service DODGE CHARGER SRT 2014 7.G Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2014, Model line: CHARGER SRT, Model: DODGE CHARGER SRT 2014 7.GPages: 614, PDF Size: 4.37 MB

Page 530 of 614

puddles on the ground. If ingested by a child or pet, seek

emergency assistance immediately. Clean up any ground

spills immediately.

Coolant Level

The coolant bottle provides a quick visual method for

determining that the coolant level is adequate. With the

engine OFF and cold, the level of the engine coolant

(antifreeze) in the bottle should be between the ranges

indicated on the bottle.

The radiator normally remains completely full, so there is

no need to remove the radiator/coolant pressure cap

unless checking for engine coolant (antifreeze) freeze

point or replacing coolant. Advise your service attendant

of this. As long as the engine operating temperature is

satisfactory, the coolant bottle need only be checked once

a month.When additional engine coolant (antifreeze) is needed to

maintain the proper level, only OAT coolant that meets

the requirements of Chrysler Material Standard MS-

12106 should be added to the coolant bottle. Do not

overfill.Points To Remember

NOTE:

When the vehicle is stopped after a few miles/

kilometers of operation, you may observe vapor coming

from the front of the engine compartment. This is nor-

mally a result of moisture from rain, snow, or high

humidity accumulating on the radiator and being vapor-

ized when the thermostat opens, allowing hot engine

coolant (antifreeze) to enter the radiator.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

• Do not overfill the coolant expansion bottle.

528 MAINTAINING YOUR VEHICLE

Page 532 of 614

WARNING!(Continued)

high brake temperatures, excessive lining wear, and

possible brake damage. You would not have your full

braking capacity in an emergency.

Master Cylinder — Brake Fluid Level Check

Check the fluid level in the master cylinder immediately

if the brake system warning light indicates system fail-

ure.

Check the fluid level in the master cylinder when per-

forming underhood services.

Clean the top of the master cylinder area before removing

the cap. Add fluid to bring the level up to the top of the

“FULL” mark on the side of the master cylinder reservoir.

Overfilling of fluid is not recommended because it may

cause leaking in the system. Add enough fluid to bring the level up to the require-

ments described on the brake fluid reservoir. With disc

brakes, fluid level can be expected to fall as the brake

pads wear. However, low fluid level may be caused by a

leak and a checkup may be needed.

Use only manufacturer’s recommended brake fluid. Re-

fer to “Fluids, Lubricants, and Genuine Parts” in “Main-

taining Your Vehicle” for further information.

WARNING!

•

Use only manufacturer’s recommended brake

fluid. Refer to “Fluids, Lubricants, and Genuine

Parts” in “Maintaining Your Vehicle” for further

information. Using the wrong type of brake fluid

can severely damage your brake system and/or

impair its performance. The proper type of brake

fluid for your vehicle is also identified on the

(Continued)

530 MAINTAINING YOUR VEHICLE

Page 535 of 614

transmission filler tube is capped and no dipstick is

provided. Your authorized dealer can check your trans-

mission fluid level using a special service dipstick.

If you notice fluid leakage or transmission malfunction,

visit your authorized dealer immediately to have the

transmission fluid level checked. Operating the vehicle

with an improper fluid level can cause severe transmis-

sion damage.

CAUTION!

If a transmission fluid leak occurs, visit your autho-

rized dealer immediately. Severe transmission dam-

age may occur. Your authorized dealer has the proper

tools to adjust the fluid level accurately.

Fluid And Filter Changes

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.In addition, change the fluid and filter if the fluid

becomes contaminated (with water, etc.), or if the trans-

mission is disassembled for any reason.

Rear Axle

For normal service, periodic fluid level checks are not

required. When the vehicle is serviced for other reasons

the exterior surfaces of the axle assembly should be

inspected. If gear oil leakage is suspected inspect the

fluid level. Refer to “Fluids, Lubricants, and Genuine

Parts” in “Maintaining Your Vehicle” for further informa-

tion.

