lock DODGE CHALLENGER 2020 Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2020, Model line: CHALLENGER, Model: DODGE CHALLENGER 2020Pages: 396, PDF Size: 16.64 MB

Page 214 of 396

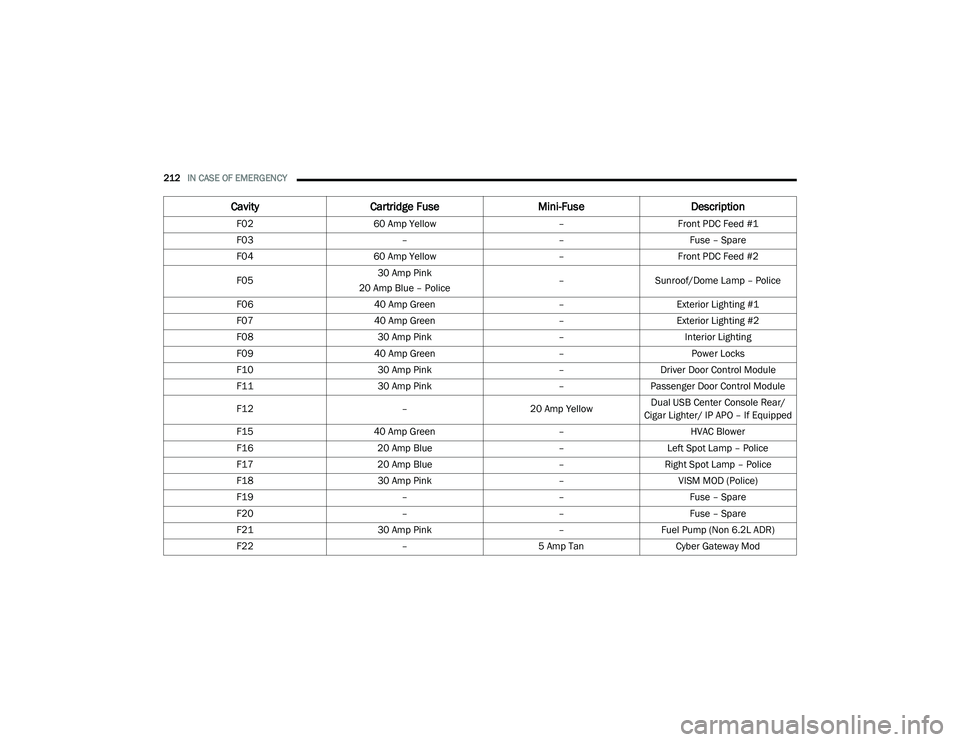

212IN CASE OF EMERGENCY

Cavity Cartridge Fuse Mini-FuseDescription

F02 60 Amp Yellow –Front PDC Feed #1

F03 ––Fuse – Spare

F04 60 Amp Yellow –Front PDC Feed #2

F05 30 Amp Pink

20 Amp Blue – Police –

Sunroof/Dome Lamp – Police

F06 40 Amp Green –Exterior Lighting #1

F07 40 Amp Green –Exterior Lighting #2

F08 30 Amp Pink –Interior Lighting

F09 40 Amp Green –Power Locks

F10 30 Amp Pink –Driver Door Control Module

F11 30 Amp Pink –Passenger Door Control Module

F12 –20 Amp YellowDual USB Center Console Rear/

Cigar Lighter/ IP APO – If Equipped

F15 40 Amp Green –HVAC Blower

F16 20 Amp Blue –Left Spot Lamp – Police

F17 20 Amp Blue –Right Spot Lamp – Police

F18 30 Amp Pink –VISM MOD (Police)

F19 ––Fuse – Spare

F20 ––Fuse – Spare

F21 30 Amp Pink –Fuel Pump (Non 6.2L ADR)

