change wheel DODGE CHALLENGER 2022 User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2022, Model line: CHALLENGER, Model: DODGE CHALLENGER 2022Pages: 336, PDF Size: 16.47 MB

Page 199 of 336

SAFETY197

NOTE:

The TPMS is not intended to replace normal tire

care and maintenance or to provide warning of

a tire failure or condition.

The TPMS should not be used as a tire pressure

gauge while adjusting your tire pressure, unless

your vehicle is equipped with a Tire Fill Alert

(TFA) system.

Driving on a significantly underinflated tire

causes the tire to overheat and can lead to tire

failure. Underinflation also reduces fuel effi -

ciency and tire tread life, and may affect the

vehicle’s handling and stopping ability.

The TPMS is not a substitute for proper tire

maintenance, and it is the driver’s responsibility

to maintain correct tire pressure using an accu -

rate tire pressure gauge, even if underinflation

has not reached the level to trigger illumination

of the TPMS Warning Light.

Seasonal temperature changes will affect tire

pressure, and the TPMS will monitor the actual

tire pressure in the tire.

Premium System

The Tire Pressure Monitoring System (TPMS) uses

wireless technology with wheel rim mounted

electronic sensors to monitor tire pressure levels.

Sensors, mounted to each wheel as part of the

valve stem, transmit tire pressure readings to the

receiver module.

NOTE:It is particularly important for you to check the tire

pressure in all of the tires on your vehicle monthly

and to maintain the proper pressure.

The TPMS consists of the following components:

Receiver module

Four Tire Pressure Monitoring System sensors

Various Tire Pressure Monitoring System

messages, which display in the instrument

cluster

Tire Pressure Monitoring System Warning Light

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures

and warning have been established for the tire

size equipped on your vehicle. Undesirable

system operation or sensor damage may

result when using replacement equipment

that is not of the same size, type, and/or style.

The TPMS sensor is not designed for use on

aftermarket wheels and may contribute to a

poor overall system performance or sensor

damage. Customers are encouraged to use

OEM wheels to ensure proper TPMS feature

operation.

Using aftermarket tire sealants may cause the

Tire Pressure Monitoring System (TPMS)

sensor to become inoperable. After using an

aftermarket tire sealant it is recommended

that you take your vehicle to an authorized

dealer to have your sensor function checked.

After inspecting or adjusting the tire pressure

always reinstall the valve stem cap. This will

prevent moisture and dirt from entering the

valve stem, which could damage the TPMS

sensor.

6

22_LA_OM_EN_USC_t.book Page 197

Page 200 of 336

198SAFETY

Tire Pressure Monitoring System Low

Pressure Warnings

The TPMS Warning Light will illuminate in

the instrument cluster and a chime will

sound when tire pressure is low in one or

more of the four active road tires. In

addition, the instrument cluster will display an

“Inflate to XX” message and a graphic showing the

pressure values of each tire with the low tire

pressure values shown in a different color.

Tire Pressure Monitoring System Display

Should this occur, you should stop as soon as

possible and inflate the tires with a low pressure

condition (those shown in a different color in the

instrument cluster graphic) to the vehicle’s

recommended cold placard pressure inflation

value as shown in the “Inflate to XX” message. Once the system receives the updated tire

pressures, the system will automatically update,

the graphic display in the instrument cluster will

change color back to the original color, and the

TPMS Warning Light will turn off. The vehicle may

need to be driven for up to 20 minutes above

15 mph (24 km/h) in order for the TPMS to receive

this information.

NOTE:When filling warm tires, the tire pressure may need

to be increased up to an additional 4 psi (28 kPa)

above the recommended cold placard pressure in

order to turn the TPMS Warning Light off.

Low Tire Pressure Monitoring System Display

Service Tire Pressure System Warning

If a system fault is detected, the Tire Pressure

Monitoring System (TPMS) Warning Light will flash

on and off for 75 seconds and then remain on

solid. The system fault will also sound a chime. In

addition, the instrument cluster will display a

"Service Tire Pressure System" message for a

minimum of five seconds and then display dashes

(- -) in place of the pressure value to indicate which

sensor is not being received.

