engine oil DODGE CHALLENGER 2022 Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2022, Model line: CHALLENGER, Model: DODGE CHALLENGER 2022Pages: 336, PDF Size: 16.47 MB

Page 266 of 336

264SERVICING AND MAINTENANCE

Shaker Hood — If Equipped

Shaker Hood Oil Filler

For vehicles equipped with a “Shaker Hood”, the

upper scoop will need to be removed so that oil can

be properly added to the engine.

To do this, you will need follow the procedure

below:

1. Remove the four nuts with the Shaker tool

located in glove compartment.

2. Lift off the upper scoop.

NOTE:Be sure to clean off all debris around or inside for

the Shaker assembly.

3. Locate the oil fill cover in base assembly to expose the oil fill cap.

4. Remove oil fill cap to add oil.

5. Re-install Shaker assembly.

Shaker Hood Air Filter Cleaning

Shaker air filters are made of a unique, washable

synthetic material. Base program air filters with

paper media cannot be washed. All filters follow

the same service interval, though Shaker systems

substitute a cleaning while paper air filter

elements are to be replaced.

1. Remove the air filter from the intake and set

the filter clamp aside.

2. Measure the length of the filter media.

3. Fill a bucket with warm clean water to the depth matching the filter media measurement

and add a mild household detergent or air

filter cleaning solution.

NOTE:Never use strong detergents, high pressure, or

gasoline on air filters.

4. Without allowing the solution to flow back into the inside of the air filter, submerge the filter

media into the water and let it soak for ten

minutes.

5. Empty the bucket filled with dirty water and repeat steps 3 and 4.

6. Refill the bucket with clean warm water and rinse the filter by rotating the filter.

NOTE:The water should be clean with no signs of dirt in

the bucket.

7. Allow the filter to air dry. Reinstall the filter on the intake system once it is dry.

NOTE:Do not use forced air pressure to dry the air filter

as damage may occur and void the warranty. Shaker Hood Removal And Cleaning

1. Remove the four nuts with the Shaker tool

located in the glove compartment.

2. Lift off the upper scoop.

NOTE:Be sure to clean off all debris around or inside of

the Shaker assembly.

3. Using a water and mild detergent clean the following locations:

The water drain slot located at the front

forward edge of the Shaker assembly.

The seals attached to the scoop and air box.

Lower water drains located in the lower

Shaker assembly and air box as well as the

hood interface areas for the seals. Apply

Mopar® Leather, Rubber & Vinyl Protectant

after cleaning to seals.

4. Reinstall Shaker assembly.

Materials Added To Engine Oil

The manufacturer strongly recommends against

the addition of any additives (other than leak

detection dyes) to the engine oil. Engine oil is an

engineered product and its performance may be

impaired by supplemental additives.

22_LA_OM_EN_USC_t.book Page 264

Page 267 of 336

SERVICING AND MAINTENANCE265

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used engine

oil and oil filters from your vehicle. Used oil and oil

filters, indiscriminately discarded, can present a

problem to the environment. Contact an

authorized dealer, service station or governmental

agency for advice on how and where used oil and

oil filters can be safely discarded in your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a new

filter at every engine oil change.

Engine Oil Filter Selection

A full-flow type disposable oil filter should be used

for replacement. The quality of replacement filters

varies considerably. Only high quality Mopar®

certified filters should be used.

ENGINE AIR CLEANER FILTER

For the proper maintenance intervals Úpage 255.

NOTE:Be sure to follow the “Severe Duty Conditions”

maintenance interval if applicable. Engine Air Cleaner Filter Selection

The quality of replacement filters varies

considerably. Only high quality Mopar® certified

filters should be used.

T/A Air Filter Maintenance — If Equipped

Clean Engine Air Filter

T/A air filters are made of a unique, washable

material. Follow the recommended service interval

as for non-T/A air filters, substituting a cleaning for

replacement.Cleaning your engine air filter with the

recommended Mopar® Performance Air Filter

Service Kit is not required if you can still see any

part of the wire screen on the entire air filter

regardless of how dirty it may appear. When any

part of the wire screen is no longer visible on the air

filter, that is an indication it is time to clean the air

filter.

For cleaning instructions see steps 1-7 from the

Shaker Hood Air Filter Cleaning section

Ú

page 264.

