service DODGE DAKOTA 2004 3.G Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: DAKOTA, Model: DODGE DAKOTA 2004 3.GPages: 300, PDF Size: 5.23 MB

Page 234 of 300

WARNING!

²Use only refrigerants and compressor lubricants

approved by the manufacturer for your air condi-

tioning system. Some unapproved refrigerants are

flammable and can explode, injuring you. Other

unapproved refrigerants or lubricants can cause

the system to fail, requiring costly repairs.

²The air conditioning system contains refrigerant

under high pressure. To avoid risk of personal

injury or damage to the system, adding refrigerant

or any repair requiring lines to be disconnected

should be done by an experienced repairman.

Refrigerant Recovery and Recycling

R-134a Air Conditioning Refrigerant is a hydrofluorocar-

bon (HFC) that is endorsed by the Environmental Pro-

tection Agency and is an ozone-saving product. How-

ever, the manufacturer recommends that air conditioning

service be performed by dealers or other service facilities

using recovery and recycling equipment.

Power Steering Ð Fluid Check

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises are

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through a certified

DaimlerChrysler Dealership.9

WARNING!

Fluid level should be checked on a level surface and

with the engine off to prevent injury from moving

parts and to insure accurate fluid level reading. Do

not overfill. Use only manufacturers recommended

power steering fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to Recommended Fluids, Lubricants, and

Genuine Parts for correct fluid type.

234 MAINTAINING YOUR VEHICLE

Page 235 of 300

Front Suspension Ball Joints

The ball joints and seals should be inspected whenever

the vehicle is serviced for other reasons. Damaged seals

should be replaced to prevent leakage or contamination

of the grease.

Steering Linkage

Whenever the vehicle is hoisted, all steering linkage

joints should be inspected for evidence of damage. Dam-

aged seals should be replaced to prevent leakage or

contamination of the grease.

Drive Shaft Constant Velocity Joints Ð 4X4

Models

All four-wheel drive models are equipped with four

constant velocity joints. Periodic lubrication of these

joints is not required. However, the joint boot should be

inspected for external leakage or damage periodically. If

external leakage or damage is evident, the joint boot and

grease should be replaced immediately. Continued op-

eration could result in failure of the joint due to water

and dirt contamination of the grease. This would require

complete replacement of the joint assembly. Refer to the

Service Manual for the detailed replacement procedure.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, doors,liftgate and hood hinges, should be

lubricated periodically to assure quiet, easy operation

and to protect against rust and wear. Prior to the appli-

cation of any lubricant, the parts concerned should be

wiped clean to remove dust and grit; after lubricating

excess oil and grease should be removed. Particular

attention should also be given to hood latching compo-

nents to insure proper function. When performing other

underhood services, the hood latch, release mechanism

and safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the fall and spring. Apply a small

amount of a high quality lubricant such as MopartLock

Cylinder Lubricant directly into the lock cylinder.

Windshield Wiper Blades

The rubber edges of the wiper blades and the windshield

should be cleaned periodically with a sponge or soft cloth

and a mild nonabrasive cleaner. This will remove accu-

mulations of salt or road film.

MAINTAINING YOUR VEHICLE 235

7

Page 241 of 300

The radiator normally remains completely full, so there is

no need to remove the pressure cap except when check-

ing coolant freeze point or when replacing coolant. Your

service attendant should be advised of this. When addi-

tional coolant is needed to maintain the proper level, it

should be added to the overflow bottle. Do not overfill.

Points To Remember

A. Do not overfill the reserve tank (overflow bottle).

B. Check coolant freeze point in the radiator and in the

reserve tank. If antifreeze needs to be added, contents of

reserve tank also must be protected against freezing.

C. If frequent coolant additions are required, or if the

level in the reserve tank does not drop when the engine

cools, the cooling system should be pressure tested for

leaks.D. Maintain a minimum coolant concentration of 50%

ethylene glycol.

E. Make sure that the radiator and reserve tank overflow

hoses are not kinked or obstructed.

F. Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean also.

G. The thermostat should not be changed for summer or

winter operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory cooling performance.

Emission Related Components

Fuel System Hoses And Vapor/Vacuum Harnesses

When the vehicle is serviced for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, checking, tears, cuts, abrasions, and excessive

swelling suggest deterioration of the rubber. Particular

attention should be given to examining hose surfaces

nearest to high heat sources, such as the exhaust mani-

fold.