Fluid Level Check

Check the fluid level by removing the fill plug on the

axle. The fluid level should be at the bottom of the fill

hole. Add fluid, if necessary, to maintain the proper level.

Refer to “Fluids, Lubricants, and Genuine Parts” in

“Maintaining Your Vehicle” for further information.

7

MAINTAINING YOUR VEHICLE 533

Page 542 of 614

WARNING!

A frayed or torn belt could rip apart in a collision and

leave you with no protection. Inspect the belt system

periodically, checking for cuts, frays, or loose parts.

Damaged parts must be replaced immediately. Do

not disassemble or modify the system. Seat belt

assemblies must be replaced after a collision if they

have been damaged (i.e., bent retractor, torn web-

bing, etc.).

Cleaning The Center Console Cupholders

Clean with a damp cloth or towel using a mild detergent

with the cupholder in the center console.

NOTE:The cupholder cannot be removed.

FUSES

WARNING!

•When replacing a blown fuse, always use an ap-

propriate replacement fuse with the same amp

rating as the original fuse. Never replace a fuse

with another fuse of higher amp rating. Never

replace a blown fuse with metal wires or any other

material. Failure to use proper fuses may result in

serious personal injury, fire and/or property dam-

age.

• Before replacing a fuse, make sure that the ignition

is off and that all the other services are switched off

and/or disengaged.

• If the replaced fuse blows again, contact an autho-

rized dealer.

(Continued)

