engine oil DODGE CHALLENGER SRT 2018 Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2018, Model line: CHALLENGER SRT, Model: DODGE CHALLENGER SRT 2018Pages: 486, PDF Size: 4.56 MB

Page 326 of 486

CAUTION!(Continued)

positive post and the negative cable is attached to the

negative post. Battery posts are marked positive (+)

and negative (-) and are identified on the battery

case. Cable clamps should be tight on the terminal

posts and free of corrosion.

• If a “fast charger” is used while the battery is in the

vehicle, disconnect both vehicle battery cables before

connecting the charger to the battery. Do not use a

“fast charger” to provide starting voltage.

DEALER SERVICE

An authorized dealer has the qualified service personnel,

special tools, and equipment to perform all service opera-

tions in an expert manner. Service Manuals are available

which include detailed service information for your ve-

hicle. Refer to these Service Manuals before attempting any

procedure yourself.

NOTE: Intentional tampering with emissions control sys-

tems may void your warranty and could result in civil

penalties being assessed against you.

WARNING!

You can be badly injured working on or around a

motor vehicle. Only do service work for which you

have the knowledge and the proper equipment. If you

have any doubt about your ability to perform a service

job, take your vehicle to a competent mechanic.

Engine Oil

Change Engine Oil

The oil change indicator system will remind you that it is

time to take your vehicle in for scheduled maintenance.

Refer to “Scheduled Servicing” in this section for the

proper maintenance intervals.

NOTE: Under no circumstances should oil change inter-

vals exceed 6,000 miles (10,000 km) or six months, which-

ever occurs first.

Engine Oil Selection

For best performance and maximum protection under all

types of operating conditions, the manufacturer only rec-

ommends full synthetic engine oils that meet the American

Petroleum Institute (API) categories of SN.

324 SERVICING AND MAINTENANCE

Page 327 of 486

The manufacturer recommends the use of a full synthetic

SAE 0W-40 engine oil or equivalent meeting the require-

ments of FCA Material Standard MS-12633.

CAUTION!

Do not use chemical flushes in your engine oil as the

chemicals can damage your engine. Such damage is not

covered by the New Vehicle Limited Warranty.

Engine Oil Viscosity

Use Pennzoil Ultra Platinum 0W-40 engine or equivalent

Mopar oil meeting the FCA Material Standard MS-12633

for use in all operating temperatures.

The engine oil filler cap also shows the recommended

engine oil viscosity for your engine. For information on

engine oil filler cap location, refer to “Engine Compart-

ment” in this section for further information.

Synthetic Engine Oils

You may use synthetic engine oils provided the recom-

mended oil quality requirements are met, and the recom-

mended maintenance intervals for oil and filter changes are

followed.Synthetic engine oils which do not have both the engine oil

certification mark and the correct SAE viscosity grade

number should not be used.

Materials Added To Engine Oil

The manufacturer strongly recommends against the addi-

tion of any additives (other than leak detection dyes) to the

engine oil. Engine oil is an engineered product and its

performance may be impaired by supplemental additives.

Engine Oil Change Requirements — 6.2L

Supercharged Engine (If Equipped)

We recommend having your oil changed and vehicle

serviced by an authorized dealer. You should only perform

maintenance procedures and/or repairs for which you

have the knowledge and the right equipment.

Your 6.2L Supercharged engine (if equipped) has a unique

engine oil system. The system contains a drain in the

engine oil pan and the engine oil cooler. It is necessary for

the service technician to drain both the engine oil pan and

the engine oil cooler to properly perform the engine oil

change procedure. Failure to drain the engine oil cooler

will result in overfilling your vehicle’s engine oil system.

NOTE:

Do not overfill crankcase with engine oil, pressure

loss or oil foaming can result.8

SERVICING AND MAINTENANCE 325

Page 328 of 486

To access these oil drains, the vehicle needs to be safely

lifted and supported to remove the front underbody

shields (belly pan). Your service technician will refer to the

Service Manual for proper under body shield (belly pan)

removal and installation procedures.

An authorized dealer has the qualified service personnel,

special tools, and equipment to perform all service opera-

tions in an expert manner. Service Manuals are available

which include detailed service information for your ve-

hicle. Refer to these Service Manuals before attempting any

procedure yourself.

WARNING!

You can be badly injured working on or around a

motor vehicle. Do only that service work for which you

have the knowledge and the right equipment. If you

have any doubt about your ability to perform a service

job, take your vehicle to a competent mechanic.