F22 –5 Amp Tan Cyber Gateway Mod

20_LA_OM_EN_USC_t.book Page 212

Page 215 of 396

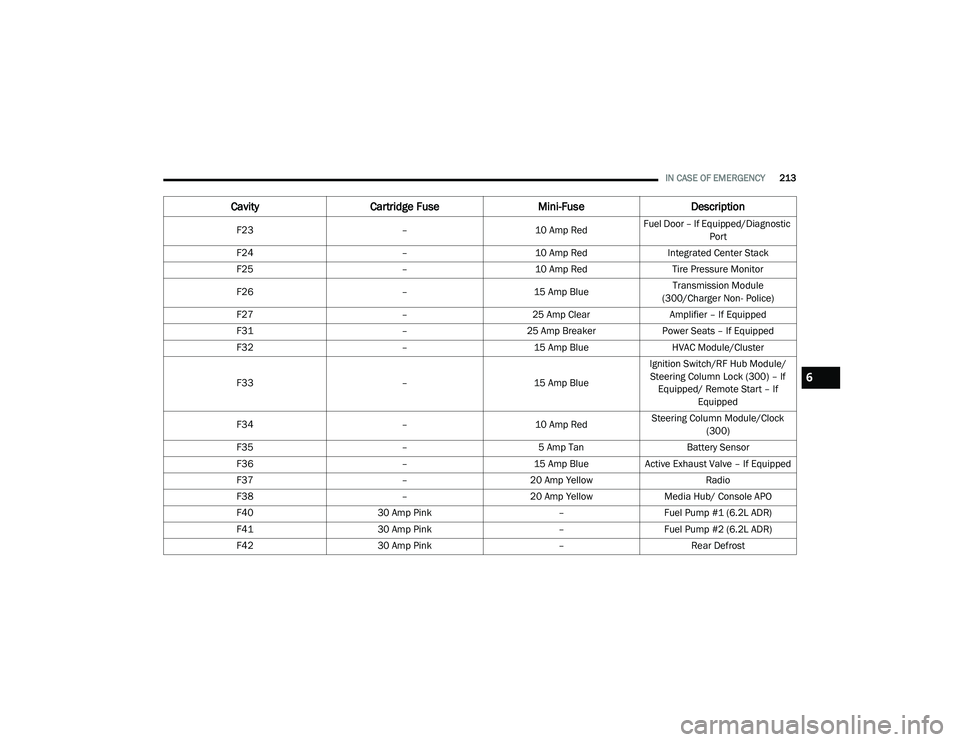

IN CASE OF EMERGENCY213

F23 –10 Amp RedFuel Door – If Equipped/Diagnostic

Port

F24 –10 Amp RedIntegrated Center Stack

F25 –10 Amp Red Tire Pressure Monitor

F26 –15 Amp Blue Transmission Module

(300/Charger Non- Police)

F27 –25 Amp Clear Amplifier – If Equipped

F31 –25 Amp Breaker Power Seats – If Equipped

F32 –15 Amp Blue HVAC Module/Cluster

F33 –15 Amp BlueIgnition Switch/RF Hub Module/

Steering Column Lock (300) – If Equipped/ Remote Start – If Equipped

F34 –10 Amp RedSteering Column Module/Clock

(300)

F35 –5 Amp Tan Battery Sensor

F36 –15 Amp BlueActive Exhaust Valve – If Equipped

F37 –20 Amp Yellow Radio

F38 –20 Amp Yellow Media Hub/ Console APO

F40 30 Amp Pink –Fuel Pump #1 (6.2L ADR)

F41 30 Amp Pink –Fuel Pump #2 (6.2L ADR)

