service interval DODGE CHARGER 2020 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2020, Model line: CHARGER, Model: DODGE CHARGER 2020Pages: 412, PDF Size: 18.96 MB

Page 137 of 412

SAFETY135

(Continued)

The Air Bag Warning Light does not come on

during the four to eight seconds when the

ignition switch is first in the ON/RUN position.

The Air Bag Warning Light remains on after

the four to eight-second interval.

The Air Bag Warning Light comes on intermit -

tently or remains on while driving.

NOTE:

If the speedometer, tachometer, or any engine

related gauges are not working, the Occupant

Restraint Controller (ORC) may also be

disabled. In this condition the air bags may not

be ready to inflate for your protection. Have an

authorized dealer service the air bag system

immediately.

Redundant Air Bag Warning Light

If a fault with the Air Bag

Warning Light is detected, which

could affect the Supplemental

Restraint System (SRS), the

Redundant Air Bag Warning

Light will illuminate on the

instrument panel. The Redundant Air Bag Warning

Light will stay on until the fault is cleared. In

addition, a single chime will sound to alert you that

the Redundant Air Bag Warning Light has come on

and a fault has been detected. If the Redundant Air

Bag Warning Light comes on intermittently or

remains on while driving have an authorized dealer

service the vehicle immediately.

For additional information regarding the

Redundant Air Bag Warning Light refer to

“Getting To Know Your Instrument Panel”

section of this manual.

Front Air Bags

This vehicle has front air bags and lap/shoulder

belts for both the driver and front passenger. The

front air bags are a supplement to the seat belt

restraint systems. The driver front air bag is

mounted in the center of the steering wheel. The

passenger front air bag is mounted in the

instrument panel, above the glove compartment. The words “SRS AIRBAG” or “AIRBAG” are

embossed on the air bag covers.

Front Air Bag/Knee Bolster Locations

WARNING!

Ignoring the Air Bag Warning Light in your

instrument panel could mean you won’t have

the air bag system to protect you in a

collision. If the light does not come on as a

bulb check when the ignition is first turned

on, stays on after you start the vehicle, or if it

comes on as you drive, have an authorized

dealer service the air bag system

immediately.

1 — Driver And Passenger Front Air Bags

2 — Passenger Knee Impact Bolster

3 — Driver Knee Impact Bolster/Supplemental

Driver Knee Air Bag

WARNING!

Being too close to the steering wheel or

instrument panel during front air bag

deployment could cause serious injury,

including death. Air bags need room to

inflate. Sit back, comfortably extending

your arms to reach the steering wheel or

instrument panel.

4

20_LD_OM_EN_USC_t.book Page 135

Page 252 of 412

250

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

3.6L AND 5.7L ENGINES

These vehicles are equipped with an automatic

oil change indicator system. The oil change

indicator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent

short-trips, trailer tow, and extremely hot or cold

ambient temperatures will influence when the

“Change Oil” or “Oil Change Required” message

is displayed. Severe Operating Conditions can

cause the change oil message to illuminate as

early as 3,500 miles (5,600 km) since last

reset. Have your vehicle serviced as soon as

possible, within the next 500 miles (805 km).

The “Oil Change Required” message will be

displayed in the instrument cluster and a single

chime will sound, indicating that an oil change

is necessary.An authorized dealer will reset the oil change

indicator message after completing the

scheduled oil change. If a scheduled oil change

is performed by someone other than an

authorized dealer, the message can be reset by

referring to “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel” for

further information.

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

Change Engine Oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off-road environment,

or is operated predominantly at idle or only very

low engine RPM. This type of vehicle use is

considered Severe Duty.

Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual

wear or damage. Rotate tires at the first sign

of irregular wear, even if it occurs before your

next scheduled service.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and power steering

(if equipped) and fill as needed.

Check function of all interior and exterior

lights.

Maintenance Plan — 3.6L And 5.7L

Required Maintenance Intervals:

Refer to the maintenance schedules on the

following page for the required maintenance

intervals. More frequent maintenance may be

needed in severe conditions, such as dusty

areas and very short trip driving. In some

extreme conditions, additional maintenance

not specified in the maintenance schedule may

be required.

