ECU DODGE CARAVAN 2006 4.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: CARAVAN, Model: DODGE CARAVAN 2006 4.GPages: 504, PDF Size: 7.92 MB

Page 358 of 504

Towing Requirements

To promote proper break-in of your new vehicle driv-

etrain components the following guidelines are recom-

mended:

CAUTION!

•Avoid towing a trailer for the first 500 miles (805

km) of vehicle operation. Doing so may damage

your vehicle.

•During the first 500 miles (805 km) of trailer

towing, limit your speed to 50 mph (80 km/h).

Perform the maintenance listed in Section 8 of this

manual. When towing a trailer, never exceed the GAWR,

or GCWR, ratings.

WARNING!

Improper towing can lead to an injury accident.

Follow these guidelines to make your trailer towing

as safe as possible:

Make certain that the load is secured in the trailer

and will not shift during travel. When trailering

cargo that is not fully secured, dynamic load shifts

can occur that may be difficult for the driver to

control. You could lose control of your vehicle and

have an accident.

•When hauling cargo or towing a trailer, do not over-

load your vehicle or trailer. Overloading can cause a

loss of control, poor performance or damage to brakes,

axle, engine, transmission, steering, suspension, chas-

sis structure or tires.

358 STARTING AND OPERATING

Page 376 of 504

6. These locations are on the sill flange of the body and

consist of a pair of downstanding tabs. The jack is to be

located, engaging the flange, between the pair of tabs

closest to the wheel to be changed. Place the wrench on

the jack screw and turn to the right until the jack head is

properly engaged in the described location.Do not raise

the vehicle until you are sure the jack is securely

engaged.

7. Raise the vehicle by turning the jack screw to the right,

using the swivel wrench. Raise the vehicle only until the

tire just clears the surface and enough clearance is

obtained to install the spare tire. Minimum tire lift

provides maximum stability.WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

8. Remove the wheel lug nuts, for vehicles with wheel

covers, remove the cover from the wheel by hand. Do not

pry the wheel cover off. Then pull the wheel off the hub.

9. Install the compact spare tire. Lightly tighten the lug

nuts. To avoid the risk of forcing the vehicle off the jack,

do not tighten the lug nuts fully until the vehicle has been

lowered.

NOTE:Do not install the wheel cover on the compact

spare.

Do not use a hammer or force to install the wheel covers.

376 WHAT TO DO IN EMERGENCIES

Page 377 of 504

10. Lower the vehicle by turning the jack screw to the

left.

11. Finish tightening the lug nuts. Push down on the

wrench while tightening for increased leverage. Alternate

lug nuts until each nut has been tightened twice. Correct

wheel nut tightness is 130 N·m (95 ft. lbs). If in doubt

about the correct tightness, have them checked with a

torque wrench by your dealer or at a service station.

12. Lower the jack to its fully closed position.

13. Secure the flat tire as follows:

•Place the deflated (flat) tire and compact spare tire

cover assembly in the rear cargo area,have the tire

repaired or replaced as soon as possible.

WARNING!

A loose deflated (flat) tire thrown forward in a

collision or hard stop could injure the occupants in

the vehicle. Have the deflated (flat) tire repaired or

replaced immediately.

CAUTION!

Vehicle damage will occur if the compact spare tire

cover assembly is installed without the compact

spare tire in position. Place the deflated (flat) tire

and compact spare tire cover assembly in the rear

cargo area.

