ECU DODGE CHARGER 2006 6.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: CHARGER, Model: DODGE CHARGER 2006 6.GPages: 368, PDF Size: 6.13 MB

Page 204 of 368

Park Position

The PARK position is to be used when parking the

vehicle. Engage only with the vehicle stopped. The PARK

position is not intended to serve as a brake when the

vehicle is parked. Rather, the driver should always use

the parking brake in addition to placing the selector lever

in PARK to secure the vehicle.

PARK supplements the parking brake by locking the

transmission. The engine can be started in this range.

Never attempt to use PARK while the vehicle is in

motion.

NOTE:

•

If the key is in the ACC or ON position, you must press

the brake pedal to shift out of the PARK position.

•The key can be removed from the ignition switch only

with the selector lever in the PARK position. With the

key removed, the selector lever is locked in the PARK

position.

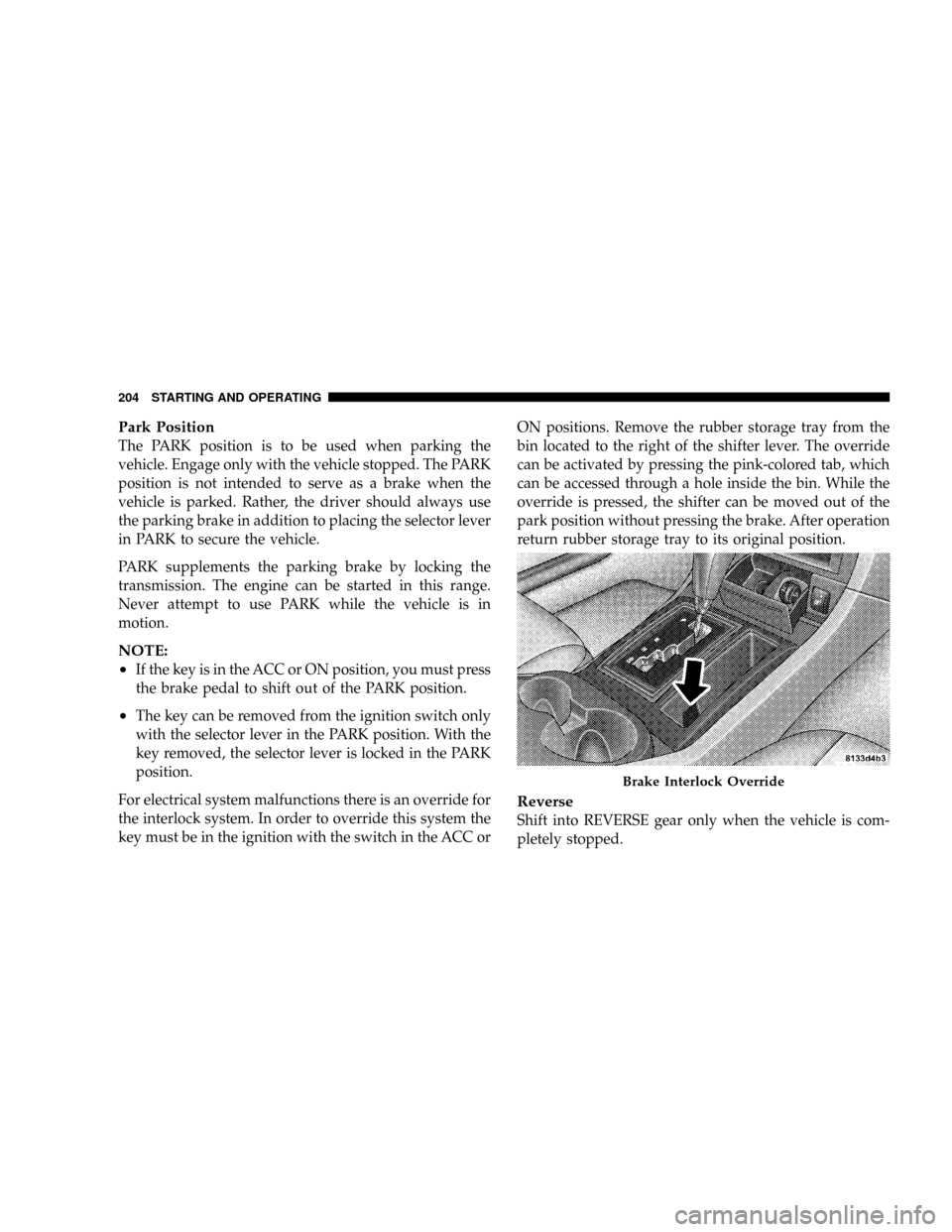

For electrical system malfunctions there is an override for

the interlock system. In order to override this system the

key must be in the ignition with the switch in the ACC orON positions. Remove the rubber storage tray from the