20_LD_OM_EN_USC_t.book Page 250

Page 253 of 412

SERVICING AND MAINTENANCE251

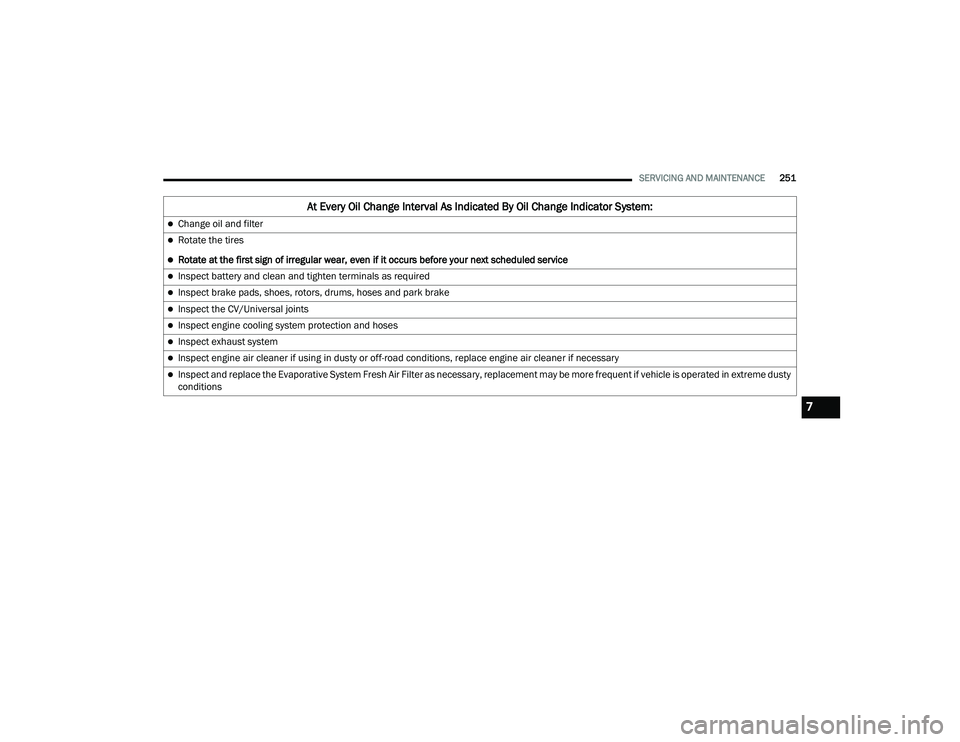

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

Change oil and filter

Rotate the tires

Rotate at the first sign of irregular wear, even if it occurs before your next scheduled service

Inspect battery and clean and tighten terminals as required

Inspect brake pads, shoes, rotors, drums, hoses and park brake

Inspect the CV/Universal joints

Inspect engine cooling system protection and hoses

Inspect exhaust system

Inspect engine air cleaner if using in dusty or off-road conditions, replace engine air cleaner if necessary

Inspect and replace the Evaporative System Fresh Air Filter as necessary, replacement may be more frequent if vehicle is operated in extreme dusty

conditions

7

20_LD_OM_EN_USC_t.book Page 251

Page 256 of 412

254SERVICING AND MAINTENANCE

Heavy Duty Use Of The Vehicle

Change engine oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off road environment or

is operated predominately at idle or only very

low engine RPM. This type of vehicle use is

considered Severe Duty.

6.2L SUPERCHARGED AND 6.4L

E

NGINES

The scheduled maintenance services listed in

this manual must be done at the times or

mileages specified to protect your vehicle

warranty and ensure the best vehicle

performance and reliability. More frequent

maintenance may be needed for vehicles in

severe operating conditions, such as dusty

areas and very short trip driving. Inspection and

service should also be done anytime a

malfunction is suspected.