WHAT TO DO IN EMERGENCIES 377

6

Page 378 of 504

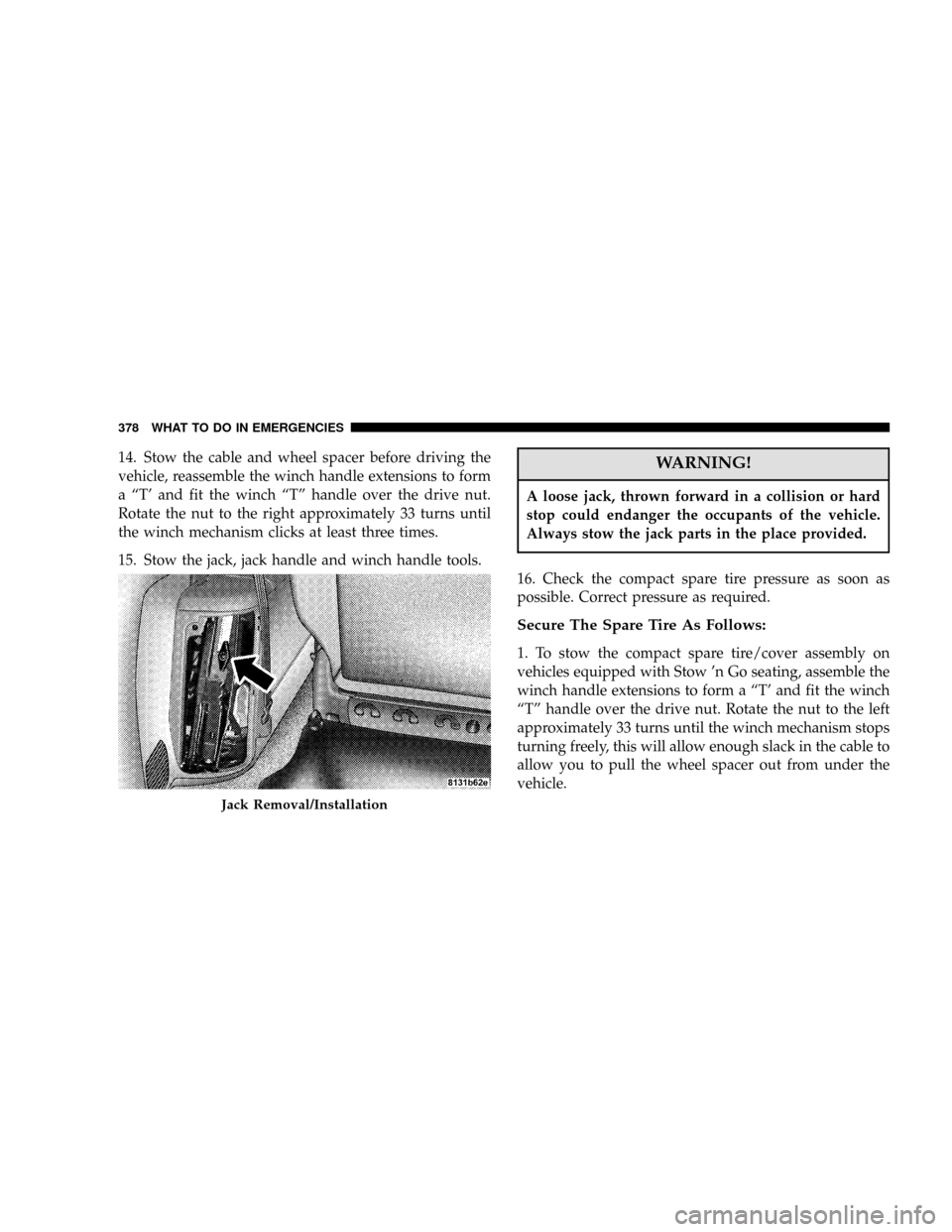

14. Stow the cable and wheel spacer before driving the

vehicle, reassemble the winch handle extensions to form

a“T’and fit the winch“T”handle over the drive nut.

Rotate the nut to the right approximately 33 turns until

the winch mechanism clicks at least three times.

15. Stow the jack, jack handle and winch handle tools.WARNING!

A loose jack, thrown forward in a collision or hard

stop could endanger the occupants of the vehicle.

Always stow the jack parts in the place provided.

16. Check the compact spare tire pressure as soon as

possible. Correct pressure as required.

Secure The Spare Tire As Follows:

1. To stow the compact spare tire/cover assembly on

vehicles equipped with Stow’n Go seating, assemble the

winch handle extensions to form a“T’and fit the winch

“T”handle over the drive nut. Rotate the nut to the left

approximately 33 turns until the winch mechanism stops

turning freely, this will allow enough slack in the cable to

allow you to pull the wheel spacer out from under the

vehicle.

Jack Removal/Installation

378 WHAT TO DO IN EMERGENCIES

Page 385 of 504

5. These locations are on the sill flange of the body and

consist of a pair of downstanding tabs. The jack is to be

located, engaging the flange, between the pair of tabs

closest to the wheel to be changed. Place the wrench on

the jack screw and turn to the right until the jack head is

properly engaged in the described location.Do not raise

the vehicle until you are sure the jack is securely

engaged.

