ignition DODGE DART 2013 PF / 1.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2013, Model line: DART, Model: DODGE DART 2013 PF / 1.GPages: 132, PDF Size: 4.13 MB

Page 85 of 132

- Anti-Lock Brake (ABS) Light

• This light monitors the Anti-Lock Brake System (ABS).

• If the light is not on during starting, stays on, or turns on while driving, we recommend you drive to the nearest authorized dealer immediately and have the vehicle serviced

immediately.

- Electronic Throttle Control (ETC) Indicator Light

• This light informs you of a problem with the system.

• If a problem is detected, the light will come on while the engine is running. Cycle the ignition when the vehicle has completely stopped and the shift lever is placed in the

PARK position; the light should turn off.

• If the light remains lit with the engine running, your vehicle will usually be drivable; however, see an authorized dealer immediately. If the light is flashing when the engine is

running, immediate service is required and you may experience reduced performance,

an elevated/rough idle or engine stall and your vehicle may require towing.

- Air Bag Warning Light

• If the light is not on during starting, stays on, or turns on while driving, have the vehicle serviced by an authorized dealer immediately.

Fuel Cap/Loose Gas Cap Message

• If a “gas cap” message (shown as gASCAP) appears, tighten the gas cap until a “clicking” sound is heard.

• Press the odometer reset button to turn the message off.

• If the message continues to appear for more than three days after tightening the gas cap, see your authorized service center.

Oil Change Indicator

• Your vehicle is equipped with an engine oil change indicator system. The “Oil Change Due” message will flash in the EVIC display for approximately 10 seconds after a single

chime has sounded, to indicate the next scheduled oil change interval. The engine oil

change indicator system is duty cycle based, which means the engine oil change interval

may fluctuate, dependent upon your personal driving style

• Unless reset, this message will continue to display each time you turn the ignition switch to the ON/RUN position or cycle the ignition to the ON/RUN position if equipped with

Keyless Enter-N-Go™. To turn off the message temporarily, press and release the MENU

button. To reset the oil change indicator system (after performing the scheduled main-

tenance) refer to the following procedure.

WHAT TO DO IN EMERGENCIES

83

Page 86 of 132

Vehicles Equipped With Keyless Enter-N-Go™

1. Without pressing the brake pedal, cycle the ignition to the ON/RUN position (do not startthe engine).

2. Fully depress the accelerator pedal, slowly, three times within 10 seconds.

3. Cycle the ignition to the OFF/LOCK position.

Vehicles Not Equipped With Keyless Enter-N-Go™

1. Turn the ignition switch to the ON/RUN position (do not start the engine).

2. Fully depress the accelerator pedal, slowly, three times within 10 seconds.

3. Turn the ignition switch to the OFF/LOCK position.

NOTE:

If the indicator message illuminates when you start the vehicle, the oil change indicator

system did not reset. If necessary, repeat this procedure.

Resetting The Light After Servicing

• Vehicles Equipped With Keyless Enter-N-Go™

• Without pressing the brake pedal, push the ENGINE START/STOP button and cycle the ignition to the ON/RUN position (Do not start the engine.)

• Fully depress the accelerator pedal, slowly, three times within 10 seconds.

• Without pressing the brake pedal, push the ENGINE START/STOP button once to return the ignition to the OFF/LOCK position.

• Vehicles Not Equipped With Keyless Enter-N-Go™

• Turn the ignition switch to the ON/RUN position (Do not start the engine.)

• Fully depress the accelerator pedal, slowly, three times within 10 seconds.

• Turn the ignition switch to the OFF/LOCK position.

WHAT TO DO IN EMERGENCIES

84

Page 89 of 132

Preparations For Jacking

1. Park the vehicle on a firm, level surface as far from the edge of the roadway as possible.Avoid icy or slippery areas.

2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Place the shift lever into PARK.

5. Turn OFF the ignition.

6. Block the front and rear of the wheel diagonally opposite of the jacking position. For example, if changing the right front tire,

block the left rear wheel.

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.