If the ignition switch is cycled, this sequence will

repeat, providing the system fault still exists. If the

system fault no longer exists, the TPMS Warning

Light will no longer flash, and the "Service Tire

Pressure System" message will no longer display,

and a pressure value will display in place of the

dashes. A system fault can occur due to any of the

following:

Signal interference due to electronic devices or

driving next to facilities emitting the same radio

frequencies as the TPMS sensors

Accumulation of snow or ice around the wheels

or wheel housings

Using tire chains on the vehicle

Using wheels/tires not equipped with TPMS

sensors

22_LA_OM_EN_USC_t.book Page 198

Page 217 of 336

SAFETY215

(Continued)

Enhanced Accident Response System

Reset Procedure

In order to reset the Enhanced Accident Response

System functions after an event, the ignition switch

must be changed from ignition START or ON/RUN

to ignition OFF. Carefully check the vehicle for fuel

leaks in the engine compartment and on the

ground near the engine compartment and fuel

tank before resetting the system and starting the

engine.

After an accident, if the vehicle will not start after

performing the reset procedure, the vehicle must

be towed to an authorized dealer to be inspected

and to have the Enhanced Accident Response

System reset.

Maintaining Your Air Bag System Event Data Recorder (EDR)

This vehicle is equipped with an event data

recorder (EDR). The main purpose of an EDR is to

record, in certain crash or near crash-like

situations, such as an air bag deployment or hitting

a road obstacle, data that will assist in

understanding how a vehicle’s systems performed.

The EDR is designed to record data related to

vehicle dynamics and safety systems for a short

period of time, typically 30 seconds or less.The

EDR in this vehicle is designed to record such data

as:

How various systems in your vehicle were

operating;

Whether or not the driver and passenger safety

belts were buckled/fastened;

How far (if at all) the driver was depressing the

accelerator and/or brake pedal; and,

How fast the vehicle was traveling.

These data can help provide a better

understanding of the circumstances in which

crashes and injuries occur.

WARNING!

Modifications to any part of the air bag system

could cause it to fail when you need it. You

could be injured if the air bag system is not

there to protect you. Do not modify the compo -

nents or wiring, including adding any kind of

badges or stickers to the steering wheel hub

trim cover or the upper passenger side of the

instrument panel. Do not modify the front

fascia/bumper, vehicle body structure, or add

aftermarket side steps or running boards.

It is dangerous to try to repair any part of the

air bag system yourself. Be sure to tell anyone

who works on your vehicle that it has an air

bag system.

Do not attempt to modify any part of your air

bag system. The air bag may inflate acciden -

tally or may not function properly if modifica -

tions are made. Take your vehicle to an

authorized dealer for any air bag system

service. If your seat, including your trim cover

and cushion, needs to be serviced in any way

(including removal or loosening/tightening of

seat attachment bolts), take the vehicle to an

authorized dealer. Only manufacturer

approved seat accessories may be used. If it is

necessary to modify the air bag system for

persons with disabilities, contact an autho -

rized dealer.

WARNING!

6

22_LA_OM_EN_USC_t.book Page 215

Page 238 of 336

236IN CASE OF EMERGENCY

Even if the SOS Call system is fully functional,

factors beyond FCA US LLC’s control may prevent

or stop the SOS Call system operation. These

include, but are not limited to, the following

factors:

The ignition is in the OFF position.

The vehicle’s electrical systems are not intact.

The SOS Call system software and/or hardware

are damaged during a crash.

The vehicle battery loses power or becomes

disconnected during a vehicle crash.

LTE (voice/data) or 4G (data) network and/or

Global Positioning Satellite signals are unavail -

able or obstructed.

Equipment malfunction at the SOS operator

facility.

Operator error by the SOS operator.

LTE (voice/data) or 4G (data) network conges -

tion.

Weather.

Buildings, structures, geographic terrain, or

tunnels.

NOTE:

Your vehicle may be transmitting data as autho -

rized by the subscriber.

