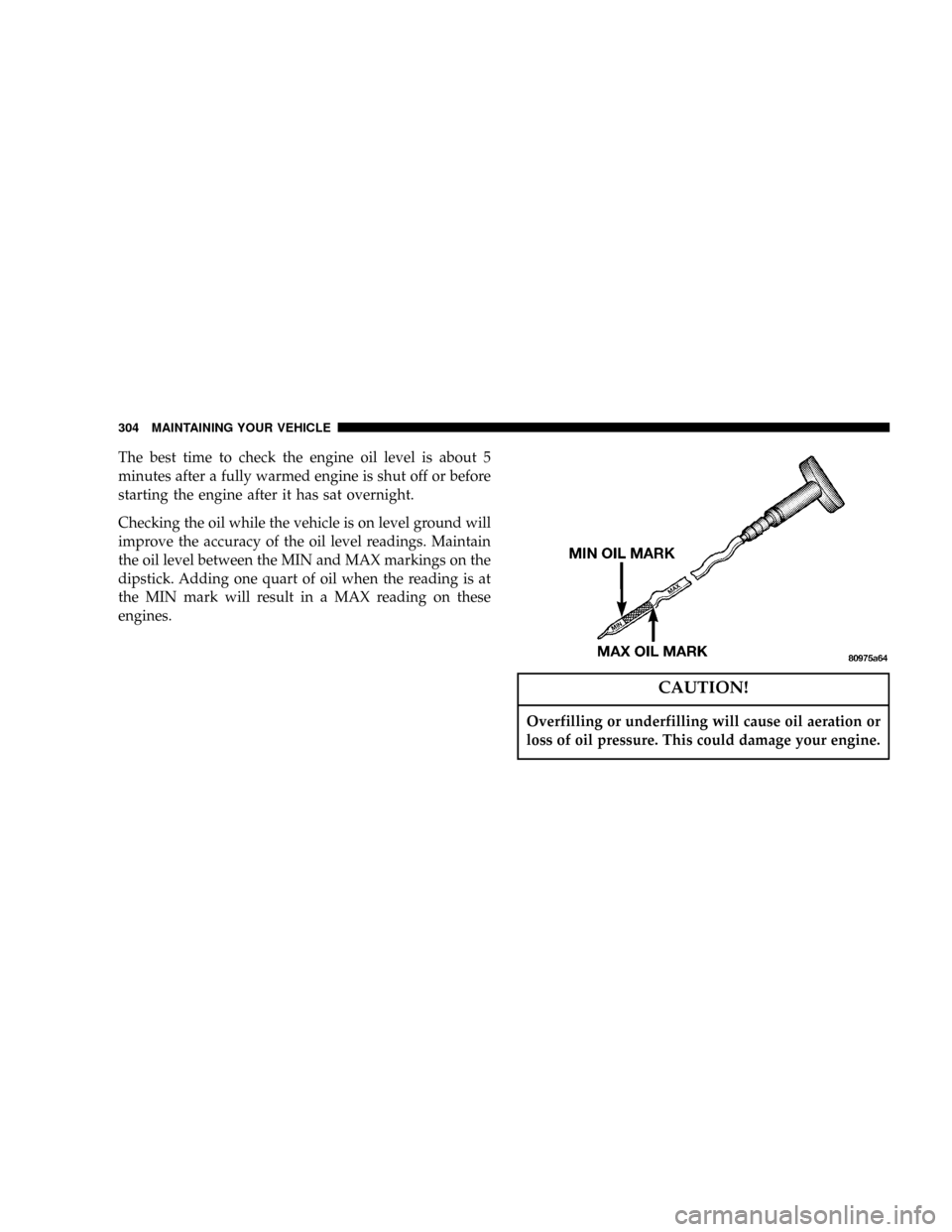

The best time to check the engine oil level is about 5

minutes after a fully warmed engine is shut off or before

starting the engine after it has sat overnight.

Checking the oil while the vehicle is on level ground will

improve the accuracy of the oil level readings. Maintain

the oil level between the MIN and MAX markings on the

dipstick. Adding one quart of oil when the reading is at

the MIN mark will result in a MAX reading on these

engines.

CAUTION!

Overfilling or underfilling will cause oil aeration or

loss of oil pressure. This could damage your engine.

304 MAINTAINING YOUR VEHICLE

Page 305 of 397

Change Engine Oil

Road conditions and your kind of driving affects the

interval at which your oil should be changed. Check the

following list to see if any apply to you.

²Day or night temperatures are below 32ÉF (0ÉC).

