engine DODGE CHALLENGER 2014 3.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2014, Model line: CHALLENGER, Model: DODGE CHALLENGER 2014 3.GPages: 148, PDF Size: 3.71 MB

Page 98 of 148

BATTERY LOCATION

The battery is stored under an access cover in the trunk. Remote battery posts are located

on the right side of the engine compartment for jump-starting.

TIREFIT KIT

Your vehicle may be equipped with a TIREFIT Kit.

Small punctures up to 1/4” (6 mm) in the tire tread can be sealed with TIREFIT. Foreign

objects (e.g., screws or nails) should not be removed from the tire. TIREFIT can be used in

outside temperatures down to approximately -4°F (-20°C).

This kit will provide a temporary tire seal, allowing you to drive your vehicle up to 100 miles

(160 km) with a maximum speed of 55 mph (90 km/h).

TIREFIT Storage

• The TIREFIT kit is located in the trunk.

TIREFIT Kit Components And Operation

Using The Mode Select Knob And Hoses

Your TIREFIT kit is equipped with the following

symbols to indicate the air or sealant mode.

Selecting Air Mode

Turn the Mode Select Knob (5) to this position

for air pump operation only. Use the Black Air

Pump Hose (7) when selecting this mode.

Selecting Sealant Mode

Turn the Mode Select Knob (5) to this posi-

tion to inject the TIREFIT Sealant and to in-

flate the tire. Use the Sealant Hose (clear

hose) (6) when selecting this mode.

Using The Power Button

Push and release the Power Button (4) once

to turn On the TIREFIT kit. Push and release

the Power Button (4) again to turn Off the

TIREFIT kit.

Using The Deflation Button

Press the Deflation Button (2) to reduce the

air pressure in the tire if it becomes over-

inflated.

TIREFIT Components

1 — Sealant Bottle

2 — Deflation Button

3 — Pressure Gauge

4 — Power Button

5 — Mode Select Knob

6 — Sealant Hose (Clear)

7 — Air Pump Hose (Black)

8 — Power Plug (located on bottom side of

TIREFIT Kit)

WHAT TO DO IN EMERGENCIES

96

Page 100 of 148

(C) Injecting TIREFIT Sealant Into The Deflated Tire:

Always start the engine before turning ON the TIREFIT kit.

NOTE:

Manual transmission vehicles must have the parking brake engaged and the shift lever in

NEUTRAL.

After pressing the Power Button (4), the sealant (white fluid) will flow from the Sealant Bottle (1)

through the Sealant Hose (6) and into the tire.

NOTE:

Sealant may leak out through the puncture in the tire.

If the sealant (white fluid) does not flow within0–10seconds through the Sealant

Hose (6):

1. Press the Power Button (4) to turn Off the TIREFIT kit. Disconnect the Sealant Hose (6) from the valve stem. Make sure the valve stem is free of debris. Reconnect the Sealant

Hose (6) to the valve stem. Check that the Mode Select Knob (5) is in the Sealant Mode

position and not Air Mode. Press the Power Button (4) to turn On the TIREFIT kit.

2. Connect the Power Plug (8) to a different 12 Volt power outlet in your vehicle or another vehicle, if available. Make sure the engine is running before turning ON the TIREFIT kit.

3. The Sealant Bottle (1) may be empty due to previous use. Call for assistance.

NOTE:

If the Mode Select Knob (5) is on Air Mode and the pump is operating, air will dispense from

the Air Pump Hose (7) only, not the Sealant Hose (6).

If the sealant (white fluid) does flow through the Sealant Hose (6):

1. Continue to operate the pump until sealant is no longer flowing through the hose (typically takes 30 - 70 seconds). As the sealant flows through the Sealant Hose (6), the

Pressure Gauge (3) can read as high as 70 psi (4.8 Bar). The Pressure Gauge (3) will

decrease quickly from approximately 70 psi (4.8 Bar) to the actual tire pressure when the

Sealant Bottle (1) is empty.

2. The pump will start to inject air into the tire immediately after the Sealant Bottle (1) is empty. Continue to operate the pump and inflate the tire to the pressure indicated on the

tire pressure label on the driver-side latch pillar (recommended pressure). Check the tire

pressure by looking at the Pressure Gauge (3).

