light DODGE CHARGER 2022 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2022, Model line: CHARGER, Model: DODGE CHARGER 2022Pages: 312, PDF Size: 18.99 MB

Page 217 of 312

IN CASE OF EMERGENCY215

(Continued)

SOS Call System Limitations

Vehicles sold in Mexico

DO NOT have SOS Call

system capabilities.

SOS or other emergency line operators in Mexico

may not answer or respond to SOS system calls.

If the SOS Call system detects a malfunction, any

of the following may occur at the time the

malfunction is detected, and at the beginning of

each ignition cycle:

The Rearview Mirror light located between the

ASSIST and SOS buttons will continuously illumi -

nate red.

The Device Screen will display the following

message “Vehicle device requires service.

Please contact an authorized dealer”.

An In-Vehicle Audio message will state “Vehicle

device requires service. Please contact an

authorized dealer”. Even if the SOS Call system is fully functional,

factors beyond FCA US LLC’s control may prevent

or stop the SOS Call system operation. These

include, but are not limited to, the following

factors:

The ignition is in the OFF position.

The vehicle’s electrical systems are not intact.

The SOS Call system software and/or hardware

are damaged during a crash.

The vehicle battery loses power or becomes

disconnected during a vehicle crash.

LTE (voice/data) or 4G (data) network and/or

Global Positioning Satellite signals are unavail

-

able or obstructed.

Equipment malfunction at the SOS operator

facility.

Operator error by the SOS operator.

Never place anything on or near the vehicle’s

operable network and GPS antennas. You

could prevent operable network and GPS

signal reception, which can prevent your

vehicle from placing an emergency call. An

operable network and GPS signal reception is

required for the SOS Call system to function

properly.

The SOS Call system is embedded into the

vehicle’s electrical system. Do not add after -

market electrical equipment to the vehicle’s

electrical system. This may prevent your

vehicle from sending a signal to initiate an

emergency call. To avoid interference that can

cause the SOS Call system to fail, never add

aftermarket equipment (e.g., two-way mobile

radio, CB radio, data recorder, etc.) to your

vehicle’s electrical system or modify the

antennas on your vehicle. IF YOUR VEHICLE

LOSES BATTERY POWER FOR ANY REASON

(INCLUDING DURING OR AFTER AN ACCI -

DENT), THE UCONNECT FEATURES, APPS AND

SERVICES, AMONG OTHERS, WILL NOT

OPERATE.

Modifications to any part of the SOS Call

system could cause the air bag system to fail

when you need it. You could be injured if the

air bag system is not there to help protect you.

WARNING!

WARNING!

Ignoring the Rearview Mirror light could mean

you will not have SOS Call services. If the Rear -

view Mirror light is illuminated, have an autho -

rized dealer service the SOS Call system

immediately.

The Occupant Restraint Control module turns

on the air bag Warning Light on the instrument

panel if a malfunction in any part of the

system is detected. If the Air Bag Warning

Light is illuminated, have an authorized dealer

service the Occupant Restraint Control system

immediately.

WARNING!