Never place anything on or near the vehicle’s

LTE (voice/data) or 4G (data) and GPS

antennas. You could prevent LTE (voice/data) or

4G (data) and GPS signal reception, which can

prevent your vehicle from placing an emergency

call. An operable LTE (voice/data) or 4G (data)

network connection and a GPS signal is

required for the SOS Call system to function

properly.

NOTE:Changes or modifications not expressly approved

by the party responsible for compliance could void

the user's authority to operate the equipment.

Automatic SOS — If Equipped

Automatic SOS is a hands-free safety service that

can immediately connect you with help in the event

that your vehicle’s airbags deploy. Please refer to

your provided radio supplement for complete

information.

WARNING!

Ignoring the Rearview Mirror light could mean

you will not have SOS Call services. If the Rear -

view Mirror light is illuminated, have an autho -

rized dealer service the SOS Call system

immediately.

The Occupant Restraint Control module turns

on the air bag Warning Light on the instrument

panel if a malfunction in any part of the

system is detected. If the Air Bag Warning

Light is illuminated, have an authorized dealer

service the Occupant Restraint Control system

immediately.

WARNING!

ALWAYS obey traffic laws and pay attention to

the road. ALWAYS drive safely with your hands on

the steering wheel. You have full responsibility

and assume all risks related to the use of the

Uconnect and SiriusXM Guardian™ features and

applications in this vehicle. Only use Uconnect

features and SiriusXM Guardian™ services when

it is safe to do so. Failure to do so may result in

an accident involving serious injury or death.CAUTION!

To avoid damage to the mirror during cleaning,

never spray any cleaning solution directly onto

the mirror. Apply the solution onto a clean cloth

and wipe the mirror clean.

22_LA_OM_EN_USC_t.book Page 236

Page 239 of 336

IN CASE OF EMERGENCY237

JACKING AND TIRE CHANGINGPREPARATIONS FOR JACKING

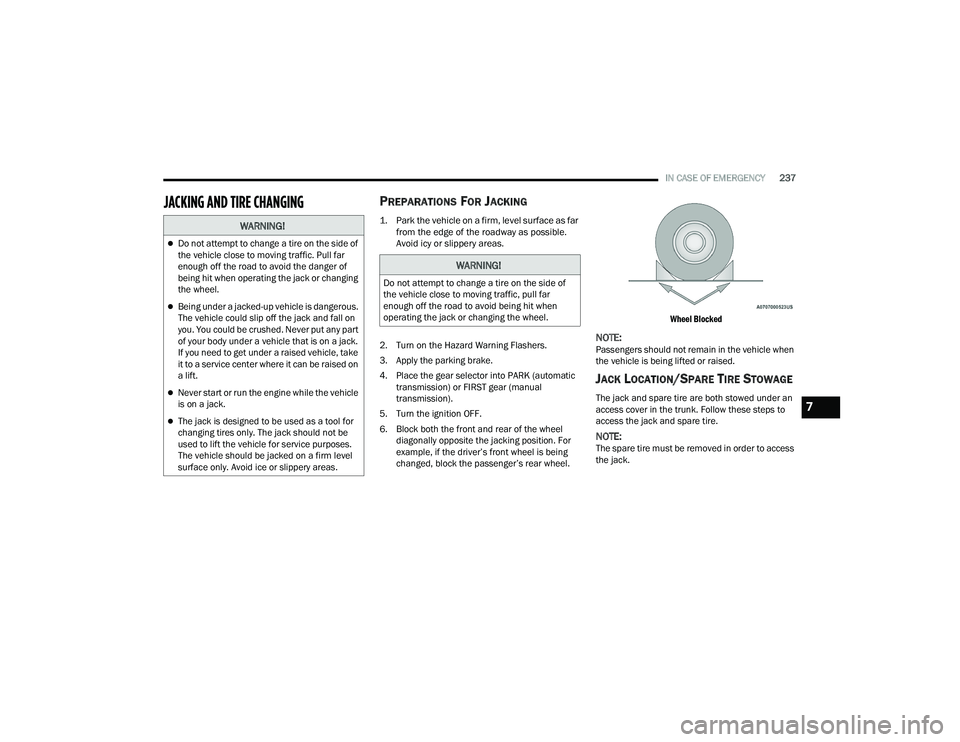

1. Park the vehicle on a firm, level surface as far

from the edge of the roadway as possible.

