warning DODGE CHALLENGER 2020 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2020, Model line: CHALLENGER, Model: DODGE CHALLENGER 2020Pages: 396, PDF Size: 16.64 MB

Page 258 of 396

256SERVICING AND MAINTENANCE

Engine Air Cleaner Filter Selection

The quality of replacement engine air cleaner

filters varies considerably. Only high quality

filters should be used to ensure most efficient

service. Mopar engine air cleaner filters are a

high quality filter and are recommended.

T/A Air Filter Maintenance — If Equipped

Clean Engine Air Filter

The scheduled air filter cleaning interval is

30,000 miles (48,280 km), or if in a dusty

environment the engine air filter should be

checked periodically to ensure optimal air flow.

Cleaning your engine air filter with the

recommended Mopar Performance Air Filter

Service Kit is not required if you can still see any

part the wire screen on the entire air filter

regardless of how dirty it may appear. When any

part of the wire screen is no longer visible on the

air filter, that is an indication it is time to clean

the air filter.

1. Spray the air filter with the recommended

Mopar air filter cleaner and let sit for at

least 10 minutes to loosen dirt, before

rinsing.

NOTE:

Never use strong detergents, high pressure, or

gasoline on air filter. 2. Rinse the air filter with cool low-pressure

water applied from the inside (clean side)

out in order to flush the dirt out of the filter.

Continue to rinse the filter until all traces of

the cleaner have been removed.

NOTE:

It may be necessary to repeat steps 1 and 2 if

the air filter is not completely clean.

3. After rinsing the air filter, gently shake off the excess water and allow air filter to dry

naturally. Do not apply oil until air filter is

completely dry.

NOTE:

Do not use forced air pressure as it may

damage the filtering capabilities of the filter’s

microfibers and also void its warranty.

4. Using the Mopar Performance Air Filter Service Kit, spray oil evenly along the crown

of each filter pleat holding the nozzle about

3 inches (76 mm) away from the air filter.

One spray per 2 square inches

(1,290 square mm) of air filter. With one

complete coat of oil, let it wick (saturate) for

about 20 minutes, and if required touch up

any light areas on either side of the filter.WARNING!

The air induction system (air cleaner, hoses,

etc.) can provide a measure of protection in

the case of engine backfire. Do not remove

the air induction system (air cleaner, hoses,

etc.) unless such removal is necessary for

repair or maintenance. Make sure that no

one is near the engine compartment before

starting the vehicle with the air induction

system (air cleaner, hoses, etc.) removed.

Failure to do so can result in serious personal

injury.

20_LA_OM_EN_USC_t.book Page 256

Page 259 of 396

SERVICING AND MAINTENANCE257

AIR CONDITIONER MAINTENANCE

For best possible performance, your air

conditioner should be checked and serviced by

an authorized dealer at the start of each warm

season. This service should include cleaning of

the condenser fins and a performance test.

Drive belt tension should also be checked at

this time.

Refrigerant Recovery And Recycling

R-134a — If Equipped

R-134a Air Conditioning Refrigerant is a

hydrofluorocarbon (HFC) that is an

ozone-friendly substance. The manufacturer

recommends that air conditioning service be

performed by an authorized dealer or other

service facilities using recovery and recycling

equipment.

NOTE:

Use only manufacturer approved A/C system

PAG compressor oil and refrigerants.

Refrigerant Recovery And Recycling

R-1234yf — If Equipped

R–1234yf Air Conditioning Refrigerant is a

hydrofluoroolefin (HFO) that is endorsed by the

Environmental Protection Agency and is an

ozone-friendly substance with a low

global-warming potential. The manufacturer

recommends that air conditioning service be

performed by an authorized dealer using

recovery and recycling equipment.

NOTE:

Use only manufacturer approved A/C system

PAG compressor oil, and refrigerants.

WARNING!

Use only refrigerants and compressor lubri -

cants approved by the manufacturer for

your air conditioning system. Some unap -

proved refrigerants are flammable and can

explode, injuring you. Other unapproved

refrigerants or lubricants can cause the

system to fail, requiring costly repairs.

