engine oil DODGE CHALLENGER SRT 2019 Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2019, Model line: CHALLENGER SRT, Model: DODGE CHALLENGER SRT 2019Pages: 500, PDF Size: 4.73 MB

Page 344 of 500

NOTE:Do not overfill crankcase with engine oil, pressure

loss or oil foaming can result.

To access these oil drains, the vehicle needs to be safely

lifted and supported to remove the front underbody

shields (belly pan). Your service technician will refer to the

Service Manual for proper under body shield (belly pan)

removal and installation procedures.

An authorized dealer has the qualified service personnel,

special tools, and equipment to perform all service opera-

tions in an expert manner. Service Manuals are available

which include detailed service information for your ve-

hicle. Refer to these Service Manuals before attempting any

procedure yourself.

WARNING!

You can be badly injured working on or around a

motor vehicle. Do only that service work for which you

have the knowledge and the right equipment. If you

have any doubt about your ability to perform a service

job, take your vehicle to a competent mechanic.

Disposing Of Used Engine Oil And Oil Filters

Care should be taken in disposing of used engine oil and

oil filters from your vehicle. Used oil and oil filters,

indiscriminately discarded, can present a problem to the

environment. Contact an authorized dealer, service station

or governmental agency for advice on how and where used

oil and oil filters can be safely discarded in your area.

Engine Oil Filter

The engine oil filter should be replaced with a new filter at

every engine oil change.

Engine Oil Filter Selection

This manufacturer’s engines have a full-flow type dispos-

able oil filter. Use a filter of this type for replacement. The

quality of replacement filters varies considerably. Only

high quality filters should be used to assure most efficient

service. Mopar engine oil filters are high quality oil filters

and are recommended.

Engine Air Cleaner Filter

Refer to the “Maintenance Plan” in this section for the

proper maintenance intervals.

342 SERVICING AND MAINTENANCE

Page 349 of 500

•Noise (objectionable squeal, squeak, or rumble is heard

or felt while drive belt is in operation)

Some conditions can be caused by a faulty component such

as a belt pulley. Belt pulleys should be carefully inspected

for damage and proper alignment.

Belt replacement on some models requires the use of

special tools, we recommend having your vehicle serviced

at an authorized dealer.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, door hinge pivot points and rollers, liftgate,

tailgate, decklid, sliding doors and hood hinges, should be

lubricated periodically with a lithium based grease, such as

Mopar Spray White Lube to assure quiet, easy operation

and to protect against rust and wear. Prior to the applica-

tion of any lubricant, the parts concerned should be wiped

clean to remove dust and grit; after lubricating excess oil

and grease should be removed. Particular attention should

also be given to hood latching components to ensure

proper function. When performing other underhood ser-

vices, the hood latch, release mechanism and safety catch

should be cleaned and lubricated. The external lock cylinders should be lubricated twice a

year, preferably in the Fall and Spring. Apply a small

amount of a high quality lubricant, such as Mopar Lock

Cylinder Lubricant directly into the lock cylinder.

Windshield Wiper Blades

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild nonabrasive cleaner. This will remove accumulations

of salt or road film.

Operation of the wipers on dry glass for long periods may

cause deterioration of the wiper blades. Always use washer

fluid when using the wipers to remove salt or dirt from a

dry windshield.

Avoid using the wiper blades to remove frost or ice from

the windshield. Keep the blade rubber out of contact with

petroleum products such as engine oil, gasoline, etc.

NOTE:

Life expectancy of wiper blades varies depending

on geographical area and frequency of use. Poor perfor-

mance of blades may be present with chattering, marks,

water lines or wet spots. If any of these conditions are

present, clean the wiper blades or replace as necessary.