8. Unique for T/A, using the Mopar® Performance

Air Filter Service Kit, spray oil evenly along the

crown of each filter pleat holding the nozzle about

3 inches (76 mm) away from the air filter. One

spray per 2 square inches (1,290 square mm) of

air filter. With one complete coat of oil, let it wick

(saturate) for about 20 minutes, and if required

touch up any light areas on either side of the filter.

WARNING!

The air induction system (air cleaner, hoses,

etc.) can provide a measure of protection in the

case of engine backfire. Do not remove the air

induction system (air cleaner, hoses, etc.) unless

such removal is necessary for repair or

maintenance. Make sure that no one is near the

engine compartment before starting the vehicle

with the air induction system (air cleaner, hoses,

etc.) removed. Failure to do so can result in

serious personal injury.

8

22_LA_OM_EN_USC_t.book Page 265

Page 270 of 336

268SERVICING AND MAINTENANCE

Conditions that would require replacement:

Rib chunking (one or more ribs has separated

from belt body)

Rib or belt wear

Longitudinal belt cracking (cracks between two

ribs)

Belt slips

“Groove jumping" (belt does not maintain

correct position on pulley)

Belt broken (note: identify and correct problem

before new belt is installed)

Noise (objectionable squeal, squeak, or rumble

is heard or felt while drive belt is in operation) Some conditions can be caused by a faulty

component such as a belt pulley. Belt pulleys

should be carefully inspected for damage and

proper alignment.

Belt replacement on some models requires the

use of special tools, we recommend having your

vehicle serviced at an authorized dealer.

BODY LUBRICATION

Locks and all body pivot points, including such

items as seat tracks, door hinge pivot points and

rollers, liftgate, tailgate, decklid, sliding doors and

hood hinges, should be lubricated periodically with

a lithium-based grease, such as Mopar® Spray

White Lube to ensure quiet, easy operation and to

protect against rust and wear. Prior to the

application of any lubricant, the parts concerned

should be wiped clean to remove dust and grit;

after lubricating, excess oil and grease should be

removed. Particular attention should also be given

to hood latching components to ensure proper

function. When performing other underhood

services, the hood latch, release mechanism and

safety catch should be cleaned and lubricated. The external lock cylinders should be lubricated

twice a year, preferably in the Autumn and Spring.

Apply a small amount of a high quality lubricant,

such as Mopar® Lock Cylinder Lubricant directly

into the lock cylinder.

WINDSHIELD WIPER BLADES

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth

and a mild nonabrasive cleaner. This will remove

accumulations of salt or road film.

Operation of the wipers on dry glass for long

periods may cause deterioration of the wiper

blades. Always use washer fluid when using the

wipers to remove salt or dirt from a dry windshield.

Avoid using the wiper blades to remove frost or ice

from the windshield. Keep the blade rubber out of

contact with petroleum products such as engine

oil, gasoline, etc.

22_LA_OM_EN_USC_t.book Page 268

Page 272 of 336

270SERVICING AND MAINTENANCE

(Continued)

Installing The Front Wipers

1. Lift the wiper arm off of the glass, until the

wiper arm is in the full up position.

2. Position the wiper blade near the hook on the tip of the wiper arm.

3. Insert the hook on the tip of the arm through the opening in the wiper blade.

4. Slide the wiper blade up into the hook on the wiper arm, latch engagement will be

accompanied by an audible click.

5. Gently lower the wiper blade onto the glass.

EXHAUST SYSTEM

The best protection against carbon monoxide entry

into the vehicle body is a properly maintained

engine exhaust system.

If you notice a change in the sound of the exhaust

system; or if the exhaust fumes can be detected

inside the vehicle; or when the underside or rear of

the vehicle is damaged; have an authorized

technician inspect the complete exhaust system

and adjacent body areas for broken, damaged,

deteriorated, or mispositioned parts. Open seams

or loose connections could permit exhaust fumes

to seep into the passenger compartment. In

addition, have the exhaust system inspected each

time the vehicle is raised for lubrication or oil

change. Replace as required. Under normal operating conditions, the catalytic

converter will not require maintenance. However, it

is important to keep the engine properly tuned to

ensure proper catalyst operation and prevent

possible catalyst damage.

NOTE:Intentional tampering with emissions control

systems can result in civil penalties being

assessed against you.

WARNING!

Exhaust gases can injure or kill. They contain

carbon monoxide (CO), which is colorless and

odorless. Breathing it can make you uncon

-

scious and can eventually poison you. To

avoid breathing CO, Ú page 230.