Refer to Warranty Information Book, for

further warranty information.

The air conditioning system contains refrig -

erant under high pressure. To avoid risk of

personal injury or damage to the system,

adding refrigerant or any repair requiring

lines to be disconnected should be done by

an experienced technician.

CAUTION!

Do not use chemical flushes in your air

conditioning system as the chemicals can

damage your air conditioning components.

Such damage is not covered by the New

Vehicle Limited Warranty.

7

20_LA_OM_EN_USC_t.book Page 257

Page 260 of 396

258SERVICING AND MAINTENANCE

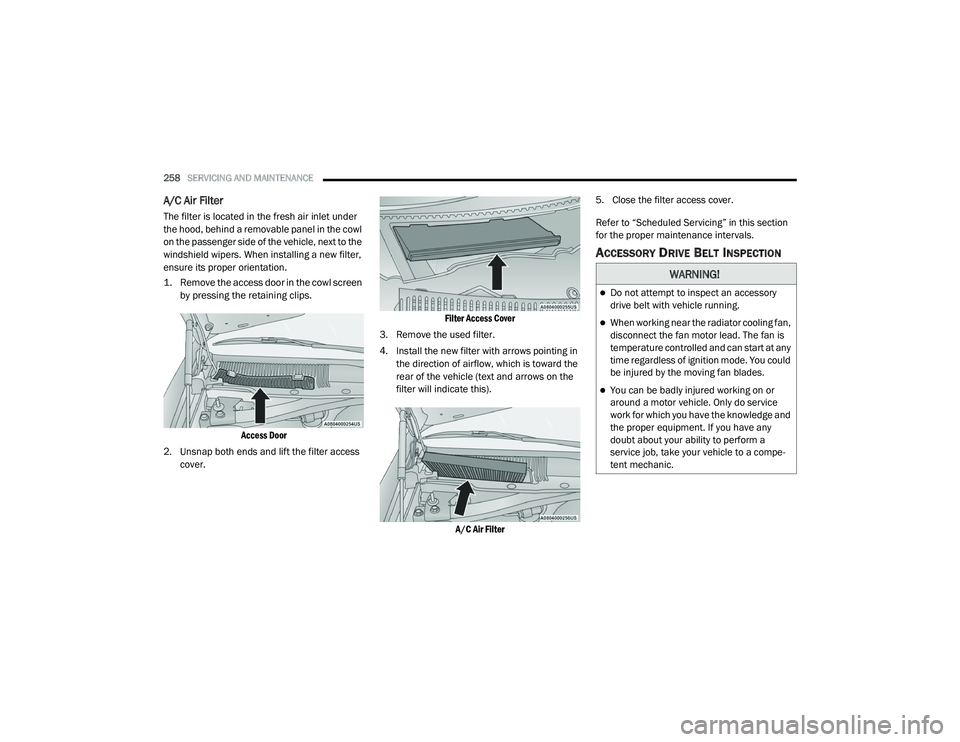

A/C Air Filter

The filter is located in the fresh air inlet under

the hood, behind a removable panel in the cowl

on the passenger side of the vehicle, next to the

windshield wipers. When installing a new filter,

ensure its proper orientation.

1. Remove the access door in the cowl screen

by pressing the retaining clips.

Access Door

2. Unsnap both ends and lift the filter access cover.

Filter Access Cover

3. Remove the used filter.

4. Install the new filter with arrows pointing in the direction of airflow, which is toward the

rear of the vehicle (text and arrows on the

filter will indicate this).

A/C Air Filter

5. Close the filter access cover.

Refer to “Scheduled Servicing” in this section

for the proper maintenance intervals.

ACCESSORY DRIVE BELT INSPECTION

WARNING!

Do not attempt to inspect an accessory

drive belt with vehicle running.

When working near the radiator cooling fan,

disconnect the fan motor lead. The fan is

temperature controlled and can start at any

time regardless of ignition mode. You could

be injured by the moving fan blades.