Disposing Of Used Engine Oil And Oil Filters

Care should be taken in disposing of used engine oil and

oil filters from your vehicle. Used oil and oil filters,

indiscriminately discarded, can present a problem to the

environment. Contact an authorized dealer, service stationor governmental agency for advice on how and where used

oil and oil filters can be safely discarded in your area.

Engine Oil Filter

The engine oil filter should be replaced with a new filter at

every engine oil change.

Engine Oil Filter Selection

This manufacturer’s engines have a full-flow type dispos-

able oil filter. Use a filter of this type for replacement. The

quality of replacement filters varies considerably. Only

high quality filters should be used to assure most efficient

service. Mopar engine oil filters are high quality oil filters

and are recommended.

Engine Air Cleaner Filter

Refer to the “Maintenance Plan” in this section for the

proper maintenance intervals.

WARNING!

The air induction system (air cleaner, hoses, etc.) can

provide a measure of protection in the case of engine

backfire. Do not remove the air induction system (air

(Continued)

326 SERVICING AND MAINTENANCE

Page 333 of 486

•Noise (objectionable squeal, squeak, or rumble is heard

or felt while drive belt is in operation)

Some conditions can be caused by a faulty component such

as a belt pulley. Belt pulleys should be carefully inspected

for damage and proper alignment.

Belt replacement on some models requires the use of

special tools, we recommend having your vehicle serviced

at an authorized dealer.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, door hinge pivot points and rollers, liftgate,

tailgate, decklid, sliding doors and hood hinges, should be

lubricated periodically with a lithium based grease, such as

Mopar Spray White Lube to assure quiet, easy operation

and to protect against rust and wear. Prior to the applica-

tion of any lubricant, the parts concerned should be wiped

clean to remove dust and grit; after lubricating excess oil

and grease should be removed. Particular attention should

also be given to hood latching components to ensure

proper function. When performing other underhood ser-

vices, the hood latch, release mechanism and safety catch

should be cleaned and lubricated. The external lock cylinders should be lubricated twice a

year, preferably in the Fall and Spring. Apply a small

amount of a high quality lubricant, such as Mopar Lock

Cylinder Lubricant directly into the lock cylinder.

Windshield Wiper Blades

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild nonabrasive cleaner. This will remove accumulations

of salt or road film.

Operation of the wipers on dry glass for long periods may

cause deterioration of the wiper blades. Always use washer

fluid when using the wipers to remove salt or dirt from a

dry windshield.

Avoid using the wiper blades to remove frost or ice from

the windshield. Keep the blade rubber out of contact with

petroleum products such as engine oil, gasoline, etc.

NOTE:

Life expectancy of wiper blades varies depending

on geographical area and frequency of use. Poor perfor-

mance of blades may be present with chattering, marks,

water lines or wet spots. If any of these conditions are

present, clean the wiper blades or replace as necessary.

8

SERVICING AND MAINTENANCE 331

Page 336 of 486

Installing The Front Wipers

1. Lift the wiper arm off of the glass, until the wiper arm isin the full up position.

2. Position the wiper blade under the hook on the tip of the wiper arm with the wiper locking tab open.

3. Insert the receiver bracket on the wiper assembly into the hook on the tip of the arm through the opening in

the wiper blade under the locking tab.

4. Slide the wiper blade up into the hook on the wiper arm until it is latched (engagement will be accompanied by

an audible click). Fold down the latch release tab and

snap it into its locked position.

5. Gently lower the wiper blade onto the glass.

Exhaust System

The best protection against carbon monoxide entry into the

vehicle body is a properly maintained engine exhaust

system.

If you notice a change in the sound of the exhaust system;

or if the exhaust fumes can be detected inside the vehicle;

or when the underside or rear of the vehicle is damaged; have an authorized technician inspect the complete ex-

haust system and adjacent body areas for broken, dam-

aged, deteriorated, or mispositioned parts. Open seams or

loose connections could permit exhaust fumes to seep into

the passenger compartment. In addition, have the exhaust

system inspected each time the vehicle is raised for lubri-

cation or oil change. Replace as required.

WARNING!

•

Exhaust gases can injure or kill. They contain carbon

monoxide (CO), which is colorless and odorless.

Breathing it can make you unconscious and can

eventually poison you. To avoid breathing CO, refer

to “Safety Tips” in “Safety” for further information.

• A hot exhaust system can start a fire if you park over

materials that can burn. Such materials might be

grass or leaves coming into contact with your exhaust

system. Do not park or operate your vehicle in areas

where your exhaust system can contact anything that

can burn.

