DODGE DAKOTA 2004 3.G Owners Manual

Manufacturer: DODGE, Model Year: 2004, Model line: DAKOTA, Model: DODGE DAKOTA 2004 3.GPages: 300, PDF Size: 5.23 MB

Page 161 of 300

AWD to 4HI or 4HI to AWD

Rotate the 4WD Control Switch to the desired position.

Shifts between AWD and 4HI can be done with the

vehicle stopped or in motion. With the vehicle in motion,

the transfer case will engage / disengage faster if you

momentarily release the accelerator pedal after turning

the control switch. If the vehicle is stopped the ignition

key must be in the ON position with the engine either

RUNNING or OFF. This shift cannot be completed if the

key is in the accessory position.

NOTE:On vehicles equipped with a Anti-Lock Brake

Systems, the 4x4 system will not allow shifts between

AWD/ 4HI if the rear wheels are spinning (no traction).

In this situation the selected position indicator light will

flash and the original position indicator light will remain

ON. At this time, reduce speed and stop spinning the

wheels to complete the shift. There may be a delay up to

10 seconds for the shift to complete after the wheels have

stopped spinning.

NOTE:Delayed shifting out of the 4HI position may be

experienced due to uneven tire wear, low tire pressure, or

excessive loading.

4HI to 4LO or 4LO to 4HI

NOTE:

When shifting into or out of 4LO some gear

noise may be heard. This noise is normal and is not

detrimental to the vehicle or occupants.

Shifting can be performed with the vehicle rolling 2-3

mph (3-5 km/h) or completely stopped. USE EITHER OF

THE FOLLOWING PROCEDURES:

Preferred Procedure

1. With engine RUNNING, slow vehicle to 2-3 mph (3-5

km/h).

2. Shift the transmission into NEUTRAL (depress clutch

on manual transmissions).

3. Ensure ignition key is in the ON position with the

engine either RUNNING or OFF. While still rolling,

rotate the transfer case control switch to the desired

position.

4. After the desired position indicator light is ON (not

flashing), shift transmission back into gear (release clutch

on manual transmissions).

STARTING AND OPERATING 161

5

Page 162 of 300

Alternate Procedure

1. Bring the vehicle to complete stop.

2. With the key ON and the engine either OFF or

RUNNING, shift the transmission into NEUTRAL (de-

press clutch on manual transmissions).

3. Rotate the transfer case control switch to the desired

position.

4. After the desired position indicator light is ON (not

flashing), shift transmission back into gear (release clutch

on manual transmissions).

NOTE:If steps 1 or 2 of either the Preferred or Alternate

Procedure are not satisfied prior to attempting the shift or

if they no longer are being met while the shift attempt is

in process, then the desired position indicator light will

flash continuously while the original position indicator

light is ON, until all requirements have been met.

NOTE:The ignition key must be ON for a shift to take

place and for the position indicator lights to be operable.

If the key is not ON then the shift will not take place and

no position indicator lights will be on or flashing.

LIMITED-SLIP DIFFERENTIAL Ð IF EQUIPPED

The limited-slip differential provides additional traction

on snow, ice, mud, sand and gravel. It improves traction

when there is a difference between the characteristics of

the surface under the right and left rear wheels. During

normal driving and cornering, the limited-slip unit is

similar to a conventional differential. But on a slippery

surface, the differential delivers more of the driving effort

to the wheel having the better traction.

WARNING!

On vehicles equipped with a limited-slip differen-

tial, never run the engine with one rear wheel off the

ground. The vehicle may drive through the rear

wheel remaining on the ground and cause you to

lose control of the vehicle.

Care should be taken to avoid sudden accelerations when

both rear wheels are on a slippery surface. This could

cause both rear wheels to spin, and allow the vehicle to

slide sideways on the crowned surface of a road or in a

turn.