You can be badly injured working on or

around a motor vehicle. Only do service

work for which you have the knowledge and

the proper equipment. If you have any

doubt about your ability to perform a

service job, take your vehicle to a compe

-

tent mechanic.

20_LA_OM_EN_USC_t.book Page 258

Page 263 of 396

SERVICING AND MAINTENANCE261

Installing The Front Wipers

1. Lift the wiper arm off of the glass, until the

wiper arm is in the full up position.

2. Position the wiper blade near the hook on the tip of the wiper arm.

3. Insert the hook on the tip of the arm through the opening in the wiper blade.

4. Slide the wiper blade up into the hook on the wiper arm, latch engagement will be

accompanied by an audible click.

5. Gently lower the wiper blade onto the glass.

EXHAUST SYSTEM

The best protection against carbon monoxide

entry into the vehicle body is a properly

maintained engine exhaust system.

If you notice a change in the sound of the

exhaust system; or if the exhaust fumes can be

detected inside the vehicle; or when the

underside or rear of the vehicle is damaged;

have an authorized technician inspect the

complete exhaust system and adjacent body

areas for broken, damaged, deteriorated, or

mispositioned parts. Open seams or loose connections could permit

exhaust fumes to seep into the passenger

compartment. In addition, have the exhaust

system inspected each time the vehicle is

raised for lubrication or oil change. Replace as

required.

WARNING!

Exhaust gases can injure or kill. They

contain carbon monoxide (CO), which is

colorless and odorless. Breathing it can

make you unconscious and can eventually

poison you. To avoid breathing CO, refer

to “Safety Tips” in “Safety” for further

information.

A hot exhaust system can start a fire if you

park over materials that can burn. Such

materials might be grass or leaves coming

into contact with your exhaust system. Do

not park or operate your vehicle in areas

where your exhaust system can contact

anything that can burn.

CAUTION!

The catalytic converter requires the use of

unleaded fuel only. Leaded gasoline will

destroy the effectiveness of the catalyst as

an emissions control device and may seri

-

ously reduce engine performance and

cause serious damage to the engine.

Damage to the catalytic converter can

result if your vehicle is not kept in proper

operating condition. In the event of engine

malfunction, particularly involving engine

misfire or other apparent loss of perfor -

mance, have your vehicle serviced

promptly. Continued operation of your

vehicle with a severe malfunction could

cause the converter to overheat, resulting

in possible damage to the converter and

vehicle.

7

20_LA_OM_EN_USC_t.book Page 261

Page 264 of 396

262SERVICING AND MAINTENANCE

(Continued)

Under normal operating conditions, the

catalytic converter will not require

maintenance. However, it is important to keep

the engine properly tuned to ensure proper

catalyst operation and prevent possible catalyst

damage.

NOTE:

Intentional tampering with emissions control

systems can result in civil penalties being

assessed against you.

In unusual situations involving grossly

malfunctioning engine operation, a scorching

odor may suggest severe and abnormal catalyst

overheating. If this occurs, stop the vehicle, turn

off the engine and allow it to cool. Service,

including a tune-up to manufacturer's

specifications, should be obtained immediately.

To minimize the possibility of catalytic converter

damage:

Do not shut off the engine or interrupt the

ignition when the transmission is in gear and

the vehicle is in motion.

Do not try to start the engine by pushing or

towing the vehicle.

Do not idle the engine with any spark plug

wires disconnected or removed, such as

when diagnostic testing, or for prolonged

periods during very rough idle or malfunc-

tioning operating conditions.

NOTE:

The vehicle exhaust system may be equipped

with an Electronic Exhaust Valve (EEV) system,

if the exhaust system is replaced with after -

market products a Malfunction Indicator Lamp

(MIL) will illuminate.

COOLING SYSTEM

Coolant Checks

Check engine coolant (antifreeze) protection

every 12 months (before the onset of freezing

weather, where applicable). If coolant is dirty or

rusty in appearance, the system should be

drained, flushed, and refilled with fresh coolant.