MAINTAINING YOUR VEHICLE 241

7

Page 242 of 300

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

NOTE:Fluids such as oil, power steering fluid, and

brake fluid are used during assembly plant operations to

ease the assembly of hoses to couplings. Therefore, oil

wetness at the hose-coupling area is not necessarily an

indication of leakage. Actual dripping of hot fluid when

systems are under pressure (during vehicle operation),

should be noted before hose is replaced based on leakage.

You are urged to use only manufacturer specified hoses

and clamps, or their equivalent in material and specifi-

cation, in any fuel system servicing. It is mandatory to

replace all clamps that have been loosened or removed

during service. Care should be taken in installing new

clamps to insure they are properly torqued.

Positive Crankcase Ventilation (PCV) Valve

Proper operation of the crankcase ventilation system

requires that the PCV valve be free of sticking or plug-

ging because of deposits. Deposits can accumulate in thePCV valve and passage with increasing mileage. Have

the PCV valve, hoses, and passages checked for proper

operation at the intervals specified. If the valve is

plugged or sticking, replace with a new valve.Do not

attempt to clean the oil PCV valve!Check ventilating

hose for indication of damage or plugging with deposits.

Replace if necessary.

242 MAINTAINING YOUR VEHICLE

Page 243 of 300

Brake System

Power Disc Brakes (Front)

Disc brakes do not require adjustment; however, several

hard stops during the break-in period are recommended

to seat the linings and wear off any foreign material.

Self-Adjusting Rear Brakes

To maintain the correct adjustment, you need only drive

your vehicle in reverse and apply the brakes. If further

adjustment is needed, drive forward about 20 feet (6

meters) before you repeat the reverse application. To

avoid poor braking, brake pull, or damage to brake

drums, the brake linings should be inspected as specified

in the Maintenance Schedule.