162 STARTING AND OPERATING

Page 163 of 300

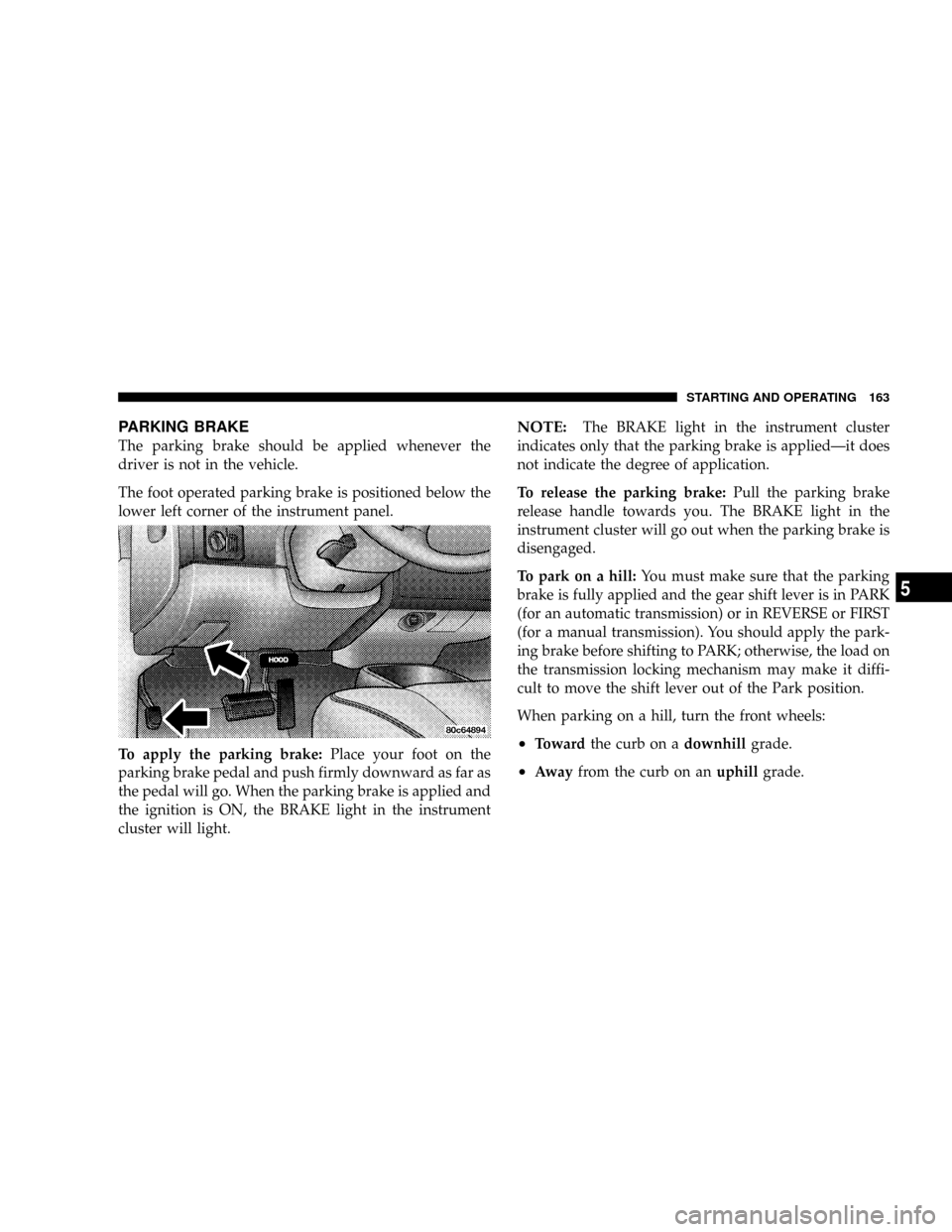

PARKING BRAKE

The parking brake should be applied whenever the

driver is not in the vehicle.

The foot operated parking brake is positioned below the

lower left corner of the instrument panel.

To apply the parking brake:Place your foot on the

parking brake pedal and push firmly downward as far as

the pedal will go. When the parking brake is applied and

the ignition is ON, the BRAKE light in the instrument

cluster will light.