540 MAINTAINING YOUR VEHICLE

Page 554 of 614

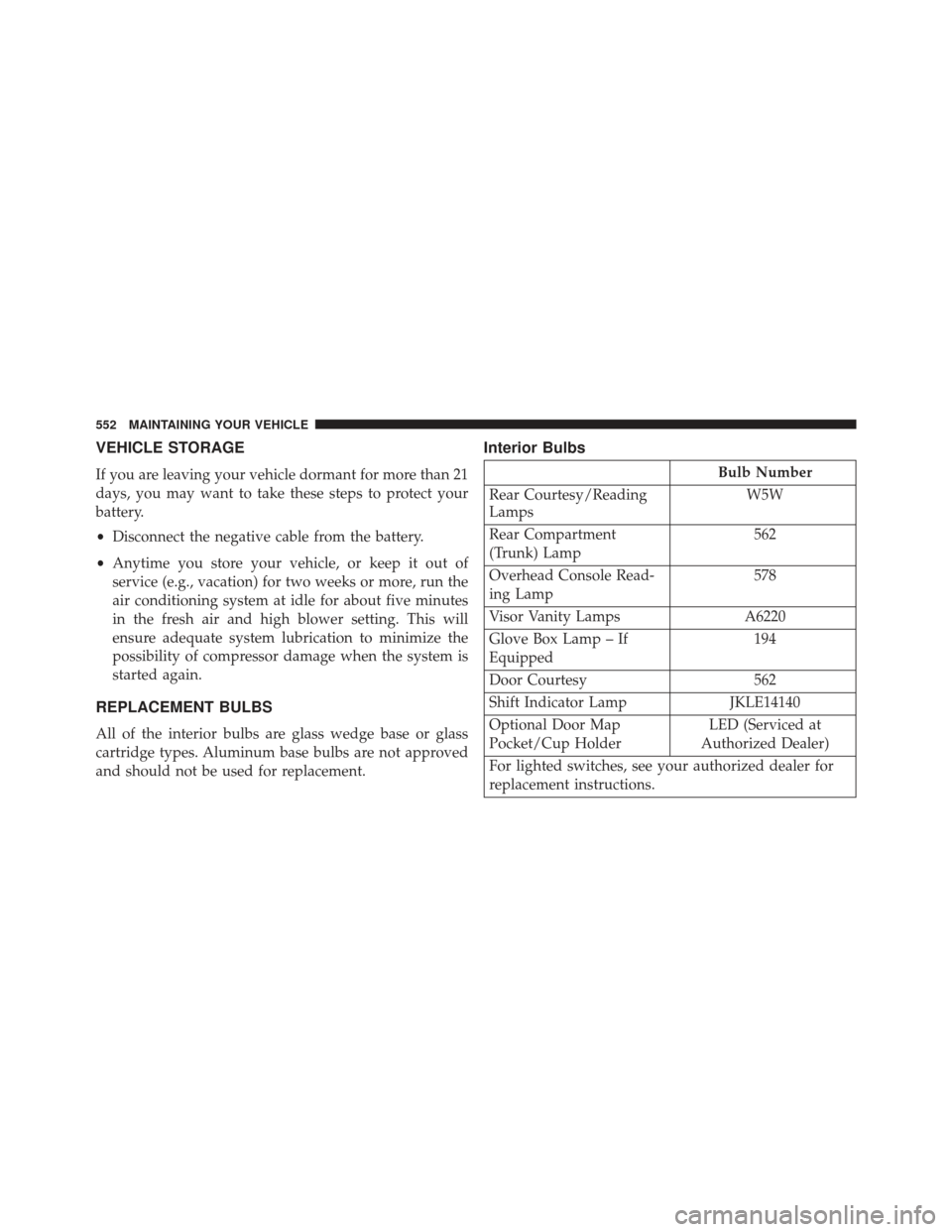

VEHICLE STORAGE

If you are leaving your vehicle dormant for more than 21

days, you may want to take these steps to protect your

battery.

•Disconnect the negative cable from the battery.

• Anytime you store your vehicle, or keep it out of

service (e.g., vacation) for two weeks or more, run the

air conditioning system at idle for about five minutes

in the fresh air and high blower setting. This will

ensure adequate system lubrication to minimize the

possibility of compressor damage when the system is

started again.

REPLACEMENT BULBS

All of the interior bulbs are glass wedge base or glass

cartridge types. Aluminum base bulbs are not approved

and should not be used for replacement.

Interior Bulbs

Bulb Number

Rear Courtesy/Reading

Lamps W5W

Rear Compartment

(Trunk) Lamp 562

Overhead Console Read-

ing Lamp 578

Visor Vanity Lamps A6220

Glove Box Lamp – If

Equipped 194

Door Courtesy 562

Shift Indicator Lamp JKLE14140

Optional Door Map

Pocket/Cup Holder LED (Serviced at

Authorized Dealer)

For lighted switches, see your authorized dealer for

replacement instructions.