A hot exhaust system can start a fire if you

park over materials that can burn. Such mate -

rials might be grass or leaves coming into

contact with your exhaust system. Do not park

or operate your vehicle in areas where your

exhaust system can contact anything that can

burn.

CAUTION!

The catalytic converter requires the use of

unleaded fuel only. Leaded gasoline will

destroy the effectiveness of the catalyst as an

emissions control device and may seriously

reduce engine performance and cause

serious damage to the engine.

Damage to the catalytic converter can result if

your vehicle is not kept in proper operating

condition. In the event of engine malfunction,

particularly involving engine misfire or other

apparent loss of performance, have your

vehicle serviced promptly. Continued opera -

tion of your vehicle with a severe malfunction

could cause the converter to overheat,

resulting in possible damage to the converter

and vehicle.

CAUTION!

22_LA_OM_EN_USC_t.book Page 270

Page 276 of 336

274SERVICING AND MAINTENANCE

(Continued)

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning, keep

the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever neces-

sary, install ONLY the correct type thermostat.

Other designs may result in unsatisfactory

engine cooling performance, poor gas mileage,

and increased emissions.

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically Ú page 255.

Fluid Level Check — Brake Master Cylinder

Check the fluid level in the master cylinder

immediately if the Brake System Warning Light

indicates system failure.

Check the fluid level in the master cylinder when

performing underhood services.

Clean the top of the master cylinder area before

removing the cap. Add fluid to bring the level up to

the top of the “FULL” mark on the side of the

master cylinder reservoir.

Overfilling of fluid is not recommended because it

may cause leaking in the system.

Add enough fluid to bring the level up to the

requirements described on the brake fluid

reservoir. With disc brakes, fluid level can be

expected to fall as the brake pads wear. However,

low fluid level may be caused by a leak and a

checkup may be needed.

Use only brake fluid that has been recommended

by the manufacturer, and has been kept in a tightly

closed container to avoid contamination from

foreign matter or moisture Ú page 316.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting

or riding on the brake pedal can result in

abnormally high brake temperatures, excessive

lining wear, and possible brake damage. You

would not have your full braking capacity in an

emergency.

WARNING!

Use only manufacturer's recommended brake

fluid Úpage 316. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in a open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This

could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

22_LA_OM_EN_USC_t.book Page 274

Page 313 of 336

311

TECHNICAL SPECIFICATIONS

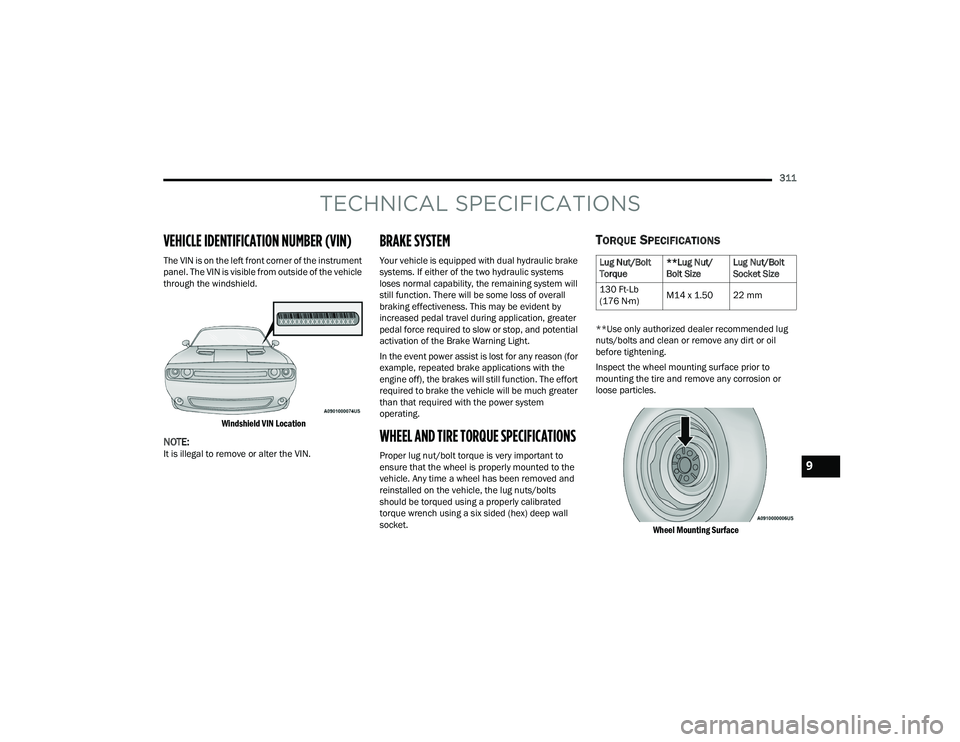

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is on the left front corner of the instrument

panel. The VIN is visible from outside of the vehicle

through the windshield.