F42 30 Amp Pink –Rear Defrost

CavityCartridge Fuse Mini-FuseDescription

6

20_LA_OM_EN_USC_t.book Page 213

Page 218 of 396

216IN CASE OF EMERGENCY

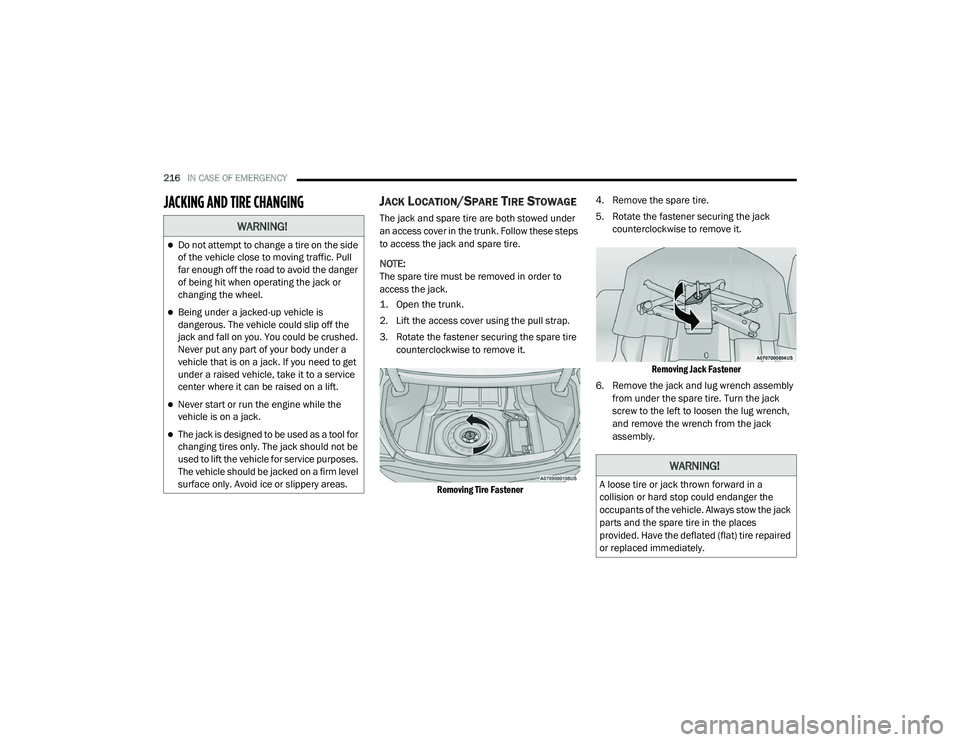

JACKING AND TIRE CHANGINGJACK LOCATION/SPARE TIRE STOWAGE

The jack and spare tire are both stowed under

an access cover in the trunk. Follow these steps

to access the jack and spare tire.

NOTE:

The spare tire must be removed in order to

access the jack.

1. Open the trunk.

2. Lift the access cover using the pull strap.

3. Rotate the fastener securing the spare tire

counterclockwise to remove it.

Removing Tire Fastener

4. Remove the spare tire.

5. Rotate the fastener securing the jack

counterclockwise to remove it.

Removing Jack Fastener

6. Remove the jack and lug wrench assembly from under the spare tire. Turn the jack

screw to the left to loosen the lug wrench,

and remove the wrench from the jack

assembly.WARNING!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic. Pull

far enough off the road to avoid the danger

of being hit when operating the jack or

changing the wheel.

Being under a jacked-up vehicle is

dangerous. The vehicle could slip off the

jack and fall on you. You could be crushed.

Never put any part of your body under a

vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service

center where it can be raised on a lift.

Never start or run the engine while the

vehicle is on a jack.

The jack is designed to be used as a tool for

changing tires only. The jack should not be

used to lift the vehicle for service purposes.

The vehicle should be jacked on a firm level

surface only. Avoid ice or slippery areas.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired

or replaced immediately.

20_LA_OM_EN_USC_t.book Page 216

Page 219 of 396

IN CASE OF EMERGENCY217

(Continued)