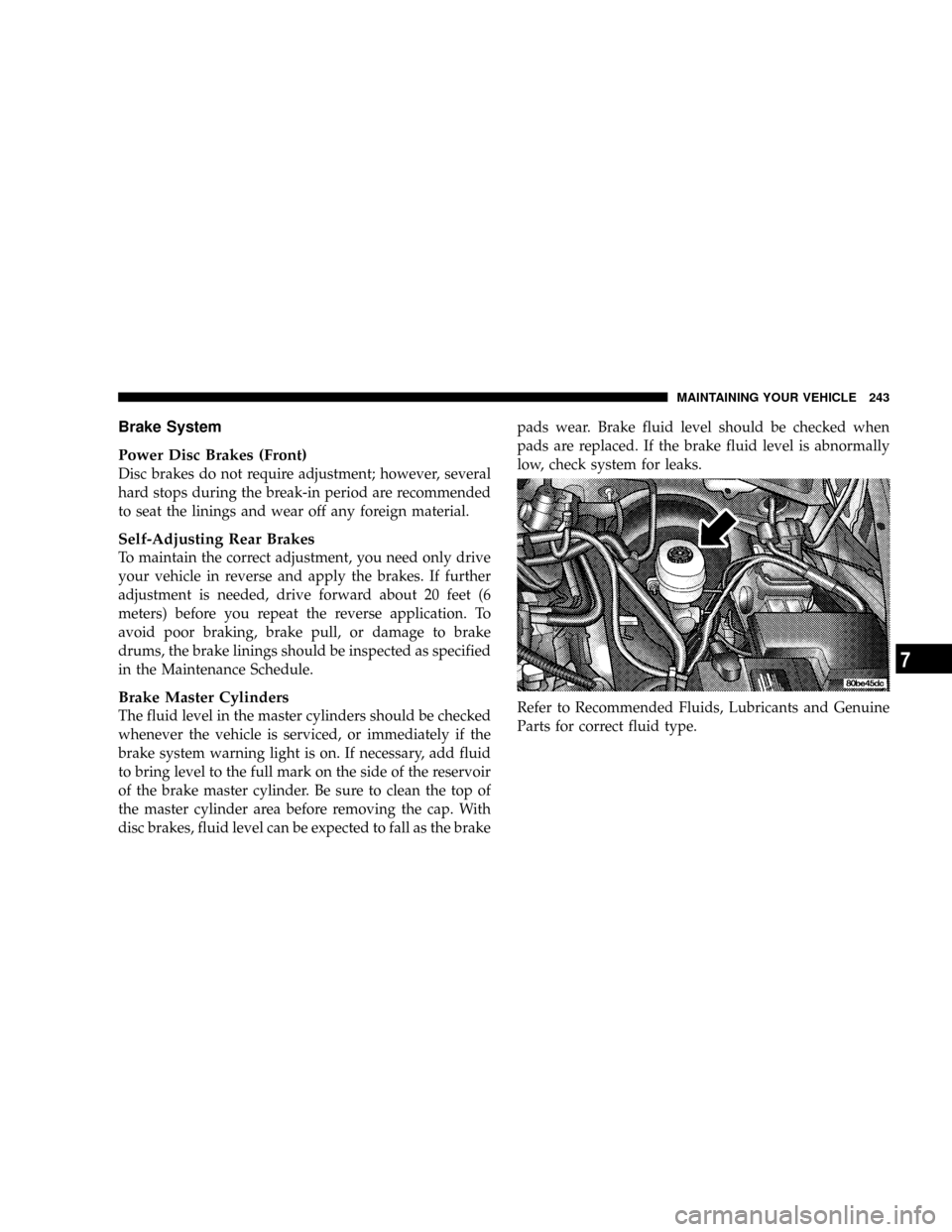

Brake Master Cylinders

The fluid level in the master cylinders should be checked

whenever the vehicle is serviced, or immediately if the

brake system warning light is on. If necessary, add fluid

to bring level to the full mark on the side of the reservoir

of the brake master cylinder. Be sure to clean the top of

the master cylinder area before removing the cap. With

disc brakes, fluid level can be expected to fall as the brakepads wear. Brake fluid level should be checked when

pads are replaced. If the brake fluid level is abnormally

low, check system for leaks.

Refer to Recommended Fluids, Lubricants and Genuine

Parts for correct fluid type.

MAINTAINING YOUR VEHICLE 243

7

Page 244 of 300

WARNING!

Use of brake fluid that may have a lower initial

boiling point, or is unidentified as to specifications,

may result in sudden brake failure during hard

prolonged braking. You could have an accident.

WARNING!

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching fire.

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter or

moisture.

CAUTION!

Do not allow a petroleum-base fluid to contaminate

the brake fluid. Seal damage may result.

Brake Linings

Your vehicle is equipped with self-adjusting brakes. A

few brake applications while moving in reverse will

maintain your brakes at the specified adjustment. Adjust-

ment will continue until the brake linings are worn. To

avoid brake failure, brake pull or damage to drums,

inspect the brake linings as specified. If excessively worn,

the brake linings must be replaced.

Brake Hoses

Inspection should be performed whenever the brake

system is serviced or at intervals specified. Inspect hy-

draulic brake hoses for surface cracking, scuffing or worn

spots. If there is any evidence of cracking, scuffing, or

worn spots, the hose should be replaced immediately!

Eventual deterioration of the hose can take place with

possible burst failure.

244 MAINTAINING YOUR VEHICLE

Page 245 of 300

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any sign of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Clutch Hydraulic System

The clutch hydraulic system is a sealed maintenance free

system. In the event of leakage or other malfunction, the

system must be replaced.

Manual Transmission

Fluid Level Check

This fluid should be checked whenever other underhood

services are performed. The fluid level is checked by

removing the fill plug. If the level of the lubricant is more

than 1/49(6.35 mm) below the bottom of the filler hole

while the vehicle is level, enough lubricant should be

added to bring the level to the bottom of the filler hole.

NV-3500 5-Speed Transmission Lubricant Selection

These transmissions are filled with manual transmission

fluid at the factory. This fluid does not require periodic

changing. If it becomes necessary to add or change the

fluid in these transmissions, Refer to Recommended

Fluids, Lubricants and Genuine Parts for correct fluid

type.

Automatic Transmission

Fluid Level Check ± 3.7/4.7L Engine

Check the fluid level while the transmission is at normal

operating temperature 180ÉF (82ÉC). This occurs after at

least 15 miles (25 km) of driving. At normal operating

temperature the fluid cannot be held comfortably be-

tween the fingertips.

To check the automatic transmission fluid level properly,

the following procedure must be used:

1. Operate the engine at idle speed and normal operating

temperature.

2. The vehicle must be on level ground.

MAINTAINING YOUR VEHICLE 245

7

Page 247 of 300

7. Check for leaks. Release parking brake.

To prevent dirt and water from entering the transmission

after checking or replenishing fluid, make certain that the

dipstick cap is properly reseated. It is normal for the

dipstick cap to spring back slightly from its fully seated

position, as long as its seal remains engaged in the

dipstick tube.

