DODGE DAKOTA 2009 3.G Owners Manual

Manufacturer: DODGE, Model Year: 2009, Model line: DAKOTA, Model: DODGE DAKOTA 2009 3.GPages: 449, PDF Size: 10.96 MB

Page 271 of 449

When parking on a hill, turn the front wheels toward the

curb on a downhill grade and away from the curb on an

uphill grade.

The parking brake should be applied whenever the

driver is not in the vehicle.

BRAKE SYSTEM

In the event power assist is lost for any reason (for

example, repeated brake applications with the engine

off), the brakes will still function. The effort required to

brake the vehicle will be significantly more than that

required with the power system operating.

If either the front or rear hydraulic system loses normal

capability, the remaining system will still function with

some loss of braking effectiveness. This will be evident by

increased pedal travel during application, greater pedal

force required to slow or stop, and activation of the Brake

Warning light and the ABS light during brake use.

Rear-Wheel Anti-Lock Brake System (ABS) ± If

Equipped

The Rear-Wheel ABS provides increased vehicle stability

and brake performance under most braking conditions.

The system automatically controls the operation of the

rear brakes to prevent rear wheel lockup.

The ABS remains operational in the 4-wheel drive mode.

The level of performance is reduced when the front

brakes are locked up. This will cause the rear brakes to

lock-up through the drivetrain, which may reduce the

effectiveness of the anti-lock system.

During severe braking conditions, particularly with

changing road surfaces, such as ice to concrete, a slight

drop or minor pulsation may be felt in the brake pedal.

STARTING AND OPERATING 269

5

Page 272 of 449

WARNING!

Both Anti-Lock Brake Systems contain sophisticated

electronic equipment. It may be susceptible to inter-

ference caused by improperly installed or high out-

put radio transmitting equipment. This interference

can cause possible loss of anti-lock braking capabil-

ity. Installation of such equipment should be done by

qualified professionals.

Four-Wheel Anti-Lock Brake System (ABS)

4-Wheel ABS is designed to aid the driver in maintaining

vehicle control under adverse braking conditions. The

system operates with a separate computer to modulate

hydraulic pressure, to prevent wheel lock-up and help

avoid skidding on slippery surfaces.The system's pump motor runs during an ABS stop to

provide regulated hydraulic pressure. The pump motor

makes a low humming noise during operation, which is

normal.

The ABS includes an amber ABS warning light. When the

light is illuminated, the ABS is not functioning. The

system reverts to standard non-anti-lock brakes. Turning

the ignition OFF and ON again may reset the ABS if the

fault detected was only momentary.WARNING!

Pumping of the Anti-Lock Brakes will diminish their

effectiveness and may lead to an accident. Pumping

makes the stopping distance longer. Just press firmly

on your brake pedal when you need to slow down or

stop.

270 STARTING AND OPERATING

Page 273 of 449

WARNING!

²Anti-Lock Brake Systems (ABS) cannot prevent

the natural laws of physics from acting on the

vehicle, nor can it increase braking or steering

efficiency beyond that afforded by the condition

of the vehicle brakes and tires or the traction

afforded.

²The ABS cannot prevent accidents, including

those resulting from excessive speed in turns,

following another vehicle too closely, or hydro-

planing. Only a safe, attentive, and skillful driver

can prevent accidents.

²The capabilities of an ABS-equipped vehicle must

never be exploited in a reckless or dangerous

manner, which could jeopardize the user's safety

or the safety of others.When you are in a severe braking condition involving

use of the ABS, you will experience some pedal drop as

the vehicle comes to a stop. This is the result of the

system reverting to the base brake system.

Engagement of the ABS may be accompanied by a

pulsing sensation. You may also hear a clicking noise.

These occurrences are normal, and indicate that the

system is functioning properly.