6. Raise the vehicle by turning the jack screw to the right,

using the swivel wrench. Raise the vehicle only until the

tire just clears the surface and enough clearance is

obtained to install the spare tire. Minimum tire lift

provides maximum stability.WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

7. Remove the wheel lug nuts, for vehicles with wheel

covers, remove the cover from the wheel by hand. Do not

pry the wheel cover off. Then pull the wheel off the hub.

8. Install the spare wheel, for vehicles with wheel covers,

align the notch in the wheel cover with the valve stem on

the wheel. Install the cover on the wheel by hand only

and install the wheel lug nuts with the cone shaped end

of the nut toward the wheel. Lightly tighten the lug nuts.

To avoid the risk of forcing the vehicle off the jack, do not

tighten the lug nuts fully until the vehicle has been

lowered.

WHAT TO DO IN EMERGENCIES 385

6

Page 386 of 504

NOTE:Do not install the wheel cover on the compact

spare.

Do not use a hammer or force to install the wheel covers.

9. Lower the vehicle by turning the jack screw to the left.

10. Finish tightening the lug nuts. Push down on the

wrench while tightening for increased leverage. Alternate

lug nuts until each nut has been tightened twice. Correct

wheel nut tightness is 130 N·m (95 ft. lbs). If in doubt

about the correct tightness, have them checked with a

torque wrench by your dealer or at a service station.

11. Lower the jack to its fully closed position.WARNING!

A loose tire or jack, thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided.

12. Secure the flat or spare tire as follows:

•If your vehicle is equipped with cast aluminum

wheels, the center cap of the wheel must be re-

moved prior to flat tire stowage. Store the center cap

inside the glove box or other storage compartment.

•Turn the wheel so that the valve stem is down. Slide

the wheel retainer through the center of the wheel

and position it properly across the wheel opening.

386 WHAT TO DO IN EMERGENCIES

Page 387 of 504

•For convenience in checking the spare tire inflation,

stow with the valve stem toward the rear of the

vehicle.

•Using the jack handle, rotate the drive nut to the

right until the wheel is drawn into place against the

underside of the vehicle.

•Continue to rotate the nut until you hear the mecha-

nism click three times. It cannot be overtightened.

Push against the tire several times to be sure it is

securely in place.

13. Stow the jack and jack handle.

14. Check the tire pressure as soon as possible. Correct

pressure as required.

JUMP-STARTING PROCEDURES IF BATTERY IS

LOW

WARNING!

Take care to avoid the radiator cooling fan whenever

the hood is raised. It can start anytime the ignition

switch is on. You can be hurt by the fan.

WHAT TO DO IN EMERGENCIES 387

6

Page 421 of 504

•Do not change the thermostat for summer or winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory coolant performance, poor gas

mileage, and increased emissions.

Hoses And Vacuum/Vapor Harnesses

Inspect surfaces of hoses and nylon tubing for evidence

of heat and mechanical damage. Hard or soft spots,

brittle rubber, cracking, tears, cuts, abrasions, and exces-

sive swelling indicate deterioration of the rubber.

Pay particular attention to those hoses nearest to high

heat sources such as the exhaust manifold. Inspect hose

routing to be sure hoses do not come in contact with any

heat source or moving component which may cause heat

damage or mechanical wear.Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

Components should be replaced immediately if there is

any evidence of wear or damage that could cause failure.

Brakes

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in the Mainte-

nance Schedules.

MAINTAINING YOUR VEHICLE 421

7

Page 422 of 504

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn’t have your full

braking capacity in an emergency.

Brake And Power Steering Hoses

When the vehicle is serviced for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, tears, cuts, abrasion, and excessive swelling

indicate deterioration of the rubber. Particular attention

should be made to examining those hose surfaces nearest

to high heat sources, such as the exhaust manifold.Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

NOTE:Often, fluid such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to facilitate the assembly of hoses to couplings.

Therefore, oil wetness at the hose-coupling area is not

necessarily an indication of leakage. Actual dripping of

hot fluid when systems are under pressure (during

vehicle operation), should be noted before hose is re-

placed based on leakage.