The oil change indicator system will remind you

that it is time to take your vehicle in for

scheduled maintenance.

An “Oil Change Required” message will be

displayed in the instrument cluster and a single

chime will sound, indicating that an oil change

is necessary. Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Have your vehicle serviced as soon as possible,

within the next 500 miles (805 km).

NOTE:

The oil change indicator message will not

monitor the time since the last oil change.

Change your vehicle's oil if it has been six

months since your last oil change, even if the

oil change indicator message is NOT illumi-

nated.

Change your engine oil more often if you drive

your vehicle off-road/track usage for an

extended period of time.

Under no circumstances should oil change

intervals exceed 6,000 miles (10,000 km) or

6 months, whichever comes first.

WARNING!

You can be badly injured working on or

around a motor vehicle. Do only service

work for which you have the knowledge and

the right equipment. If you have any doubt

about your ability to perform a service job,

take your vehicle to a competent mechanic.

Failure to properly inspect and maintain

your vehicle could result in a component

malfunction and effect vehicle handling

and performance. This could cause an

accident.

20_LD_OM_EN_USC_t.book Page 254

Page 274 of 412

272SERVICING AND MAINTENANCE

DEALER SERVICE

An authorized dealer has the qualified service

personnel, special tools, and equipment to

perform all service operations in an expert

manner. Service Manuals are available which

include detailed service information for your

vehicle. Refer to these Service Manuals before

attempting any procedure yourself.

NOTE:

Intentional tampering with emissions control

systems may void your warranty and could

result in civil penalties being assessed against

you.

ENGINE OIL

Change Engine Oil — 3.6L And 5.7L Engine

The oil change indicator system will remind you

that it is time to take your vehicle in for

scheduled maintenance. Refer to “Scheduled

Servicing” in this section for the proper

maintenance intervals.

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Change Engine Oil — 6.2L And 6.4L Engine

The oil change indicator system will remind you

that it is time to take your vehicle in for

scheduled maintenance. Refer to “Scheduled

Servicing” in this section for the proper

maintenance intervals.

NOTE:

Under no circumstances should oil change

intervals exceed 6,000 miles (10,000 km) or

6 months, whichever occurs first.

Engine Oil Selection — 3.6L And 5.7L

Engine

For best performance and maximum protection

under all types of operating conditions, the

manufacturer only recommends engine oils

that are API Certified and meet the

requirements of FCA Material Standard

MS-6395.

NOTE:

Hemi engines (5.7L) at times can tick right after

startup and then quiet down after approxi -

mately 30 seconds. This is normal and will not

harm the engine. This characteristic can be

caused by short drive cycles. For example, if the

vehicle is started then shut off after driving a

short distance. Upon restarting, you may experi -

ence a ticking sound. Other causes could be if

the vehicle is unused for an extended period of

time, incorrect oil, extended oil changes or

extended idling. If the engine continues to tick

or if the Malfunction Indicator Light (MIL) comes

on, see the nearest authorized dealer.

WARNING!

You can be badly injured working on or

around a motor vehicle. Only do service work

for which you have the knowledge and the

proper equipment. If you have any doubt

about your ability to perform a service job,

take your vehicle to a competent mechanic.

20_LD_OM_EN_USC_t.book Page 272

Page 276 of 412

274SERVICING AND MAINTENANCE

Engine Oil Viscosity (SAE Grade) — 5.7L

Engine

Mopar SAE 5W-20 engine oil approved to FCA

Material Standard MS-6395 such as Pennzoil,

Shell Helix Ultra or equivalent is recommended

for all operating temperatures. This engine oil

improves low temperature starting and vehicle

fuel economy.

The engine oil filler cap also shows the

recommended engine oil viscosity for your

engine. For information on engine oil filler cap

location, refer to the “Engine Compartment”

illustration in this section.

NOTE:

Vehicles equipped with a 5.7L engine must use

SAE 5W-20 oil. Failure to do so may result in

improper operation of the Fuel Saver Tech -

nology. Refer to “Fuel Saver Technology – If

Equipped” in “Starting And Operating” for

further information.