8

SERVICING AND MAINTENANCE 347

Page 351 of 500

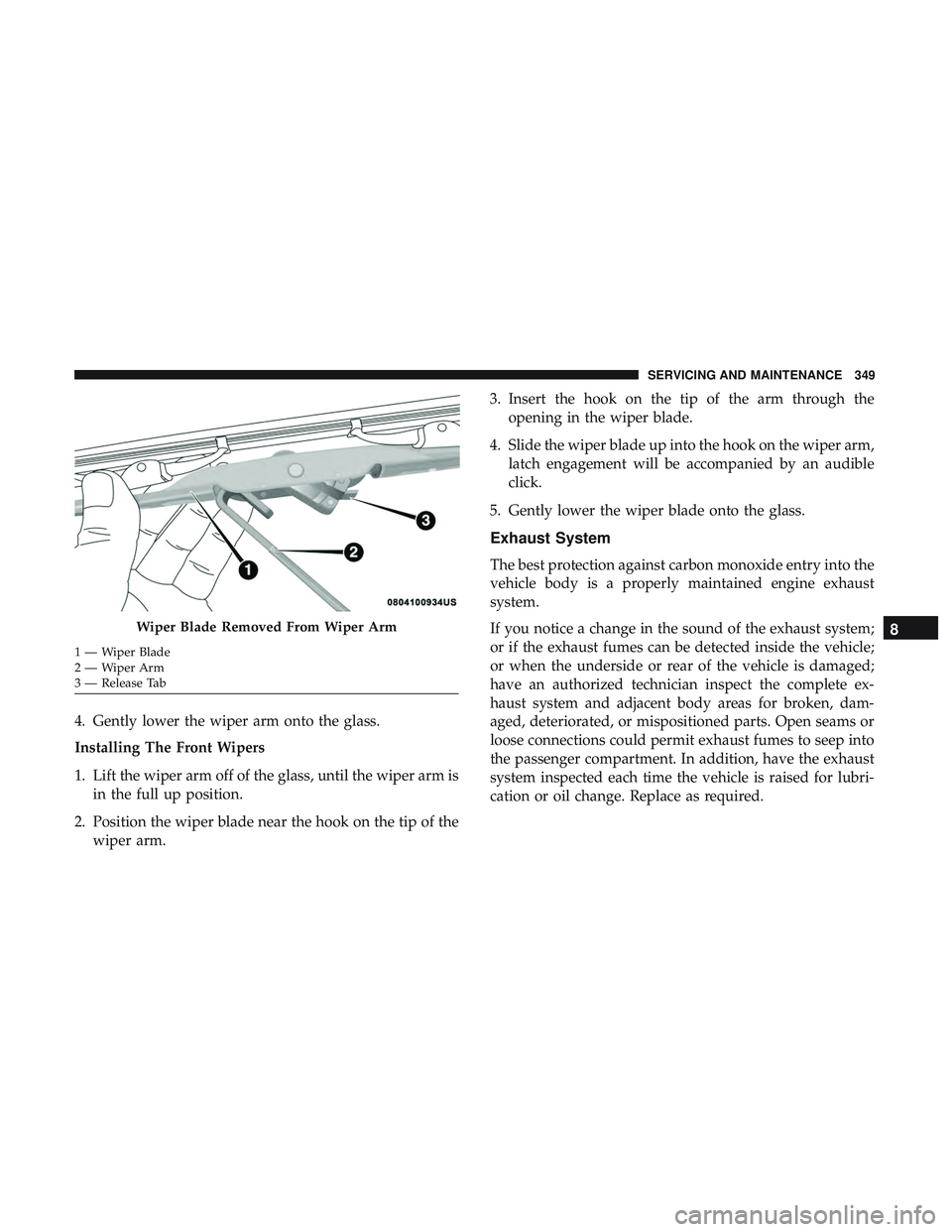

4. Gently lower the wiper arm onto the glass.

Installing The Front Wipers

1. Lift the wiper arm off of the glass, until the wiper arm isin the full up position.

2. Position the wiper blade near the hook on the tip of the wiper arm. 3. Insert the hook on the tip of the arm through the

opening in the wiper blade.

4. Slide the wiper blade up into the hook on the wiper arm, latch engagement will be accompanied by an audible

click.

5. Gently lower the wiper blade onto the glass.

Exhaust System

The best protection against carbon monoxide entry into the

vehicle body is a properly maintained engine exhaust

system.

If you notice a change in the sound of the exhaust system;

or if the exhaust fumes can be detected inside the vehicle;

or when the underside or rear of the vehicle is damaged;

have an authorized technician inspect the complete ex-

haust system and adjacent body areas for broken, dam-

aged, deteriorated, or mispositioned parts. Open seams or

loose connections could permit exhaust fumes to seep into

the passenger compartment. In addition, have the exhaust

system inspected each time the vehicle is raised for lubri-

cation or oil change. Replace as required.