NOTE:The BRAKE light in the instrument cluster

indicates only that the parking brake is appliedÐit does

not indicate the degree of application.

To release the parking brake:Pull the parking brake

release handle towards you. The BRAKE light in the

instrument cluster will go out when the parking brake is

disengaged.

To park on a hill:You must make sure that the parking

brake is fully applied and the gear shift lever is in PARK

(for an automatic transmission) or in REVERSE or FIRST

(for a manual transmission). You should apply the park-

ing brake before shifting to PARK; otherwise, the load on

the transmission locking mechanism may make it diffi-

cult to move the shift lever out of the Park position.

When parking on a hill, turn the front wheels:

²Towardthe curb on adownhillgrade.

²Awayfrom the curb on anuphillgrade.

STARTING AND OPERATING 163

5

Page 164 of 300

WARNING!

²Always fully apply the parking brake when leav-

ing your vehicle, or vehicle may roll and cause

damage or injury. Also be certain to leave an

automatic transmission in Park, a manual trans-

mission in Reverse or first gear. Failure to do so

may cause the vehicle to roll and cause damage or

injury.

²Be sure the parking brake is fully disengaged

before driving. Failure to do so can lead to brake

failure and an accident.

²Leaving children in a vehicle unattended is dan-

gerous for a number of reasons. A child or others

could be injured. Children should be warned not

to touch the parking brake or the gear selector

lever. Don't leave the key in the ignition. A child

could operate power windows, other controls, or

move the vehicle.

BRAKE SYSTEM

In the event power assist is lost for any reason (for

example, repeated brake applications with the engine

off), the brakes will still function. The effort required to

brake the vehicle will be significantly increased over that

required with the power system operating.

If either the front or rear hydraulic system loses normal

capability, the remaining system will still function with

some loss of braking effectiveness. This will be evident by

increased pedal travel during application, greater pedal

force required to slow or stop, and activation of the Brake

Warning light and the ABS light during brake use.

Rear Wheel Anti-Lock Brake System

This Anti-Lock Brake System provides increased vehicle

stability and brake performance under most braking

conditions. The system automatically controls the opera-

tion of the rear brakes to prevent rear wheel lockup.

The system remains operational in the four-wheel drive

mode. The level of performance is reduced when the

front brakes are locked up. This will cause the rear brakes

to lock-up through the drivetrain, which may reduce the

effectiveness of the anti-lock system.

164 STARTING AND OPERATING

Page 165 of 300

During severe braking conditions, particularly with

changing road surfaces, such as ice to concrete, a slight

drop or minor pulsation may be felt in the brake pedal.

WARNING!

Both Anti-Lock Brake Systems contain sophisticated

electronic equipment. It may be susceptible to inter-

ference caused by improperly installed or high out-

put radio transmitting equipment. This interference

can cause possible loss of anti-lock braking capabil-

ity. Installation of such equipment should be done

by qualified professionals.

Four-Wheel Anti-Lock Brake System Ð If

Equipped

This Anti-Lock Brake System is designed to aid the driver

in maintaining vehicle control under adverse braking

conditions. The system operates with a separate com-

puter to modulate hydraulic pressure to prevent wheel

lock-up and help avoid skidding on slippery surfaces.The system's pump motor runs during an ABS stop to

provide regulated hydraulic pressure. The pump motor

makes a low humming noise during operation, which is

normal.

The Anti-Lock Brake System includes an amber ABS

warning light. When the light is illuminated, the Anti-

Lock Brake System is not functioning. The system reverts

to standard non-anti-lock brakes. Turning the ignition

OFF and ON again may reset the Anti-Lock Brake System

if the fault detected was only momentary.

WARNING!

Pumping of the Anti-Lock Brakes will diminish

their effectiveness and may lead to an accident.

Pumping makes the stopping distance longer. Just

press firmly on your brake pedal when you need to

slow down or stop.

STARTING AND OPERATING 165

5

Page 166 of 300

WARNING!