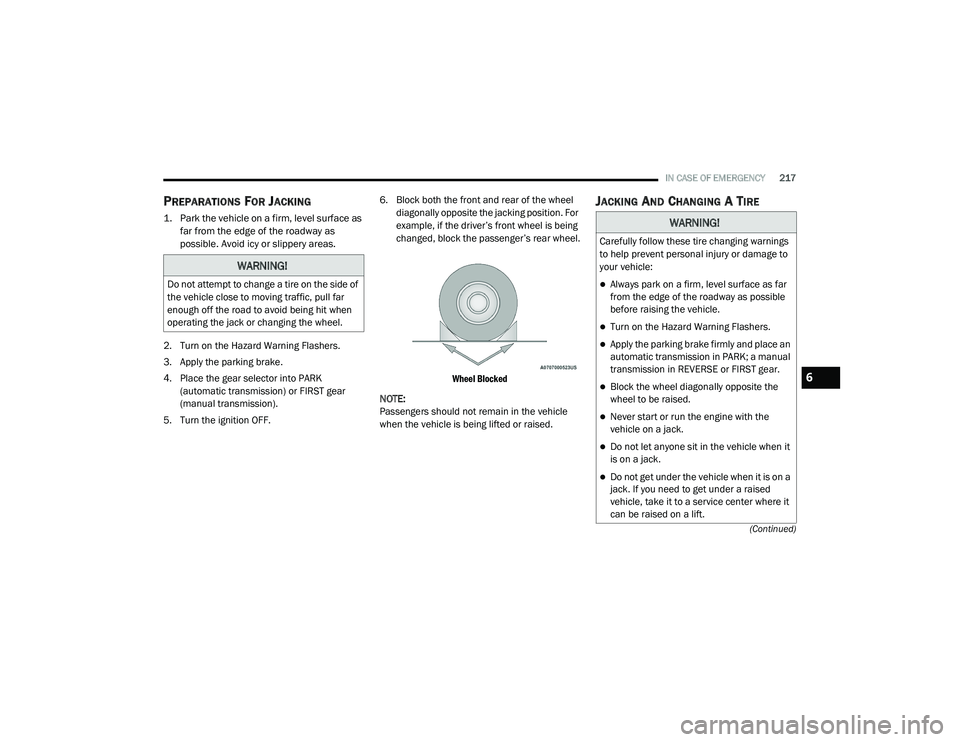

PREPARATIONS FOR JACKING

1. Park the vehicle on a firm, level surface as far from the edge of the roadway as

possible. Avoid icy or slippery areas.

2. Turn on the Hazard Warning Flashers.

3. Apply the parking brake.

4. Place the gear selector into PARK (automatic transmission) or FIRST gear

(manual transmission).

5. Turn the ignition OFF. 6. Block both the front and rear of the wheel

diagonally opposite the jacking position. For

example, if the driver’s front wheel is being

changed, block the passenger’s rear wheel.

Wheel Blocked

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being lifted or raised.

JACKING AND CHANGING A TIRE

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic, pull far

enough off the road to avoid being hit when

operating the jack or changing the wheel.

WARNING!

Carefully follow these tire changing warnings

to help prevent personal injury or damage to

your vehicle:

Always park on a firm, level surface as far

from the edge of the roadway as possible

before raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and place an

automatic transmission in PARK; a manual

transmission in REVERSE or FIRST gear.

Block the wheel diagonally opposite the

wheel to be raised.

Never start or run the engine with the

vehicle on a jack.

Do not let anyone sit in the vehicle when it

is on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised

vehicle, take it to a service center where it

can be raised on a lift.