Lubricants which do not have both the engine

oil certification mark and the correct SAE

viscosity grade number should not be used.

Engine Oil Viscosity — 6.2L And 6.4L

Engine

Use Pennzoil Ultra Platinum 0W-40 engine or

equivalent Mopar oil meeting the FCA Material

Standard MS-12633 for use in all operating

temperatures.

The engine oil filler cap also shows the

recommended engine oil viscosity for your

engine. For information on engine oil filler cap

location, refer to “Engine Compartment” in this

section for further information.

Synthetic Engine Oils

You may use synthetic engine oils provided the

recommended oil quality requirements are met,

and the recommended maintenance intervals

for oil and filter changes are followed.

Synthetic engine oils which do not have both the

engine oil certification mark and the correct SAE

viscosity grade number should not be used.

Materials Added To Engine Oil

The manufacturer strongly recommends

against the addition of any additives (other than

leak detection dyes) to the engine oil. Engine oil

is an engineered product and its performance

may be impaired by supplemental additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used

engine oil and oil filters from your vehicle. Used

oil and oil filters, indiscriminately discarded, can

present a problem to the environment. Contact

an authorized dealer, service station or

governmental agency for advice on how and

where used oil and oil filters can be safely

discarded in your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a

new filter at every engine oil change.

Engine Oil Filter Selection

This manufacturer's engines have a full-flow

type disposable oil filter. Use a filter of this type

for replacement. The quality of replacement

filters varies considerably. Only high quality

filters should be used to ensure most efficient

service. Mopar engine oil filters are high quality

oil filters and are recommended.

20_LD_OM_EN_USC_t.book Page 274

Page 277 of 412

SERVICING AND MAINTENANCE275

ENGINE AIR CLEANER FILTER

Refer to the “Maintenance Plan” in this section

for the proper maintenance intervals.

NOTE:

Be sure to follow the “Severe Duty Conditions”

maintenance interval if applicable.

Engine Air Cleaner Filter Selection

The quality of replacement engine air cleaner

filters varies considerably. Only high quality

filters should be used to ensure most efficient

service. Mopar engine air cleaner filters are a

high quality filter and are recommended.

AIR CONDITIONER MAINTENANCE

For best possible performance, your air

conditioner should be checked and serviced by

an authorized dealer at the start of each warm

season. This service should include cleaning of

the condenser fins and a performance test.

Drive belt tension should also be checked at

this time.

Refrigerant Recovery And Recycling

R-134a — If Equipped

R-134a Air Conditioning Refrigerant is a hydroflu -

orocarbon (HFC) that is an ozone-friendly

substance. The manufacturer recommends that

air conditioning service be performed by an

authorized dealer or other service facilities using

recovery and recycling equipment.

NOTE:

Use only manufacturer approved A/C system

PAG compressor oil and refrigerants.

Refrigerant Recovery And Recycling

R-1234yf — If Equipped

R-1234yf Air Conditioning Refrigerant is a

hydrofluoroolefin (HFO) that is endorsed by the

Environmental Protection Agency and is an

ozone-friendly substance with a low

global-warming potential. The manufacturer

WARNING!

The air induction system (air cleaner, hoses,

etc.) can provide a measure of protection in the

case of engine backfire. Do not remove the air

induction system (air cleaner, hoses, etc.)

unless such removal is necessary for repair or

maintenance. Make sure that no one is near

the engine compartment before starting the

vehicle with the air induction system (air

cleaner, hoses, etc.) removed. Failure to do so

can result in serious personal injury.

WARNING!

Use only refrigerants and compressor lubri -

cants approved by the manufacturer for

your air conditioning system. Some unap -

proved refrigerants are flammable and can

explode, injuring you. Other unapproved

refrigerants or lubricants can cause the

system to fail, requiring costly repairs.

Refer to Warranty Information Book, for

further warranty information.

The air conditioning system contains refrig -

erant under high pressure. To avoid risk of

personal injury or damage to the system,

adding refrigerant or any repair requiring

lines to be disconnected should be done by

an experienced technician.