²Anti-lock system (ABS) cannot prevent the natu-

ral laws of physics from acting on the vehicle, nor

can it increase braking or steering efficiency be-

yond that afforded by the condition of the vehicle

brakes and tires or the traction afforded.

²The ABS cannot prevent accidents, including

those resulting from excessive speed in turns,

following another vehicle too closely, or hydro-

planing. Only a safe, attentive, and skillful driver

can prevent accidents.

²The capabilities of an ABS equipped vehicle must

never be exploited in a reckless or dangerous

manner which could jeopardize the user's safety

or the safety of others.

When you are in a severe braking condition involving

use of the Anti-lock Brake System, you will experience

some pedal drop as the vehicle comes to a stop. This is

the result of the system reverting to the base brake

system.

Engagement of the Anti-lock Brake System may be

accompanied by a pulsing sensation. You may also hear a

clicking noise. These occurrences are normal, and indi-

cate that the system is functioning properly.

POWER STEERING

Your power steering system will provide mechanical

steering capability if power assist is lost.

If for any reason the hydraulic pressure is interrupted, it

will still be possible to steer your vehicle. Under these

conditions you will experience an increase in steering

effort and a noticeable amount of ªfree playº in the

steering wheel.

166 STARTING AND OPERATING

Page 167 of 300

ROCKING THE VEHICLE

If vehicle becomes stuck in snow, sand, or mud, it can

often be moved by a rocking motion. Move the gear

selector rhythmically between FIRST and REVERSE,

while applying slight pressure to the accelerator.

The least amount of accelerator pedal pressure to main-

tain the rocking motion without spinning the wheels or

racing the engine is most effective. Allow the engine to

idle with the transmission selector in NEUTRAL for at

least one minute after every five rocking-motion cycles.

This will minimize overheating and reduce the risk of

transmission failure during prolonged efforts to free a

stuck vehicle.

