lock DODGE DAKOTA 2005 3.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2005, Model line: DAKOTA, Model: DODGE DAKOTA 2005 3.GPages: 392, PDF Size: 24.29 MB

Page 215 of 392

WARNING!

You or others could be injured if you leave the

vehicle unattended with the transfer case in the

Neutral (N) position without first fully engaging the

parking brake. The transfer case Neutral (N) position

disengages both the front and rear driveshafts from

the powertrain and will allow the vehicle to move

regardless of the transmission position. The parking

brake should always be applied when the driver is

not in the vehicle.

For additional information on the appropriate use of each

transfer case mode position see the information below:

AW D

Normal All Wheel Drive High Range - Employs inter-

axle differential. Allows front and rear wheels to rotate at

different speeds. All road surfaces.4HI

4 Wheel Drive High Range - Locks the transfer case

inter-axle differential. Forces front and rear wheels to

rotate at the same speed. Additional traction for loose,

slippery road surfaces only.

4LO

4 Wheel Drive Low Range - Low speed 4 wheel drive.

Locks the transfer case inter-axle differential. Forces the

front and rear wheels to rotate at the same speed.

Additional traction and maximum pulling power for

loose, slippery road surfaces only. Do not exceed 25 mph

(40 km/h).

N

Neutral - Disengages both the front and rear driveshafts

from the powertrain. To be used for flat towing behind

another vehicle. See Recreational Towing for more infor-

mation.