7

22_LD_OM_EN_USC_t.book Page 215

Page 222 of 312

220IN CASE OF EMERGENCY

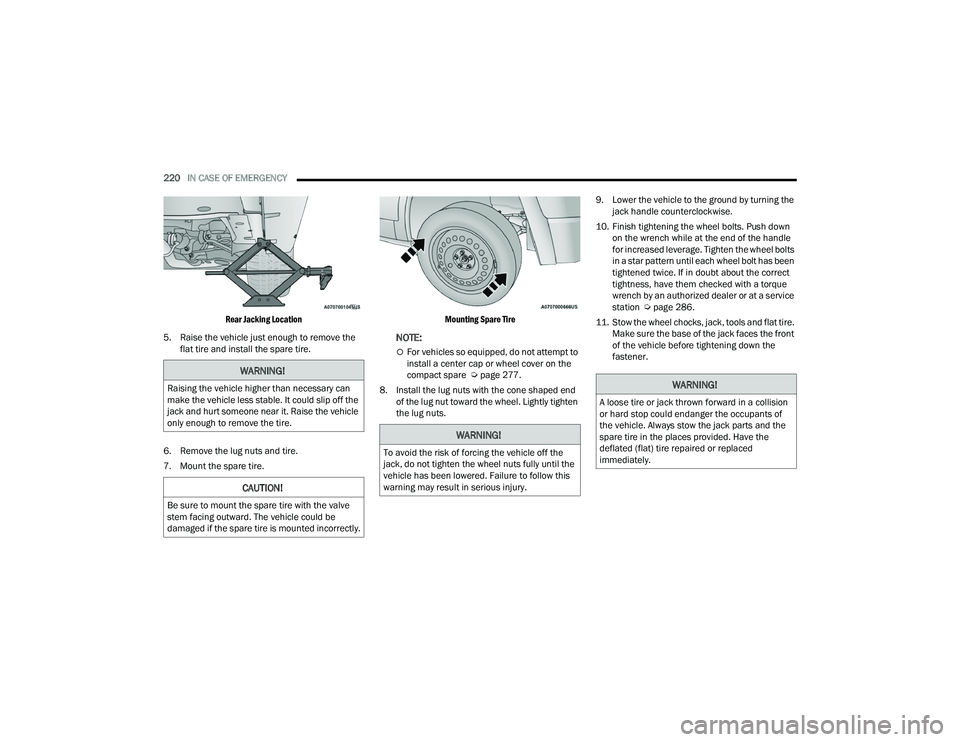

Rear Jacking Location

5. Raise the vehicle just enough to remove the flat tire and install the spare tire.

6. Remove the lug nuts and tire.

7. Mount the spare tire.

Mounting Spare Tire

NOTE:

For vehicles so equipped, do not attempt to

install a center cap or wheel cover on the

compact spare Ú

page 277.

8. Install the lug nuts with the cone shaped end of the lug nut toward the wheel. Lightly tighten

the lug nuts. 9. Lower the vehicle to the ground by turning the

jack handle counterclockwise.

10. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle

for increased leverage. Tighten the wheel bolts

in a star pattern until each wheel bolt has been

tightened twice. If in doubt about the correct

tightness, have them checked with a torque

wrench by an authorized dealer or at a service

station Ú page 286.

11. Stow the wheel chocks, jack, tools and flat tire. Make sure the base of the jack faces the front

of the vehicle before tightening down the

fastener.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off the

jack and hurt someone near it. Raise the vehicle

only enough to remove the tire.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the spare tire is mounted incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided. Have the

deflated (flat) tire repaired or replaced

immediately.

22_LD_OM_EN_USC_t.book Page 220

Page 229 of 312

IN CASE OF EMERGENCY227

3. Connect the negative (-) end of the jumper

cable to the negative (-) post of the booster

battery.

4. Connect the opposite end of the negative (-)

jumper cable to the remote negative (-) post

(exposed metallic/unpainted post of the

discharge vehicle) located directly behind the

underhood fuse box.

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few

minutes, and then start the engine in the

vehicle with the discharged battery.

6. Once the engine is started, follow the discon -

nection procedure. Disconnecting The Jumper Cables

1. Disconnect the negative

(-) end of the jumper

cable from the remote negative (-)

post of the

vehicle with the discharged battery.

2. Disconnect the opposite end of the negative (-)

jumper cable from the negative (-) post of the

booster battery.

3. Disconnect the positive (+) end of the jumper

cable from the positive (+) post of the booster

battery.

4. Disconnect the opposite end of the positive (+)

jumper cable from the remote positive (+) post

of the vehicle with the discharged battery, and

reinstall the protective cap.

If frequent jump starting is required to start your

vehicle you should have the battery and charging

system inspected at an authorized dealer.