STARTING AND OPERATING 271

5

Page 274 of 449

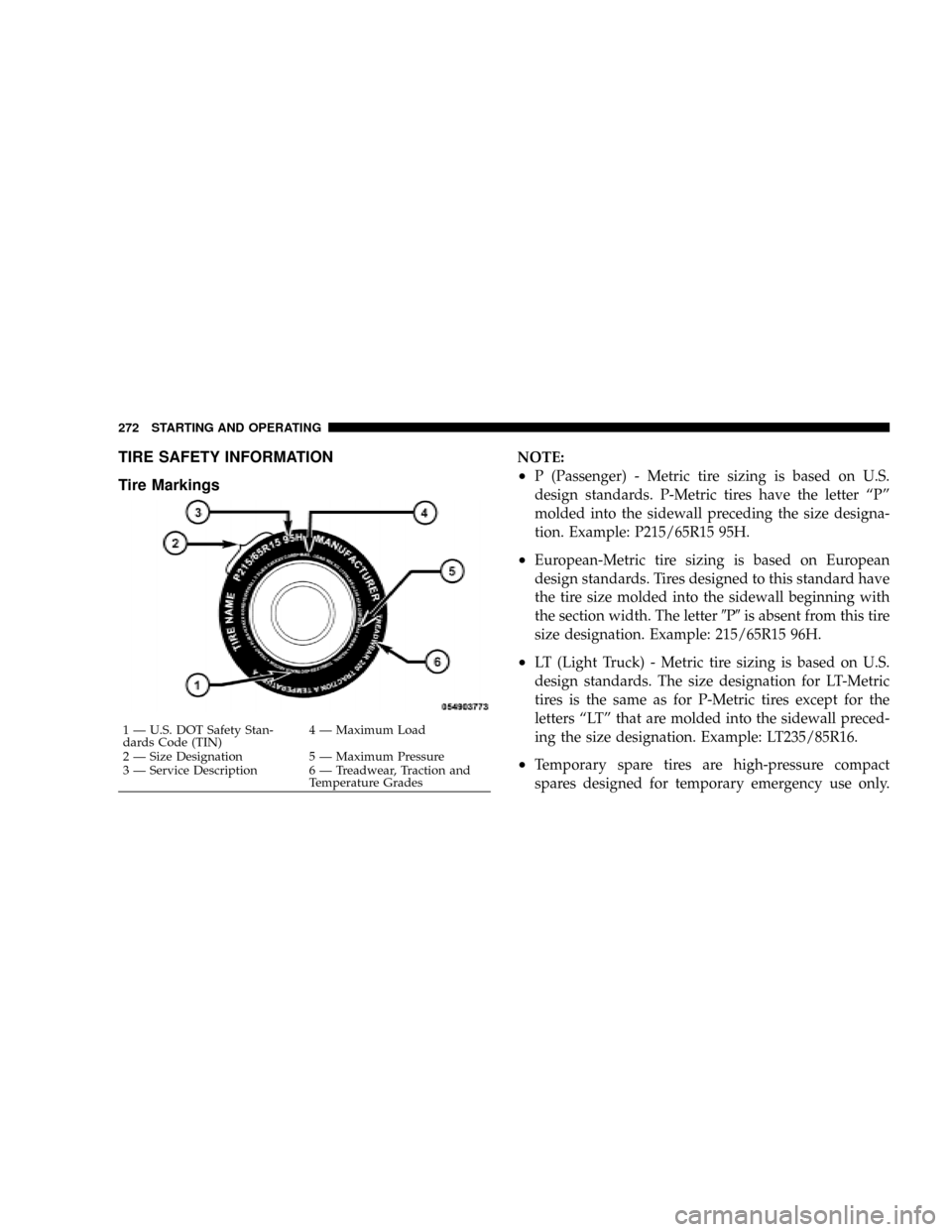

TIRE SAFETY INFORMATION

Tire MarkingsNOTE:

²P (Passenger) - Metric tire sizing is based on U.S.

design standards. P-Metric tires have the letter ªPº

molded into the sidewall preceding the size designa-

tion. Example: P215/65R15 95H.

²European-Metric tire sizing is based on European

design standards. Tires designed to this standard have

the tire size molded into the sidewall beginning with

the section width. The letter9P9is absent from this tire

size designation. Example: 215/65R15 96H.

²LT (Light Truck) - Metric tire sizing is based on U.S.

design standards. The size designation for LT-Metric

tires is the same as for P-Metric tires except for the

letters ªLTº that are molded into the sidewall preced-

ing the size designation. Example: LT235/85R16.

²Temporary spare tires are high-pressure compact

spares designed for temporary emergency use only.

1 Ð U.S. DOT Safety Stan-

dards Code (TIN)4 Ð Maximum Load

2 Ð Size Designation 5 Ð Maximum Pressure

3 Ð Service Description 6 Ð Treadwear, Traction and

Temperature Grades 272 STARTING AND OPERATING

Page 275 of 449

Tires designed to this standard have the letter ªTº

molded into the sidewall preceding the size designa-

tion. Example: T145/80D18 103M.²High flotation tire sizing is based on U.S. design

standards, and it begins with the tire diameter molded

into the sidewall. Example: 31x10.5 R15 LT.