Windshield VIN Location

NOTE:It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic brake

systems. If either of the two hydraulic systems

loses normal capability, the remaining system will

still function. There will be some loss of overall

braking effectiveness. This may be evident by

increased pedal travel during application, greater

pedal force required to slow or stop, and potential

activation of the Brake Warning Light.

In the event power assist is lost for any reason (for

example, repeated brake applications with the

engine off), the brakes will still function. The effort

required to brake the vehicle will be much greater

than that required with the power system

operating.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to the

vehicle. Any time a wheel has been removed and

reinstalled on the vehicle, the lug nuts/bolts

should be torqued using a properly calibrated

torque wrench using a six sided (hex) deep wall

socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug

nuts/bolts and clean or remove any dirt or oil

before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

Wheel Mounting Surface

Lug Nut/Bolt

Torque **Lug Nut/

Bolt SizeLug Nut/Bolt

Socket Size

130 Ft-Lb

(176 N·m) M14 x 1.50 22 mm

9

22_LA_OM_EN_USC_t.book Page 311

Page 317 of 336

TECHNICAL SPECIFICATIONS315

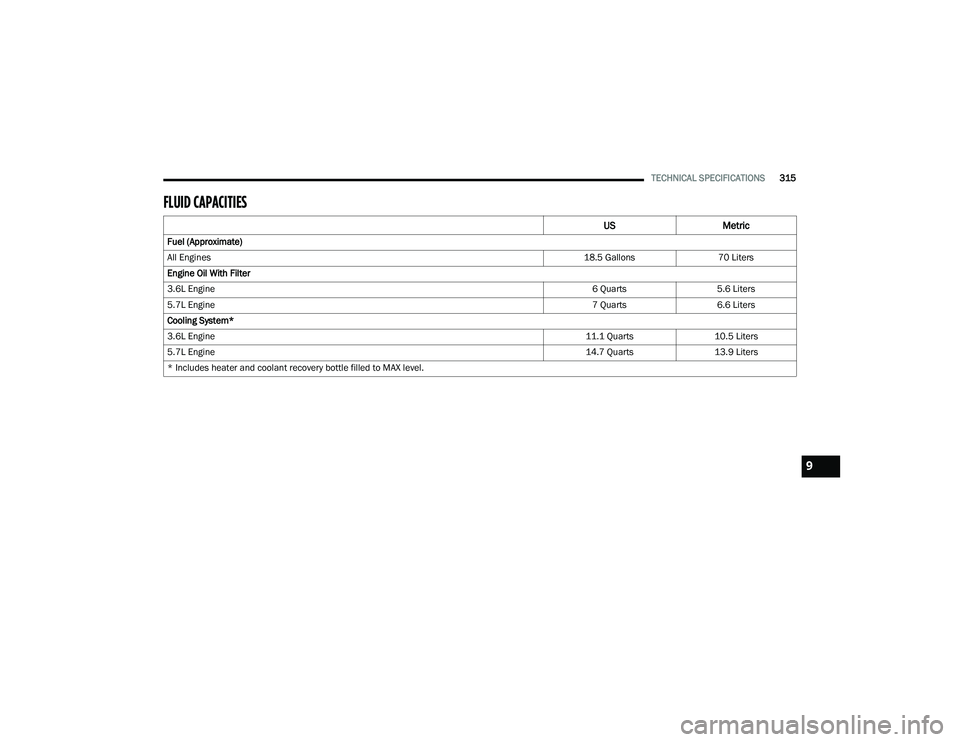

FLUID CAPACITIES

USMetric

Fuel (Approximate)

All Engines 18.5 Gallons70 Liters

Engine Oil With Filter

3.6L Engine 6 Quarts5.6 Liters

5.7L Engine 7 Quarts6.6 Liters

Cooling System*

3.6L Engine 11.1 Quarts10.5 Liters

5.7L Engine 14.7 Quarts13.9 Liters

* Includes heater and coolant recovery bottle filled to MAX level.