If the tire does not inflate to at least 26 psi (1.8 Bar) pressure within 15 minutes:

The tire is too badly damaged. Do not attempt to drive the vehicle further. Call for assis-

tance.

NOTE:

If the tire becomes over-inflated, press the Deflation Button to reduce the tire pressure to

the recommended inflation pressure before continuing.

WHAT TO DO IN EMERGENCIES

98

Page 104 of 148

JUMP-STARTING

• If your vehicle has a discharged battery itcan be jumpstarted using a set of jumper

cables and a battery in another vehicle or

by using a portable battery booster pack.

• Jump-starting can be dangerous if done improperly so please follow the proce-

dures in this section carefully.

NOTE:

When using a portable battery booster pack

follow the manufacturer’s operating instruc-

tions and precautions.

Preparations For Jump-Start

• The battery is stored under an access cover in the trunk. Remote battery posts are located on the right side of the engine compartment for jump-starting.

NOTE:

The remote battery posts are viewed by standing on the right side of the vehicle looking over

the fender.

• Set the parking brake, shift the automatic transmission into PARK and turn the ignition to LOCK.

• Turn off the heater, radio, and all unnecessary electrical accessories.

• If using another vehicle to jump-start the battery, park the vehicle within the jumper cables reach, set the parking brake and make sure the ignition is OFF.

Jump-Starting Procedure

1. Connect the positive (+) end of the jumper cable to the remote positive (+) post of the

discharged vehicle.

2. Connect the opposite end of the positive (+) jumper cable to the positive (+) post of the booster battery.

3. Connect the negative end (-) of the jumper cable to the negative (-) post of the booster battery.

4. Connect the opposite end of the negative (-) jumper cable to the remote negative (-) post of the vehicle with the discharged battery.

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few minutes, and then start the engine in the vehicle with the discharged battery.

WHAT TO DO IN EMERGENCIES

102

Page 105 of 148

Once the engine is started, remove the jumper cables in the reverse sequence:

1. Disconnect the negative (-) jumper cable from the remote negative (-) post of the vehiclewith the discharged battery.

2. Disconnect the negative end (-) of the jumper cable from the negative (-) post of the booster battery.

3. Disconnect the opposite end of the positive (+) jumper cable from the positive (+) post of the booster battery.

4. Disconnect the positive (+) end of the jumper cable from the remote positive (+) post of the discharged vehicle.

5. If frequent jump-starting is required to start your vehicle you should have the battery and charging system inspected at your authorized dealer.

CAUTION!

• Do not use a portable battery booster pack or any other booster source with a system voltage greater than 12 Volts or damage to the battery, starter motor, alternator or

electrical system may occur.

• Failure to follow these procedures could result in damage to the charging system of the booster vehicle or the discharged vehicle.

• Accessories that can be plugged into the vehicle power outlets draw power from the vehicle’s battery, even when not in use (e.g., cellular phones, etc.). Eventually, if

plugged in long enough, the vehicle’s battery discharges sufficiently to degrade

battery life and/or prevent the engine from starting.

WHAT TO DO IN EMERGENCIES

103

Page 106 of 148

WARNING!

• When temperatures are below the freezing point, electrolyte in a discharged batterymay freeze. Do not attempt jump-starting because the battery could rupture or

explode and cause personal injury. Battery temperature must be brought above

freezing point before attempting a jump-start.

• Take care to avoid the radiator cooling fan whenever the hood is raised. It can start anytime the ignition switch is on. You can be injured by moving fan blades.

• Remove any metal jewelry, such as watch bands or bracelets, that might make an

inadvertent electrical contact. You could be severely injured.

• Batteries contain sulfuric acid that can burn your skin or eyes and generate hydrogen

gas which is flammable and explosive. Keep open flames or sparks away from the

battery.

• Do not allow vehicles to touch each other as this could establish a ground connection and personal injury could result.

• Failure to follow this procedure could result in personal injury or property damage due to battery explosion.

• Do not connect the cable to the negative post (-)of the discharged battery. The

resulting electrical spark could cause the battery to explode and could result in

personal injury.