STARTING AND OPERATING 215

5

Page 216 of 392

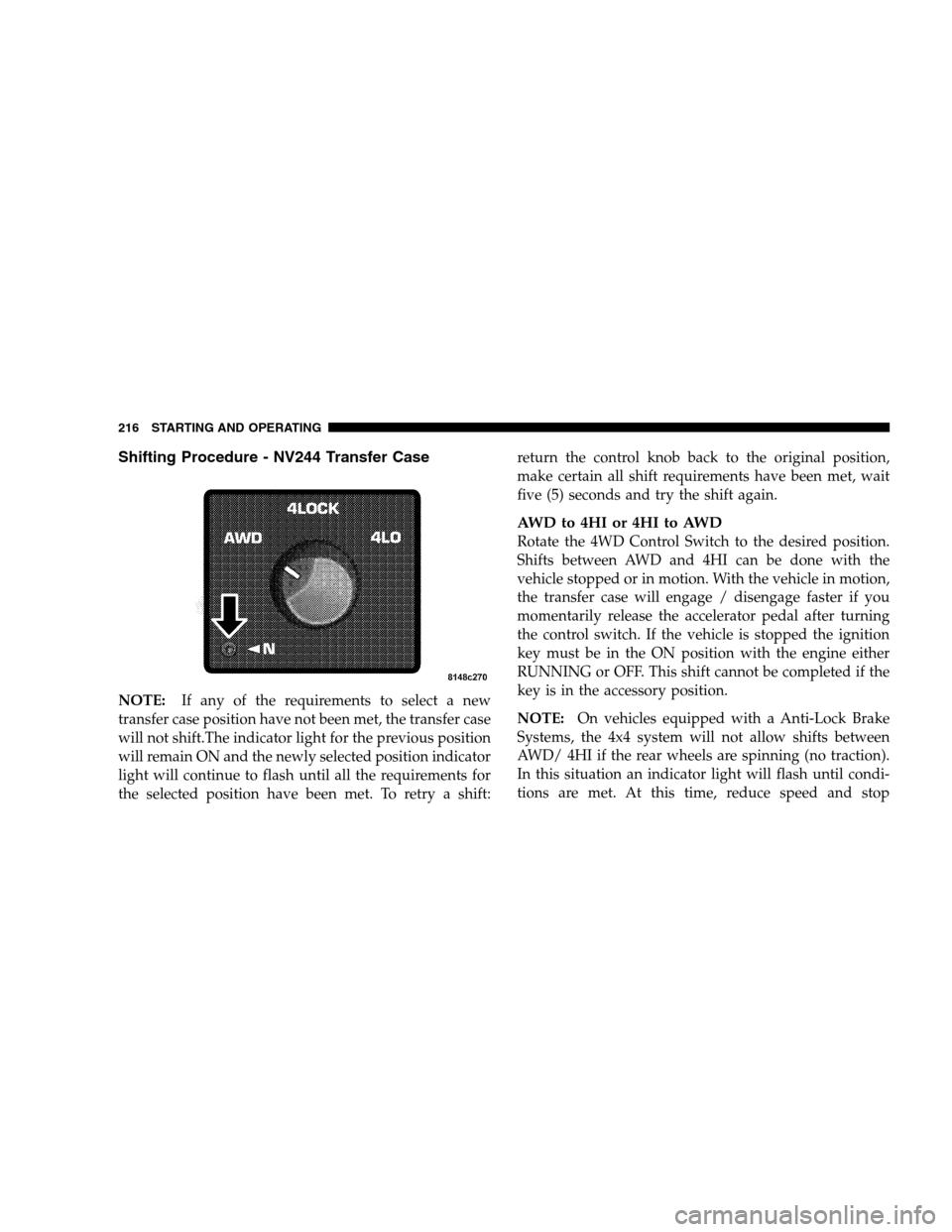

Shifting Procedure - NV244 Transfer Case

NOTE:If any of the requirements to select a new

transfer case position have not been met, the transfer case

will not shift.The indicator light for the previous position

will remain ON and the newly selected position indicator

light will continue to flash until all the requirements for

the selected position have been met. To retry a shift:return the control knob back to the original position,

make certain all shift requirements have been met, wait

five (5) seconds and try the shift again.

AWD to 4HI or 4HI to AWD

Rotate the 4WD Control Switch to the desired position.

Shifts between AWD and 4HI can be done with the

vehicle stopped or in motion. With the vehicle in motion,

the transfer case will engage / disengage faster if you

momentarily release the accelerator pedal after turning

the control switch. If the vehicle is stopped the ignition

key must be in the ON position with the engine either

RUNNING or OFF. This shift cannot be completed if the

key is in the accessory position.

NOTE:On vehicles equipped with a Anti-Lock Brake

Systems, the 4x4 system will not allow shifts between

AWD/ 4HI if the rear wheels are spinning (no traction).

In this situation an indicator light will flash until condi-

tions are met. At this time, reduce speed and stop

216 STARTING AND OPERATING

Page 219 of 392

Care should be taken to avoid sudden accelerations when

both rear wheels are on a slippery surface. This could

cause both rear wheels to spin, and allow the vehicle to

slide sideways on the crowned surface of a road or in a

turn.