9

22_LA_OM_EN_USC_t.book Page 315

Page 318 of 336

316TECHNICAL SPECIFICATIONS

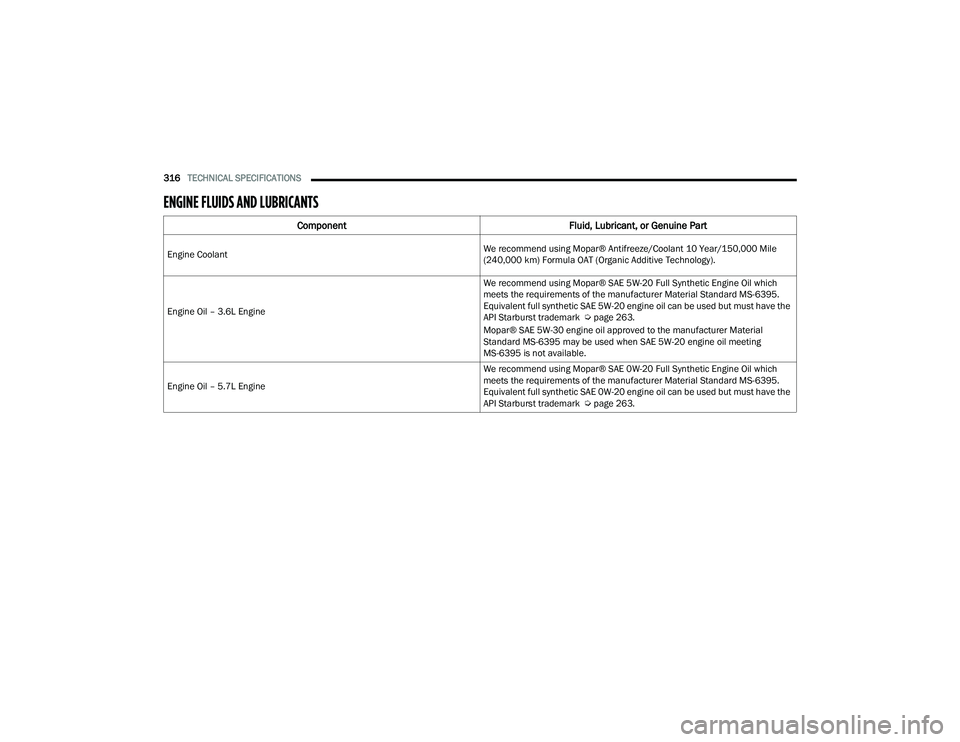

ENGINE FLUIDS AND LUBRICANTS

Component Fluid, Lubricant, or Genuine Part

Engine Coolant

We recommend using Mopar® Antifreeze/Coolant 10 Year/150,000 Mile

(240,000 km) Formula OAT (Organic Additive Technology).

Engine Oil – 3.6L Engine

We recommend using Mopar® SAE 5W-20 Full Synthetic Engine Oil which

meets the requirements of the manufacturer Material Standard MS-6395.

Equivalent full synthetic SAE 5W-20 engine oil can be used but must have the

API Starburst trademark Ú

page 263.

Mopar® SAE 5W-30 engine oil approved to the manufacturer Material

Standard MS-6395 may be used when SAE 5W-20 engine oil meeting

MS-6395 is not available.

Engine Oil – 5.7L Engine

We recommend using Mopar® SAE 0W-20 Full Synthetic Engine Oil which

meets the requirements of the manufacturer Material Standard MS-6395.

Equivalent full synthetic SAE 0W-20 engine oil can be used but must have the

API Starburst trademark Ú

page 263.