Wiper Blade Removed From Wiper Arm

1—WiperBlade

2—WiperArm

3 — Release Tab

8

SERVICING AND MAINTENANCE 349

Page 359 of 500

WARNING!

•Use only manufacturer’s recommended brake fluid.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information. Using the

wrong type of brake fluid can severely damage your

brake system and/or impair its performance. The

proper type of brake fluid for your vehicle is also

identified on the original factory installed hydraulic

master cylinder reservoir.

• To avoid contamination from foreign matter or mois-

ture, use only new brake fluid or fluid that has been

in a tightly closed container. Keep the master cylin-

der reservoir cap secured at all times. Brake fluid in

a open container absorbs moisture from the air

resulting in a lower boiling point. This may cause it

to boil unexpectedly during hard or prolonged brak-

ing, resulting in sudden brake failure. This could

result in a collision.

• Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing the

brake fluid to catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

(Continued)

WARNING! (Continued)

•Do not allow petroleum based fluid to contaminate

the brake fluid. Brake seal components could be

damaged, causing partial or complete brake failure.

This could result in a collision.

Clutch Hydraulic System — Manual Transmission

(If Equipped)

The clutch hydraulic system is fed by a segregated volume

of fluid within the brake system master cylinder reservoir.

In the event of leakage or wear, use only the manufactur-

er’s recommended brake fluid. Refer to “Fluids And Lu-

bricants” in “Technical Specifications” for further informa-

tion.

Manual Transmission — If Equipped

Fluid Level Check

Check the fluid level by removing the fill plug on the left

side of the transmission. The fluid level should be 1/4 inch

(6.4mm) below the bottom of the fill hole. Add fluid, if

necessary, to maintain the proper level. Refer to “Fluids

And Lubricants” in “Technical Specifications” for further

information.

8

SERVICING AND MAINTENANCE 357

Page 393 of 500

In the event power assist is lost for any reason (for

example, repeated brake applications with the engine

OFF), the brakes will still function. The effort required to

brake the vehicle will be much greater than that required

with the power system operating.

NOTE:Your vehicle is equipped with a high performance

braking system. The brake pads are a semi-metallic com-

pound, which offer superior fade resistance for consistent

operation. A compromise to using this type of brake pad is

that the brakes may produce more brake dust and may

squeal slightly under certain weather and operating con-

ditions (i.e., during light brake applications). These are

considered normal conditions.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure that

the wheel is properly mounted to the vehicle. Any time a

wheel has been removed and reinstalled on the vehicle, the

lug nuts/bolts should be torqued using a properly cali-

brated torque wrench using a high quality six sided (hex)

deep wall socket.

Torque Specifications

Lug Nut/Bolt Torque **Lug Nut/Bolt

Size Lug Nut/Bolt

Socket Size

111 Ft-Lbs (150 N·m) M14 x 1.50 22 mm

**Use only your authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

Inspect the wheel mounting surface prior to mounting the

tire and remove any corrosion or loose particles.