Check the front of the radiator for any

accumulation of bugs, leaves, etc. If dirty, clean

by gently spraying water from a garden hose

vertically down the face of the condenser.

Check the coolant recovery bottle tubing for

brittle rubber, cracking, tears, cuts, and

tightness of the connection at the bottle and

radiator. Inspect the entire system for leaks. DO

NOT REMOVE THE COOLANT PRESSURE CAP

WHEN THE COOLING SYSTEM IS HOT.

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from

your radiator. If you see or hear steam

coming from under the hood, do not open

the hood until the radiator has had time to

cool. Never open a cooling system pressure

cap when the radiator or coolant bottle is

hot.

Keep hands, tools, clothing, and jewelry

away from the radiator cooling fan when

the hood is raised. The fan starts automati -

cally and may start at any time, whether the

engine is running or not.

When working near the radiator cooling fan,

disconnect the fan motor lead or turn the

ignition to the OFF mode. The fan is

temperature controlled and can start at any

time the ignition is in the ON mode.

WARNING! (Continued)

20_LA_OM_EN_USC_t.book Page 262

Page 266 of 396

264SERVICING AND MAINTENANCE

We recommend using Mopar Antifreeze/

Coolant 10 Year/150,000 Mile

(240,000 km) Formula OAT (Organic Additive

Technology) that meets the requirements of

FCA Material Standard MS.90032.

Mix a minimum solution of 50% OAT engine

coolant that meets the requirements of

FCA Material Standard MS.90032 and

distilled water. Use higher concentrations

(not to exceed 70%) if temperatures below

−34°F (−37°C) are anticipated. Please

contact an authorized dealer for assistance.

Use only high purity water such as distilled or

deionized water when mixing the water/

engine coolant (antifreeze) solution. The use

of lower quality water will reduce the amount

of corrosion protection in the engine

cooling system.

NOTE:

It is the owner's responsibility to maintain the

proper level of protection against freezing

according to the temperatures occurring in

the area where the vehicle is operated.

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added

to the system, please contact a local autho -

rized dealer.

Mixing engine coolant (antifreeze) types is

not recommended and can result in cooling

system damage. If HOAT and OAT coolant are

mixed in an emergency, have a authorized

dealer drain, flush, and refill with OAT coolant

(conforming to MS.90032) as soon as

possible.

Cooling System Pressure Cap

The cap must be fully tightened to prevent loss

of engine coolant (antifreeze), and to ensure

that engine coolant (antifreeze) will return to

the radiator from the coolant expansion

bottle/recovery tank (if equipped).

The cap should be inspected and cleaned if

there is any accumulation of foreign material on

the sealing surfaces. NOTE:

Be sure you do not mix the engine coolant

system pressure cap with the intercooler

system pressure cap. These caps are not inter

-

changeable.

WARNING!

Do not open hot engine cooling system.

Never add engine coolant (antifreeze) when

the engine is overheated. Do not loosen or

remove the cap to cool an overheated

engine. Heat causes pressure to build up in

the cooling system. To prevent scalding or

injury, do not remove the pressure cap

while the system is hot or under pressure.

Do not use a pressure cap other than the

one specified for your vehicle. Personal

injury or engine damage may result.

20_LA_OM_EN_USC_t.book Page 264

Page 268 of 396

266SERVICING AND MAINTENANCE

(Continued)

BRAKE SYSTEM

In order to ensure brake system performance,

all brake system components should be

inspected periodically. Refer to the

“Maintenance Plan” in this section for the

proper maintenance intervals.

Fluid Level Check — Brake Master Cylinder

Check the fluid level in the master cylinder

immediately if the brake system warning light

indicates system failure.

Check the fluid level in the master cylinder

when performing underhood services.

Clean the top of the master cylinder area before

removing the cap. Add fluid to bring the level up

to the top of the “FULL” mark on the side of the

master cylinder reservoir.Overfilling of fluid is not recommended because

it may cause leaking in the system.