22_LA_OM_EN_USC_t.book Page 316

Page 319 of 336

TECHNICAL SPECIFICATIONS317

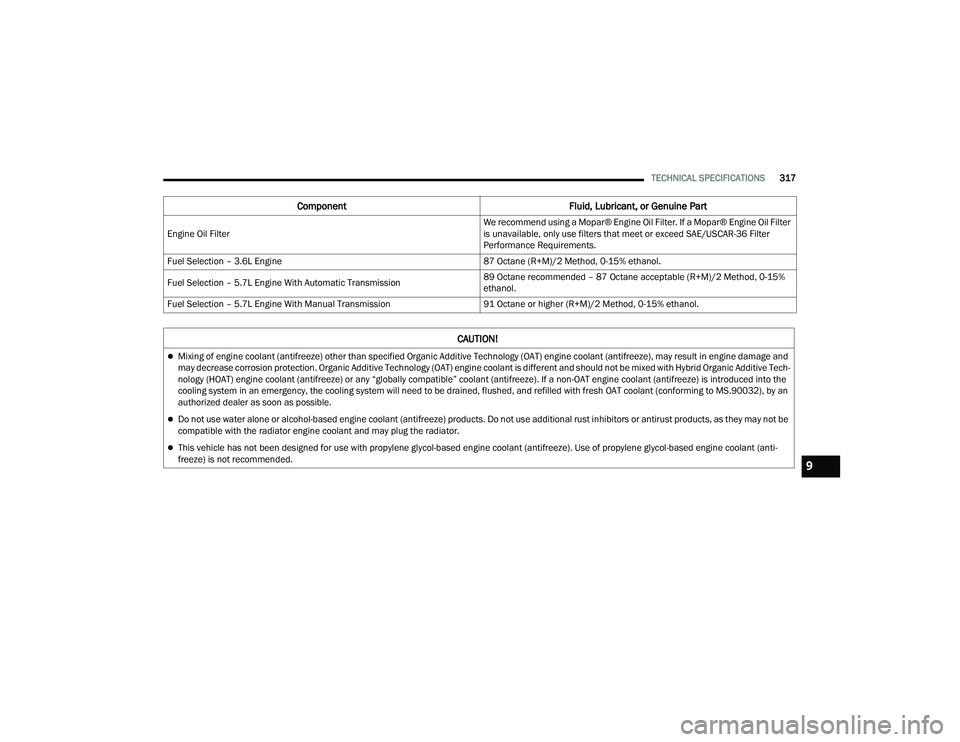

Engine Oil Filter We recommend using a Mopar® Engine Oil Filter. If a Mopar® Engine Oil Filter

is unavailable, only use filters that meet or exceed SAE/USCAR-36 Filter

Performance Requirements.

Fuel Selection – 3.6L Engine 87 Octane (R+M)/2 Method, 0-15% ethanol.

Fuel Selection – 5.7L Engine With Automatic Transmission 89 Octane recommended – 87 Octane acceptable (R+M)/2 Method, 0-15%

ethanol.

Fuel Selection – 5.7L Engine With Manual Transmission 91 Octane or higher (R+M)/2 Method, 0-15% ethanol.

ComponentFluid, Lubricant, or Genuine Part

CAUTION!

Mixing of engine coolant (antifreeze) other than specified Organic Additive Technology (OAT) engine coolant (antifreeze), may result in engine damage and

may decrease corrosion protection. Organic Additive Technology (OAT) engine coolant is different and should not be mixed with Hybrid Organic Additive Tech -

nology (HOAT) engine coolant (antifreeze) or any “globally compatible” coolant (antifreeze). If a non-OAT engine coolant (antifreeze) is introduced into the

cooling system in an emergency, the cooling system will need to be drained, flushed, and refilled with fresh OAT coolant (conforming to MS.90032), by an

authorized dealer as soon as possible.

Do not use water alone or alcohol-based engine coolant (antifreeze) products. Do not use additional rust inhibitors or antirust products, as they may not be

compatible with the radiator engine coolant and may plug the radiator.

This vehicle has not been designed for use with propylene glycol-based engine coolant (antifreeze). Use of propylene glycol-based engine coolant (anti -

freeze) is not recommended.