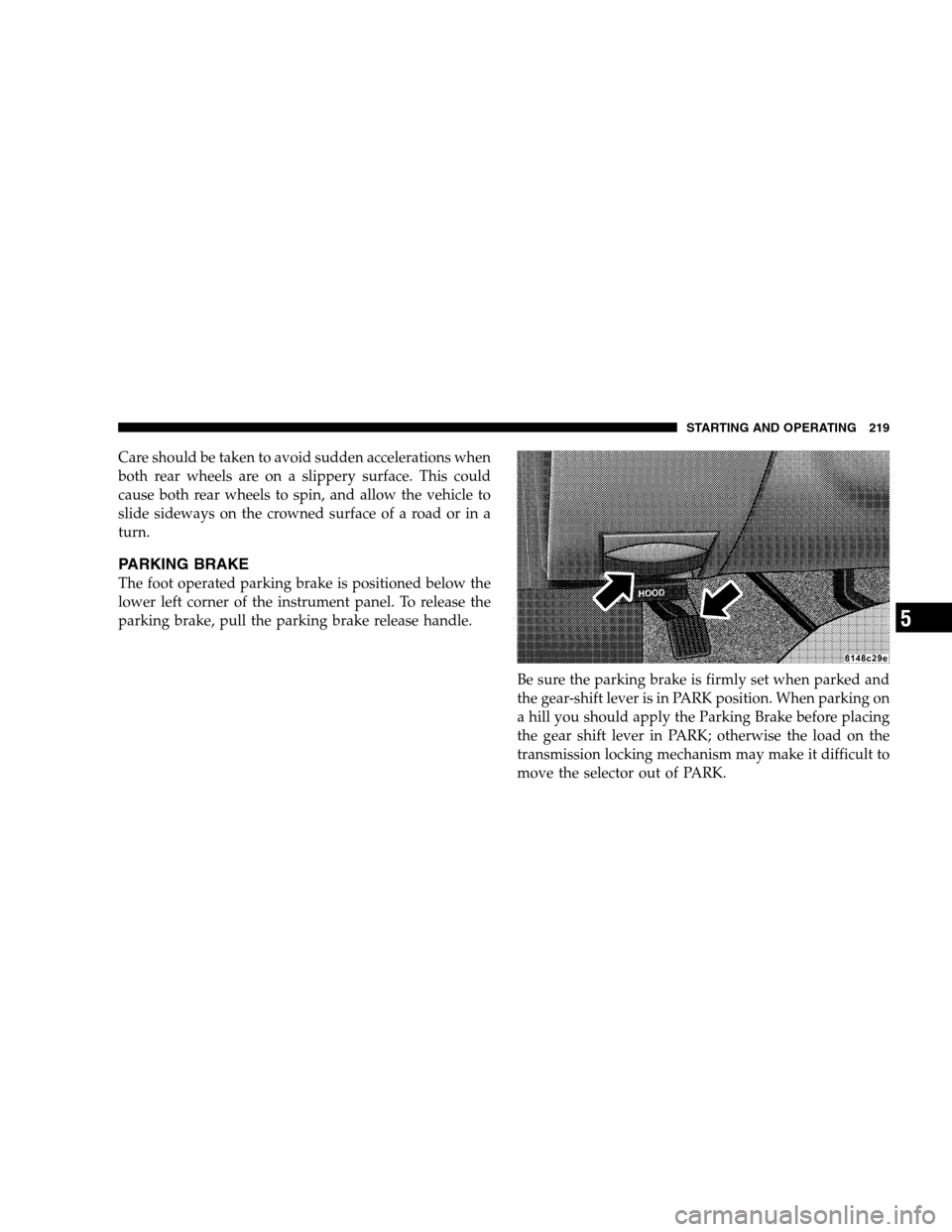

PARKING BRAKE

The foot operated parking brake is positioned below the

lower left corner of the instrument panel. To release the

parking brake, pull the parking brake release handle.

Be sure the parking brake is firmly set when parked and

the gear-shift lever is in PARK position. When parking on

a hill you should apply the Parking Brake before placing

the gear shift lever in PARK; otherwise the load on the

transmission locking mechanism may make it difficult to

move the selector out of PARK.

STARTING AND OPERATING 219

5

Page 221 of 392

BRAKE SYSTEM

In the event power assist is lost for any reason (for

example, repeated brake applications with the engine

off), the brakes will still function. The effort required to

brake the vehicle will be significantly increased over that

required with the power system operating.

If either the front or rear hydraulic system loses normal

capability, the remaining system will still function with

some loss of braking effectiveness. This will be evident by

increased pedal travel during application, greater pedal

force required to slow or stop, and activation of the Brake

Warning light and the ABS light during brake use.

Rear Wheel Anti-Lock Brake System — (If

Equipped)

This Anti-Lock Brake System provides increased vehicle

stability and brake performance under most braking

conditions. The system automatically controls the opera-

tion of the rear brakes to prevent rear wheel lockup.The system remains operational in the four-wheel drive

mode. The level of performance is reduced when the

front brakes are locked up. This will cause the rear brakes

to lock-up through the drivetrain, which may reduce the

effectiveness of the anti-lock system.

During severe braking conditions, particularly with

changing road surfaces, such as ice to concrete, a slight

drop or minor pulsation may be felt in the brake pedal.

WARNING!

Both Anti-Lock Brake Systems contain sophisticated

electronic equipment. It may be susceptible to inter-

ference caused by improperly installed or high out-

put radio transmitting equipment. This interference

can cause possible loss of anti-lock braking capabil-

ity. Installation of such equipment should be done

by qualified professionals.

STARTING AND OPERATING 221

5

Page 222 of 392

Four-Wheel Anti-Lock Brake System — If

Equipped

This Anti-Lock Brake System is designed to aid the driver

in maintaining vehicle control under adverse braking

conditions. The system operates with a separate com-

puter to modulate hydraulic pressure to prevent wheel

lock-up and help avoid skidding on slippery surfaces.