bin located to the right of the shifter lever. The override

can be activated by pressing the pink-colored tab, which

can be accessed through a hole inside the bin. While the

override is pressed, the shifter can be moved out of the

park position without pressing the brake. After operation

return rubber storage tray to its original position.

Reverse

Shift into REVERSE gear only when the vehicle is com-

pletely stopped.

Brake Interlock Override

204 STARTING AND OPERATING

Page 207 of 368

A reset feature is available to allow the vehicle to be

driven to a dealer for service. To reset the transmission,

use the following procedure:

1. Stop the vehicle.

2. Move the selector lever to the PARK position.

3. Turn off the engine.

4. Wait approximately 10 seconds.

5. Restart the engine.

6. Move the shift lever to the desired range. If the

problem is no longer detected, the transmission will

return to normal operation.

NOTE:Even if the transmission can be reset, we

recommend that you visit a dealer at your earliest

possible convenience. Your dealer has diagnostic equip-

ment to determine if the problem could recur.Have the transmission checked at your authorized dealer

as soon as possible.

If the problem has been momentary, the transmission can

be reset to regain all forward gears.

Permanent Transmission Limp Home Mode

Permanent Limp Home Mode will be activated if the

transmission enters temporary Limp Home Mode three

times. Follow the reset procedure described under“Tem-

porary Transmission Limp Home Mode”in this section.

In Permanent Limp Home Mode, PARK (P), REVERSE

(R) and NEUTRAL (N) will continue to operate. SEC-

OND gear will operate in the DRIVE (D) shifter position.

The malfunction indicator light may illuminate.

STARTING AND OPERATING 207

5

Page 246 of 368

NOTE:

•

Tighten the gas cap until you hear a“clicking”sound.

This is an indication that the gas cap is properly

tightened. If the gas cap is not secured properly the

Malfunction Indicator Light in the instrument cluster

will turn on. Make sure that the gas cap is tightened

each time the vehicle is refueled.

•When the fuel nozzle“clicks”or shuts off, the fuel

tank is full.

Loose Fuel Filler Cap Message

If the vehicle diagnostic system determines that the fuel

filler cap is loose, improperly installed, or damaged, a

“Check Gascap”message will display in the Electronic

Vehicle Information Center (EVIC)—if equipped. Refer

to“Electronic Vehicle Information Center (EVIC)”in

Section 4 of this manual. Tighten the fuel filler cap

properly and press the odometer reset button to turn the

message off. If the problem continues, the message will

appear the next time the vehicle is started. Refer to

“Onboard Diagnostic System”in Section 7 of this manual

for more information.

WARNING!

•Remove the fuel tank filler tube cap (gas cap)

slowly to prevent fuel spray from the filler neck

which may cause injury.

•The volatility of some gasolines may cause a

buildup of pressure in the fuel tank that may

increase while you drive. This pressure can result

in a spray of gasoline and/or vapors when the cap

is removed from a hot vehicle. Removing the cap

slowly allows the pressure to vent and prevents

fuel spray.

•Never have any smoking materials lit in or near

the vehicle when the gas cap is removed or the

tank filled.

•Never add fuel to the vehicle when the engine is

running.

•A fire may result if gasoline is pumped into a

portable container that is inside of a vehicle. You

could be burned. Always place gas containers on

the ground while filling.

246 STARTING AND OPERATING

Page 248 of 368

Overloading

The load carrying components (axle, springs, tires,

wheels, etc.) of your vehicle will provide satisfactory

service as long as you do not exceed the GVWR and front

and rear GAWR.

The best way to figure out the total weight of your

vehicle is to weigh it when it is fully loaded and ready for

operation. Weigh it on a commercial scale to insure that it

is not over the GVWR.

Figure out the weight on the front and rear of the vehicle

separately. It is important that you distribute the load

evenly over the front and rear axles.