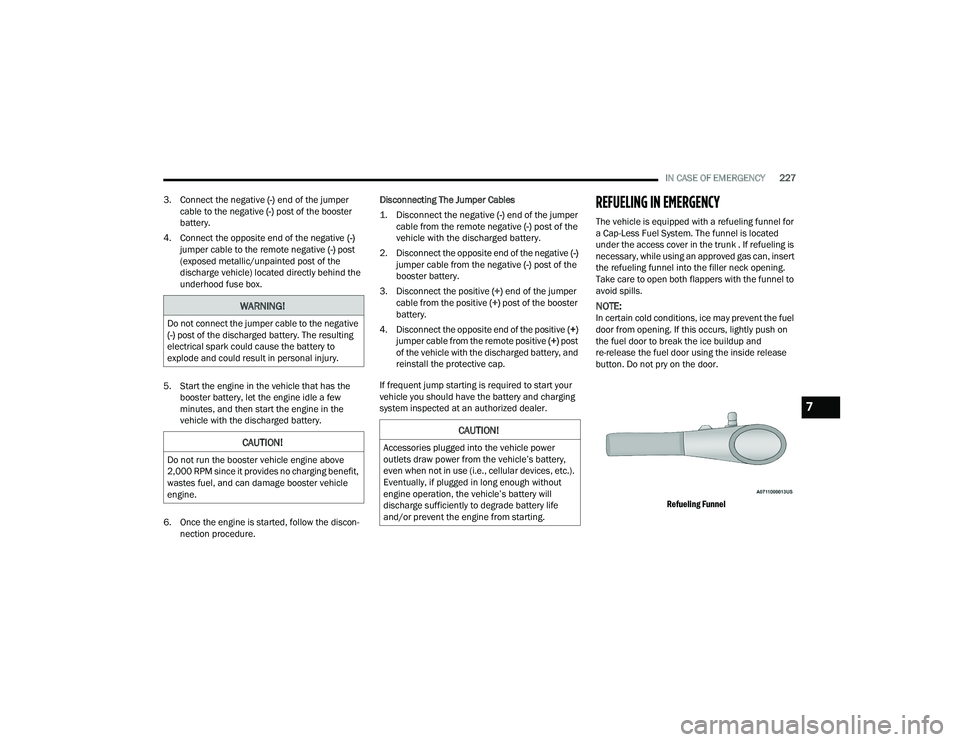

REFUELING IN EMERGENCY

The vehicle is equipped with a refueling funnel for

a Cap-Less Fuel System. The funnel is located

under the access cover in the trunk . If refueling is

necessary, while using an approved gas can, insert

the refueling funnel into the filler neck opening.

Take care to open both flappers with the funnel to

avoid spills.

NOTE:In certain cold conditions, ice may prevent the fuel

door from opening. If this occurs, lightly push on

the fuel door to break the ice buildup and

re-release the fuel door using the inside release

button. Do not pry on the door.

Refueling Funnel

WARNING!

Do not connect the jumper cable to the negative

(-) post of the discharged battery. The resulting

electrical spark could cause the battery to

explode and could result in personal injury.

CAUTION!

Do not run the booster vehicle engine above

2,000 RPM since it provides no charging benefit,

wastes fuel, and can damage booster vehicle

engine.

CAUTION!

Accessories plugged into the vehicle power

outlets draw power from the vehicle’s battery,

even when not in use (i.e., cellular devices, etc.).

Eventually, if plugged in long enough without

engine operation, the vehicle’s battery will

discharge sufficiently to degrade battery life

and/or prevent the engine from starting.

7

22_LD_OM_EN_USC_t.book Page 227

Page 230 of 312

228IN CASE OF EMERGENCY

Emergency Refueling Funnel

Most gas cans will not open the flapper doors. A

funnel is provided to allow emergency refueling

with a gas can.

See the following steps for refueling:

1. Retrieve funnel from the spare tire storage area.

Fuel Funnel Location

2. Insert funnel into same filler pipe opening as the fuel nozzle.

Inserting Funnel

3. Ensure funnel is inserted fully to hold flapper doors open.

4. Pour fuel into funnel opening.

5. Remove funnel from filler pipe, clean off prior to putting back in the spare tire storage area.

IF YOUR ENGINE OVERHEATS

If the vehicle is overheating, it will need to be

serviced by an authorized dealer.

In any of the following situations, you can reduce

the potential for overheating by taking the

appropriate action.

On the highways — slow down.

In city traffic — while stopped, place the trans -

mission in NEUTRAL, but do not increase the

engine idle speed while preventing vehicle

motion with the brakes.

CAUTION!

To avoid fuel spillage and overfilling, do not “top

off” the fuel tank after filling.

WARNING!

Never have any smoking materials lit in or

near the vehicle when the fuel door is open or

the tank is being filled.

Never add fuel when the engine is running.