The system’s pump motor runs during an ABS stop to

provide regulated hydraulic pressure. The pump motor

makes a low humming noise during operation, which is

normal.

The Anti-Lock Brake System includes an amber ABS

warning light. When the light is illuminated, the Anti-

Lock Brake System is not functioning. The system reverts

to standard non-anti-lock brakes. Turning the ignition

OFF and ON again may reset the Anti-Lock Brake System

if the fault detected was only momentary.

WARNING!

Pumping of the Anti-Lock Brakes will diminish

their effectiveness and may lead to an accident.

Pumping makes the stopping distance longer. Just

press firmly on your brake pedal when you need to

slow down or stop.

222 STARTING AND OPERATING

Page 223 of 392

WARNING!

•Anti-lock system (ABS) cannot prevent the natu-

ral laws of physics from acting on the vehicle, nor

can it increase braking or steering efficiency be-

yond that afforded by the condition of the vehicle

brakes and tires or the traction afforded.

•The ABS cannot prevent accidents, including

those resulting from excessive speed in turns,

following another vehicle too closely, or hydro-

planing. Only a safe, attentive, and skillful driver

can prevent accidents.

•The capabilities of an ABS equipped vehicle must

never be exploited in a reckless or dangerous

manner which could jeopardize the user’s safety

or the safety of others.

When you are in a severe braking condition involving

use of the Anti-lock Brake System, you will experience

some pedal drop as the vehicle comes to a stop. This is

the result of the system reverting to the base brake

system.

Engagement of the Anti-lock Brake System may be

accompanied by a pulsing sensation. You may also hear a

clicking noise. These occurrences are normal, and indi-

cate that the system is functioning properly.

POWER STEERING

Your power steering system will provide mechanical

steering capability if power assist is lost.

If for any reason the hydraulic pressure is interrupted, it

will still be possible to steer your vehicle. Under these

conditions you will experience an increase in steering

effort and a noticeable amount of “free play” in the

steering wheel.

STARTING AND OPERATING 223

5

Page 266 of 392

6. Using the point of a ballpoint pen or similar object,

depress the recessed transfer case Neutral (N) button for

4 seconds.

7. After shift is completed and the Neutral (N) light

comes on release Neutral (N) button.

8. Start engine.

9. Shift automatic transmission into Reverse (R).

10. Release brake pedal for five seconds and ensure that

there is no vehicle movement.

11. Repeat steps 9 and 10 with the transmission in Drive

(D).

12. Shut engine OFF and place ignition key to the

unlocked OFF position.

13. Shift automatic transmission into Park (P). Shift

Manual transmissions into 4th gear.14. Attach vehicle to tow vehicle with tow bar.

NOTE:Items 1 through 5 are requirements that must be

met prior to depressing the Neutral (N) selection button,

and must continue to be met until the 4 seconds elapses

and the shift has been completed. If any of these require-

ments (with the exception of 3 - Key ON) are not met

prior to depressing the Neutral (N) button or are no

longer met during the 4 second timer, then the Neutral

(N) indicator light will flash continuously until all re-

quirements are met or until the Neutral (N) button is

released.

NOTE:The ignition key must be ON for a shift to take

place and for the position indicator lights to be operable.

If the key in not ON, the shift will not take place and no

position indicator lights will be on or flashing.

NOTE:Flashing neutral (N) position indicator light

indicates that shift requirements have not been met.