Tire Sizing Chart

EXAMPLE:

Size Designation:

P= Passenger Car tire size based on U.S. design standards

(....blank....(= Passenger Car tire based on European design standards

LT= Light Truck tire based on U.S. design standards

T= Temporary spare tire

31= Overall diameter in inches (in)

215= Section width in millimeters (mm)

65= Aspect ratio in percent (%)

Ð Ratio of section height to section width of tire

10.5= Section width in inches (in)

R= Construction code

Ð9R9means radial construction

Ð9D9means diagonal or bias construction

STARTING AND OPERATING 273

5

Page 276 of 449

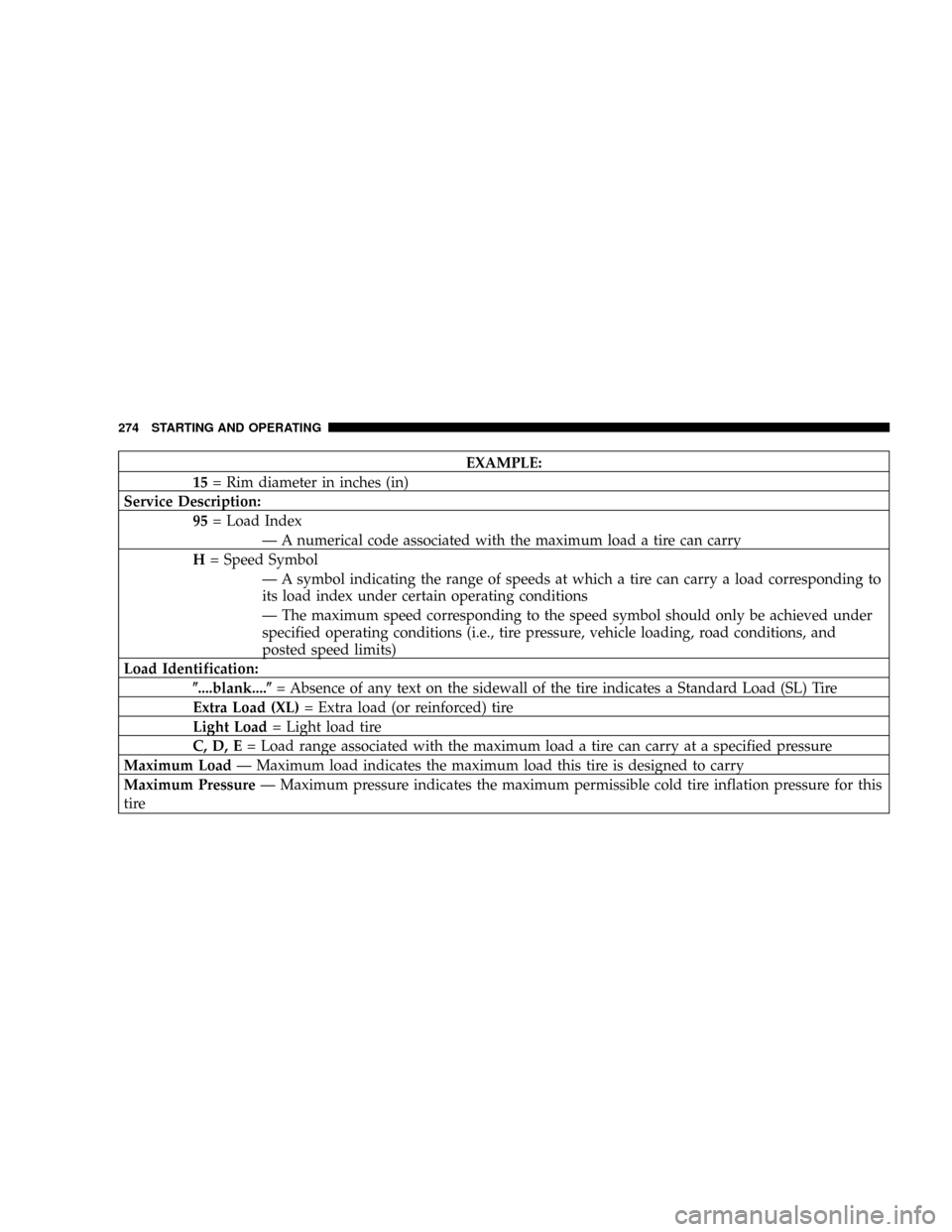

EXAMPLE:

15= Rim diameter in inches (in)

Service Description:

95= Load Index

Ð A numerical code associated with the maximum load a tire can carry

H= Speed Symbol

Ð A symbol indicating the range of speeds at which a tire can carry a load corresponding to

its load index under certain operating conditions

Ð The maximum speed corresponding to the speed symbol should only be achieved under

specified operating conditions (i.e., tire pressure, vehicle loading, road conditions, and

posted speed limits)