Avoid icy or slippery areas.

2. Turn on the Hazard Warning Flashers.

3. Apply the parking brake.

4. Place the gear selector into PARK (automatic transmission) or FIRST gear (manual

transmission).

5. Turn the ignition OFF.

6. Block both the front and rear of the wheel diagonally opposite the jacking position. For

example, if the driver’s front wheel is being

changed, block the passenger’s rear wheel.

Wheel Blocked

NOTE:Passengers should not remain in the vehicle when

the vehicle is being lifted or raised.

JACK LOCATION/SPARE TIRE STOWAGE

The jack and spare tire are both stowed under an

access cover in the trunk. Follow these steps to

access the jack and spare tire.

NOTE:The spare tire must be removed in order to access

the jack.

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid the danger of

being hit when operating the jack or changing

the wheel.

Being under a jacked-up vehicle is dangerous.

The vehicle could slip off the jack and fall on

you. You could be crushed. Never put any part

of your body under a vehicle that is on a jack.

If you need to get under a raised vehicle, take

it to a service center where it can be raised on

a lift.

Never start or run the engine while the vehicle

is on a jack.

The jack is designed to be used as a tool for

changing tires only. The jack should not be

used to lift the vehicle for service purposes.

The vehicle should be jacked on a firm level

surface only. Avoid ice or slippery areas.

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic, pull far

enough off the road to avoid being hit when

operating the jack or changing the wheel.

7

22_LA_OM_EN_USC_t.book Page 237

Page 241 of 336

IN CASE OF EMERGENCY239

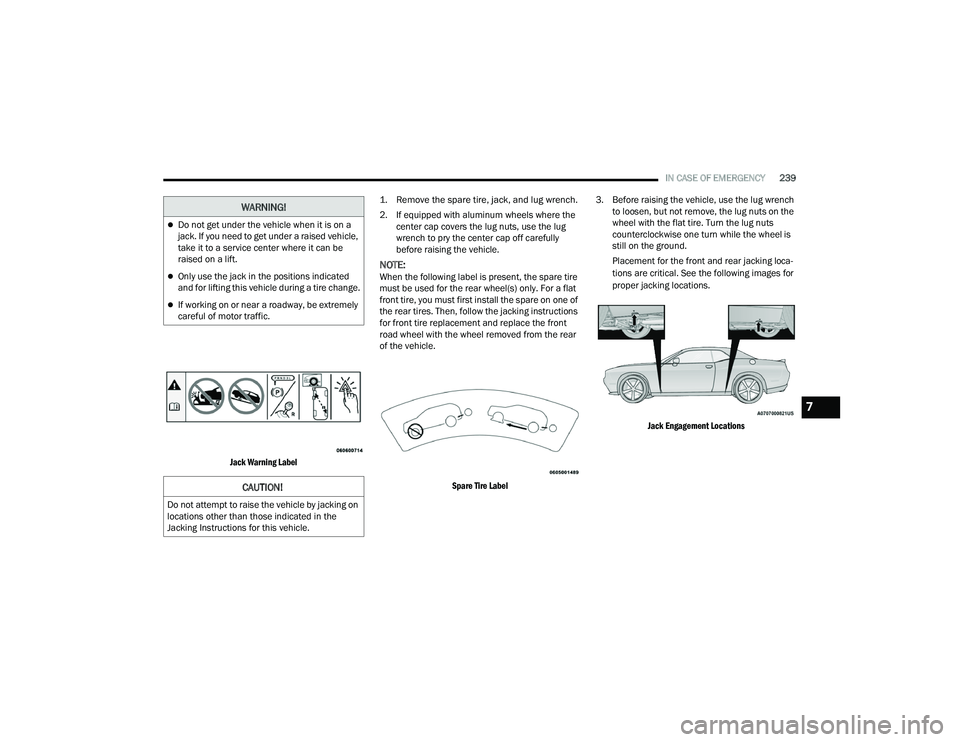

Jack Warning Label

1. Remove the spare tire, jack, and lug wrench.

2. If equipped with aluminum wheels where the

center cap covers the lug nuts, use the lug

wrench to pry the center cap off carefully

before raising the vehicle.

