warning DODGE CHARGER 2008 6.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: CHARGER, Model: DODGE CHARGER 2008 6.GPages: 466, PDF Size: 6.37 MB

Page 330 of 466

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front and rear

axles. Distribute the load over the front and rear axles

evenly. Make sure that you do not exceed either front or

rear GAWR.

WARNING!

It is important that you do not exceed the maximum

front or rear GAWR. A dangerous driving condition

can result if either rating is exceeded. You could lose

control of the vehicle and have an accident.

Tongue Weight (TW)

Tongue weight (TW) is the downward force exerted on

the hitch ball by the trailer. In most cases, it should not be

less than 10% or more than 15% of the trailer load. You

must consider this as part of the load on your vehicle.

Frontal Area

Frontal area is the maximum height and maximum width

of the front of a trailer.

Trailer Sway Control

The trailer sway control is a telescoping link that can be

installed between the hitch receiver and the trailer tongue

that typically provides adjustable friction associated with

the telescoping motion to dampen any unwanted trailer

swaying motions while traveling.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer tongue

weight, just as if it were luggage located at a hitch ball or

some other connecting point of the vehicle. These kinds

of hitches are the most popular on the market today and

they are commonly used to tow small- and medium-

sized trailers.

330 STARTING AND OPERATING

Page 331 of 466

Weight-Distributing Hitch

A weight-distributing system works by applying lever-

age through spring (load) bars. They are typically used

for heavier loads, to distribute trailer tongue weight to

the tow vehicle's front axle and the trailer axle(s). When

used in accordance with the manufacturers' directions, it

provides for a more level ride, offering more consistent

steering and brake control thereby enhancing towing

safety. The addition of a friction / hydraulic sway control

also dampens sway caused by traffic and crosswinds and

contributes positively to tow vehicle and trailer stability.

Trailer sway control and a weight distributing (load

equalizing) hitch are recommended for heavier Tongue

Weights (TW) and may be required depending on Vehicle

and Trailer configuration / loading to comply with Gross

Axle Weight Rating (GAWR) requirements.WARNING!

²An improperly adjusted Weight Distributing

Hitch system may reduce handling, stability, brak-

ing performance, and could result in an accident.

²Weight Distributing Systems may not be compat-

ible with Surge Brake Couplers. Consult with your

hitch and trailer manufacturer or a reputable Rec-

reational Vehicle dealer for additional

information.

STARTING AND OPERATING 331

5

Page 336 of 466

NOTE:Remember that everything put into or on the

trailer adds to the load on your vehicle. Also, additional

factory-installed options, or dealer-installed options,

must be considered as part of the total load on your

vehicle. Refer to the ªTire and Loading Informationº

placard for the maximum combined weight of occupants

and cargo for your vehicle.

Towing Requirements

To promote proper break-in of your new vehicle drivetrain

components the following guidelines are recommended:

CAUTION!

²Avoid towing a trailer for the first 500 miles (805

km) of vehicle operation. Doing so may damage

your vehicle.

²During the first 500 miles (805 km) of trailer

towing, limit your speed to 50 mph (80 km/h).Perform the maintenance listed in Section 8 of this

manual. When towing a trailer, never exceed the GAWR,

or GCWR, ratings.

WARNING!

Improper towing can lead to an injury accident.

Follow these guidelines to make your trailer towing

as safe as possible:

Make certain that the load is secured in the trailer

and it will not shift during travel. When trailering

cargo that is not fully secured, dynamic load shifts

can occur that may be difficult for the driver to

control. You could lose control of your vehicle and

have an accident.

336 STARTING AND OPERATING

Page 339 of 466

WARNING!

Do not connect trailer brakes to your vehicle's hy-

draulic brake lines. It can overload your brake sys-

tem and cause it to fail. You might not have brakes

when you need them and could have an accident.

Towing any trailer will increase your stopping dis-

tance. When towing, you should allow for additional

space between your vehicle and the vehicle in front

of you. Failure to do so could result in an accident.