NOTE:Inspection of brake hoses should be performed

whenever the brake system is serviced and every engine

oil change. Inspect hydraulic brake hoses for surface

cracking, scuffing, or worn spots. If there is any evidence

of cracking, scuffing, or worn spots, the hose should be

422 MAINTAINING YOUR VEHICLE

Page 438 of 504

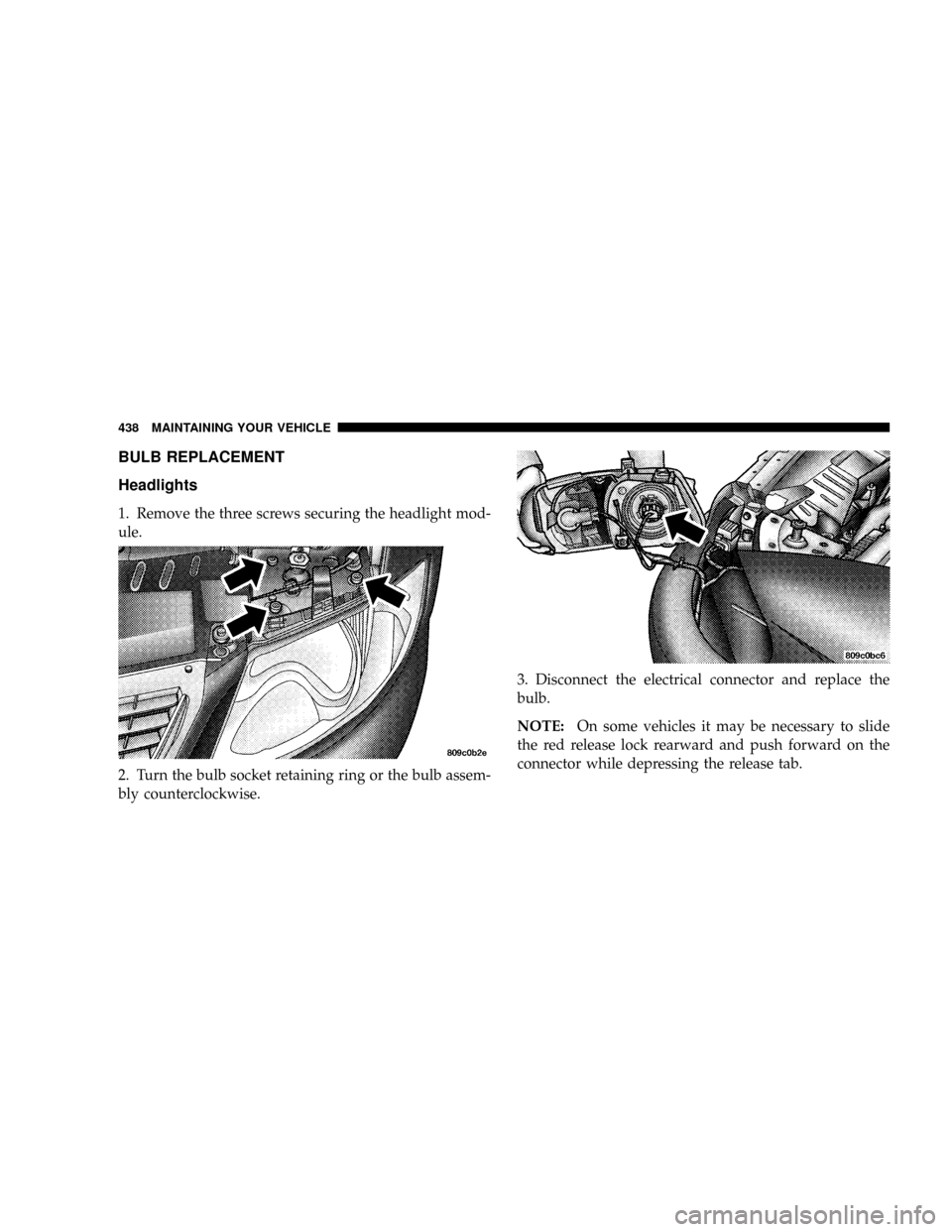

BULB REPLACEMENT

Headlights

1. Remove the three screws securing the headlight mod-

ule.

2. Turn the bulb socket retaining ring or the bulb assem-

bly counterclockwise.3. Disconnect the electrical connector and replace the

bulb.

NOTE:On some vehicles it may be necessary to slide

the red release lock rearward and push forward on the

connector while depressing the release tab.

438 MAINTAINING YOUR VEHICLE