266 STARTING AND OPERATING

Page 272 of 392

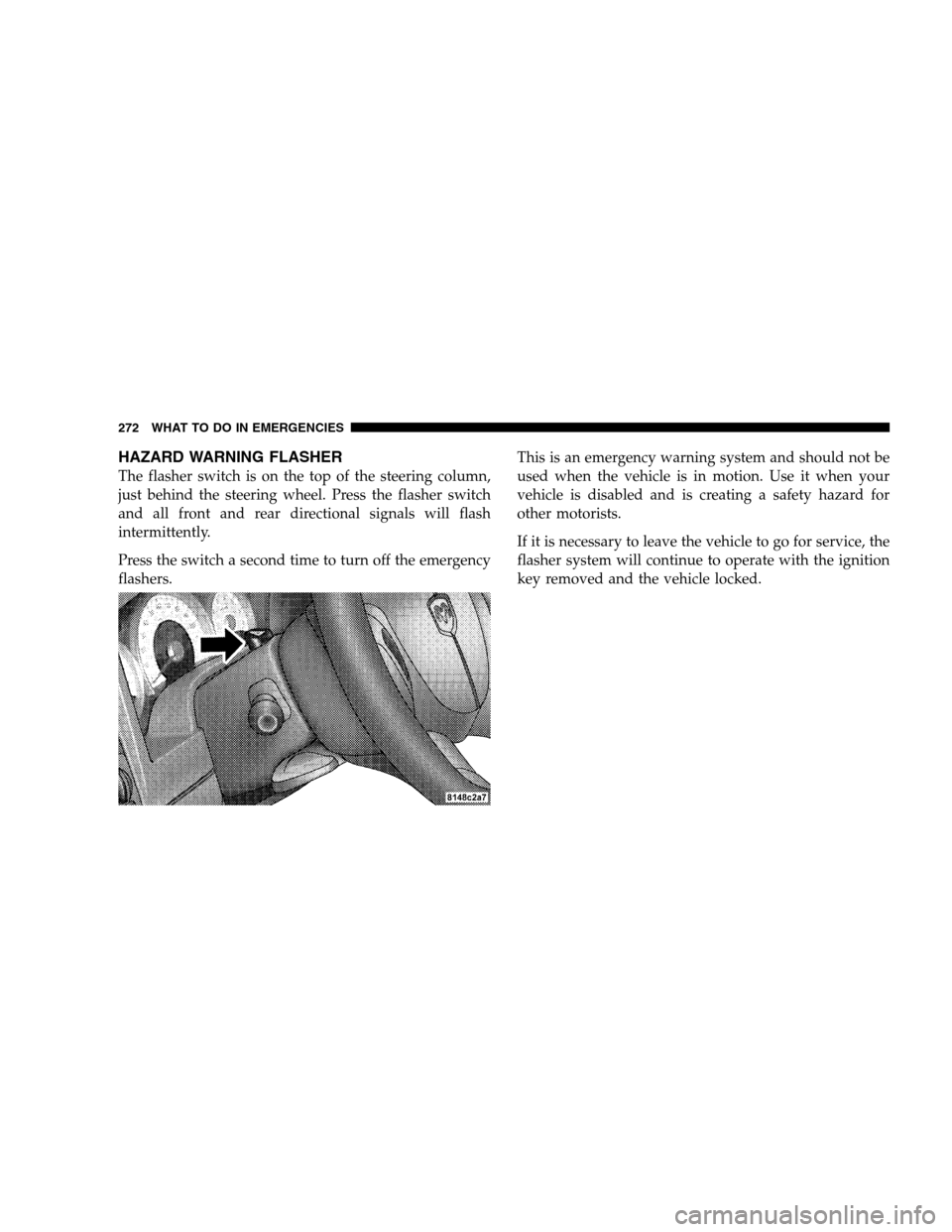

HAZARD WARNING FLASHER

The flasher switch is on the top of the steering column,

just behind the steering wheel. Press the flasher switch

and all front and rear directional signals will flash

intermittently.

Press the switch a second time to turn off the emergency

flashers.This is an emergency warning system and should not be

used when the vehicle is in motion. Use it when your

vehicle is disabled and is creating a safety hazard for

other motorists.

If it is necessary to leave the vehicle to go for service, the

flasher system will continue to operate with the ignition

key removed and the vehicle locked.

272 WHAT TO DO IN EMERGENCIES

Page 276 of 392

WARNING!

The jack is designed as a tool for changing tires only.

The jack should not be used to lift the vehicle for

service purposes, unless suitable supports are placed

under the vehicle as a safety measure. The vehicle

should be jacked on a firm level surface only. Avoid

ice or slippery areas.