Towing Requirements Ð Trailer Lights & Wiring

Whenever you pull a trailer, regardless of the trailer size,

stoplights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may includea4and7pin

wiring harness. Use a factory approved trailer harness

and connector.

NOTE:Do not cut or splice wiring into the vehicles

wiring harness.

STARTING AND OPERATING 339

5

Page 343 of 466

WHAT TO DO IN EMERGENCIES

CONTENTS

mHazard Warning Flasher..................344

mIf Your Engine Overheats.................345

mJacking And Tire Changing................346

NPreparations For Jacking................347

NJack Location/Spare Tire Stowage..........348

NJacking And Changing a Tire.............350

NCompact Spare Tire....................354

NWheel Cover Or Center Cap Installation

(If Required).........................354mJump-Starting Procedures.................356

mFreeing A Stuck Vehicle..................359

mTowing A Disabled Vehicle................360

NWithout The Ignition Key...............360

NTowing This Vehicle Behind Another Vehicle

(Flat Towing With All Four Wheels On The

Ground)............................361

NTowing This Vehicle Behind Another Vehicle

With A Tow Dolly.....................362

6

Page 344 of 466

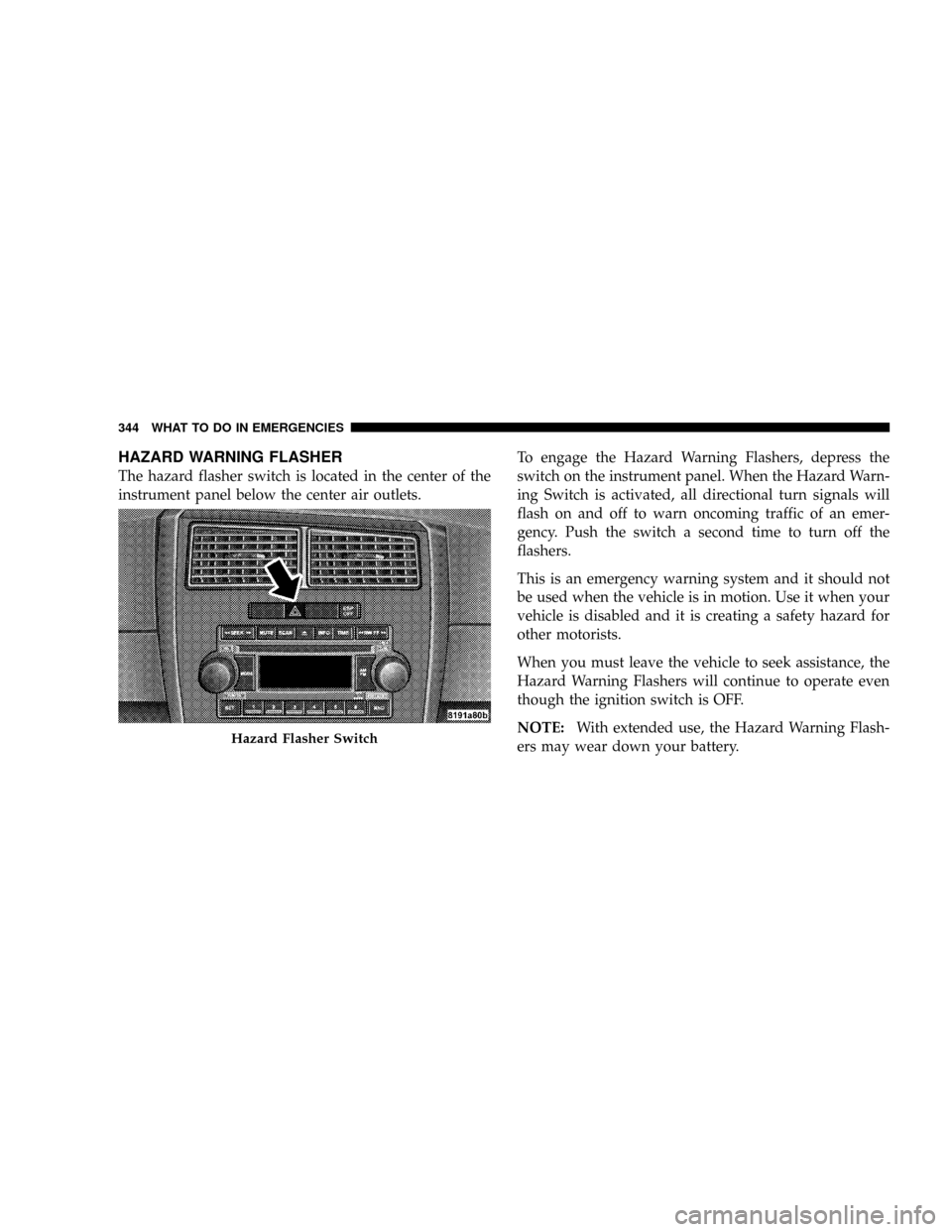

HAZARD WARNING FLASHER

The hazard flasher switch is located in the center of the

instrument panel below the center air outlets.To engage the Hazard Warning Flashers, depress the

switch on the instrument panel. When the Hazard Warn-

ing Switch is activated, all directional turn signals will