This is in violation of most state and federal

fire regulations and may cause the Malfunc -

tion Indicator Light to turn on.

A fire may result if fuel is pumped into a

portable container that is inside of a vehicle.

You could be burned. Always place fuel

containers on the ground while filling.

22_LD_OM_EN_USC_t.book Page 228

Page 236 of 312

234

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

3.6L AND 5.7L ENGINES

These vehicles are equipped with an automatic oil

change indicator system. The oil change indicator

system will remind you that it is time to take your

vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent short-trips,

trailer tow, and extremely hot or cold ambient

temperatures will influence when the “Change Oil”

or “Oil Change Required” message is displayed.

Have your vehicle serviced as soon as possible,

within the next 500 miles (805 km).

The “Oil Change Required” message will be

displayed in the instrument cluster and a single

chime will sound, indicating that an oil change is

necessary. An authorized dealer will reset the oil change

indicator message after completing the scheduled

oil change. If a scheduled oil change is performed

by someone other than an authorized dealer, the

message can be reset by referring to “Instrument

Cluster Display” Ú

page 69.

NOTE:Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for fleet

customers.

Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual wear

or damage. Rotate tires at the first sign of irreg -

ular wear, even if it occurs before your next

scheduled service.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and power steering (if

equipped) and fill as needed.

Check function of all interior and exterior lights.

Maintenance Plan — 3.6L And 5.7L

Required Maintenance Intervals:

Refer to the maintenance schedules on the

following page for the required maintenance

intervals. More frequent maintenance may be

needed in severe conditions, such as dusty areas

and very short trip driving. In some extreme

conditions, additional maintenance not specified

in the maintenance schedule may be required.

22_LD_OM_EN_USC_t.book Page 234

Page 244 of 312

242SERVICING AND MAINTENANCE

NOTE:Intentional tampering with emissions control

systems may void your warranty and could result in

civil penalties being assessed against you.

ENGINE OIL

Engine Oil Selection — 3.6L/5.7L Engines

Use only the manufacturer's recommended fluids

Úpage 291.

NOTE:

Hemi engines at times can tick right after startup

and then quiet down after approximately 30

seconds. This is normal and will not harm the

engine. This characteristic can be caused by short

drive cycles. For example, if the vehicle is started

then shut off after driving a short distance. Upon

restarting, you may experience a ticking sound.

Other causes could be if the vehicle is unused for an

extended period of time, incorrect oil, extended oil

changes or extended idling. If the engine continues

to tick or if the Malfunction Indicator Light (MIL)

comes on, see the nearest authorized dealer.