²Stop and Go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 10 miles (16 km).

²More than 50% of your driving is at sustained high

speeds during hot weather, above 90ÉF (32ÉC).

²Trailer towing.

²Taxi, Police or delivery service (commercial service).

²Off-Road or desert operation.IfANYof these apply to you, then change your engine oil

at every interval shown in schedule ªBº of the ªMainte-

nance Schedulesº section of this manual.

If none of these apply to you, then change your engine oil

at every interval shown on schedule ªAº of the ªMain-

tenance Schedulesº section of this manual

NOTE:Under no circumstances should oil change in-

tervals exceed 6000 miles (10 000 km) or 6 months

whichever comes first.

Engine Oil Selection

For best performance and maximum protection under all

types of operating conditions, the manufacture only

recommends engine oils that are API certified and meet

the requirements of DaimlerChrysler Material Standard

MS-6395. Use Mopar or an equivalent oil meeting the

specification MS-6395.

MAINTAINING YOUR VEHICLE 305

7

Page 307 of 397

Synthetic Engine Oils

There are a number of engine oils being promoted as

either synthetic or semi-synthetic. If you chose to use

such a product, useonlythose oils that meet the Ameri-

can Petroleum Institute (API) and SAE viscosity stan-

dard. Follow the service schedule that describes your

driving type.

Materials Added to Engine Oil

The manufacture strongly recommends against the addi-

tion of any additives (other than leak detection dyes) to

the engine oil. Engine oil is an engineered product and

it's performance may be impaired by supplemental ad-

ditives.

Disposing of Used Engine Oil And Oil Filters

Care should be taken in disposing of used engine oil and

oil filters from your vehicle. Used oil and oil filters,

indiscriminately discarded, can present a problem to the

environment. Contact your dealer, service station, orgovernmental agency for advice on how and where used

oil and oil filters can be safely discarded in your area.

Engine Oil Filter

The engine oil filter should be replaced at every engine

oil change.

Engine Oil Filter Selection

All the manufacturers engines have a full-flow type oil

filter. Use a filter of this type for replacement. The quality

of replacement filters varies considerably. Only high

quality filters should be used to assure most efficient

service. Mopar Engine Oil Filters are a high quality oil

filter and are recommended.

Drive Belts Ð Check Condition and Tension

At the mileage indicated in the maintenance schedule, all

belts should be checked for condition and proper tension.

Improper belt tension can cause belt slippage and failure.