flash on and off to warn oncoming traffic of an emer-

gency. Push the switch a second time to turn off the

flashers.

This is an emergency warning system and it should not

be used when the vehicle is in motion. Use it when your

vehicle is disabled and it is creating a safety hazard for

other motorists.

When you must leave the vehicle to seek assistance, the

Hazard Warning Flashers will continue to operate even

though the ignition switch is OFF.

NOTE:With extended use, the Hazard Warning Flash-

ers may wear down your battery.

Hazard Flasher Switch

344 WHAT TO DO IN EMERGENCIES

Page 346 of 466

WARNING!

A hot engine cooling system is dangerous. You or

others could be badly burned by steam or boiling

coolant. You may want to call a service center if your

vehicle overheats. If you decide to look under the

hood yourself, see Section 7, Maintenance, of this

manual. Follow the warnings under the Cooling

System Pressure Cap paragraph.

JACKING AND TIRE CHANGING

WARNING!

²Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

²Getting under a jacked-up vehicle is dangerous.

The vehicle could slip off the jack and fall on you.

You could be crushed. Never get any part of your

body under a vehicle that is on a jack. Never start

or run the engine while the vehicle is on a jack. If

you need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

²The jack is designed to use as a tool for changing

tires only. The jack should not be used to lift the

vehicle for service purposes. The vehicle should

be jacked on a firm level surface only. Avoid ice or

slippery areas.