334 SERVICING AND MAINTENANCE

Page 343 of 486

Clean the top of the master cylinder area before removing

the cap. Add fluid to bring the level up to the top of the

“FULL” mark on the side of the master cylinder reservoir.

Overfilling of fluid is not recommended because it may

cause leaking in the system.

Add enough fluid to bring the level up to the requirements

described on the brake fluid reservoir. With disc brakes,

fluid level can be expected to fall as the brake pads wear.

However, low fluid level may be caused by a leak and a

checkup may be needed.

Use only brake fluid that has been recommended by the

manufacturer, and has been kept in a tightly closed con-

tainer to avoid contamination from foreign matter or

moisture.

Refer to “Fluids And Lubricants” in “Technical Specifica-

tions” for further information.

WARNING!

•Use only manufacturer’s recommended brake fluid.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information. Using the

(Continued)

WARNING! (Continued)

wrong type of brake fluid can severely damage your

brake system and/or impair its performance. The

proper type of brake fluid for your vehicle is also

identified on the original factory installed hydraulic

master cylinder reservoir.

• To avoid contamination from foreign matter or mois-

ture, use only new brake fluid or fluid that has been

in a tightly closed container. Keep the master cylin-

der reservoir cap secured at all times. Brake fluid in

a open container absorbs moisture from the air

resulting in a lower boiling point. This may cause it

to boil unexpectedly during hard or prolonged brak-

ing, resulting in sudden brake failure. This could

result in a collision.

• Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing the

brake fluid to catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

• Do not allow petroleum based fluid to contaminate

the brake fluid. Brake seal components could be

damaged, causing partial or complete brake failure.

This could result in a collision.

8

SERVICING AND MAINTENANCE 341

Page 377 of 486

In the event power assist is lost for any reason (for

example, repeated brake applications with the engine

OFF), the brakes will still function. The effort required to

brake the vehicle will be much greater than that required

with the power system operating.

NOTE:Your vehicle is equipped with a high performance

braking system. The brake pads are a semi-metallic com-

pound, which offer superior fade resistance for consistent

operation. A compromise to using this type of brake pad is

that the brakes may produce more brake dust and may

squeal slightly under certain weather and operating con-

ditions (i.e., during light brake applications). These are

considered normal conditions.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure that

the wheel is properly mounted to the vehicle. Any time a

wheel has been removed and reinstalled on the vehicle, the

lug nuts/bolts should be torqued using a properly cali-

brated torque wrench using a high quality six sided (hex)

deep wall socket.

Torque Specifications

Lug Nut/Bolt Torque **Lug Nut/Bolt

Size Lug Nut/Bolt

Socket Size

111 Ft-Lbs (150 N·m) M14 x 1.50 22 mm

**Use only your authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

Inspect the wheel mounting surface prior to mounting the

tire and remove any corrosion or loose particles.