CAUTION!

Do not use chemical flushes in your air

conditioning system as the chemicals can

damage your air conditioning components.

Such damage is not covered by the New

Vehicle Limited Warranty.

7

20_LD_OM_EN_USC_t.book Page 275

Page 278 of 412

276SERVICING AND MAINTENANCE

(Continued)

recommends that air conditioning service be

performed by an authorized dealer using

recovery and recycling equipment.

NOTE:

Use only manufacturer approved A/C system

PAG compressor oil, and refrigerants.

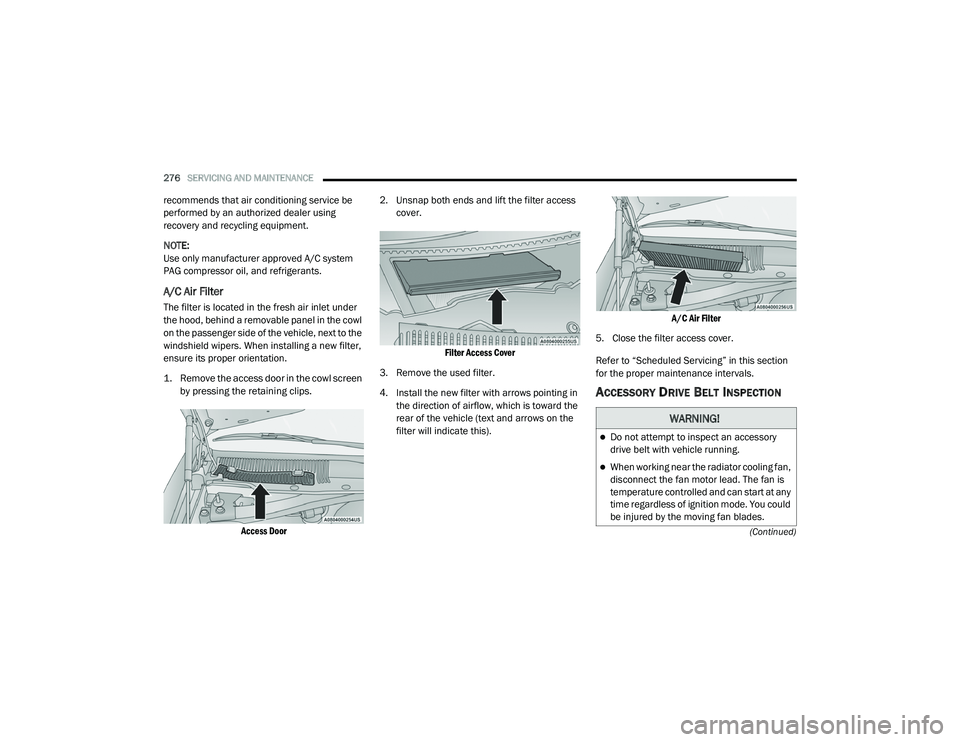

A/C Air Filter

The filter is located in the fresh air inlet under

the hood, behind a removable panel in the cowl

on the passenger side of the vehicle, next to the

windshield wipers. When installing a new filter,

ensure its proper orientation.

1. Remove the access door in the cowl screen by pressing the retaining clips.

Access Door

2. Unsnap both ends and lift the filter access

cover.

Filter Access Cover

3. Remove the used filter.

4. Install the new filter with arrows pointing in the direction of airflow, which is toward the

rear of the vehicle (text and arrows on the

filter will indicate this).

A/C Air Filter

5. Close the filter access cover.

Refer to “Scheduled Servicing” in this section

for the proper maintenance intervals.

ACCESSORY DRIVE BELT INSPECTION

WARNING!

Do not attempt to inspect an accessory

drive belt with vehicle running.

When working near the radiator cooling fan,

disconnect the fan motor lead. The fan is

temperature controlled and can start at any

time regardless of ignition mode. You could

be injured by the moving fan blades.