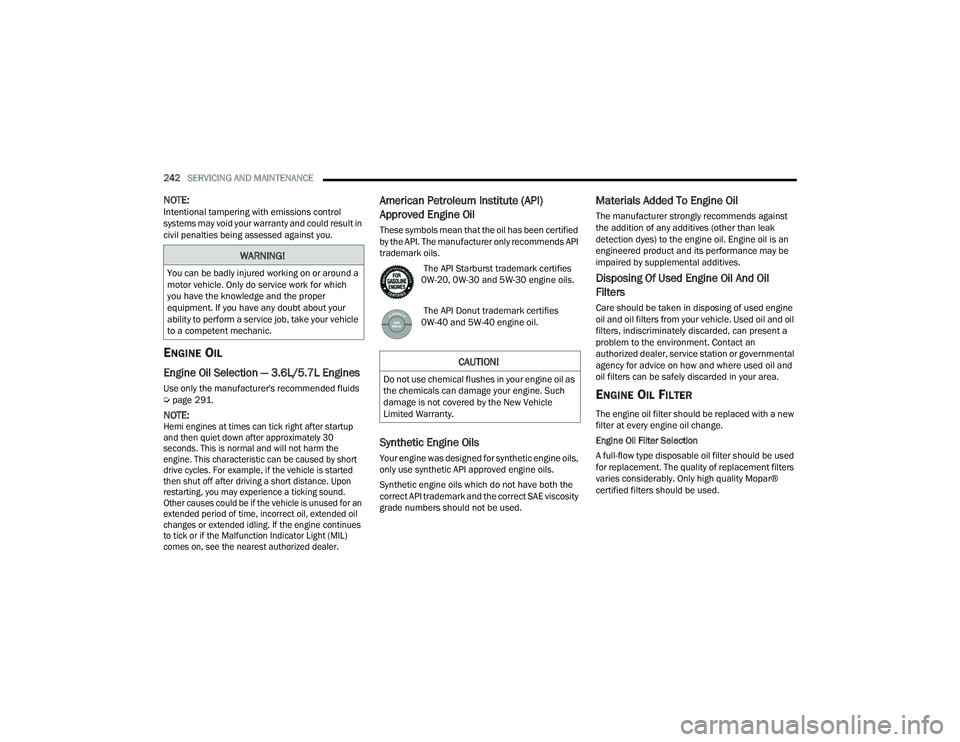

American Petroleum Institute (API)

Approved Engine Oil

These symbols mean that the oil has been certified

by the API. The manufacturer only recommends API

trademark oils.

The API Starburst trademark certifies

0W-20, 0W-30 and 5W-30 engine oils.

The API Donut trademark certifies

0W-40 and 5W-40 engine oil.

Synthetic Engine Oils

Your engine was designed for synthetic engine oils,

only use synthetic API approved engine oils.

Synthetic engine oils which do not have both the

correct API trademark and the correct SAE viscosity

grade numbers should not be used.

Materials Added To Engine Oil

The manufacturer strongly recommends against

the addition of any additives (other than leak

detection dyes) to the engine oil. Engine oil is an

engineered product and its performance may be

impaired by supplemental additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used engine

oil and oil filters from your vehicle. Used oil and oil

filters, indiscriminately discarded, can present a

problem to the environment. Contact an

authorized dealer, service station or governmental

agency for advice on how and where used oil and

oil filters can be safely discarded in your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a new

filter at every engine oil change.

Engine Oil Filter Selection

A full-flow type disposable oil filter should be used

for replacement. The quality of replacement filters

varies considerably. Only high quality Mopar®

certified filters should be used.

WARNING!

You can be badly injured working on or around a

motor vehicle. Only do service work for which

you have the knowledge and the proper

equipment. If you have any doubt about your

ability to perform a service job, take your vehicle

to a competent mechanic.

CAUTION!

Do not use chemical flushes in your engine oil as

the chemicals can damage your engine. Such

damage is not covered by the New Vehicle

Limited Warranty.

22_LD_OM_EN_USC_t.book Page 242

Page 253 of 312

SERVICING AND MAINTENANCE251

(Continued)

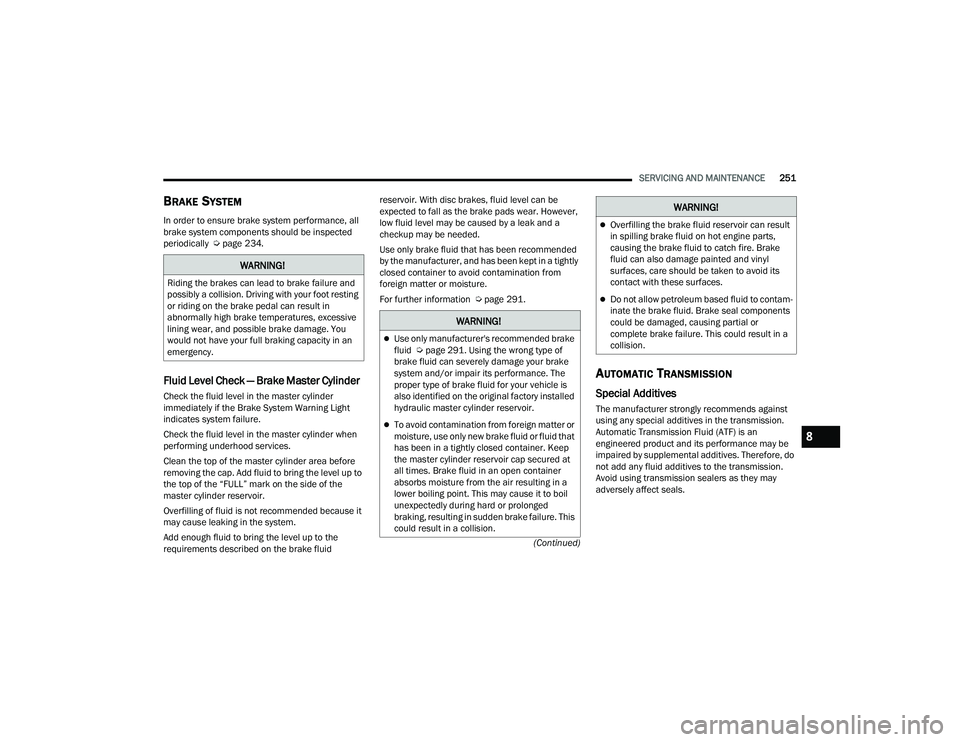

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically Ú page 234.