Wheel Mounting Surface

9

TECHNICAL SPECIFICATIONS 375

Page 383 of 486

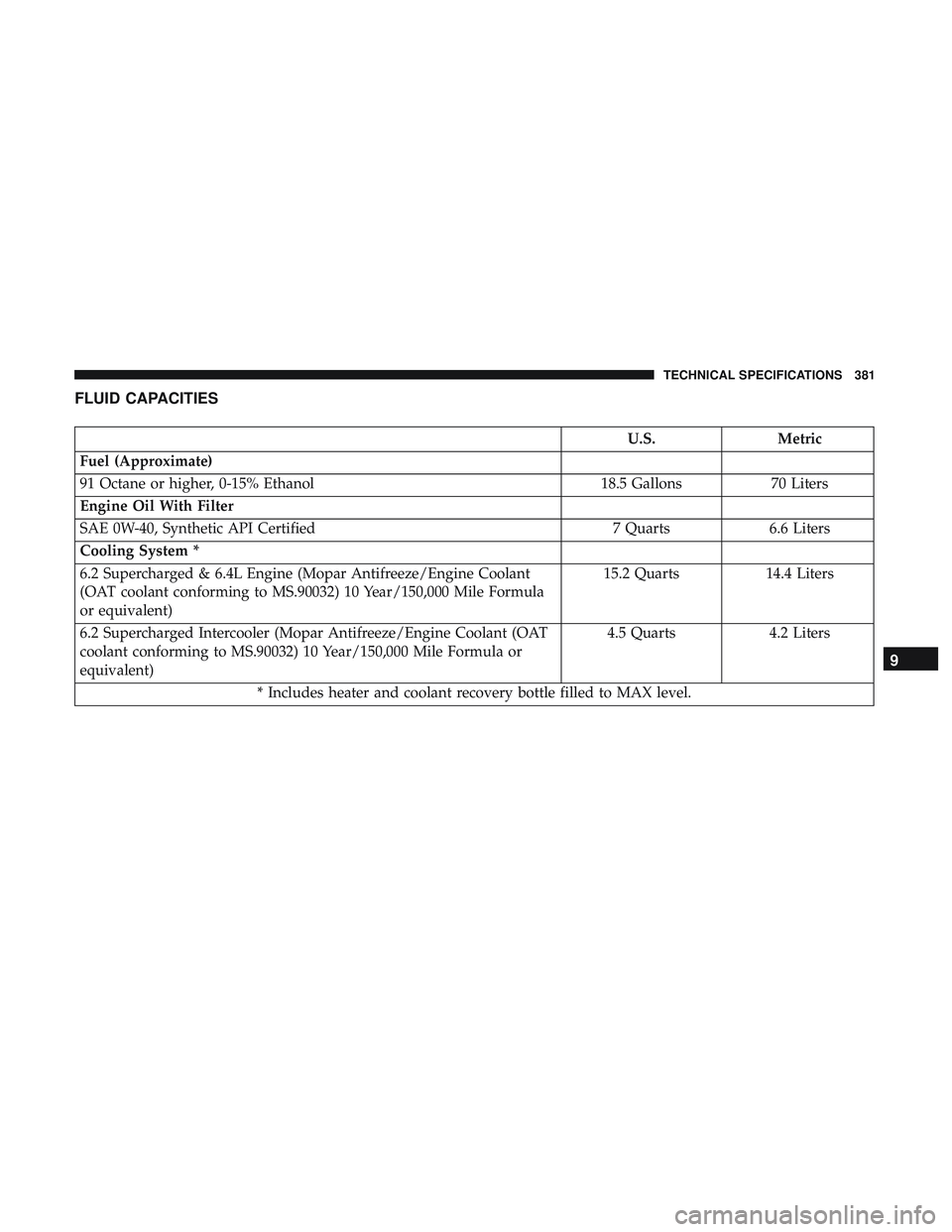

FLUID CAPACITIES

U.S.Metric

Fuel (Approximate)

91 Octane or higher, 0-15% Ethanol 18.5 Gallons70 Liters

Engine Oil With Filter

SAE 0W-40, Synthetic API Certified 7 Quarts6.6 Liters

Cooling System *

6.2 Supercharged & 6.4L Engine (Mopar Antifreeze/Engine Coolant

(OAT coolant conforming to MS.90032) 10 Year/150,000 Mile Formula

or equivalent) 15.2 Quarts

14.4 Liters

6.2 Supercharged Intercooler (Mopar Antifreeze/Engine Coolant (OAT

coolant conforming to MS.90032) 10 Year/150,000 Mile Formula or

equivalent) 4.5 Quarts

4.2 Liters

* Includes heater and coolant recovery bottle filled to MAX level.