346 WHAT TO DO IN EMERGENCIES

Page 347 of 466

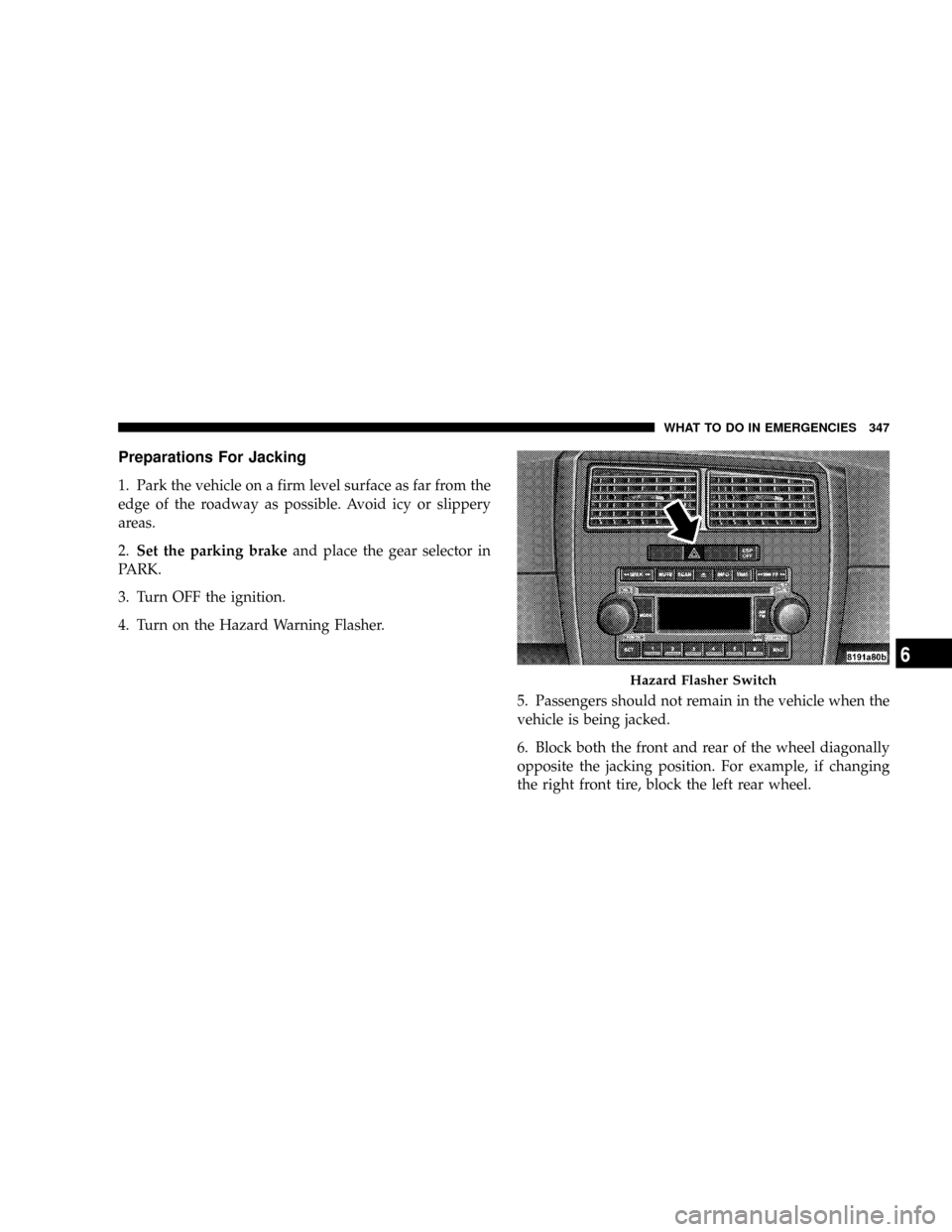

Preparations For Jacking

1. Park the vehicle on a firm level surface as far from the

edge of the roadway as possible. Avoid icy or slippery

areas.

2.Set the parking brakeand place the gear selector in

PARK.

3. Turn OFF the ignition.

4. Turn on the Hazard Warning Flasher.

5. Passengers should not remain in the vehicle when the

vehicle is being jacked.

6. Block both the front and rear of the wheel diagonally

opposite the jacking position. For example, if changing

the right front tire, block the left rear wheel.

Hazard Flasher Switch

WHAT TO DO IN EMERGENCIES 347

6

Page 350 of 466

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided.

Jacking and Changing a Tire

1. Block the wheel diagonally

opposite the flat tire. Passengers

should not remain in the vehicle

when the vehicle is being jacked.