Overloading can cause potential safety hazards and

shorten useful service life. Heavier axles or suspension

components do not necessarily increase the vehicle’s

GVWR.

Loading

To load your vehicle properly, first figure out its empty

weight, axle by axle and side by side. Store heavier items

down low and be sure you distribute their weight as

evenly as possible. Stow all loose items securely before

driving. If weighing the loaded vehicle shows that you

have exceeded either GAWR, but the total load is within

the specified GVWR, you must redistribute the weight.

Improper weight distribution can have an adverse effect

on the way your vehicle steers and handles and the way

the brakes operate.

A loaded vehicle is shown in the illustration. Note that

neither the GVWR or the GAWR capacities have been

exceeded.

248 STARTING AND OPERATING

Page 254 of 368

Towing Requirements

To promote proper break-in of your new vehicle driv-

etrain components the following guidelines are recom-

mended:

CAUTION!

•Avoid towing a trailer for the first 500 miles (805

km) of vehicle operation. Doing so may damage

your vehicle.

•During the first 500 miles (805 km) of trailer

towing, limit your speed to 50 mph (80 km/h).

Perform the maintenance listed in Section 8 of this

manual. When towing a trailer, never exceed the GAWR,

or GCWR, ratings.

WARNING!

Improper towing can lead to an injury accident.

Follow these guidelines to make your trailer towing

as safe as possible:

Make certain that the load is secured in the trailer

and will not shift during travel. When trailering

cargo that is not fully secured, dynamic load shifts

can occur that may be difficult for the driver to

control. You could lose control of your vehicle and

have an accident.

•When hauling cargo or towing a trailer, do not over-

load your vehicle or trailer. Overloading can cause a

loss of control, poor performance or damage to brakes,

axle, engine, transmission, steering, suspension, chas-

sis structure or tires.

•Safety chains must always be used between your

vehicle and trailer. Always connect the chains to the

frame or hook retainers of the vehicle hitch. Cross the

chains under the trailer tongue and allow enough

slack for turning corners.