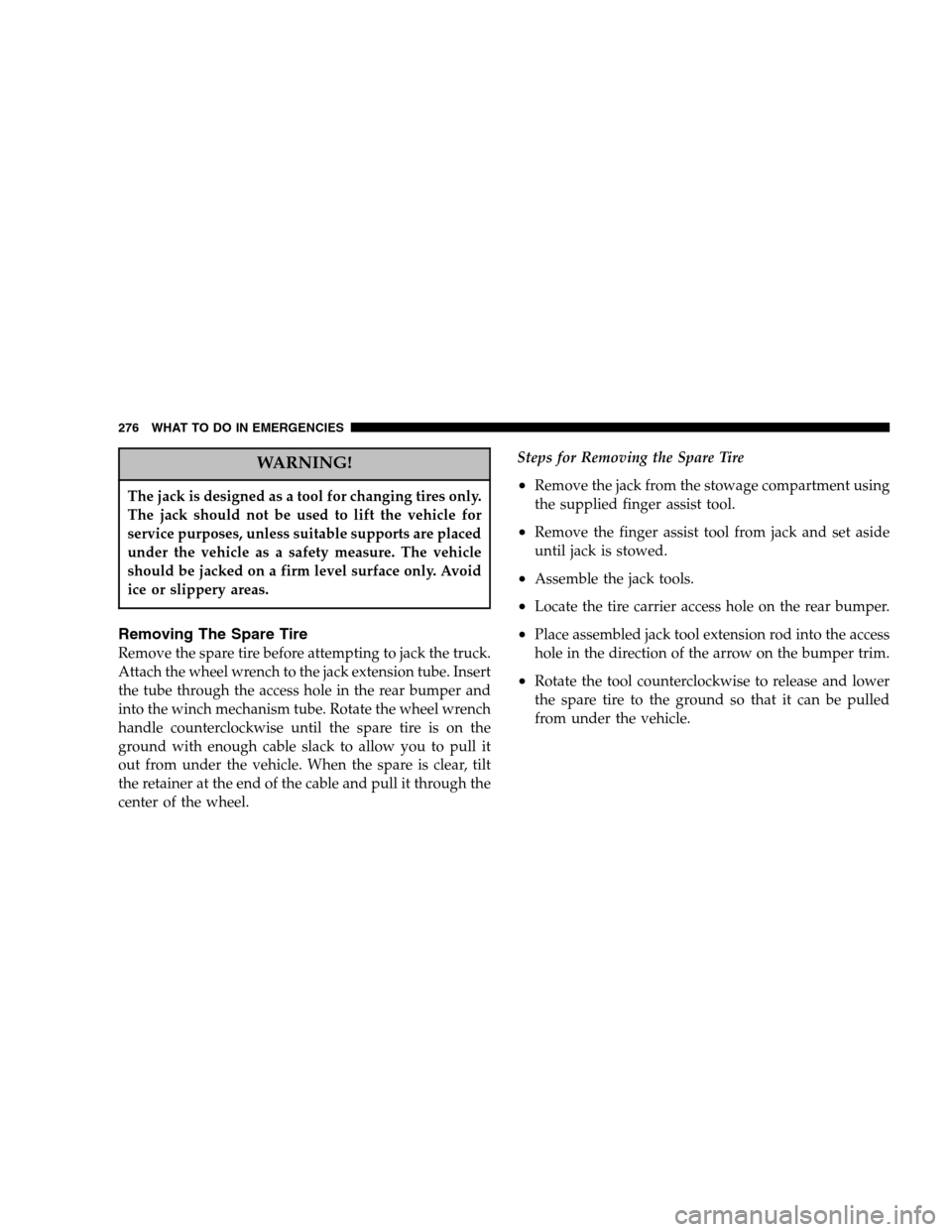

Removing The Spare Tire

Remove the spare tire before attempting to jack the truck.

Attach the wheel wrench to the jack extension tube. Insert

the tube through the access hole in the rear bumper and

into the winch mechanism tube. Rotate the wheel wrench

handle counterclockwise until the spare tire is on the

ground with enough cable slack to allow you to pull it

out from under the vehicle. When the spare is clear, tilt

the retainer at the end of the cable and pull it through the

center of the wheel.Steps for Removing the Spare Tire

•Remove the jack from the stowage compartment using

the supplied finger assist tool.

•Remove the finger assist tool from jack and set aside

until jack is stowed.

•Assemble the jack tools.

•Locate the tire carrier access hole on the rear bumper.