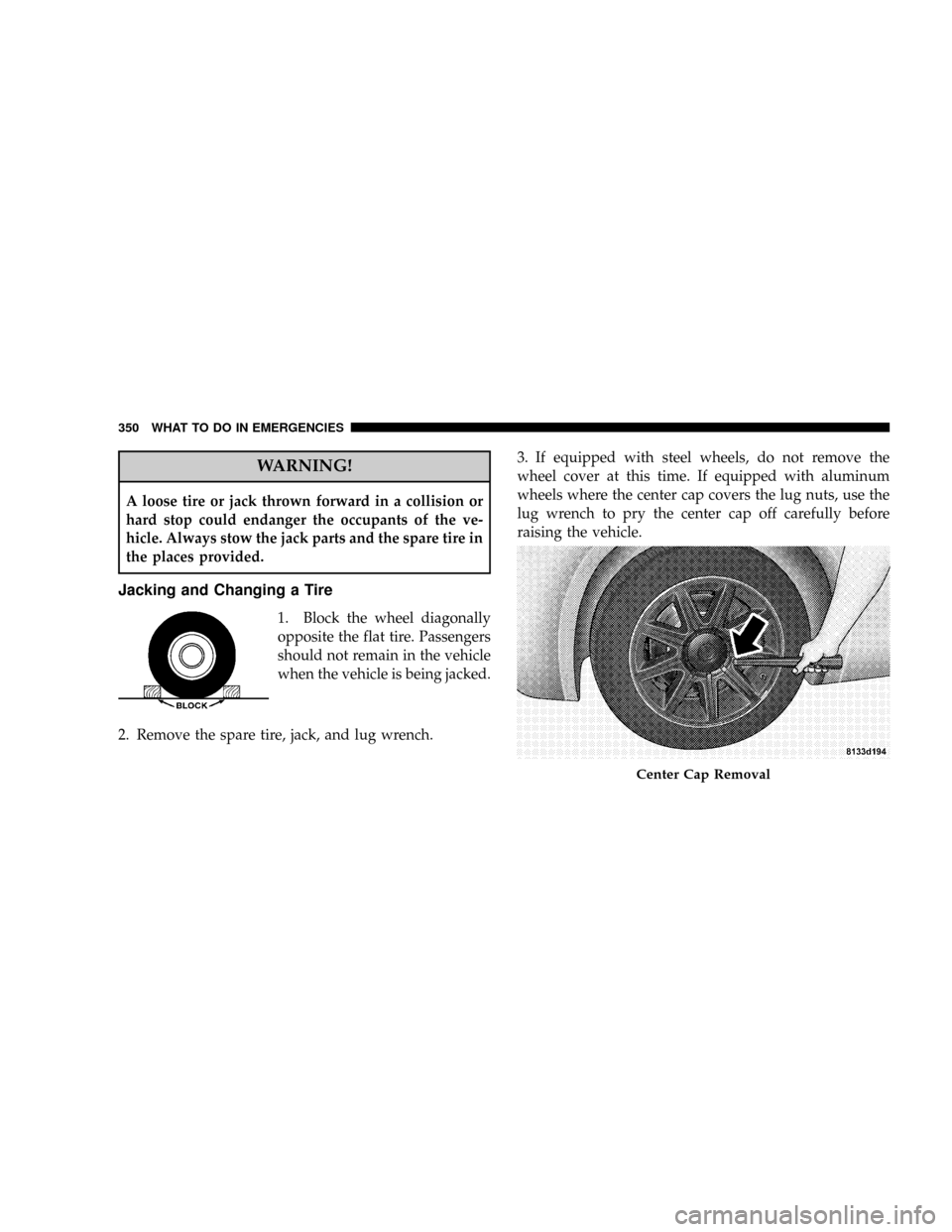

2. Remove the spare tire, jack, and lug wrench.3. If equipped with steel wheels, do not remove the

wheel cover at this time. If equipped with aluminum

wheels where the center cap covers the lug nuts, use the

lug wrench to pry the center cap off carefully before

raising the vehicle.

Center Cap Removal

350 WHAT TO DO IN EMERGENCIES

Page 351 of 466

WARNING!

To avoid possible personal injury, handle the wheel

covers with care to avoid contact with the metal edges

and retention teeth.