254 STARTING AND OPERATING

Page 265 of 368

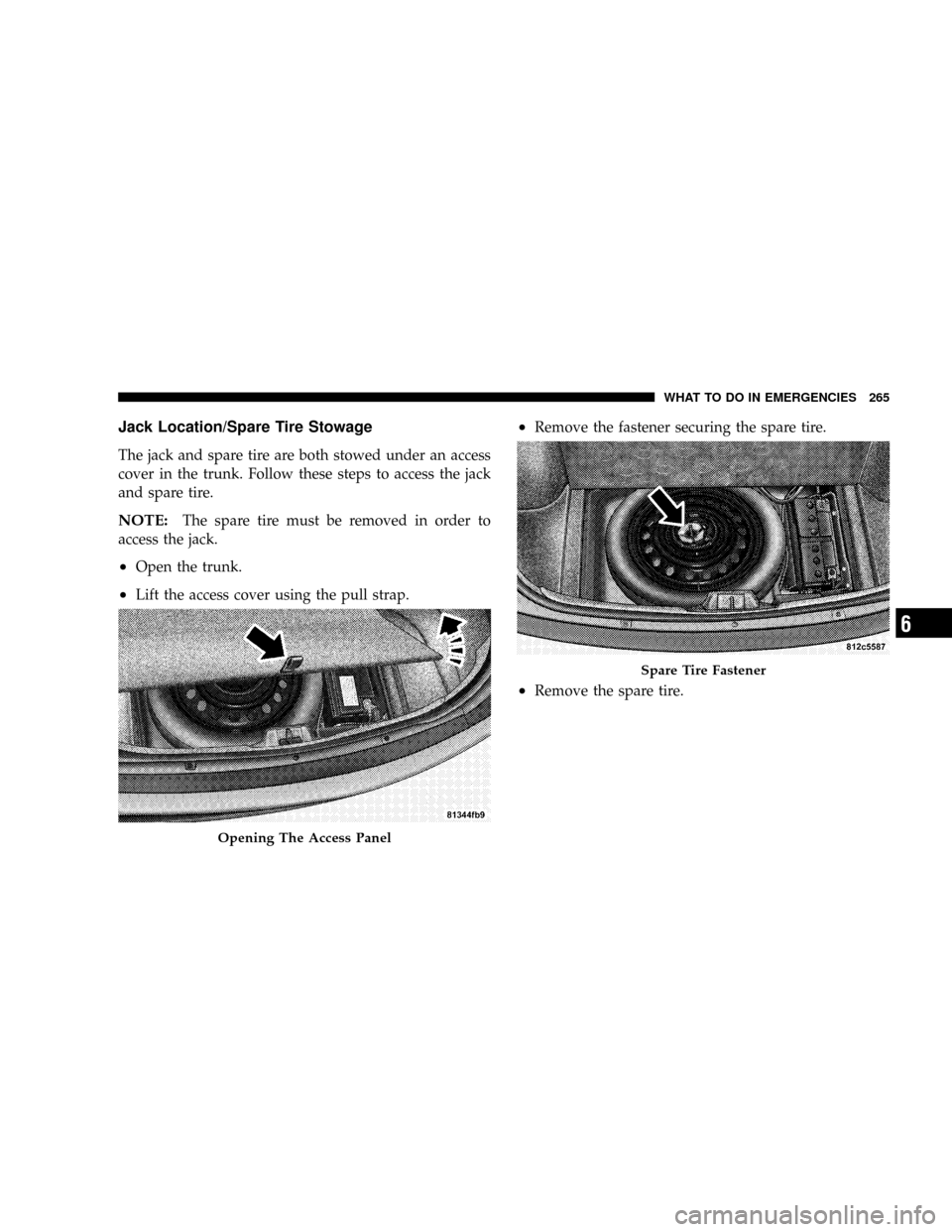

Jack Location/Spare Tire Stowage

The jack and spare tire are both stowed under an access

cover in the trunk. Follow these steps to access the jack

and spare tire.

NOTE:The spare tire must be removed in order to

access the jack.

•Open the trunk.

•Lift the access cover using the pull strap.

•Remove the fastener securing the spare tire.

•Remove the spare tire.