NOTE:When the following label is present, the spare tire

must be used for the rear wheel(s) only. For a flat

front tire, you must first install the spare on one of

the rear tires. Then, follow the jacking instructions

for front tire replacement and replace the front

road wheel with the wheel removed from the rear

of the vehicle.

Spare Tire Label

3. Before raising the vehicle, use the lug wrench

to loosen, but not remove, the lug nuts on the

wheel with the flat tire. Turn the lug nuts

counterclockwise one turn while the wheel is

still on the ground.

Placement for the front and rear jacking loca -

tions are critical. See the following images for

proper jacking locations.

Jack Engagement Locations

Do not get under the vehicle when it is on a

jack. If you need to get under a raised vehicle,

take it to a service center where it can be

raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire change.

If working on or near a roadway, be extremely

careful of motor traffic.

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the

Jacking Instructions for this vehicle.

WARNING!

7

22_LA_OM_EN_USC_t.book Page 239

Page 245 of 336

IN CASE OF EMERGENCY243

(Continued)

When the Tire Service Kit sealant is in a liquid

form, clean water and a damp cloth will remove

the material from the vehicle or tire and wheel

components. Once the sealant dries, it can

easily be peeled off and properly discarded.

For optimum performance, make sure the valve

stem on the wheel is free of debris before

connecting the Tire Service Kit.

You can use the Tire Service Kit air pump to

inflate bicycle tires. The kit also comes with two

needles, located in the Accessory Storage

Compartment (on the bottom of the air pump)

for inflating sport balls, rafts, or similar inflat -

able items. However, use only the Air Pump

Hose (8) and make sure the Mode Select Knob

(6) is in the Air Mode when inflating such items

to avoid injecting sealant into them. The Tire

Service Kit Sealant is only intended to seal

punctures less than 1/4 inch (6 mm) diameter

in the tread of your tire.

Do not lift or carry the Tire Service Kit by the

hoses.

WARNING!

Do not attempt to seal a tire on the side of the

vehicle closest to traffic. Pull far enough off

the road to avoid the danger of being hit when

using the Tire Service Kit.

Do not use Tire Service Kit or drive the vehicle

under the following circumstances:

If the puncture in the tire tread is approxi -

mately 1/4 inch (6 mm) or larger.

If the tire has any sidewall damage.

If the tire has any damage from driving

with extremely low tire pressure.

If the tire has any damage from driving on

a flat tire.

If the wheel has any damage.

If you are unsure of the condition of the

tire or the wheel.

Keep Tire Service Kit away from open flames

or heat source.

A loose Tire Service Kit thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the Tire

Service Kit in the place provided. Failure to

follow these warnings can result in injuries

that are serious or fatal to you, your passen -

gers, and others around you.

Take care not to allow the contents of Tire

Service Kit to come in contact with hair, eyes,

or clothing. Tire Service Kit sealant is harmful

if inhaled, swallowed, or absorbed through the

skin. It causes skin, eye, and respiratory irrita -

tion. Flush immediately with plenty of water if

there is any contact with eyes or skin. Change

clothing as soon as possible, if there is any

contact with clothing.

Tire Service Kit Sealant solution contains

latex. In case of an allergic reaction or rash,

consult a physician immediately. Keep Tire

Service Kit out of reach of children. If swal -

lowed, rinse mouth immediately with plenty of

water and drink plenty of water. Do not induce

vomiting! Consult a physician immediately.

WARNING!