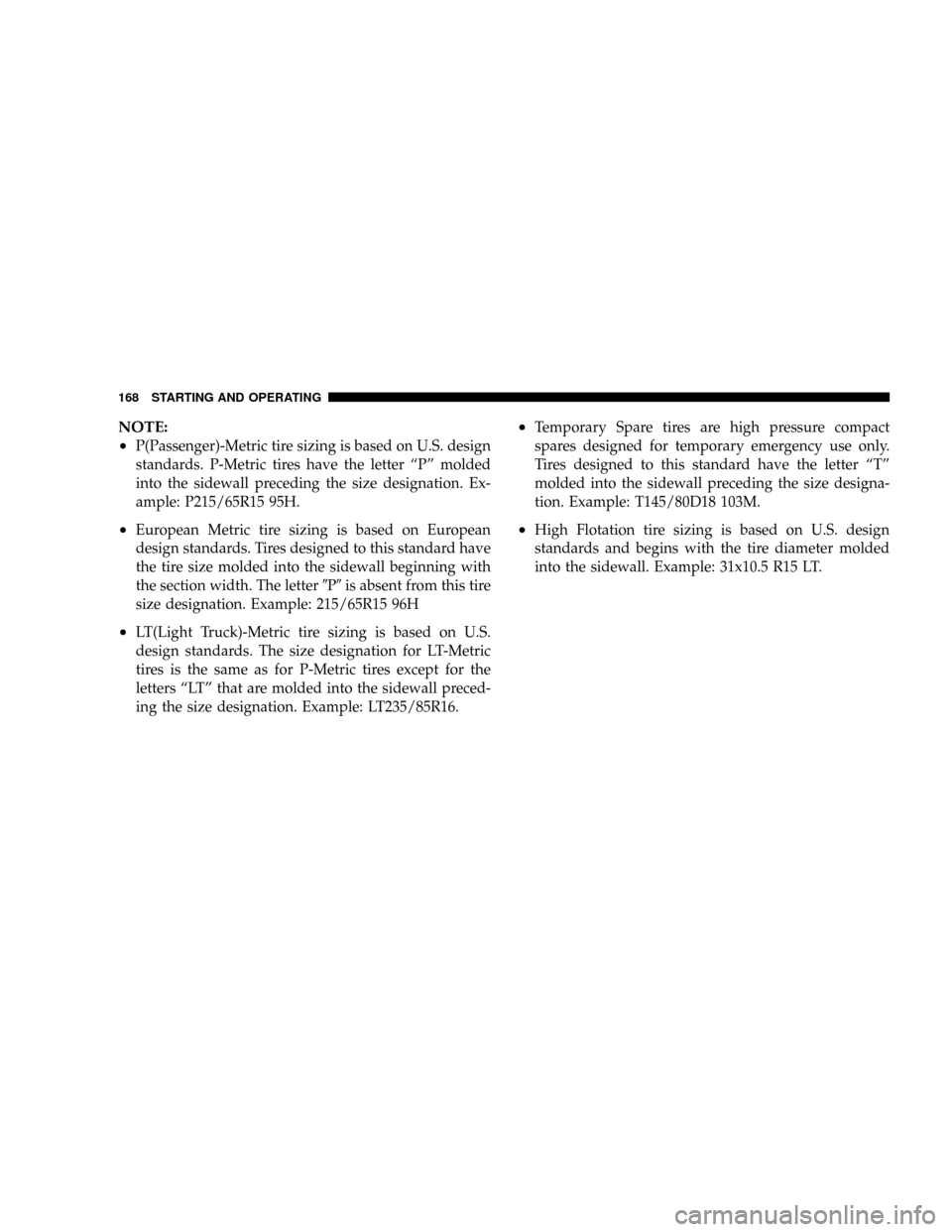

TIRE SAFETY INFORMATION

Tire Markings

STARTING AND OPERATING 167

5

Page 168 of 300

NOTE:

²

P(Passenger)-Metric tire sizing is based on U.S. design

standards. P-Metric tires have the letter ªPº molded

into the sidewall preceding the size designation. Ex-

ample: P215/65R15 95H.

²European Metric tire sizing is based on European

design standards. Tires designed to this standard have

the tire size molded into the sidewall beginning with

the section width. The letter9P9is absent from this tire

size designation. Example: 215/65R15 96H

²LT(Light Truck)-Metric tire sizing is based on U.S.

design standards. The size designation for LT-Metric

tires is the same as for P-Metric tires except for the

letters ªLTº that are molded into the sidewall preced-

ing the size designation. Example: LT235/85R16.

²Temporary Spare tires are high pressure compact

spares designed for temporary emergency use only.

Tires designed to this standard have the letter ªTº

molded into the sidewall preceding the size designa-

tion. Example: T145/80D18 103M.

²High Flotation tire sizing is based on U.S. design

standards and begins with the tire diameter molded

into the sidewall. Example: 31x10.5 R15 LT.