6

20_LA_OM_EN_USC_t.book Page 217

Page 220 of 396

218IN CASE OF EMERGENCY

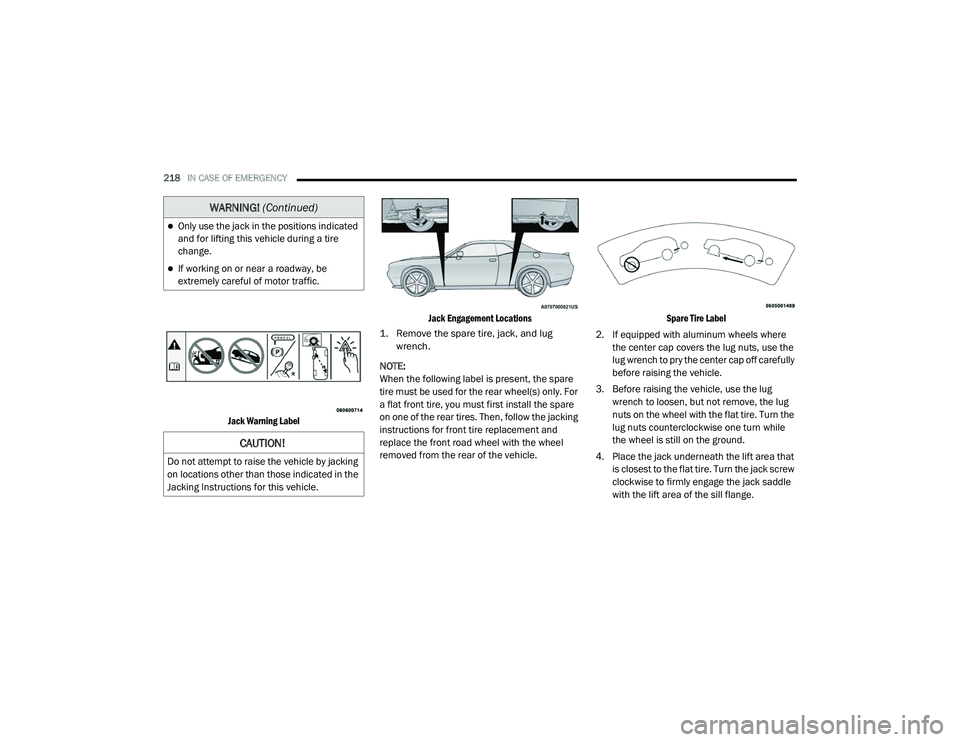

Jack Warning Label Jack Engagement Locations

1. Remove the spare tire, jack, and lug wrench.

NOTE:

When the following label is present, the spare

tire must be used for the rear wheel(s) only. For

a flat front tire, you must first install the spare

on one of the rear tires. Then, follow the jacking

instructions for front tire replacement and

replace the front road wheel with the wheel

removed from the rear of the vehicle.

Spare Tire Label

2. If equipped with aluminum wheels where the center cap covers the lug nuts, use the

lug wrench to pry the center cap off carefully

before raising the vehicle.

3. Before raising the vehicle, use the lug wrench to loosen, but not remove, the lug

nuts on the wheel with the flat tire. Turn the

lug nuts counterclockwise one turn while

the wheel is still on the ground.

4. Place the jack underneath the lift area that is closest to the flat tire. Turn the jack screw

clockwise to firmly engage the jack saddle

with the lift area of the sill flange.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire

change.

If working on or near a roadway, be

extremely careful of motor traffic.

CAUTION!

Do not attempt to raise the vehicle by jacking

on locations other than those indicated in the

Jacking Instructions for this vehicle.

WARNING! (Continued)

20_LA_OM_EN_USC_t.book Page 218

Page 222 of 396

220IN CASE OF EMERGENCY

NOTE:

For vehicles so equipped, do not attempt to

install a center cap or wheel cover on the

compact spare.

Refer to “Compact Spare Tire” and to

“Limited-Use Spare” under “Tires” in

“Servicing And Maintenance” for additional

warnings, cautions, and information about

the spare tire, its use, and operation.

8. Install the lug nuts with the cone shaped end of the lug nut toward the wheel. Lightly

tighten the lug nuts.

9. Lower the vehicle to the ground by turning the jack handle counterclockwise.

10. Refer to “Wheel And Tire Torque Specifi -

cations” in “Technical Specifications”

section for proper lug nut torque. 11. Stow the jack, tools and flat tire. Make sure

the base of the jack faces the front of the

vehicle before tightening down the fastener.

TIRE SERVICE KIT — IF EQUIPPED

Small punctures up to 1/4 inch (6 mm) in the

tire tread can be sealed with Tire Service Kit.

Foreign objects (e.g., screws or nails) should not

be removed from the tire. Tire Service Kit can be

used in outside temperatures down to

approximately -4°F (-20°C).

This kit will provide a temporary tire seal,

allowing you to drive your vehicle up to

100 miles (160 km) with a maximum speed of 50 mph (80 km/h).