Fluid Level Check — Brake Master Cylinder

Check the fluid level in the master cylinder

immediately if the Brake System Warning Light

indicates system failure.

Check the fluid level in the master cylinder when

performing underhood services.

Clean the top of the master cylinder area before

removing the cap. Add fluid to bring the level up to

the top of the “FULL” mark on the side of the

master cylinder reservoir.

Overfilling of fluid is not recommended because it

may cause leaking in the system.

Add enough fluid to bring the level up to the

requirements described on the brake fluid reservoir. With disc brakes, fluid level can be

expected to fall as the brake pads wear. However,

low fluid level may be caused by a leak and a

checkup may be needed.

Use only brake fluid that has been recommended

by the manufacturer, and has been kept in a tightly

closed container to avoid contamination from

foreign matter or moisture.

For further information Ú

page 291.

AUTOMATIC TRANSMISSION

Special Additives

The manufacturer strongly recommends against

using any special additives in the transmission.

Automatic Transmission Fluid (ATF) is an

engineered product and its performance may be

impaired by supplemental additives. Therefore, do

not add any fluid additives to the transmission.

Avoid using transmission sealers as they may

adversely affect seals.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting

or riding on the brake pedal can result in

abnormally high brake temperatures, excessive

lining wear, and possible brake damage. You

would not have your full braking capacity in an

emergency.

WARNING!

Use only manufacturer's recommended brake

fluid Úpage 291. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in an open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This

could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

Do not allow petroleum based fluid to contam -

inate the brake fluid. Brake seal components

could be damaged, causing partial or

complete brake failure. This could result in a

collision.

WARNING!