168 STARTING AND OPERATING

Page 169 of 300

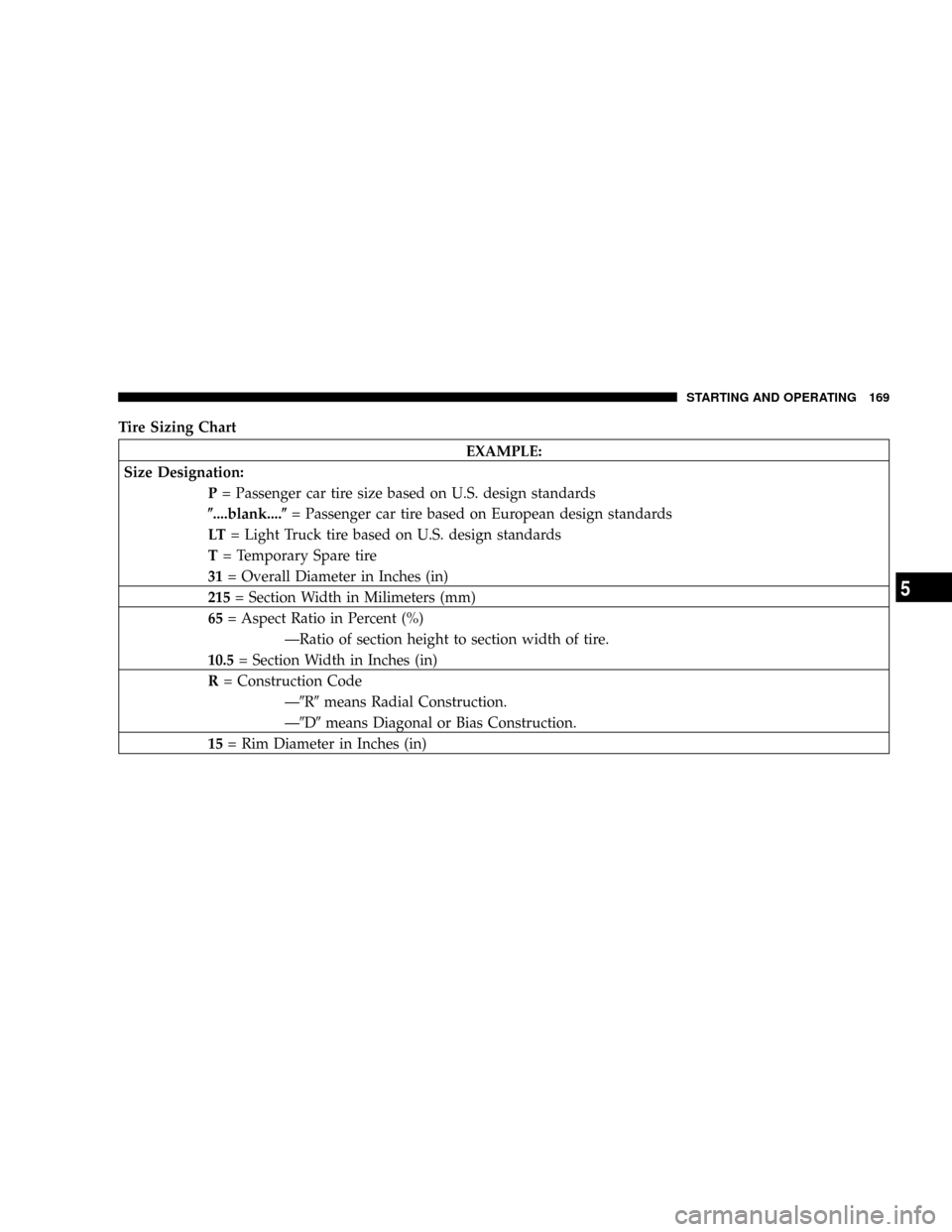

Tire Sizing Chart

EXAMPLE:

Size Designation:

P= Passenger car tire size based on U.S. design standards

(....blank....(= Passenger car tire based on European design standards

LT= Light Truck tire based on U.S. design standards

T= Temporary Spare tire

31= Overall Diameter in Inches (in)

215= Section Width in Milimeters (mm)

65= Aspect Ratio in Percent (%)

ÐRatio of section height to section width of tire.

10.5= Section Width in Inches (in)

R= Construction Code

Ð9R9means Radial Construction.

Ð9D9means Diagonal or Bias Construction.

15= Rim Diameter in Inches (in)