Add enough fluid to bring the level up to the

requirements described on the brake fluid

reservoir. With disc brakes, fluid level can be

expected to fall as the brake pads wear.

However, low fluid level may be caused by a

leak and a checkup may be needed.

Use only brake fluid that has been

recommended by the manufacturer, and has

been kept in a tightly closed container to avoid

contamination from foreign matter or moisture.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.

WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri

-

cants” in “Technical Specifications” for

further information. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory

installed hydraulic master cylinder

reservoir.

To avoid contamination from foreign matter

or moisture, use only new brake fluid or

fluid that has been in a tightly closed

container. Keep the master cylinder reser -

voir cap secured at all times. Brake fluid in

a open container absorbs moisture from

the air resulting in a lower boiling point. This

may cause it to boil unexpectedly during

hard or prolonged braking, resulting in

sudden brake failure. This could result in a

collision.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)

20_LA_OM_EN_USC_t.book Page 266

Page 278 of 396

276SERVICING AND MAINTENANCE

TIRES — GENERAL INFORMATION

Tire Pressure

Proper tire inflation pressure is essential to the

safe and satisfactory operation of your vehicle.

Four primary areas are affected by improper tire

pressure:

Safety

Fuel Economy

Tread Wear

Ride Comfort and Vehicle Stability Safety

Both underinflation and overinflation affect the

stability of the vehicle and can produce a feeling

of sluggish response or over responsiveness in

the steering.

NOTE:

Unequal tire pressures from side to side may

cause erratic and unpredictable steering

response.

Unequal tire pressure from side to side may

cause the vehicle to drift left or right.

Fuel Economy

Underinflated tires will increase tire rolling

resistance resulting in higher fuel consumption.

Tread Wear

Improper cold tire inflation pressures can cause

abnormal wear patterns and reduced tread life,

resulting in the need for earlier tire

replacement.

Ride Comfort And Vehicle Stability

Proper tire inflation contributes to a

comfortable ride. Overinflation produces a

jarring and uncomfortable ride.

WARNING!

Overloading of your tires is dangerous.

Overloading can cause tire failure, affect

vehicle handling, and increase your stopping

distance. Use tires of the recommended load

capacity for your vehicle. Never overload

them.WARNING!

Improperly inflated tires are dangerous and

can cause collisions.

Underinflation increases tire flexing and

can result in overheating and tire failure.

Overinflation reduces a tire's ability to

cushion shock. Objects on the road and

chuckholes can cause damage that result

in tire failure.

Overinflated or underinflated tires can

affect vehicle handling and can fail

suddenly, resulting in loss of vehicle

control.

Unequal tire pressures can cause steering

problems. You could lose control of your

vehicle.

Unequal tire pressures from one side of the

vehicle to the other can cause the vehicle

to drift to the right or left.

Always drive with each tire inflated to the

recommended cold tire inflation pressure.

20_LA_OM_EN_USC_t.book Page 276

Page 279 of 396

SERVICING AND MAINTENANCE277

Tire Inflation Pressures

The proper cold tire inflation pressure is listed

on the driver's side B-pillar or rear edge of the

driver's side door.

At least once a month:

Check and adjust tire pressure with a good

quality pocket-type pressure gauge. Do not

make a visual judgement when determining

proper inflation. Tires may look properly

inflated even when they are under-inflated.

Inspect tires for signs of tire wear or visible

damage.

Inflation pressures specified on the placard are

always “cold tire inflation pressure”. Cold tire

inflation pressure is defined as the tire pressure

after the vehicle has not been driven for at least

3 hours, or driven less than 1 mile (1.6 km) after

sitting for a minimum of 3 hours. The cold tire inflation pressure must not exceed

the maximum inflation pressure molded into the

tire sidewall.

Check tire pressures more often if subject to a

wide range of outdoor temperatures, as tire

pressures vary with temperature changes.

Tire pressures change by approximately 1 psi

(7 kPa) per 12°F (7°C) of air temperature

change. Keep this in mind when checking tire

pressure inside a garage, especially in the

Winter.