552 MAINTAINING YOUR VEHICLE

Page 555 of 614

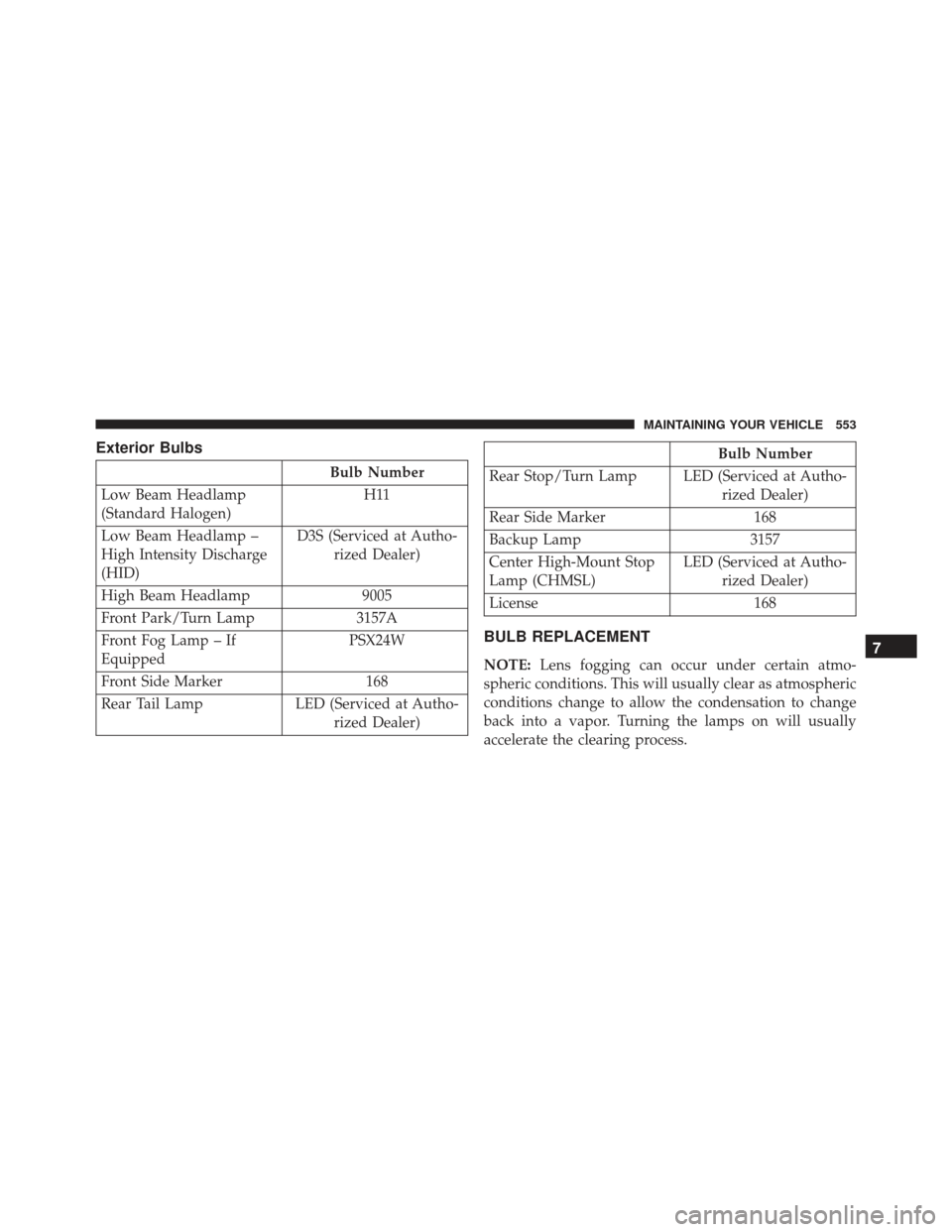

Exterior Bulbs

Bulb Number

Low Beam Headlamp

(Standard Halogen) H11

Low Beam Headlamp –

High Intensity Discharge

(HID) D3S (Serviced at Autho-

rized Dealer)

High Beam Headlamp 9005

Front Park/Turn Lamp 3157A

Front Fog Lamp – If

Equipped PSX24W

Front Side Marker 168

Rear Tail Lamp LED (Serviced at Autho- rized Dealer)

Bulb Number

Rear Stop/Turn Lamp LED (Serviced at Autho- rized Dealer)

Rear Side Marker 168

Backup Lamp 3157

Center High-Mount Stop

Lamp (CHMSL) LED (Serviced at Autho-

rized Dealer)

License 168

BULB REPLACEMENT

NOTE:Lens fogging can occur under certain atmo-

spheric conditions. This will usually clear as atmospheric

conditions change to allow the condensation to change

back into a vapor. Turning the lamps on will usually

accelerate the clearing process.

7

MAINTAINING YOUR VEHICLE 553

Page 556 of 614

Front Low Beam Headlamp, High Beam

Headlamp, Park/Turn Lamp, And Side Marker

Lamp — Models With Halogen Headlamps

1. Open the hood.

NOTE:Removal of the air cleaner filter housing may be

necessary prior to replacing bulbs in the headlamp

assembly on the driver side of the vehicle.