8

22_LD_OM_EN_USC_t.book Page 251

Page 260 of 312

258SERVICING AND MAINTENANCE

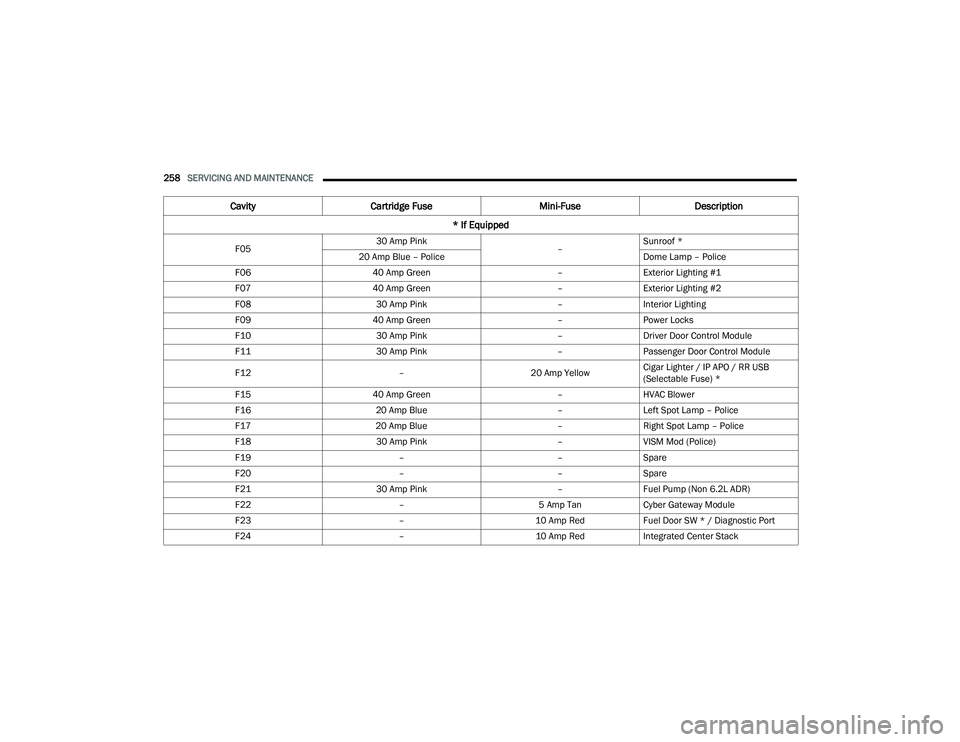

F05 30 Amp Pink

–Sunroof *

20 Amp Blue – Police Dome Lamp – Police

F06 40 Amp Green –Exterior Lighting #1

F07 40 Amp Green –Exterior Lighting #2

F08 30 Amp Pink –Interior Lighting

F09 40 Amp Green –Power Locks

F10 30 Amp Pink –Driver Door Control Module

F11 30 Amp Pink –Passenger Door Control Module

F12 –20 Amp YellowCigar Lighter / IP APO / RR USB

(Selectable Fuse) *

F15 40 Amp Green –HVAC Blower

F16 20 Amp Blue –Left Spot Lamp – Police

F17 20 Amp Blue –Right Spot Lamp – Police

F18 30 Amp Pink –VISM Mod (Police)

F19 ––Spare

F20 ––Spare

F21 30 Amp Pink –Fuel Pump (Non 6.2L ADR)