20_LD_OM_EN_USC_t.book Page 276

Page 286 of 412

284SERVICING AND MAINTENANCE

(Continued)

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning,

keep the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever

necessary, install ONLY the correct type ther-

mostat. Other designs may result in unsatis -

factory engine coolant (antifreeze)

performance, poor gas mileage, and

increased emissions.

BRAKE SYSTEM

In order to ensure brake system performance,

all brake system components should be

inspected periodically. Refer to the

“Maintenance Plan” in this section for the

proper maintenance intervals.

Fluid Level Check — Brake Master Cylinder

Check the fluid level in the master cylinder

immediately if the brake system warning light

indicates system failure.

Check the fluid level in the master cylinder

when performing underhood services.

Clean the top of the master cylinder area before

removing the cap. Add fluid to bring the level up

to the top of the “FULL” mark on the side of the

master cylinder reservoir.

Overfilling of fluid is not recommended because

it may cause leaking in the system.

Add enough fluid to bring the level up to the

requirements described on the brake fluid

reservoir. With disc brakes, fluid level can be

expected to fall as the brake pads wear.

However, low fluid level may be caused by a

leak and a checkup may be needed.

Use only brake fluid that has been

recommended by the manufacturer, and has

been kept in a tightly closed container to avoid

contamination from foreign matter or moisture.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.

WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri -

cants” in “Technical Specifications” for

further information. Using the wrong type

of brake fluid can severely damage your

brake system and/or impair its perfor -

mance. The proper type of brake fluid for

your vehicle is also identified on the orig -

inal factory installed hydraulic master

cylinder reservoir.

To avoid contamination from foreign

matter or moisture, use only new brake

fluid or fluid that has been in a tightly

closed container. Keep the master

cylinder reservoir cap secured at all times.

Brake fluid in a open container absorbs

moisture from the air resulting in a lower

boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure.

This could result in a collision.

20_LD_OM_EN_USC_t.book Page 284

Page 305 of 412

SERVICING AND MAINTENANCE303

TIRE ROTATION RECOMMENDATIONS —

SRT

Tires on the front and rear axles of vehicles

operate at different loads and perform different

steering, driving, and braking functions. For

these reasons, they wear at unequal rates.

These effects can be reduced by timely rotation

of tires. The benefits of rotation are especially

worthwhile with aggressive tread designs such

as those on all season type tires. Rotation will

increase tread life, help to maintain mud, snow

and wet traction levels, and contribute to a

smooth, quiet ride.

Refer to “Scheduled Servicing” in “Servicing

And Maintenance” for the proper maintenance

intervals. The reasons for any rapid or unusual

wear should be corrected prior to rotation being

performed.

Tire Rotation — Same Tire Size On Front And

Rear Axle

The suggested rotation method for vehicles

equipped with non directional three season and

all season tires is the “forward cross” as shown

in the following diagram.

Tire Rotation (Forward Cross)

DEPARTMENT OF TRANSPORTATION

UNIFORM TIRE QUALITY GRADES

The following tire grading categories

were established by the National

Highway Traffic Safety Administration.

The specific grade rating assigned by the

tire's manufacturer in each category is

shown on the sidewall of the tires on

your vehicle.

All passenger vehicle tires must conform

to Federal safety requirements in

addition to these grades.

TREADWEAR

The Treadwear grade is a comparative

rating, based on the wear rate of the tire

when tested under controlled conditions

on a specified government test course.

For example, a tire graded 150 would

wear one and one-half times as well on

the government course as a tire graded

100. The relative performance of tires

depends upon the actual conditions of

their use, however, and may depart

significantly from the norm due to

variations in driving habits, service

practices, and differences in road

characteristics and climate.

TRACTION GRADES

The Traction grades, from highest to

lowest, are AA, A, B, and C. These grades

represent the tire's ability to stop on wet

pavement, as measured under controlled

conditions on specified government test

surfaces of asphalt and concrete. A tire

marked C may have poor traction

performance.

7

20_LD_OM_EN_USC_t.book Page 303