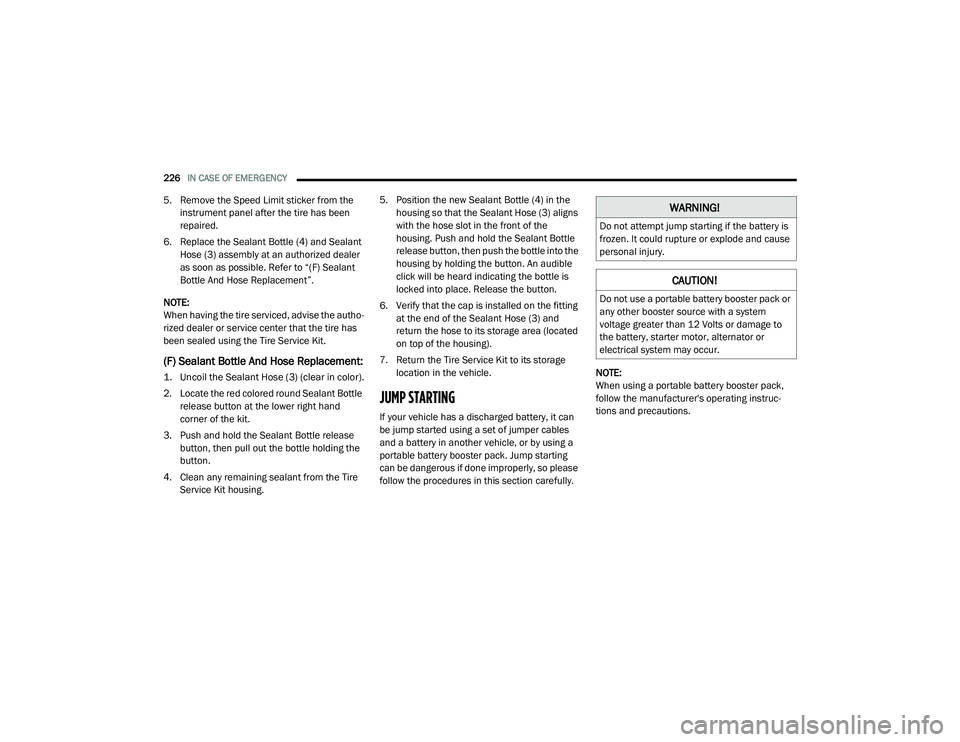

TIRE SERVICE KIT STORAGE

The Tire Service Kit is located in the trunk.

Tire Service Kit Location (SRT Model)Tire Service Kit Location

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired

or replaced immediately.

20_LA_OM_EN_USC_t.book Page 220

Page 228 of 396

226IN CASE OF EMERGENCY

5. Remove the Speed Limit sticker from the

instrument panel after the tire has been

repaired.

6. Replace the Sealant Bottle (4) and Sealant Hose (3) assembly at an authorized dealer

as soon as possible. Refer to “(F) Sealant

Bottle And Hose Replacement”.

NOTE:

When having the tire serviced, advise the autho -

rized dealer or service center that the tire has

been sealed using the Tire Service Kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (3) (clear in color).

2. Locate the red colored round Sealant Bottle release button at the lower right hand

corner of the kit.

3. Push and hold the Sealant Bottle release button, then pull out the bottle holding the

button.

4. Clean any remaining sealant from the Tire Service Kit housing. 5. Position the new Sealant Bottle (4) in the

housing so that the Sealant Hose (3) aligns

with the hose slot in the front of the

housing. Push and hold the Sealant Bottle

release button, then push the bottle into the

housing by holding the button. An audible

click will be heard indicating the bottle is

locked into place. Release the button.

6. Verify that the cap is installed on the fitting at the end of the Sealant Hose (3) and

return the hose to its storage area (located

on top of the housing).

7. Return the Tire Service Kit to its storage location in the vehicle.

JUMP STARTING

If your vehicle has a discharged battery, it can

be jump started using a set of jumper cables

and a battery in another vehicle, or by using a

portable battery booster pack. Jump starting

can be dangerous if done improperly, so please

follow the procedures in this section carefully. NOTE:

When using a portable battery booster pack,

follow the manufacturer's operating instruc

-

tions and precautions.

WARNING!

Do not attempt jump starting if the battery is

frozen. It could rupture or explode and cause

personal injury.

CAUTION!

Do not use a portable battery booster pack or

any other booster source with a system

voltage greater than 12 Volts or damage to

the battery, starter motor, alternator or

electrical system may occur.