Wheel Mounting Surface

9

TECHNICAL SPECIFICATIONS 391

Page 399 of 500

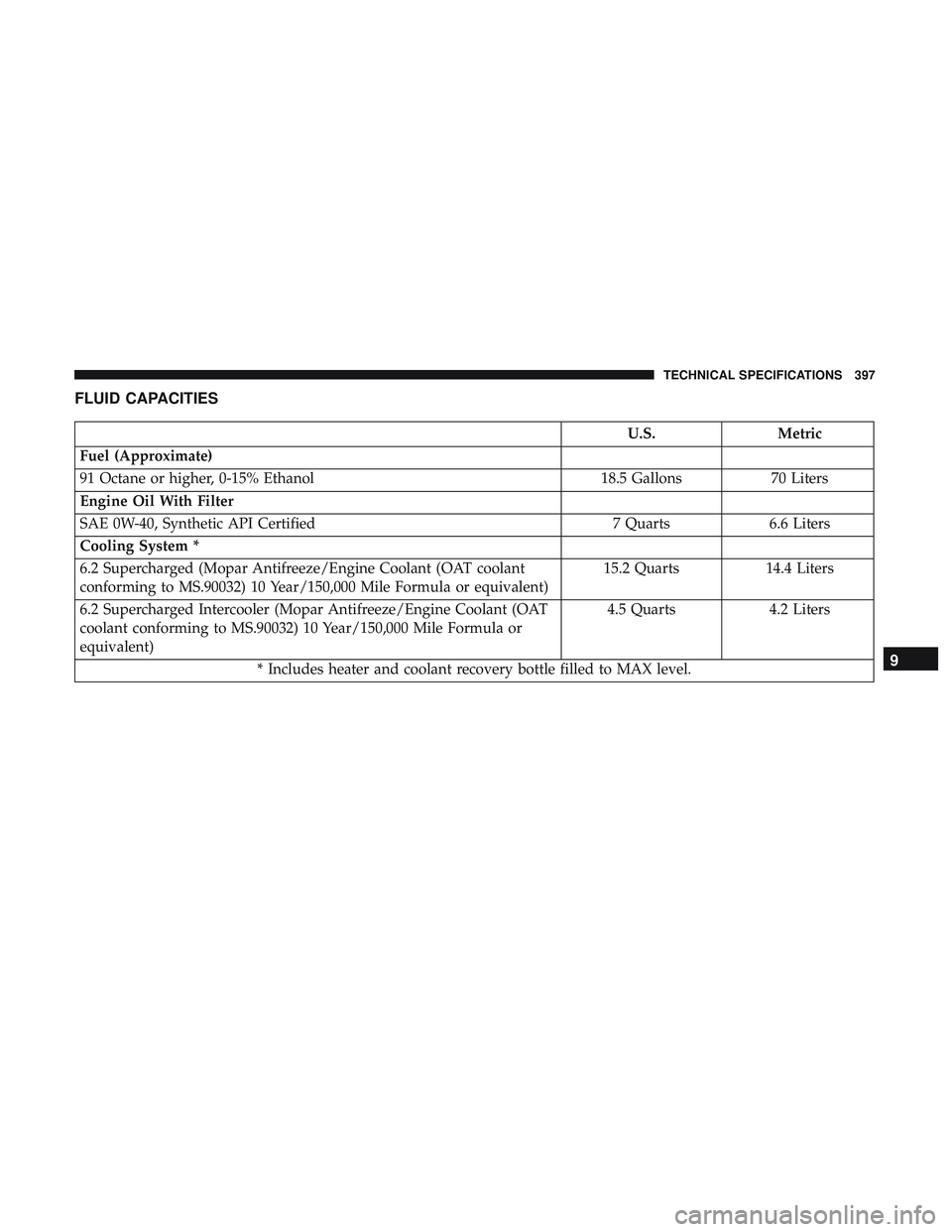

FLUID CAPACITIES

U.S.Metric

Fuel (Approximate)

91 Octane or higher, 0-15% Ethanol 18.5 Gallons70 Liters

Engine Oil With Filter

SAE 0W-40, Synthetic API Certified 7 Quarts6.6 Liters

Cooling System *

6.2 Supercharged (Mopar Antifreeze/Engine Coolant (OAT coolant

conforming to MS.90032) 10 Year/150,000 Mile Formula or equivalent) 15.2 Quarts

14.4 Liters

6.2 Supercharged Intercooler (Mopar Antifreeze/Engine Coolant (OAT

coolant conforming to MS.90032) 10 Year/150,000 Mile Formula or

equivalent) 4.5 Quarts

4.2 Liters

* Includes heater and coolant recovery bottle filled to MAX level.