SHIFT LEVER OVERRIDE

• If a malfunction occurs and the shift lever cannot be moved out of the PARK posi-

tion, you can use the following procedure

to temporarily move the shift lever:

1. Turn the engine OFF.

2. Firmly apply the parking brake.

3. Using a small screwdriver or similar tool, remove the shift lever override

access cover (located to the right of

the shift lever).

4. Press and maintain firm pressure on the brake pedal.

5. Insert the screwdriver or similar tool, into the access port, and push and

hold the override release lever down.

6. Move the shift lever into the NEUTRAL position.

7. The vehicle may then be started in NEUTRAL.

8. Reinstall the shift lever override access cover.

WHAT TO DO IN EMERGENCIES

104

Page 108 of 148

FREEING A STUCK VEHICLE

• If your vehicle becomes stuck in mud, sand or snow, it can often be moved using arocking motion. Turn your steering wheel right and left to clear the area around the front

wheels. Then shift back and forth between DRIVE and REVERSE (with automatic trans-

mission) or 2nd gear and REVERSE (with manual transmission) while gently pressing the

accelerator. Use the least amount of accelerator pedal pressure that will maintain the

rocking motion, without spinning the wheels or racing the engine.

NOTE:

Press the "ESC Off" switch, to place the Electronic Stability Control (ESC) system in "Partial

Off" mode before rocking the vehicle. Once the vehicle has been freed, press the "ESC Off"

switch again to restore "ESC On" mode.

CAUTION!

• Racing the engine or spinning the wheels may lead to transmission overheating and failure. Allow the engine to idle with the shift lever in NEUTRAL for at least one minute

after every five rocking-motion cycles. This will minimize overheating and reduce the

risk of transmission failure during prolonged efforts to free a stuck vehicle.

• When “rocking” a stuck vehicle by moving between DRIVE/2nd and REVERSE, do not

spin the wheels faster than 15 mph (24 km/h), or drivetrain damage may result.

• Revving the engine or spinning the wheels too fast may lead to transmission over-

heating and failure. It can also damage the tires. Do not spin the wheels above

30 mph (48 km/h) while in gear (no transmission shifting occurring).