STARTING AND OPERATING 169

5

Page 170 of 300

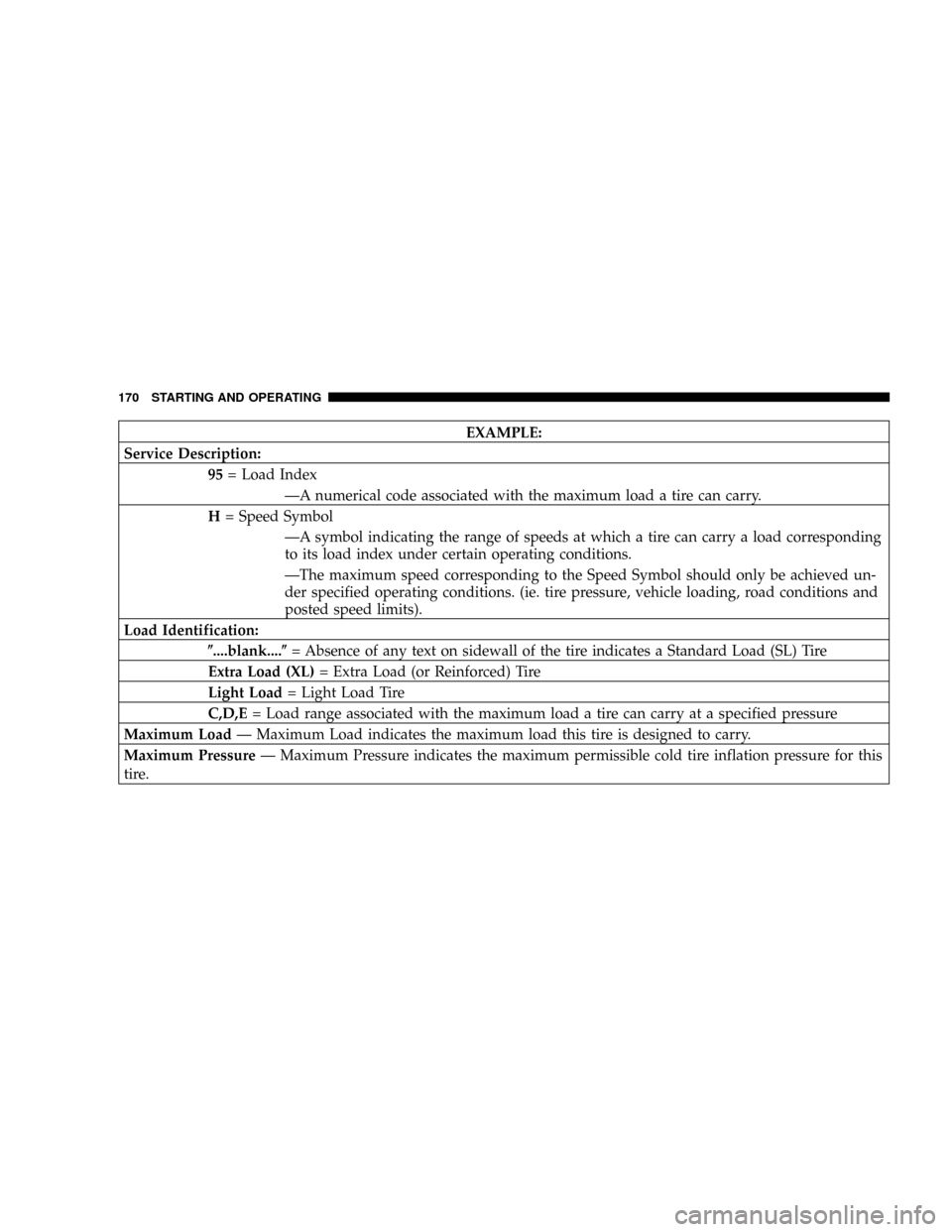

EXAMPLE:

Service Description:

95= Load Index

ÐA numerical code associated with the maximum load a tire can carry.

H= Speed Symbol

ÐA symbol indicating the range of speeds at which a tire can carry a load corresponding

to its load index under certain operating conditions.

ÐThe maximum speed corresponding to the Speed Symbol should only be achieved un-

der specified operating conditions. (ie. tire pressure, vehicle loading, road conditions and

posted speed limits).

Load Identification:

(....blank....(= Absence of any text on sidewall of the tire indicates a Standard Load (SL) Tire

Extra Load (XL)= Extra Load (or Reinforced) Tire

Light Load= Light Load Tire

C,D,E= Load range associated with the maximum load a tire can carry at a specified pressure

Maximum LoadÐ Maximum Load indicates the maximum load this tire is designed to carry.

Maximum PressureÐ Maximum Pressure indicates the maximum permissible cold tire inflation pressure for this

tire.

170 STARTING AND OPERATING