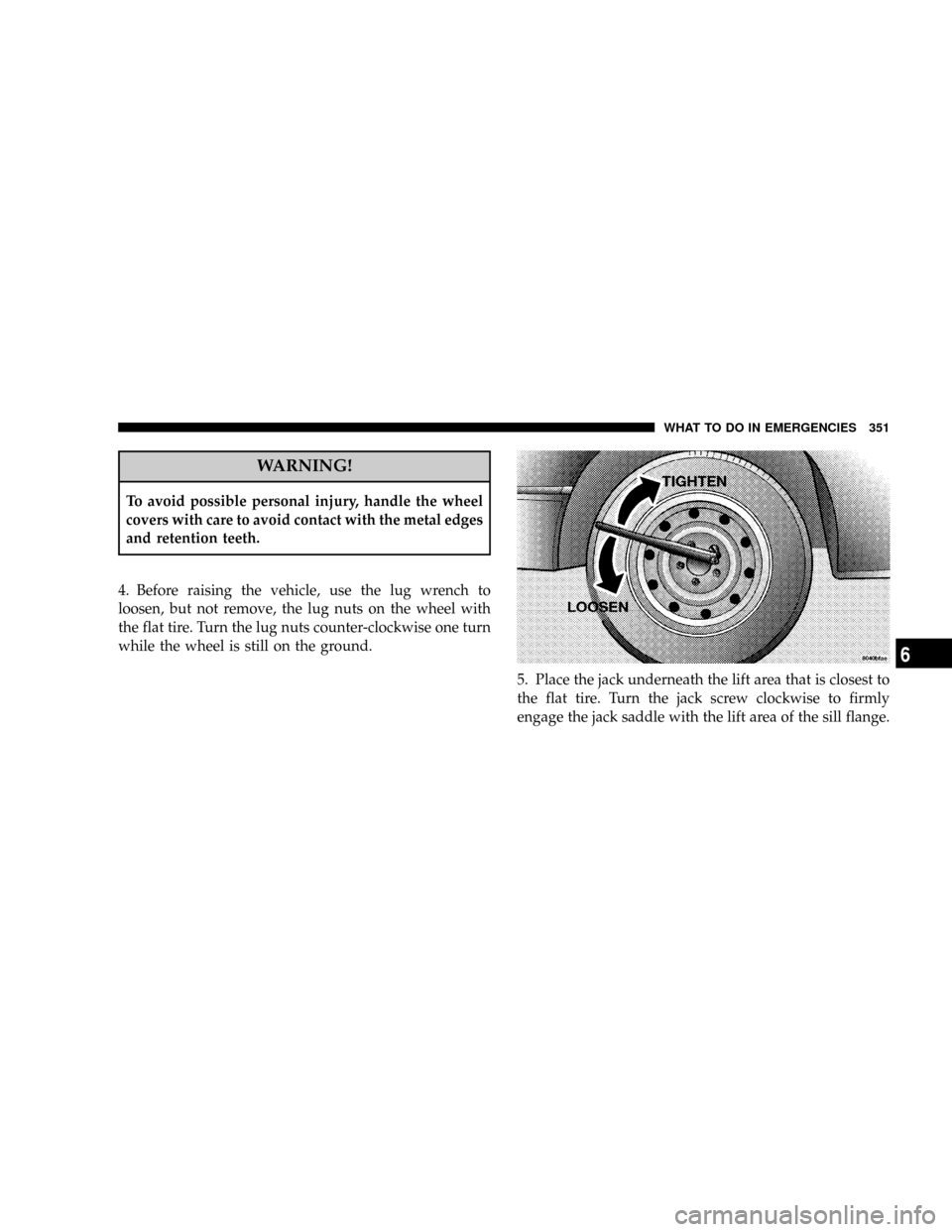

4. Before raising the vehicle, use the lug wrench to

loosen, but not remove, the lug nuts on the wheel with

the flat tire. Turn the lug nuts counter-clockwise one turn

while the wheel is still on the ground.

5. Place the jack underneath the lift area that is closest to

the flat tire. Turn the jack screw clockwise to firmly

engage the jack saddle with the lift area of the sill flange.

WHAT TO DO IN EMERGENCIES 351

6