WHAT TO DO IN EMERGENCIES

106

Page 111 of 148

ENGINE COMPARTMENT3.6L Engine

MAINTAINING YOUR VEHICLE

109

Page 112 of 148

5.7L Engine

MAINTAINING YOUR VEHICLE

110

Page 113 of 148

6.4L Engine

MAINTAINING YOUR VEHICLE

111

Page 114 of 148

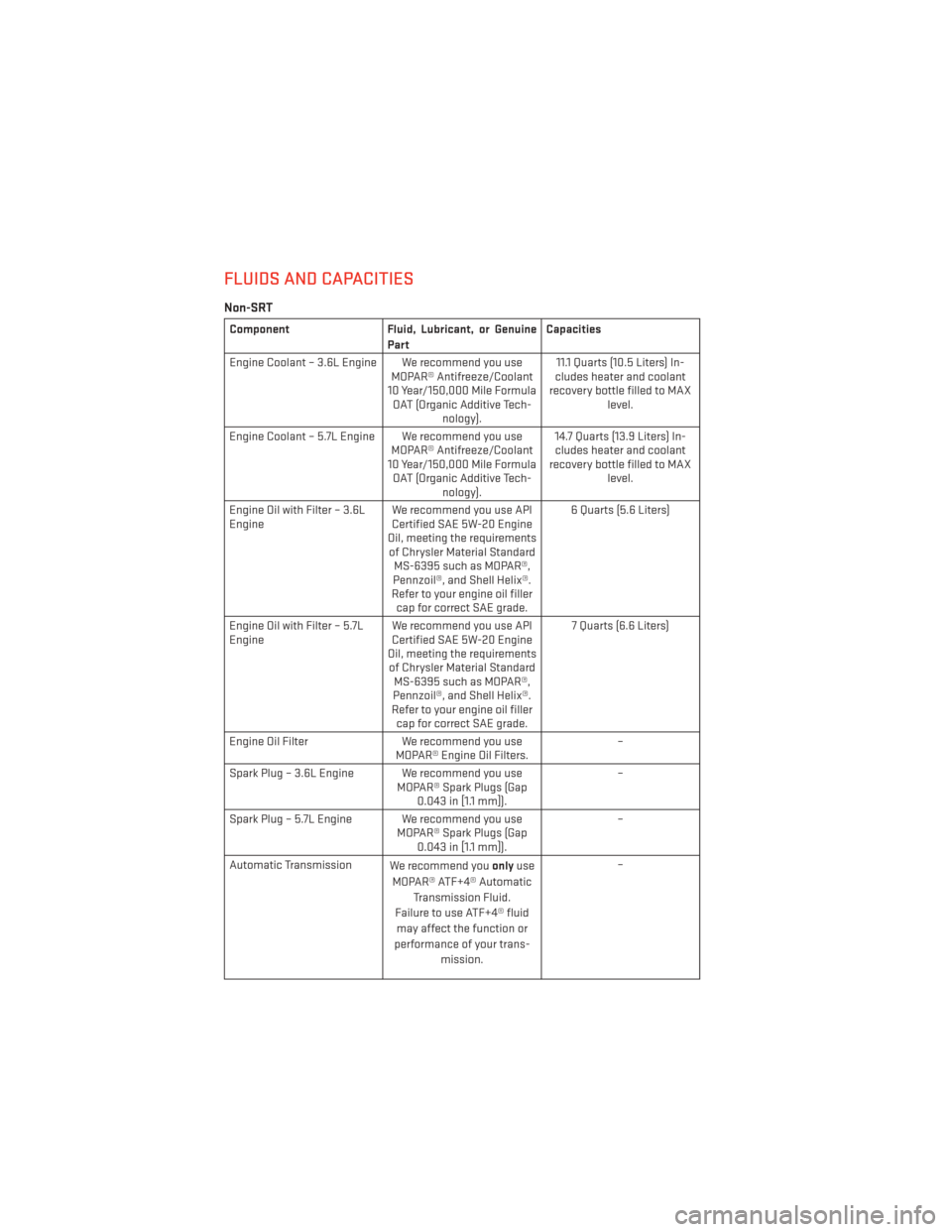

FLUIDS AND CAPACITIES

Non-SRT

ComponentFluid, Lubricant, or Genuine

Part Capacities

Engine Coolant – 3.6L Engine We recommend you use MOPAR® Antifreeze/Coolant

10 Year/150,000 Mile Formula OAT (Organic Additive Tech- nology). 11.1 Quarts (10.5 Liters) In-

cludes heater and coolant

recovery bottle filled to MAX level.

Engine Coolant – 5.7L Engine We recommend you use MOPAR® Antifreeze/Coolant

10 Year/150,000 Mile Formula OAT (Organic Additive Tech- nology). 14.7 Quarts (13.9 Liters) In-

cludes heater and coolant

recovery bottle filled to MAX level.

Engine Oil with Filter – 3.6L

Engine We recommend you use API

Certified SAE 5W-20 Engine

Oil, meeting the requirements of Chrysler Material Standard MS-6395 such as MOPAR®,

Pennzoil®, and Shell Helix®.

Refer to your engine oil filler cap for correct SAE grade. 6 Quarts (5.6 Liters)

Engine Oil with Filter – 5.7L

Engine We recommend you use API

Certified SAE 5W-20 Engine

Oil, meeting the requirements of Chrysler Material Standard MS-6395 such as MOPAR®,

Pennzoil®, and Shell Helix®.

Refer to your engine oil filler cap for correct SAE grade. 7 Quarts (6.6 Liters)

Engine Oil Filter We recommend you use

MOPAR® Engine Oil Filters. –

Spark Plug – 3.6L Engine We recommend you use MOPAR® Spark Plugs (Gap0.043 in [1.1 mm]). –

Spark Plug – 5.7L Engine We recommend you use MOPAR® Spark Plugs (Gap0.043 in [1.1 mm]). –

Automatic Transmission We recommend youonlyuse

MOPAR® ATF+4® Automatic Transmission Fluid.

Failure to use ATF+4® fluid may affect the function or

performance of your trans- mission. –

MAINTAINING YOUR VEHICLE

112