Jacking And Changing A Tire

1. Remove the spare tire, jack, and wheel bolt wrench.

2.

If equipped with aluminum wheels where

the center cap covers the wheel bolts, use

the wheel bolt wrench to pry the center cap

off carefully before raising the vehicle.

3. Before raising the vehicle, use the wheel bolt wrench to loosen, but not remove,

the wheel bolts on the wheel with the flat

tire. Turn the wheel bolts counterclock-

wise one turn while the wheel is still on

the ground.

WHAT TO DO IN EMERGENCIES

87

Page 95 of 132

TIREFIT Usage Precautions

• Replace the TIREFIT Sealant Bottle (1) and Sealant Hose (6) prior to the expiration date(printed on the bottle label) to assure optimum operation of the system. Refer to “Sealing

a Tire with TIREFIT” section (F) “Sealant Bottle and Hose Replacement”.

• The Sealant Bottle (1) and Sealant Hose (6) are a one tire application use. After each use, always replace these components immediately at an authorized dealer.

• When the TIREFIT sealant is in a liquid form, clean water, and a damp cloth will remove the material from the vehicle or tire and wheel components. Once the sealant dries, it can

easily be peeled off and properly discarded.

• For optimum performance, make sure the valve stem on the wheel is free of debris before connecting the TIREFIT kit.

• You can use the TIREFIT air pump to inflate bicycle tires. The kit also comes with two needles, located in the Accessory Storage Compartment (on the bottom of the air pump)

for inflating sport balls, rafts, or similar inflatable items. However, use only the Air Pump

Hose (7) and make sure the Mode Select Knob (5) is in the Air Mode when inflating such

items to avoid injecting sealant into them. The TIREFIT Sealant is only intended to seal

punctures less than 1/4 in (6 mm) diameter in the tread of your vehicle.

• Do not lift or carry the TIREFIT kit by the hoses.

Sealing A Tire With TIREFIT

(A) Whenever You Stop To Use TIREFIT:

1. Pull over to a safe location and turn on the vehicle’s Hazard Warning flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near to the ground. This will allow the TIREFIT Hoses (6) and (7) to reach the valve stem and

keep the TIREFIT kit flat on the ground. This will provide the best positioning of the kit

when injecting the sealant into the deflated tire and running the air pump. Move the

vehicle as necessary to place the valve stem in this position before proceeding.

3. Place the transmission in PARK (auto transmission) or in Gear (manual transmission) and cycle the ignition to the OFF position.

4. Set the parking brake.

(B) Setting Up To Use TIREFIT:

1. Turn the Mode Select Knob (5) to the Sealant Mode position.

2. Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end of the hose.

3. Place the TIREFIT kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the Sealant Hose (6) onto the valve stem.

5. Uncoil the Power Plug (8) and insert the plug into the vehicle’s 12 Volt power outlet.

6. Do not remove foreign objects (e.g., screws or nails) from the tire.

WHAT TO DO IN EMERGENCIES

93

Page 100 of 132

JUMP-STARTING

• If your vehicle has a discharged battery itcan be jump-started using a set of jumper

cables and a battery in another vehicle or

by using a portable battery booster pack.

• Jump-starting can be dangerous if done improperly so please follow the proce-

dures in this section carefully.

NOTE:

When using a portable battery booster pack

follow the manufacturer’s operating instruc-

tions and precautions.

Preparations for Jump-Start

• The battery in your vehicle is located in the front of the engine compartment, be-

hind the left headlight assembly.

NOTE:

The positive battery post is covered with a protective cap. Lift up on the cap to gain access

to the positive battery post.

• Set the parking brake, shift the automatic transmission into PARK (manual transmission in NEUTRAL) and turn the ignition to LOCK.

• Turn off the heater, radio, and all unnecessary electrical accessories.

• If using another vehicle to jump-start the battery, park the vehicle within the jumper cables reach, set the parking brake and make sure the ignition is OFF.