•Place assembled jack tool extension rod into the access

hole in the direction of the arrow on the bumper trim.

•Rotate the tool counterclockwise to release and lower

the spare tire to the ground so that it can be pulled

from under the vehicle.

276 WHAT TO DO IN EMERGENCIES

Page 277 of 392

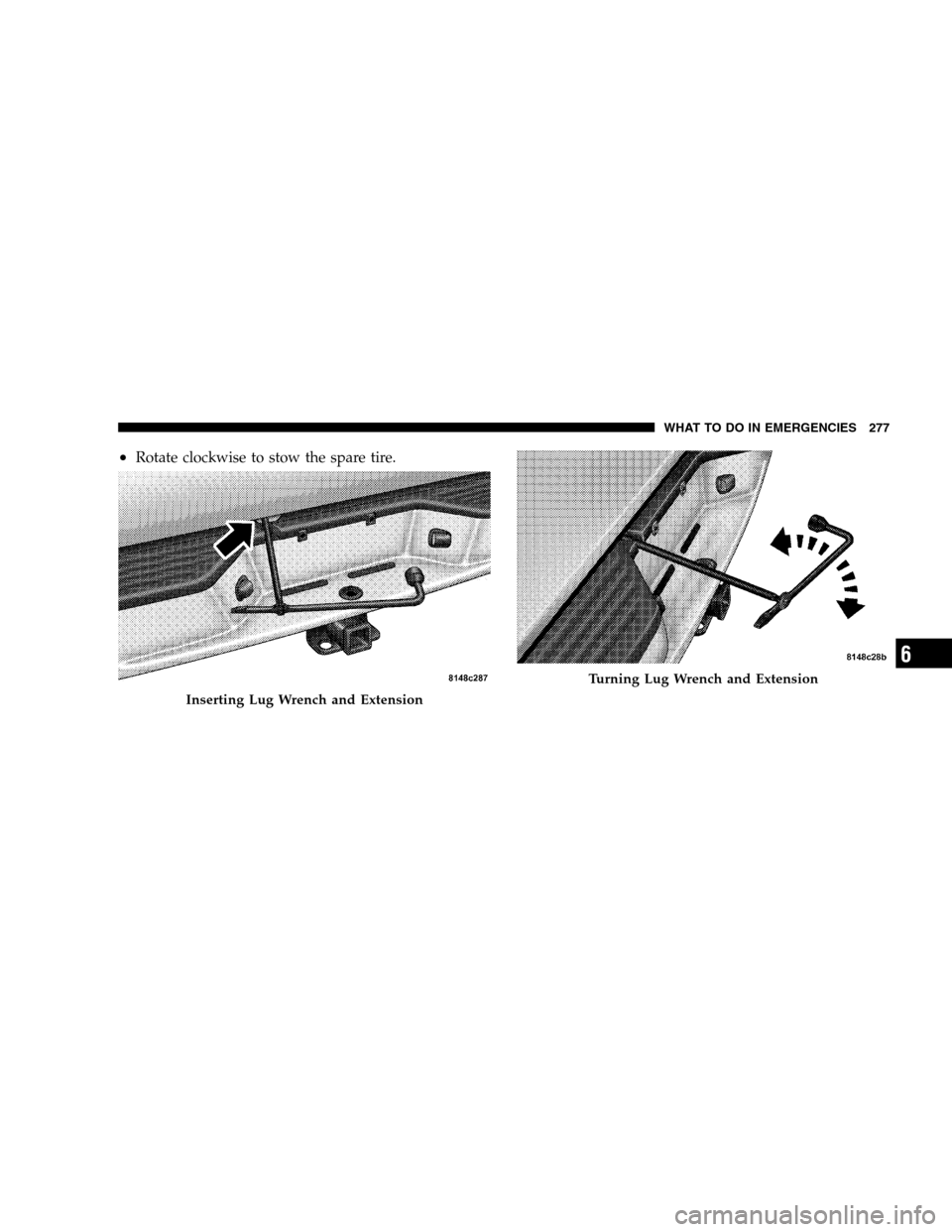

•Rotate clockwise to stow the spare tire.

Inserting Lug Wrench and Extension

Turning Lug Wrench and Extension

WHAT TO DO IN EMERGENCIES 277

6