20_LA_OM_EN_USC_t.book Page 226

Page 232 of 396

230IN CASE OF EMERGENCY

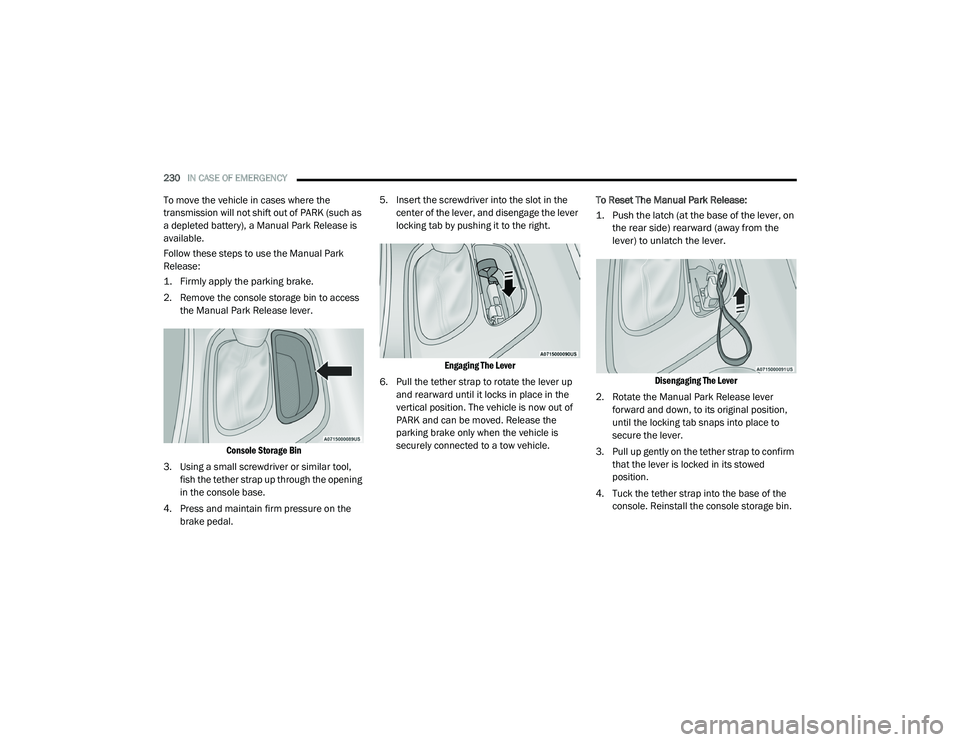

To move the vehicle in cases where the

transmission will not shift out of PARK (such as

a depleted battery), a Manual Park Release is

available.

Follow these steps to use the Manual Park

Release:

1. Firmly apply the parking brake.

2. Remove the console storage bin to access

the Manual Park Release lever.

Console Storage Bin

3. Using a small screwdriver or similar tool, fish the tether strap up through the opening

in the console base.

4. Press and maintain firm pressure on the brake pedal. 5. Insert the screwdriver into the slot in the

center of the lever, and disengage the lever

locking tab by pushing it to the right.

Engaging The Lever

6. Pull the tether strap to rotate the lever up and rearward until it locks in place in the

vertical position. The vehicle is now out of

PARK and can be moved. Release the

parking brake only when the vehicle is

securely connected to a tow vehicle. To Reset The Manual Park Release:

1. Push the latch (at the base of the lever, on

the rear side) rearward (away from the

lever) to unlatch the lever.

Disengaging The Lever

2. Rotate the Manual Park Release lever forward and down, to its original position,

until the locking tab snaps into place to

secure the lever.

3. Pull up gently on the tether strap to confirm that the lever is locked in its stowed

position.

4. Tuck the tether strap into the base of the console. Reinstall the console storage bin.

20_LA_OM_EN_USC_t.book Page 230

Page 233 of 396

IN CASE OF EMERGENCY231

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or

snow, it can often be moved using a rocking

motion. Turn the steering wheel right and left to

clear the area around the front wheels. For

vehicles with automatic transmission, push and

hold the lock button on the gear selector. Then

shift back and forth between DRIVE and

REVERSE (with automatic transmission) or

FIRST gear and REVERSE (with manual

transmission), while gently pressing the

accelerator. Use the least amount of

accelerator pedal pressure that will maintain

the rocking motion, without spinning the wheels

or racing the engine.