F22 –5 Amp TanCyber Gateway Module

F23 –10 Amp RedFuel Door SW * / Diagnostic Port

F24 –10 Amp RedIntegrated Center Stack

Cavity Cartridge Fuse Mini-FuseDescription

* If Equipped

22_LD_OM_EN_USC_t.book Page 258

Page 262 of 312

260SERVICING AND MAINTENANCE

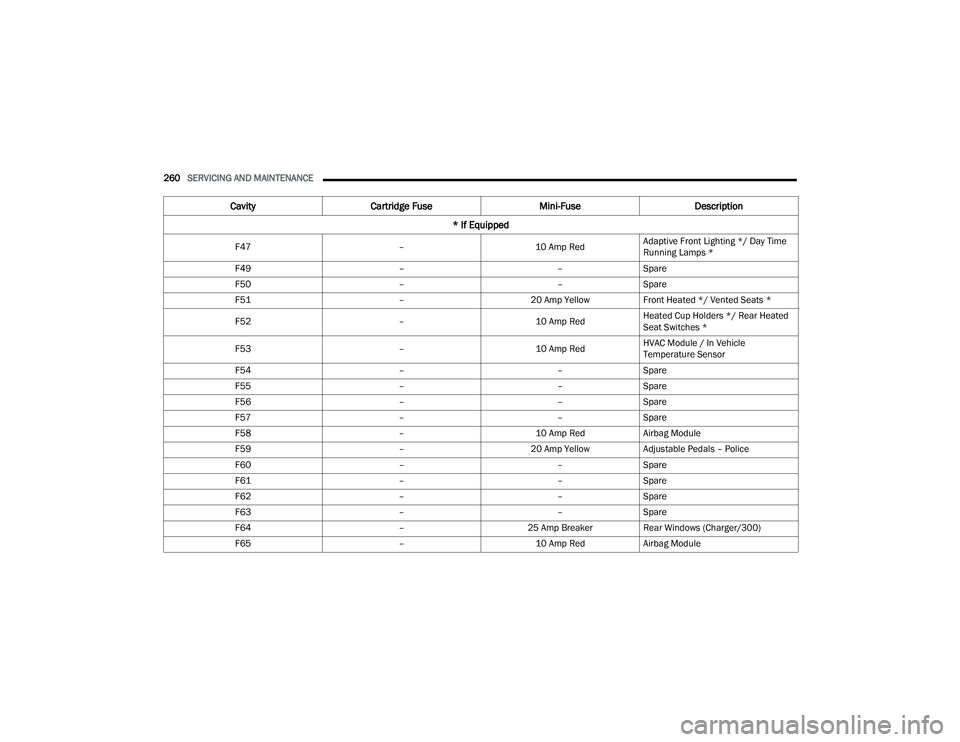

F47 –10 Amp RedAdaptive Front Lighting */ Day Time

Running Lamps *

F49 ––Spare

F50 ––Spare

F51 –20 Amp YellowFront Heated */ Vented Seats *

F52 –10 Amp RedHeated Cup Holders */ Rear Heated

Seat Switches *

F53 –10 Amp RedHVAC Module / In Vehicle

Temperature Sensor

F54 ––Spare

F55 ––Spare

F56 ––Spare

F57 ––Spare

F58 –10 Amp RedAirbag Module

F59 –20 Amp YellowAdjustable Pedals – Police

F60 ––Spare

F61 ––Spare

F62 ––Spare

F63 ––Spare

F64 –25 Amp BreakerRear Windows (Charger/300)

F65 –10 Amp RedAirbag Module

Cavity Cartridge Fuse Mini-FuseDescription

* If Equipped

22_LD_OM_EN_USC_t.book Page 260

Page 263 of 312

SERVICING AND MAINTENANCE261

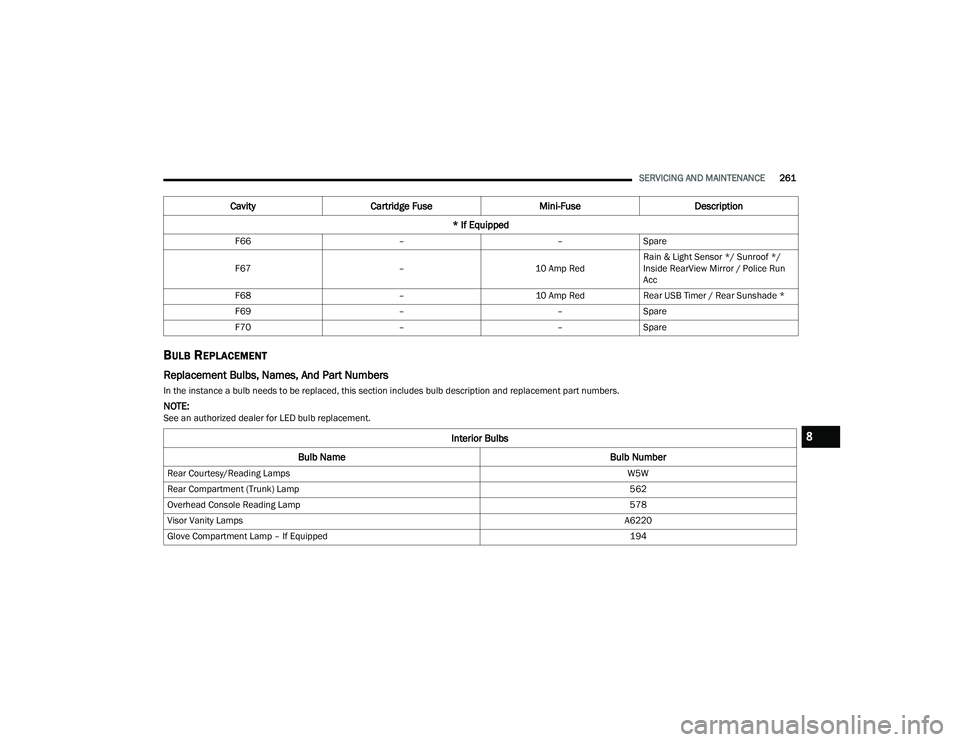

BULB REPLACEMENT

Replacement Bulbs, Names, And Part Numbers

In the instance a bulb needs to be replaced, this section includes bulb description and replacement part numbers.

NOTE:See an authorized dealer for LED bulb replacement.F66

––Spare

F67 –10 Amp RedRain & Light Sensor */ Sunroof */

Inside RearView Mirror / Police Run

Acc

F68 –10 Amp RedRear USB Timer / Rear Sunshade *

F69 ––Spare

F70 ––Spare

Cavity Cartridge Fuse Mini-FuseDescription

* If Equipped

Interior Bulbs

Bulb Name Bulb Number

Rear Courtesy/Reading Lamps W5W

Rear Compartment (Trunk) Lamp 562

Overhead Console Reading Lamp 578

Visor Vanity Lamps A6220

Glove Compartment Lamp – If Equipped 194

8

22_LD_OM_EN_USC_t.book Page 261