Load Identification:

(....blank....(= Absence of any text on the sidewall of the tire indicates a Standard Load (SL) Tire

Extra Load (XL)= Extra load (or reinforced) tire

Light Load= Light load tire

C, D, E= Load range associated with the maximum load a tire can carry at a specified pressure

Maximum LoadÐ Maximum load indicates the maximum load this tire is designed to carry

Maximum PressureÐ Maximum pressure indicates the maximum permissible cold tire inflation pressure for this

tire

274 STARTING AND OPERATING

Page 277 of 449

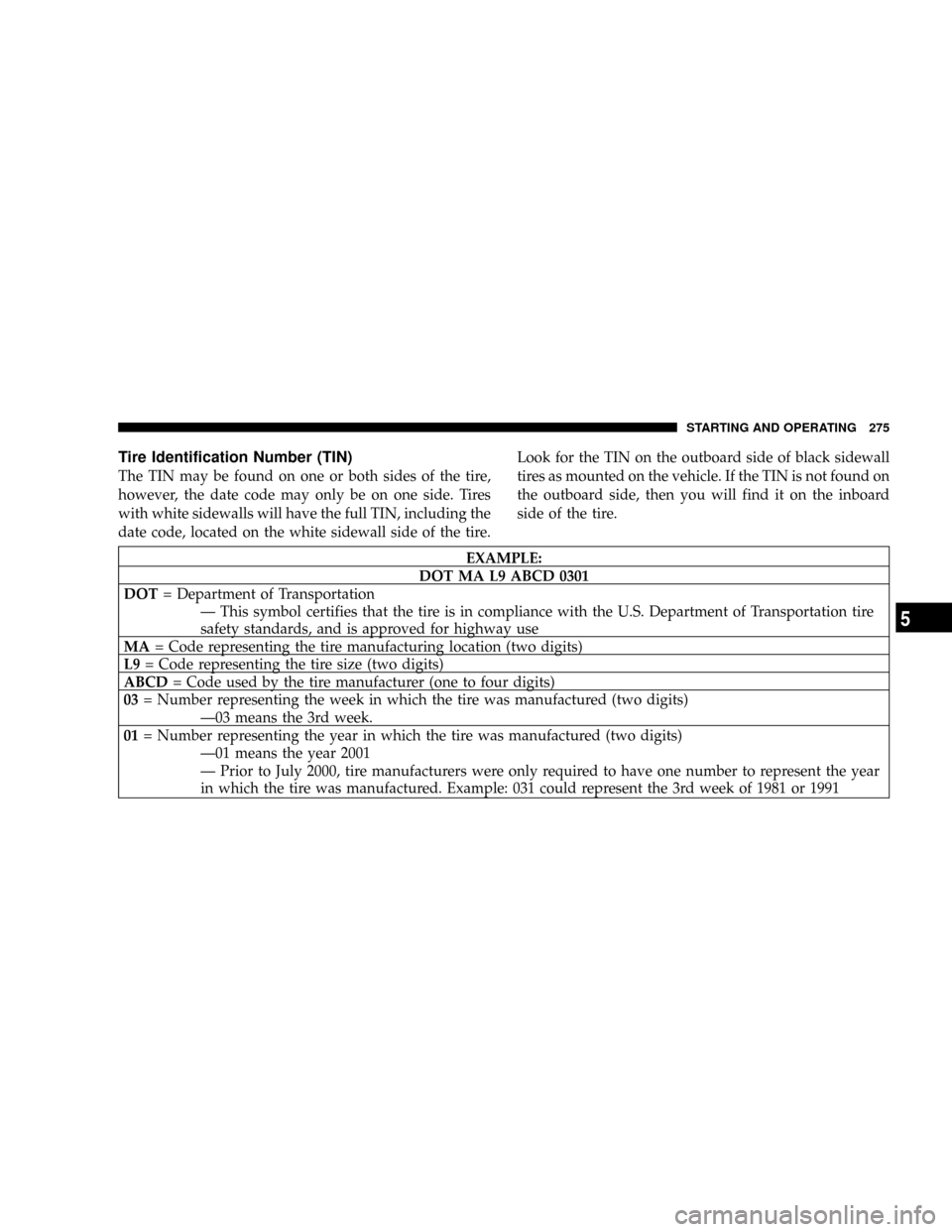

Tire Identification Number (TIN)

The TIN may be found on one or both sides of the tire,

however, the date code may only be on one side. Tires

with white sidewalls will have the full TIN, including the

date code, located on the white sidewall side of the tire.Look for the TIN on the outboard side of black sidewall

tires as mounted on the vehicle. If the TIN is not found on

the outboard side, then you will find it on the inboard

side of the tire.