2. Twist the appropriate bulb and socket assembly coun- terclockwise, and then pull it out of the headlamp

assembly.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with an oily surface, clean the

bulb with rubbing alcohol. 3. Disconnect the bulb from the socket assembly and

install the replacement bulb.

4. Reinstall the bulb and socket assembly into the head- lamp assembly, and then turn it clockwise.

Front Low Beam Headlamp And Park/Turn Lamp

— Models With High Intensity Discharge

Headlamps (HID)

HID Headlamps

The headlamps are a type of high voltage discharge tube.

High voltage can remain in the circuit even with the

headlamp switch off and the key removed. Because of

this, you should not attempt to service a headlamp bulb

yourself. If a headlamp bulb fails, take your vehicle to

an authorized dealer for service.

554 MAINTAINING YOUR VEHICLE

Page 557 of 614

WARNING!

A transient high voltage occurs at the bulb sockets of

HID headlamps when the headlight switch is turned

ON. It may cause serious electrical shock or electro-

cution if not serviced properly. See your authorized

dealer for service.

NOTE: On vehicles equipped with HID headlamps,

when the headlamps are turned on, there is a blue hue to

the lights. This diminishes and becomes more white after

approximately 10 seconds, as the system charges.

Backup Lamps

1. Open trunk.

2. Remove fastener from cover. 3. Remove cover.

4. Twist the bulb one quarter turn to remove.

5. Reinstall new bulb.

6. Install cover and fastener.

Fastener Cover

7

MAINTAINING YOUR VEHICLE 555

Page 564 of 614

MAINTENANCE SCHEDULE

The Scheduled Maintenance services listed in this

manual must be done at the times or mileages specified

to protect your vehicle warranty and ensure the best

vehicle performance and reliability. More frequent main-

tenance may be needed for vehicles in severe operating

conditions, such as dusty areas and very short trip

driving. Inspection and service should also be done

anytime a malfunction is suspected.

The oil change indicator system will remind you that it is

time to take your vehicle in for scheduled maintenance.

On Electronic Vehicle Information Center (EVIC)

equipped vehicles, “Oil Change Required” will be dis-

played in the EVIC and a single chime will sound,

indicating that an oil change is necessary.Based on engine operation conditions, the oil change

indicator message will illuminate. This means that ser-

vice is required for your vehicle. Have your vehicle

serviced as soon as possible, within the next 500 miles

(805 km).

NOTE:

•

The oil change indicator message will not monitor the

time since the last oil change. Change your vehicle’s oil

if it has been six months since your last oil change,

even if the oil change indicator message is NOT

illuminated.

• Change your engine oil more often if you drive your

vehicle off-road for an extended period of time.

• Under no circumstances should oil change intervals

exceed 6,000 miles (10,000 km) or six months, which-

ever comes first.