NOTE:

For vehicles with automatic transmission: Shifts

between DRIVE and REVERSE can only be

achieved at wheel speeds of 5 mph (8 km/h) or

less. Whenever the transmission remains in

NEUTRAL for more than two seconds, you must

press the brake pedal to engage DRIVE or

REVERSE. NOTE:

Push the ESC OFF switch (if necessary), to place

the Electronic Stability Control (ESC) system in

“Partial Off” mode, before rocking the vehicle.

Refer to “Electronic Brake Control System” in

“Safety” for further information. Once the

vehicle has been freed, push the ESC OFF

switch again to restore “ESC On” mode.

CAUTION!

Racing the engine or spinning the wheels may

lead to transmission overheating and failure.

Allow the engine to idle with the transmission

in NEUTRAL for at least one minute after

every five rocking-motion cycles. This will

minimize overheating and reduce the risk of

clutch or transmission failure during

prolonged efforts to free a stuck vehicle.

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may

cause damage, or even failure, of the axle

and tires. A tire could explode and injure

someone. Do not spin your vehicle's wheels

faster than 30 mph (48 km/h) or for longer

than 30 seconds continuously without

stopping when you are stuck and do not let

anyone near a spinning wheel, no matter

what the speed.

CAUTION!

When “rocking” a stuck vehicle by shifting

between DRIVE / FIRST gear and REVERSE,

do not spin the wheels faster than 15 mph

(24 km/h), or drivetrain damage may

result.

Revving the engine or spinning the wheels

too fast may lead to transmission over -

heating and failure. It can also damage the

tires. Do not spin the wheels above 30 mph

(48 km/h) while in gear (no transmission

shifting occurring).

6

20_LA_OM_EN_USC_t.book Page 231

Page 261 of 396

SERVICING AND MAINTENANCE259

When inspecting accessory drive belts, small

cracks that run across ribbed surface of belt

from rib to rib, are considered normal. These

are not a reason to replace belt. However,

cracks running along a rib (not across) are not

normal. Any belt with cracks running along a rib

must be replaced. Also have the belt replaced if

it has excessive wear, frayed cords or severe

glazing.

Accessory Belt (Serpentine Belt)

Conditions that would require replacement:

Rib chunking (one or more ribs has sepa -

rated from belt body)

Rib or belt wear

Longitudinal belt cracking (cracks between

two ribs)

Belt slips

“Groove jumping" (belt does not maintain

correct position on pulley)

Belt broken (note: identify and correct

problem before new belt is installed)

Noise (objectionable squeal, squeak, or

rumble is heard or felt while drive belt is in

operation)

Some conditions can be caused by a faulty

component such as a belt pulley. Belt pulleys

should be carefully inspected for damage and

proper alignment.

Belt replacement on some models requires the

use of special tools, we recommend having your

vehicle serviced at an authorized dealer.

BODY LUBRICATION

Locks and all body pivot points, including such

items as seat tracks, door hinge pivot points

and rollers, liftgate, tailgate, decklid, sliding

doors and hood hinges, should be lubricated

periodically with a lithium based grease, such

as Mopar Spray White Lube to ensure quiet,

easy operation and to protect against rust and

wear. Prior to the application of any lubricant,

the parts concerned should be wiped clean to

remove dust and grit; after lubricating, excess

oil and grease should be removed. Particular attention should also be given to

hood latching components to ensure proper

function. When performing other underhood

services, the hood latch, release mechanism

and safety catch should be cleaned and

lubricated.

The external lock cylinders should be lubricated

twice a year, preferably in the Autumn and

Spring. Apply a small amount of a high quality

lubricant, such as Mopar Lock Cylinder

Lubricant directly into the lock cylinder.

WINDSHIELD WIPER BLADES

Clean the rubber edges of the wiper blades and

the windshield periodically with a sponge or soft

cloth and a mild nonabrasive cleaner. This will

remove accumulations of salt or road film.

Operation of the wipers on dry glass for long

periods may cause deterioration of the wiper

blades. Always use washer fluid when using the

wipers to remove salt or dirt from a dry

windshield.

7

20_LA_OM_EN_USC_t.book Page 259