9

TECHNICAL SPECIFICATIONS 397

Page 400 of 500

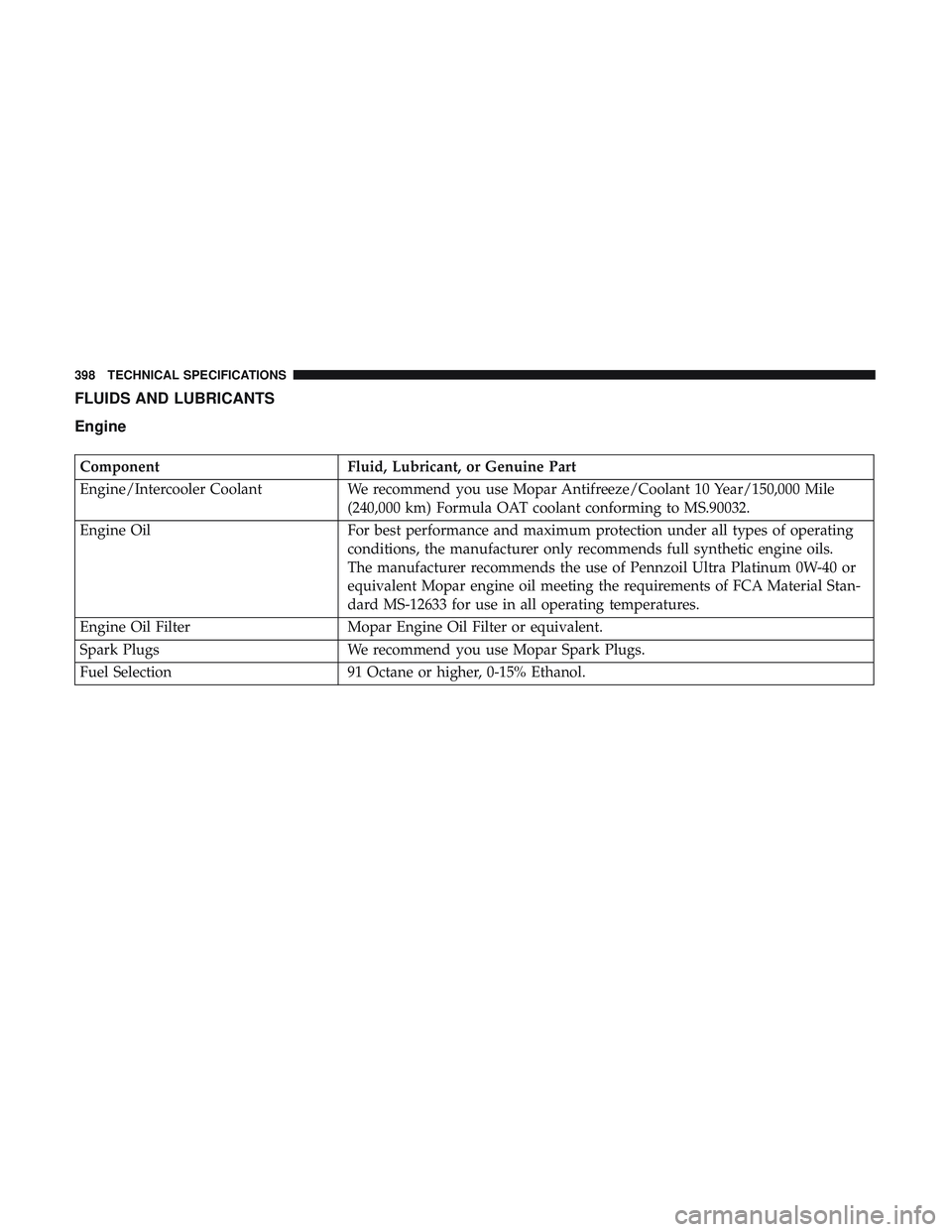

FLUIDS AND LUBRICANTS

Engine

ComponentFluid, Lubricant, or Genuine Part

Engine/Intercooler Coolant We recommend you use Mopar Antifreeze/Coolant 10 Year/150,000 Mile

(240,000 km) Formula OAT coolant conforming to MS.90032.

Engine Oil For best performance and maximum protection under all types of operating

conditions, the manufacturer only recommends full synthetic engine oils.

The manufacturer recommends the use of Pennzoil Ultra Platinum 0W-40 or

equivalent Mopar engine oil meeting the requirements of FCA Material Stan-

dard MS-12633 for use in all operating temperatures.

Engine Oil Filter Mopar Engine Oil Filter or equivalent.

Spark Plugs We recommend you use Mopar Spark Plugs.