Automatic Transmission Fluid And Filter Change

To obtain best performance and long life for automatic

transmissions, the manufacturer recommends that they

be given regular maintenance service by an Authorized

Dodge Dealer or Service Center. It is important that the

transmission be adjusted periodically, the fluid be main-

tained at the correct level, and that it be drained and

refilled as specified.

It is important that proper lubricant is used in the

transmission. Refer to Recommended Fluids, Lubricants

and Genuine Parts for correct fluid type. It is important

that the transmission fluid be maintained at the pre-

scribed level using the recommended fluid.

CAUTION!

Using a transmission fluid other than the manufac-

turers recommended fluid may cause deterioration

in transmission shift quality and/or torque converter

shudder. Using a transmission fluid other than the

manufacturers recommended fluid will result in

more frequent fluid and filter changes. Refer to

Recommended Fluids, Lubricants and Genuine Parts

for correct fluid type.

Refer to the ªMaintenance Schedulesº section for the

proper service intervals for your type of driving.

If the transmission is disassembled for any reason, the

fluid and filter should be changed, and the bands ad-

justed (if equipped).

Special Additives

The manufacturer strongly recommends against the ad-

dition of any fluid additives to the transmission. Excep-

tion to this policy is the use of special dyes to aid in

detecting fluid leaks. The use of transmission sealers

should be avoided, since they may adversely affect seals.

MAINTAINING YOUR VEHICLE 247

7

Page 248 of 300

Transfer Case

Inspect the transfer case for fluid leaks. If a fluid leak is

evident the transfer case fluid level can be checked by

removing the filler plug located on the back side of the

transfer case. The fluid level should be at the bottom edge

of the filler plug hole when the vehicle is in a level

position.

The transfer case fluid should be drained and refilled at

the intervals specified.

Lubricant Selection

Refer to Recommended Fluids, Lubricants and Genuine

Parts for correct fluid type.

Axles

Refer to Recommended Fluids, Lubricants and Genuine

Parts for correct fluid type.

The manufacturer does not recommend regularly sched-

uled oil changes for axles in vehicles whose operation is

classified as normal truck service.

NOTE:The presence of water in the gear lubricant will

result in corrosion and possible failure of differential

components. Operation of the vehicle in water, as may beencountered in some off-highway types of service, will

require draining and refilling the axle to avoid damage.

Rear Axle

Limited-slip differentials require the use of Mopartlim-

ited slip additive. Refer to Recommended Fluids, Lubri-

cants and Genuine Parts for correct fluid type. This

should be added to the gear lubricant whenever a fluid

change is made, when equipped with a limited-slip

differential. Rear axle fluid level should be 1/49(6.35

mm) below filler plug hole for 8 1/4 axles and should be

5/89(16 mm) below filler plug hole for 9 1/49axles.

Front Axle

Front axle fluid level should be at the bottom of the filler

plug hole.

Selection of Lubricating Grease

The National Lubricating Grease Institute (NLGI) has

developed a symbol (Certification Mark) to aid the

vehicle owner in the proper selection of grease for chassis

components. This symbol, an example shown below, is

located on the grease container and identifies the appli-

cation and quality of the grease.

248 MAINTAINING YOUR VEHICLE

Page 262 of 300

EMISSION CONTROL SYSTEM MAINTENANCE

The ªScheduledº maintenance services, listed inbold

typeon the following pages must be done at the times or

mileages specified to assure the continued proper func-

tioning of the emission control system. These, and all

other maintenance services included in this manual,

should be done to provide best vehicle performance and

reliability. More frequent maintenance may be needed for

vehicles in severe operating conditions such as dusty

areas and very short trip driving.

Inspection and service also should be done any time a

malfunction is suspected.

NOTE:Maintenance, replacement, or repair of the

emission control devices and systems on your vehicle

may be performed by any automotive repair establish-

ment or individual using any automotive part which has

been certified pursuant to U.S. EPA or, in the State of

California, California Air Resources Board regulations.

EMISSIONS TESTING

In some localities, it may be or will become a legal

requirement to ensure that all emissions components and

systems are functioning properly as a part of the test

procedure. The test center accomplishes this by checking

the On Board Diagnostic System (OBD) system with an

electronic scan tool. If your vehicle has recently been

serviced, the OBD system may have been reset to a9not

ready9condition because the OBD system has not had

sufficient time since the servicing to reconfirm that

emissions components are operating properly. In most

cases, a reasonable mix and amount of normal city and

highway driving and at least one overnight-off period

will be required to prepare your vehicle for this check;

however your dealer has the equipment and procedures

required to make certain that the OBD system of your

vehicle is ready for the required testing.

262 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S