MAINTAINING YOUR VEHICLE 307

7

Page 316 of 397

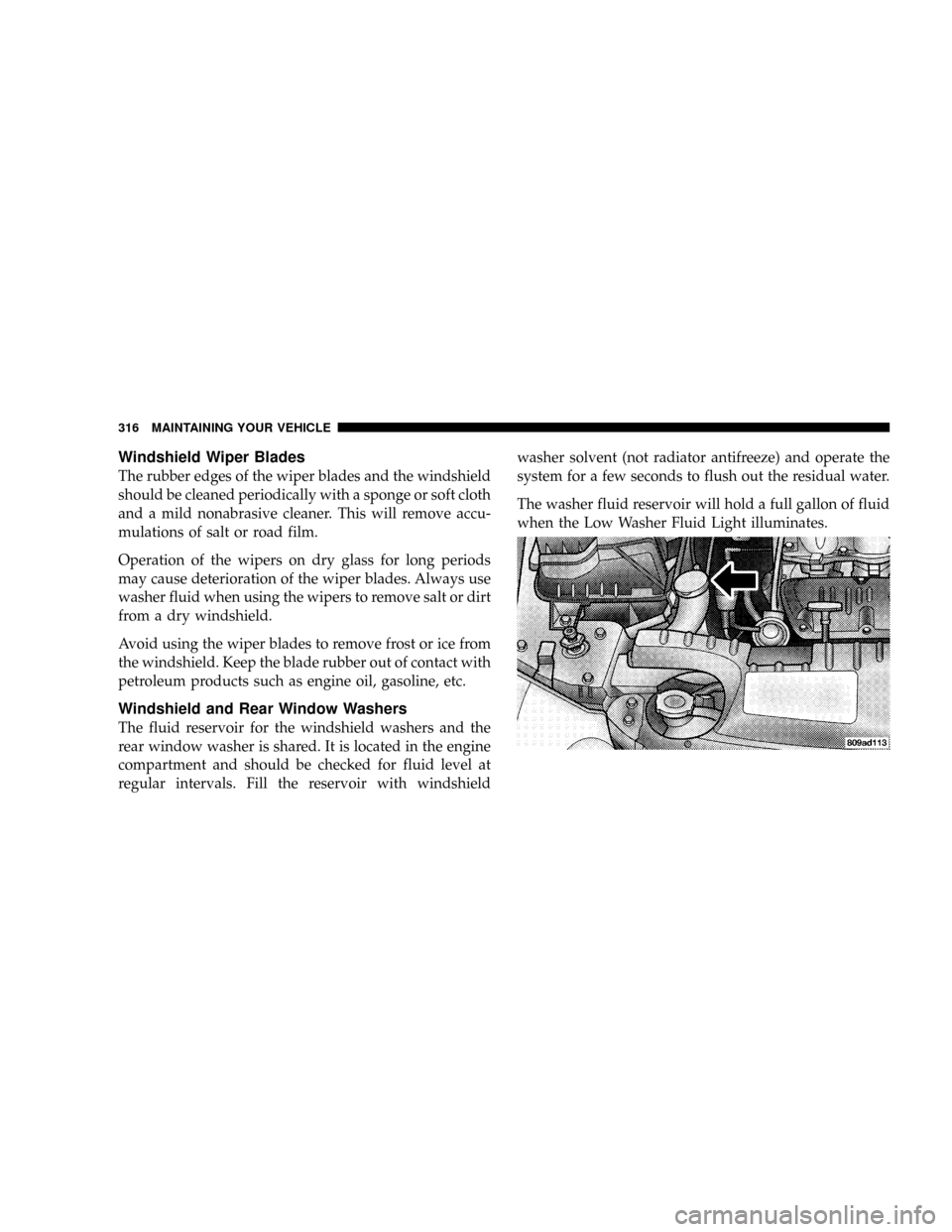

Windshield Wiper Blades

The rubber edges of the wiper blades and the windshield

should be cleaned periodically with a sponge or soft cloth

and a mild nonabrasive cleaner. This will remove accu-

mulations of salt or road film.

Operation of the wipers on dry glass for long periods

may cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield.

Avoid using the wiper blades to remove frost or ice from

the windshield. Keep the blade rubber out of contact with

petroleum products such as engine oil, gasoline, etc.

Windshield and Rear Window Washers

The fluid reservoir for the windshield washers and the

rear window washer is shared. It is located in the engine

compartment and should be checked for fluid level at

regular intervals. Fill the reservoir with windshieldwasher solvent (not radiator antifreeze) and operate the

system for a few seconds to flush out the residual water.

The washer fluid reservoir will hold a full gallon of fluid

when the Low Washer Fluid Light illuminates.

316 MAINTAINING YOUR VEHICLE

Page 324 of 397

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

NOTE:Often, fluid such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to facilitate the assembly of hoses to couplings.

Therefore, oil wetness at the hose-coupling area is not

necessarily an indication of leakage. Actual dripping of

hot fluid when systems are under pressure (during

vehicle operation), should be noted before hose is re-

placed based on leakage.

NOTE:Inspection of brake hoses should be performed

whenever the brake system is serviced and every engine

oil change. Inspect hydraulic brake hoses for surface

cracking, scuffing, or worn spots. If there is any evidence

of cracking, scuffing, or worn spots, the hose should bereplaced immediately! Eventual deterioration of the hose

can take place resulting in a possibility of a burst failure.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Master Cylinder Ð ABS Brakes Brake Fluid Level

Check

The fluid level in the master cylinder should be checked

when performing underhood services, or immediately if

the brake system warning light indicates system failure.

Clean the top of the master cylinder area before removing

the cap. Add fluid to bring the level up to the top of the

ªFULLº mark on the side of the master cylinder reservoir.

324 MAINTAINING YOUR VEHICLE

Page 325 of 397

Overfilling of fluid is not recommended because it may

cause leaking in the system.

Add enough fluid to bring the level up to the require-

ments described on the brake fluid reservoir. With disc

brakes, fluid level can be expected to fall as the brake

pads wear. However, low fluid level may be caused by a

leak and a checkup may be needed.

Use only manufacturers recommended brake fluid, refer

to Recommended Fluids, Lubricants and Genuine Parts

for correct fluid type.

WARNING!

Use of brake fluid that may have a lower initial

boiling point or unidentified as to specification, may

result in sudden brake failure during hard pro-

longed braking. You could have an accident.

WARNING!

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching fire.

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter or

moisture.

CAUTION!

Do not allow petroleum base fluid to contaminate

the brake fluid, all brake seal components could be

damaged causing partial or complete brake failure.

MAINTAINING YOUR VEHICLE 325

7