9

TECHNICAL SPECIFICATIONS 381

Page 384 of 486

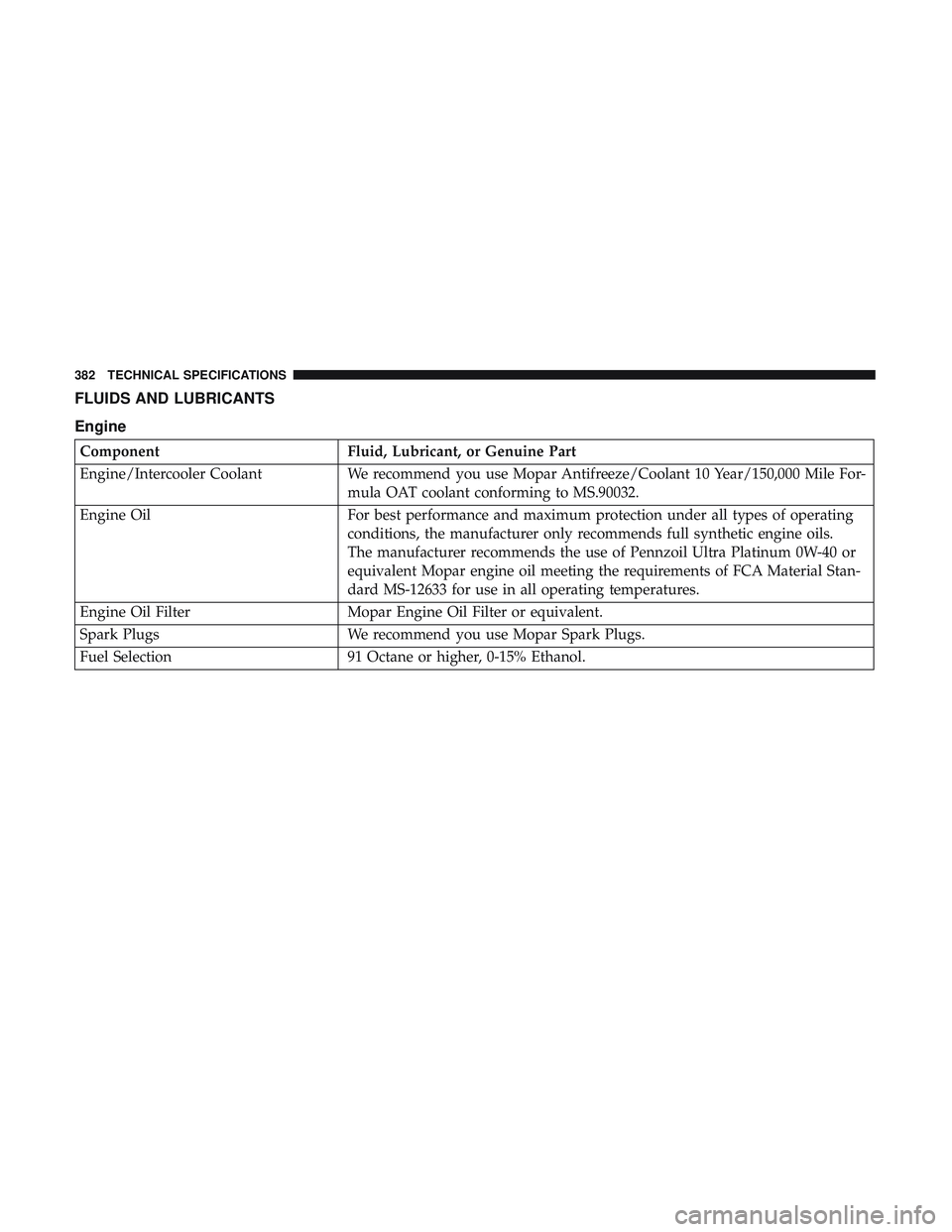

FLUIDS AND LUBRICANTS

Engine

ComponentFluid, Lubricant, or Genuine Part

Engine/Intercooler Coolant We recommend you use Mopar Antifreeze/Coolant 10 Year/150,000 Mile For-

mula OAT coolant conforming to MS.90032.

Engine Oil For best performance and maximum protection under all types of operating

conditions, the manufacturer only recommends full synthetic engine oils.

The manufacturer recommends the use of Pennzoil Ultra Platinum 0W-40 or

equivalent Mopar engine oil meeting the requirements of FCA Material Stan-

dard MS-12633 for use in all operating temperatures.

Engine Oil Filter Mopar Engine Oil Filter or equivalent.

Spark Plugs We recommend you use Mopar Spark Plugs.

Fuel Selection 91 Octane or higher, 0-15% Ethanol.

382 TECHNICAL SPECIFICATIONS

Page 415 of 486

2. Select the following option from the menu:•Set Widget: Top Left

• Set Widget: Top Right

• Set Widget: Bottom Left

• Set Widget: Bottom Right

3. After selecting a Widget location: select the gauge or timer to display:

• Gauge: Oil Temp

• Gauge: Oil Pressure

• Gauge: Coolant Temp

• Gauge: Battery Voltage

• Gauge: Trans Temp

• Gauge: Boost Pressure

• Gauge: Air/Fuel Ratio — If Equipped

• Gauge: I/C Coolant Temp

• Gauge: Intake Air Temp

• Gauge: Engine Torque •

Gauge: Engine Power

• Gauge: G-Force

• Gauge: Steering Angle

• Gauge: Current Gear

• Gauge: Current Speed

• Timer: 0–60 MPH

• Timer: 0–100 MPH

• Timer: 1/8 Mile

• Timer: 1/4 Mile

• Timer: Brake Distance

• Timer: Reaction Time

NOTE: Pressing the “Camera” icon in the upper right

corner of the Performance Pages screen will take a screen-

shot of the current screen and save it to a USB that is

connected.

10

MULTIMEDIA 413