Opening The Access Panel

Spare Tire Fastener

WHAT TO DO IN EMERGENCIES 265

6

Page 266 of 368

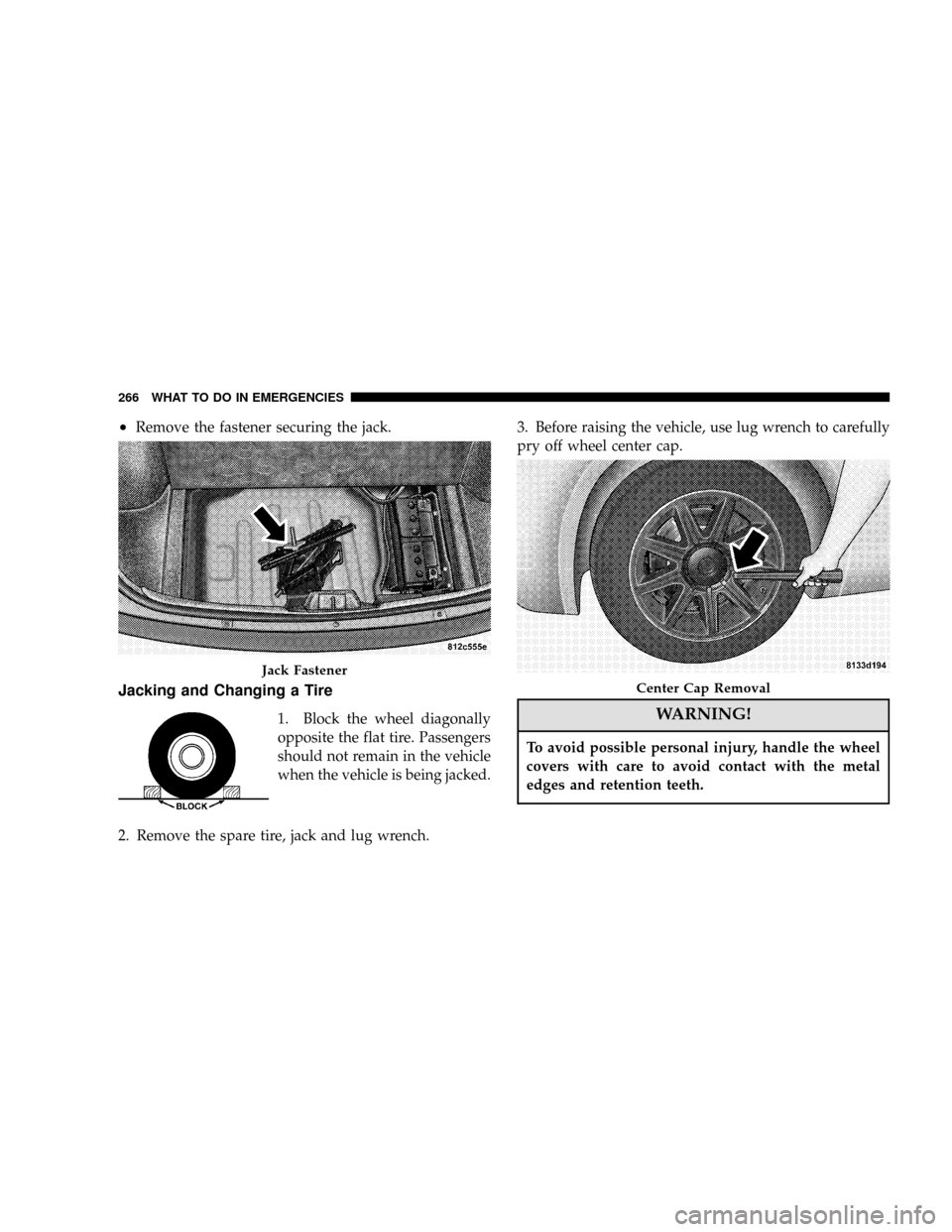

•Remove the fastener securing the jack.

Jacking and Changing a Tire

1. Block the wheel diagonally

opposite the flat tire. Passengers

should not remain in the vehicle

when the vehicle is being jacked.

2. Remove the spare tire, jack and lug wrench.3. Before raising the vehicle, use lug wrench to carefully

pry off wheel center cap.WARNING!

To avoid possible personal injury, handle the wheel

covers with care to avoid contact with the metal

edges and retention teeth.

Jack Fastener

Center Cap Removal

266 WHAT TO DO IN EMERGENCIES

Page 303 of 368

Hoses And Vacuum/Vapor Harnesses

Inspect surfaces of hoses and nylon tubing for evidence

of heat and mechanical damage. Hard or soft spots,

brittle rubber, cracking, tears, cuts, abrasions, and exces-

sive swelling indicate deterioration of the rubber.

Pay particular attention to those hoses nearest to high

heat sources such as the exhaust manifold. Inspect hose

routing to be sure hoses do not come in contact with any

heat source or moving component which may cause heat

damage or mechanical wear.

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

Components should be replaced immediately if there is

any evidence of wear or damage that could cause failure.

Brakes

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in the Mainte-

nance Schedules section of this manual.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn’t have your full

braking capacity in an emergency.

Brake And Power Steering Hoses

When the vehicle is serviced for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, tears, cuts, abrasion, and excessive swelling

indicate deterioration of the rubber. Particular attention

should be made to examining those hose surfaces nearest

to high heat sources, such as the exhaust manifold.

MAINTAINING YOUR VEHICLE 303

7

Page 304 of 368

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

NOTE:Often, fluid such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to facilitate the assembly of hoses to couplings.

Therefore, oil wetness at the hose-coupling area is not

necessarily an indication of leakage. Actual dripping of

hot fluid when systems are under pressure (during

vehicle operation), should be noted before a hose is

replaced based on leakage.

NOTE:Inspection of brake hoses should be performed

whenever the brake system is serviced and at every

engine oil change. Inspect hydraulic brake hoses for

surface cracking, scuffing, or worn spots. If there is any

evidence of cracking, scuffing, or worn spots, the hose

should be replaced immediately! Eventual deterioration

of the hose can take place resulting in a possibility of a

burst failure.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Brake Fluid Level Check

The fluid level in the master cylinder should be checked

when performing underhood services, or immediately if

the brake system warning light indicates system failure.

Clean the top of the master cylinder area before removing

the cap. Add fluid to bring the level up to the top of the

“FULL”mark on the side of the master cylinder reservoir.

Overfilling of fluid is not recommended because it may

cause leaking in the system.

Add enough fluid to bring the level up to the require-

ments described on the brake fluid reservoir. With disc

brakes, fluid level can be expected to fall as the brake

pads wear. However, low fluid level may be caused by a

leak and a checkup may be needed.