Fuel Selection 91 Octane or higher, 0-15% Ethanol.

398 TECHNICAL SPECIFICATIONS

Page 429 of 500

2. Press the pencil icon and select the following optionfrom the menu:

• Set Widget: Top Left

• Set Widget: Top Right

• Set Widget: Bottom Left

• Set Widget: Bottom Right

3. After selecting a Widget location: select the gauge to display:

• Gauge: Oil Temp

• Gauge: Oil Pressure

• Gauge: Coolant Temp

• Gauge: Battery Voltage

• Gauge: Trans Temp — If Equipped with an Automatic

Transmission

• Gauge: Boost Pressure — If Equipped

• Gauge: Air/Fuel Ratio — If Equipped •

Gauge: I/C Coolant Temp — If Equipped

• Gauge: Intake Air Temp

• Gauge: Engine Torque

• Gauge: Engine Power

• Gauge: G-Force

• Gauge: Steering Angle

• Gauge: Current Gear

• Gauge: Current Speed

• Timer: 0-60 MPH

• Timer: 0-100 MPH

• Timer: 1/8 Mile

• Timer: 1/4 Mile

• Timer: Brake Distance

• Timer: Reaction Time

10

MULTIMEDIA 427

Page 485 of 500

Arming SystemSecurity Alarm ...........................35

Assist, Hill Start .......................... .141

Audio Systems (Radio) .......................403

Auto Down Power Windows ...................79

Automatic Door Locks ........................43

Automatic Headlights ........................63

Automatic High Beams .......................62

Automatic Temperature Control (ATC) ............75

Automatic Transmission ..................... .229

Adding Fluid .....................359, 398, 400

Fluid And Filter Change ...................359

Fluid Change .......................... .359

Fluid Level Check .....................358, 359

Fluid Type .......................358, 398, 400

Special Additives ........................ .358

Automatic Transmission Limp Home Mode .....43, 234

AutoPark ............................... .217

Autostick Operation ............................. .235

Axle Fluid ............................398, 400

Axle Lubrication ........................398, 400

Back-Up .................................272

Battery ...............................120, 338 Charging System Light

....................120

Keyless Key Fob Replacement ................23

Location ...............................338

Belts, Seat ............................... .206

Blind Spot Monitoring .......................144

Body Mechanism Lubrication ..................347

B-Pillar Location .......................... .366

Brake Assist System ........................ .135

Brake Control System ........................135

Brake Fluid ........................356, 398, 400

Brake System ..........................356, 390

Fluid Check ..................... .356, 398, 400

Master Cylinder ........................ .356