Example: If garage temperature = 68°F (20°C)

and the outside temperature = 32°F (0°C) then

the cold tire inflation pressure should be

increased by 3 psi (21 kPa), which equals 1 psi

(7 kPa) for every 12°F (7°C) for this outside

temperature condition.

Tire pressure may increase from 2 to 6 psi

(13 to 40 kPa) during operation. DO NOT reduce

this normal pressure build up or your tire

pressure will be too low.

Tire Pressures For High Speed Operation

The manufacturer advocates driving at safe

speeds and within posted speed limits. Where

speed limits or conditions are such that the

vehicle can be driven at high speeds, maintaining

correct tire inflation pressure is very important.Increased tire pressure and reduced vehicle

loading may be required for high-speed vehicle

operation. Refer to an authorized tire dealer or

original equipment vehicle dealer for

recommended safe operating speeds, loading

and cold tire inflation pressures.

Radial Ply Tires

CAUTION!

After inspecting or adjusting the tire pressure,

always reinstall the valve stem cap. This will

prevent moisture and dirt from entering the

valve stem, which could damage the valve

stem.

WARNING!

High speed driving with your vehicle under

maximum load is dangerous. The added

strain on your tires could cause them to fail.

You could have a serious collision. Do not

drive a vehicle loaded to the maximum

capacity at continuous speeds above 75 mph

(120 km/h).

WARNING!

Combining radial ply tires with other types of

tires on your vehicle will cause your vehicle to

handle poorly. The instability could cause a

collision. Always use radial ply tires in sets of

four. Never combine them with other types of

tires.

7

20_LA_OM_EN_USC_t.book Page 277

Page 280 of 396

278SERVICING AND MAINTENANCE

Tire Repair

If your tire becomes damaged, it may be

repaired if it meets the following criteria:

The tire has not been driven on when flat.

The damage is only on the tread section of

your tire (sidewall damage is not repairable).

The puncture is no greater than a ¼ of an

inch (6 mm).

Consult an authorized tire dealer for tire repairs

and additional information.

Damaged Run Flat tires, or Run Flat tires that

have experienced a loss of pressure should be

replaced immediately with another Run Flat tire

of identical size and service description (Load

Index and Speed Symbol). Replace the tire

pressure sensor as well as it is not designed to

be reused.

Run Flat Tires — If Equipped

Run Flat tires allow you the capability to drive

50 miles (80 km) at 50 mph (80 km/h) after a

rapid loss of inflation pressure. This rapid loss

of inflation is referred to as the Run Flat mode.

A Run Flat mode occurs when the tire inflation

pressure is of/or below 14 psi (96 kPa). Once a

Run Flat tire reaches the run flat mode it has

limited driving capabilities and needs to be

replaced immediately. A Run Flat tire is not

repairable. When a run flat tire is changed after

driving with underinflated tire condition, please

replace the TPM sensor as it is not designed to

be reused when driven under run flat mode

14 psi (96 kPa) condition.

NOTE:

TPM Sensor must be replaced after driving the

vehicle on a flat tire condition.

It is not recommended driving a vehicle loaded

at full capacity or to tow a trailer while a tire is in

the run flat mode.

See the tire pressure monitoring section for

more information.

Tire Spinning

When stuck in mud, sand, snow, or ice

conditions, do not spin your vehicle's wheels

above 30 mph (48 km/h) or for longer than

30 seconds continuously without stopping.

Refer to “Freeing A Stuck Vehicle” in “In Case Of

Emergency” for further information.

Tread Wear Indicators

Tread wear indicators are in the original

equipment tires to help you in determining

when your tires should be replaced.

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may

cause tire damage or failure. A tire could

explode and injure someone. Do not spin your

vehicle's wheels faster than 30 mph

(48 km/h) for more than 30 seconds

continuously when you are stuck, and do not

let anyone near a spinning wheel, no matter

what the speed.

20_LA_OM_EN_USC_t.book Page 278