304 MAINTAINING YOUR VEHICLE

Page 322 of 368

8. Pull the appropriate bulb to remove it from the socket.

9. Replace the bulb, reinstall the socket, and reattach the

tail light assembly.

10. Close the trunk.

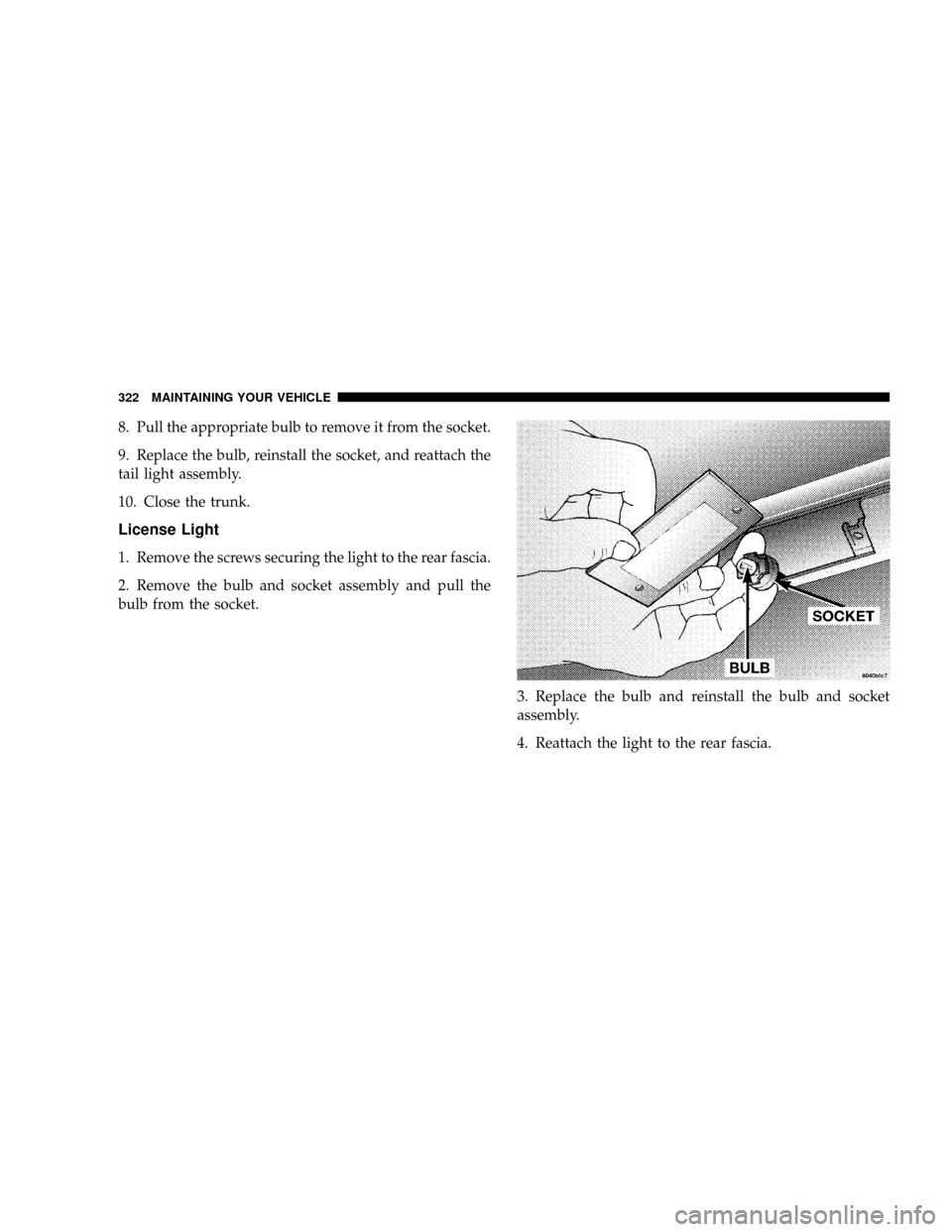

License Light

1. Remove the screws securing the light to the rear fascia.

2. Remove the bulb and socket assembly and pull the

bulb from the socket.

3. Replace the bulb and reinstall the bulb and socket

assembly.

4. Reattach the light to the rear fascia.

322 MAINTAINING YOUR VEHICLE