562 MAINTENANCE SCHEDULES

Page 567 of 614

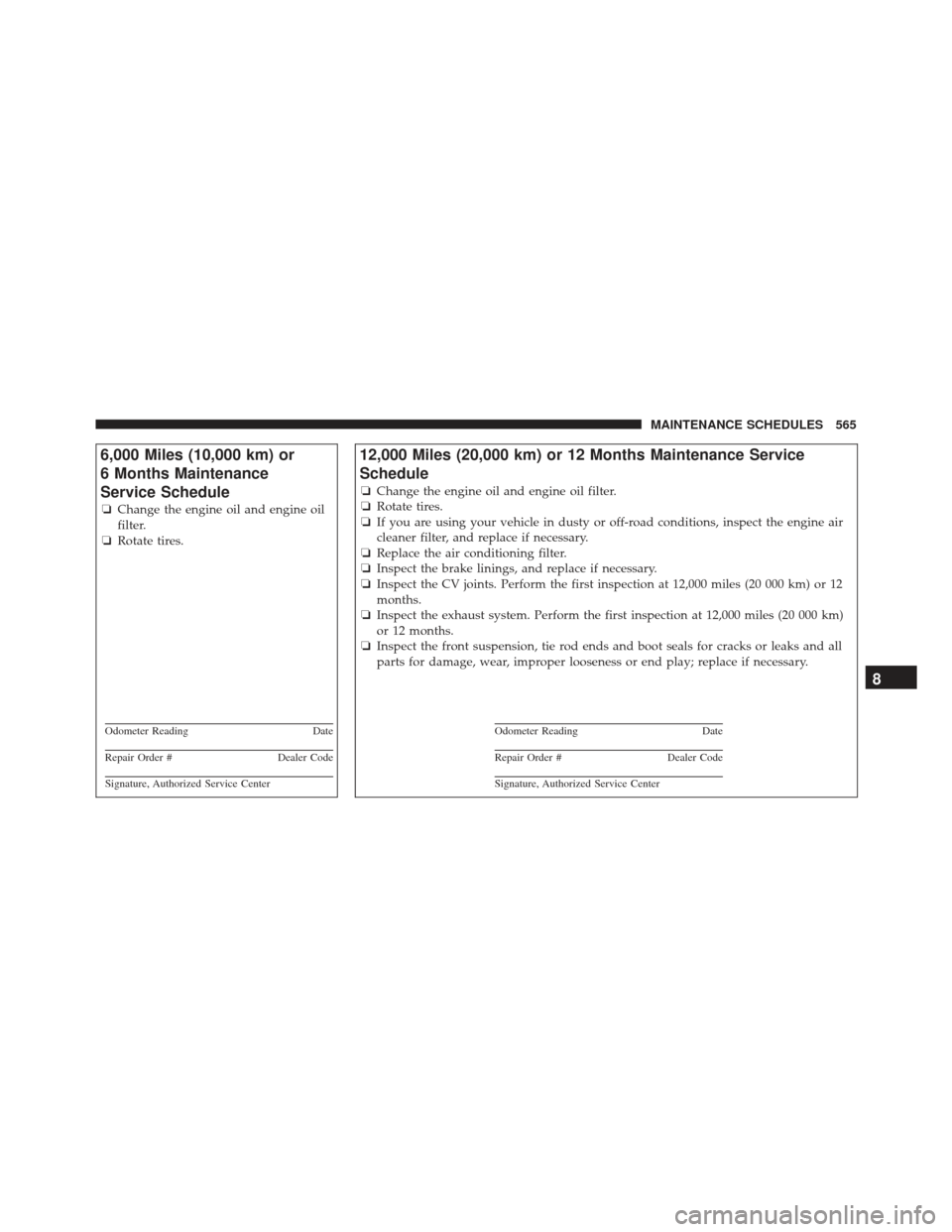

6,000 Miles (10,000 km) or

6 Months Maintenance

Service Schedule

❏Change the engine oil and engine oil

filter.

❏ Rotate tires.

Odometer Reading Date

Repair Order #Dealer Code

Signature, Authorized Service Center

12,000 Miles (20,000 km) or 12 Months Maintenance Service

Schedule

❏Change the engine oil and engine oil filter.

❏ Rotate tires.

❏ If you are using your vehicle in dusty or off-road conditions, inspect the engine air

cleaner filter, and replace if necessary.

❏ Replace the air conditioning filter.

❏ Inspect the brake linings, and replace if necessary.

❏ Inspect the CV joints. Perform the first inspection at 12,000 miles (20 000 km) or 12

months.

❏ Inspect the exhaust system. Perform the first inspection at 12,000 miles (20 000 km)

or 12 months.

❏ Inspect the front suspension, tie rod ends and boot seals for cracks or leaks and all

parts for damage, wear, improper looseness or end play; replace if necessary.

Odometer Reading Date

Repair Order #Dealer Code

Signature, Authorized Service Center

8

MAINTENANCE SCHEDULES 565