7

22_LA_OM_EN_USC_t.book Page 243

Page 259 of 336

SERVICING AND MAINTENANCE257

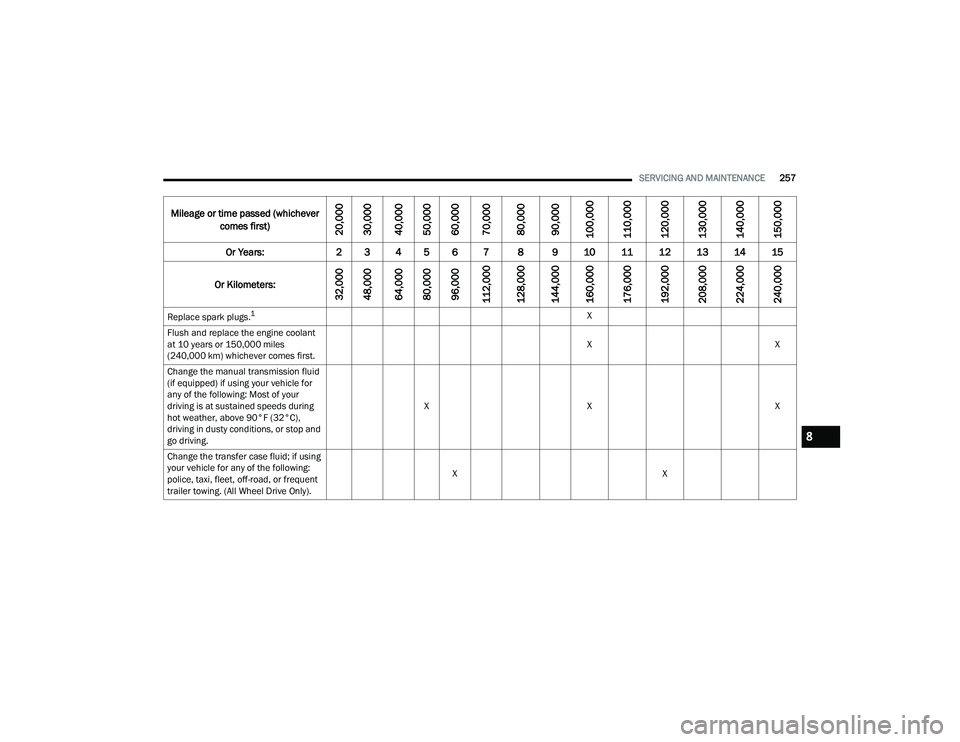

Replace spark plugs.

1X

Flush and replace the engine coolant

at 10 years or 150,000 miles

(240,000 km) whichever comes first. X

X

Change the manual transmission fluid

(if equipped) if using your vehicle for

any of the following: Most of your

driving is at sustained speeds during

hot weather, above 90°F (32°C),

driving in dusty conditions, or stop and

go driving. X

X X

Change the transfer case fluid; if using

your vehicle for any of the following:

police, taxi, fleet, off-road, or frequent

trailer towing. (All Wheel Drive Only). X

X

Mileage or time passed (whichever

comes first)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

8

22_LA_OM_EN_USC_t.book Page 257

Page 260 of 336

258SERVICING AND MAINTENANCE

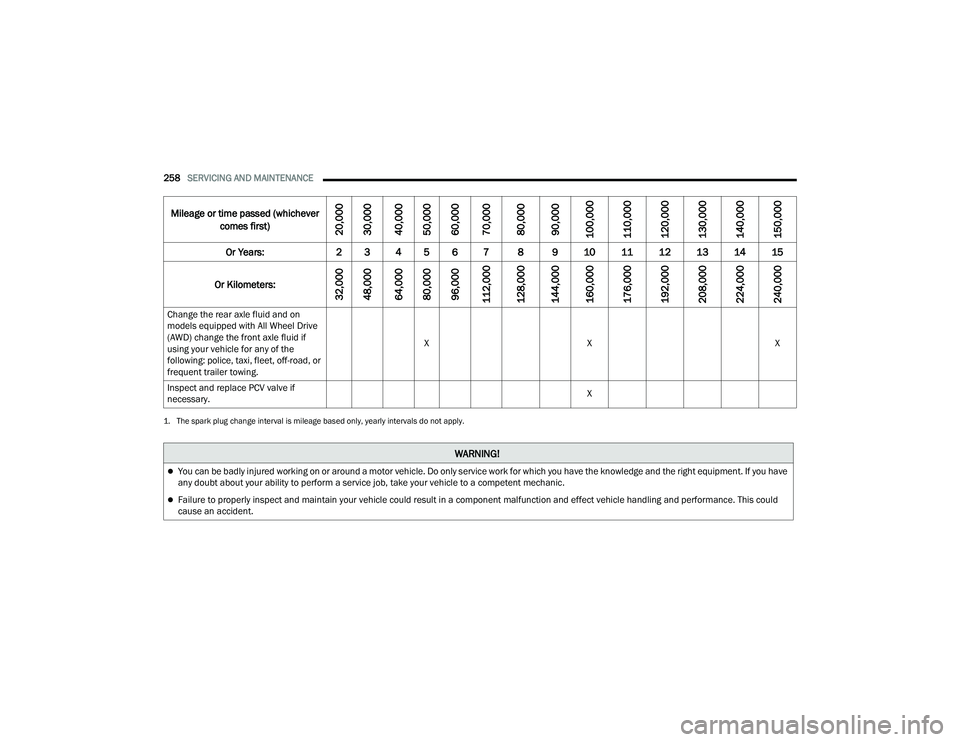

Change the rear axle fluid and on

models equipped with All Wheel Drive

(AWD) change the front axle fluid if

using your vehicle for any of the

following: police, taxi, fleet, off-road, or

frequent trailer towing. X

X X

Inspect and replace PCV valve if

necessary. X

1. The spark plug change interval is mileage based only, yearly intervals do not apply.

Mileage or time passed (whichever

comes first)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

WARNING!

You can be badly injured working on or around a motor vehicle. Do only service work for which you have the knowledge and the right equipment. If you have

any doubt about your ability to perform a service job, take your vehicle to a competent mechanic.

Failure to properly inspect and maintain your vehicle could result in a component malfunction and effect vehicle handling and performance. This could

cause an accident.

22_LA_OM_EN_USC_t.book Page 258

Page 278 of 336

276SERVICING AND MAINTENANCE

Fluid And Filter Changes

Under normal operating conditions, the fluid

installed at the factory will provide satisfactory

lubrication for the life of the vehicle.

Routine fluid and filter changes are not required.

However, change the fluid and filter if the fluid

becomes contaminated (with water, etc.), or if the

transmission is disassembled for any reason.

Selection Of Lubricant

It is important to use the proper transmission fluid

to ensure optimum transmission performance and

life. Use only the manufacturer's specified

transmission fluid Úpage 316. It is important to

maintain the transmission fluid at the correct level

using the recommended fluid.

NOTE:No chemical flushes should be used in any trans -

mission; only the approved lubricant should be

used.

ALL-WHEEL DRIVE (AWD) —

I

F EQUIPPED

The All-Wheel Drive system consists of a transfer

case and front differential. The exterior surface of

these components should be inspected for

evidence of fluid leaks. Confirmed leaks should be

repaired as soon as possible.

The transfer case fluid fill/inspection plug is

located in the middle of the rear housing. To

inspect the transfer case fluid level, remove the

fill/inspection plug. The fluid level should be even

with the bottom of the hole. Use this plug to add

fluid as required.

The front differential fill plug is located on the outer

cover near the half shaft attachment. To inspect

the differential fluid level, remove the fill plug. The

fluid level should be even with or slightly below the

bottom of the hole.

Fluid Changes

For the proper maintenance intervals Úpage 254.

REAR AXLE

Fluid Level Check

Checking the fluid level while the vehicle is on level

ground and has been stationary for 15 minutes will

improve the accuracy of the fluid level reading.

Check the fluid level by removing the fill plug on the

axle. The fluid level should be 1-2.5 mm below the

fill plug. Add fluid, if necessary, to maintain the

proper level Ú page 316.

Change Axle Fluid

For the proper maintenance intervals Úpage 254.

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may cause

deterioration in transmission shift quality and/or

torque converter shudder Ú page 316.

22_LA_OM_EN_USC_t.book Page 276