Parking ...............................221

W arning

Light .......................118,390

Brake/Transmission Interlock ..................229

Brightness, Interior Lights .....................66

Bulb Replacement ..........................288

Bulbs, Light .......................... .208, 288

Camera, Rear ............................ .272

Capacities, Fluid .......................... .397

Caps, Filler Fuel ................................. .274

Oil (Engine) ........................ .337, 341

12

INDEX 483

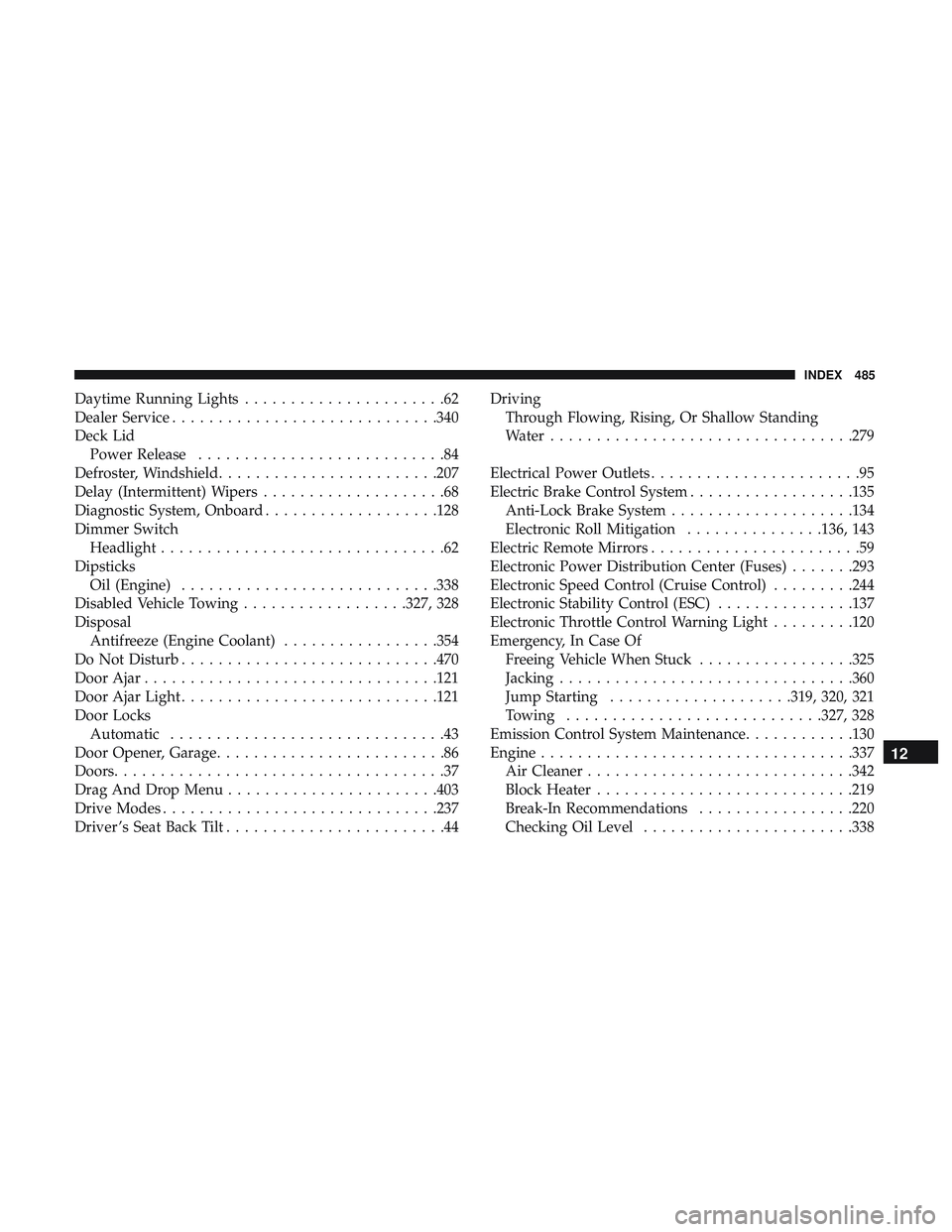

Page 487 of 500

Daytime Running Lights......................62

Dealer Service ............................ .340

Deck Lid Power Release ...........................84

Defroster, Windshield ........................207

Delay (Intermittent) Wipers ....................68

Diagnostic System, Onboard ...................128

Dimmer Switch Headlight ...............................62

Dipsticks Oil (Engine) ............................338

Disabled Vehicle Towing ..................327, 328

Disposal Antifreeze (Engine Coolant) .................354

Do Not Disturb ............................470

Door Ajar ............................... .121

Door Ajar Light ............................121

Door Locks Automatic ..............................43

Door Opener, Garage .........................86

Doors ....................................37

Drag And Drop Menu .......................403

Drive Modes ............................. .237

Driver ’s Seat Back Tilt ........................44 Driving

Through Flowing, Rising, Or Shallow Standing

Water .................................279

Electrical Power Outlets .......................95

Electric Brake Control System ..................135

Anti-Lock Brake System ....................134

Electronic Roll Mitigation ...............136, 143

Electric Remote Mirrors .......................59

Electronic Power Distribution Center (Fuses) .......293

Electronic Speed Control (Cruise Control) .........244

Electronic Stability Control (ESC) ...............137

Electronic Throttle Control Warning Light .........120

Emergency, In Case Of Freeing Vehicle When Stuck .................325

Jacking ............................... .360

Jump Starting ....................319, 320, 321

Towing ............................327, 328

Emission Control System Maintenance ............130

Engine ................................. .337

Air Cleaner ............................ .342

Block

Heater ............................219

Break-In Recommendations .................220

Checking Oil Level .......................33812

INDEX 485