EXAMPLE:

DOT MA L9 ABCD 0301

DOT= Department of Transportation

Ð This symbol certifies that the tire is in compliance with the U.S. Department of Transportation tire

safety standards, and is approved for highway use

MA= Code representing the tire manufacturing location (two digits)

L9= Code representing the tire size (two digits)

ABCD= Code used by the tire manufacturer (one to four digits)

03= Number representing the week in which the tire was manufactured (two digits)

Ð03 means the 3rd week.

01= Number representing the year in which the tire was manufactured (two digits)

Ð01 means the year 2001

Ð Prior to July 2000, tire manufacturers were only required to have one number to represent the year

in which the tire was manufactured. Example: 031 could represent the 3rd week of 1981 or 1991

STARTING AND OPERATING 275

5

Page 278 of 449

Tire Loading and Tire Pressure

Tire Placard Location

NOTE:The proper cold tire inflation pressure is listed

on either the face of the driver's door or the driver's side

B-Pillar.

Tire and Loading Information Placard

This placard tells you important information about

the:

1) number of people that can be carried in the vehicle

2) total weight your vehicle can carry

Tire and Loading Information Placard

276 STARTING AND OPERATING

Page 279 of 449

3) tire size designed for your vehicle

4) cold tire inflation pressures for the front, rear, and

spare tires.

Loading

The vehicle maximum load on the tire must not exceed

the load carrying capacity of the tire on your vehicle. You

will not exceed the tire's load carrying capacity if you

adhere to the loading conditions, tire size, and cold tire

inflation pressures specified on the Tire and Loading

Information placard and in the ªVehicle Loadingº section

of this manual.

NOTE:Under a maximum loaded vehicle condition,

gross axle weight ratings (GAWRs) for the front and rear

axles must not be exceeded. For further information on

GAWRs, vehicle loading, and trailer towing, refer to

ªVehicle Loadingº in this section.

To determine the maximum loading conditions of your

vehicle, locate the statement ªThe combined weight ofoccupants and cargo should never exceed XXX kg or XXX

lbs.º on the Tire and Loading Information placard. The

combined weight of occupants, cargo/luggage and

trailer tongue weight (if applicable) should never exceed

the weight referenced here.

Steps for Determining Correct Load Limit

1. Locate the statement ªThe combined weight of occu-

pants and cargo should never exceed XXX kg or XXX lbsº

on your vehicle's placard.

2. Determine the combined weight of the driver and

passengers that will be riding in your vehicle.

3. Subtract the combined weight of the driver and pas-

sengers from XXX kg or XXX lbs.

4. The resulting figure equals the available amount of

cargo and luggage load capacity. For example, if ªXXXº

amount equals 1,400 lbs (635 kg) and there will be five

150 lb (68 kg) passengers in your vehicle, the amount of

STARTING AND OPERATING 277

5

Page 280 of 449

![DODGE DAKOTA 2009 3.G Owners Manual available cargo and luggage load capacity is 650 lbs

(295 kg) (since 5 x 150 = 750, and 1400 ± 750 = 650 lbs

[295 kg]).

5. Determine the combined weight of luggage and cargo

being loaded on the vehic DODGE DAKOTA 2009 3.G Owners Manual available cargo and luggage load capacity is 650 lbs

(295 kg) (since 5 x 150 = 750, and 1400 ± 750 = 650 lbs

[295 kg]).

5. Determine the combined weight of luggage and cargo

being loaded on the vehic](/img/12/5591/w960_5591-279.png)

available cargo and luggage load capacity is 650 lbs

(295 kg) (since 5 x 150 = 750, and 1400 ± 750 = 650 lbs

[295 kg]).

5. Determine the combined weight of luggage and cargo

being loaded on the vehicle. That weight may not safely

exceed the available cargo and luggage load capacity

calculated in Step 4.

6. If your vehicle will be towing a trailer, load from your

trailer will be transferred to your vehicle. Consult this

manual to determine how this reduces the available

cargo and luggage load capacity of your vehicle.NOTE:

²The following table shows examples on how to calcu-

late total load, cargo/luggage, and towing capacities

of your vehicle with varying seating configurations

and number and size of occupants. This table is for

illustration purposes only and may not be accurate for

the seating and load carry capacity of your vehicle.

²For the following example, the combined weight of

occupants and cargo should never exceed 865 lbs

(392 kg).

278 STARTING AND OPERATING