9

22_LA_OM_EN_USC_t.book Page 317

Page 326 of 336

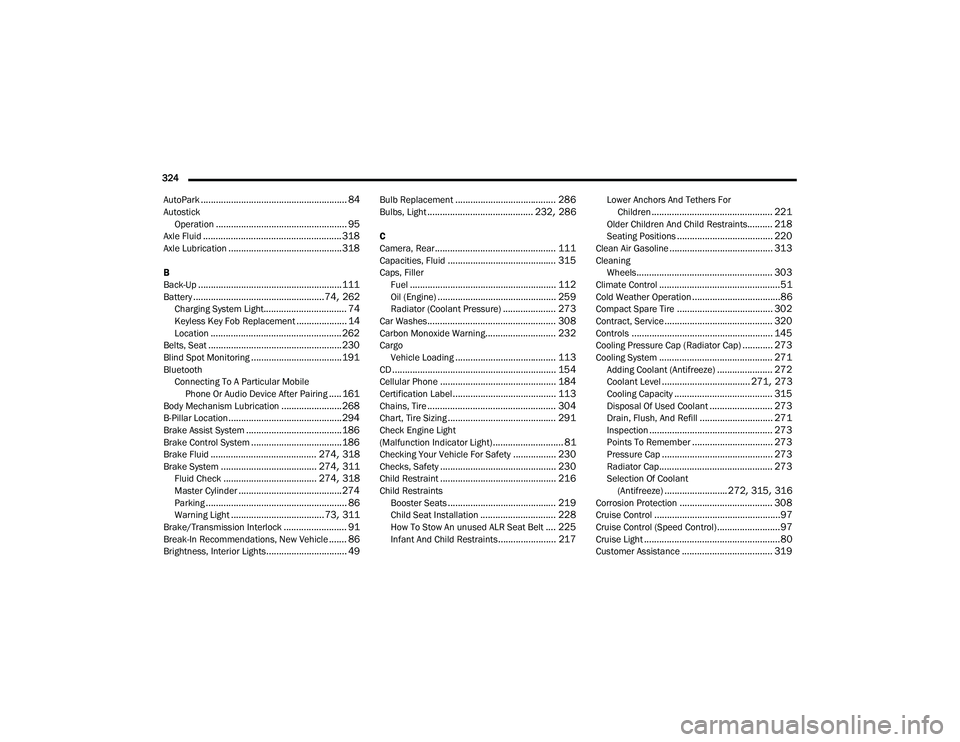

324 AutoPark

.......................................................... 84Autostick Operation.................................................... 95Axle Fluid....................................................... 318Axle Lubrication............................................. 318

B

Back-Up......................................................... 111Battery.................................................... 74, 262Charging System Light................................. 74Keyless Key Fob Replacement.................... 14Location.................................................... 262Belts, Seat..................................................... 230Blind Spot Monitoring.................................... 191BluetoothConnecting To A Particular MobilePhone Or Audio Device After Pairing

..... 161Body Mechanism Lubrication........................ 268B-Pillar Location............................................. 294Brake Assist System...................................... 186Brake Control System.................................... 186Brake Fluid.......................................... 274, 318Brake System...................................... 274, 311Fluid Check..................................... 274, 318Master Cylinder......................................... 274Parking........................................................ 86Warning Light..................................... 73, 311Brake/Transmission Interlock......................... 91Break-In Recommendations, New Vehicle....... 86Brightness, Interior Lights................................ 49

Bulb Replacement........................................ 286Bulbs, Light.......................................... 232, 286

C

Camera, Rear................................................ 111Capacities, Fluid........................................... 315Caps, FillerFuel.......................................................... 112Oil (Engine)............................................... 259Radiator (Coolant Pressure)..................... 273Car Washes................................................... 308Carbon Monoxide Warning............................ 232CargoVehicle Loading........................................ 113CD................................................................. 154Cellular Phone.............................................. 184Certification Label......................................... 113Chains, Tire................................................... 304Chart, Tire Sizing........................................... 291Check Engine Light

(Malfunction Indicator Light)............................ 81Checking Your Vehicle For Safety................. 230Checks, Safety.............................................. 230Child Restraint.............................................. 216Child RestraintsBooster Seats........................................... 219Child Seat Installation.............................. 228How To Stow An unused ALR Seat Belt.... 225Infant And Child Restraints....................... 217

Lower Anchors And Tethers ForChildren................................................ 221Older Children And Child Restraints.......... 218Seating Positions...................................... 220Clean Air Gasoline......................................... 313CleaningWheels...................................................... 303Climate Control................................................51Cold Weather Operation...................................86Compact Spare Tire...................................... 302Contract, Service........................................... 320Controls........................................................ 145Cooling Pressure Cap (Radiator Cap)............ 273Cooling System............................................. 271Adding Coolant (Antifreeze)...................... 272Coolant Level................................... 271, 273Cooling Capacity....................................... 315Disposal Of Used Coolant......................... 273Drain, Flush, And Refill............................. 271Inspection................................................. 273Points To Remember................................ 273Pressure Cap............................................ 273Radiator Cap............................................. 273Selection Of Coolant(Antifreeze)......................... 272, 315, 316Corrosion Protection..................................... 308Cruise Control..................................................97Cruise Control (Speed Control).........................97Cruise Light......................................................80Customer Assistance.................................... 319

22_LA_OM_EN_USC_t.book Page 324