Jump-Starting Procedure

1. Connect the positive (+) end of the jumper cable to the remote positive (+) post of the discharged vehicle.

2. Connect the opposite end of the positive (+) jumper cable to the positive (+) post of the booster battery.

3. Connect the negative end (-) of the jumper cable to the negative (-) post of the booster battery.

4. Connect the opposite end of the negative (-) jumper cable to the remote negative (-) post of the vehicle with the discharged battery.

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few minutes, and then start the engine in the vehicle with the discharged battery.

Once the engine is started, remove the jumper cables in the reverse sequence:

1. Disconnect the negative (-) jumper cable from the remote negative (-) post of the vehicle with the discharged battery.

WHAT TO DO IN EMERGENCIES

98

Page 101 of 132

2. Disconnect the negative end (-) of the jumper cable from the negative (-) post of thebooster battery.

3. Disconnect the opposite end of the positive (+) jumper cable from the positive (+) post of the booster battery.

4. Disconnect the positive (+) end of the jumper cable from the remote positive (+) post of the discharged vehicle.

5. If frequent jump-starting is required to start your vehicle you should have the battery and charging system inspected at your authorized dealer.

CAUTION!

• Do not use a portable battery booster pack or any other booster source with a system voltage greater than 12 Volts or damage to the battery, starter motor, alternator or

electrical system may occur.

• Failure to follow these procedures could result in damage to the charging system of the booster vehicle or the discharged vehicle.

• Accessories that can be plugged into the vehicle power outlets draw power from the vehicle’s battery, even when not in use (i.e., cellular phones, etc.). Eventually, if

plugged in long enough, the vehicle’s battery discharges sufficiently to degrade

battery life and/or prevent the engine from starting.

WARNING!

• When temperatures are below the freezing point, electrolyte in a discharged batterymay freeze. Do not attempt jump-starting because the battery could rupture or

explode and cause personal injury. Battery temperature must be brought above

freezing point before attempting a jump-start.

• Take care to avoid the radiator cooling fan whenever the hood is raised. It can start anytime the ignition switch is on. You can be injured by moving fan blades.

• Remove any metal jewelry, such as watch bands or bracelets, that might make an

inadvertent electrical contact. You could be severely injured.

• Batteries contain sulfuric acid that can burn your skin or eyes and generate hydrogen

gas which is flammable and explosive. Keep open flames or sparks away from the

battery.

• Do not allow vehicles to touch each other as this could establish a ground connection and personal injury could result.

• Failure to follow this procedure could result in personal injury or property damage due to battery explosion.

• Do not connect the cable to the negative post (-)of the discharged battery. The

resulting electrical spark could cause the battery to explode and could result in

personal injury.

WHAT TO DO IN EMERGENCIES

99

Page 102 of 132

SHIFT LEVER OVERRIDE

• If a malfunction occurs and the shift levercannot be moved out of the PARK posi-

tion, you can use the following procedure

to temporarily move the shift lever:• Turn the ignition switch to the OFF posi-

tion.

• Firmly set the parking brake.

•

Remove the rubber storage tray liner

from the center console, then lift up the

front of the shift lever bezel, carefully

disengage the bezel from the shift lever

housing, and slide it up to the top of the

shift lever.

• Press and maintain firm pressure on the brake pedal.

• Insert a small screwdriver or similar tool down into the access slot at the front of the shift lever assembly, and push and hold the

white override release lever down.

• Move the shift lever into the NEUTRAL position.

• The vehicle may then be started in NEUTRAL.

• Reinstall the shift lever bezel (use care to avoid pinching the wiring), and the rubber storage tray liner.

TOWING A DISABLED VEHICLE

Towing Condition Wheels OFF The

Ground AUTOMATIC TRANS-

MISSION MANUAL TRANSMIS-

SION

Flat Tow NONE

NOT ALLOWED Transmission in

NEUTRAL

Wheel Lift or Dolly To w Rear

NOT ALLOWED NOT ALLOWED

Front NOT ALLOWED NOT ALLOWED

Flatbed ALL

BEST METHOD BEST METHOD

WHAT TO DO IN EMERGENCIES

100

Page 119 of 132

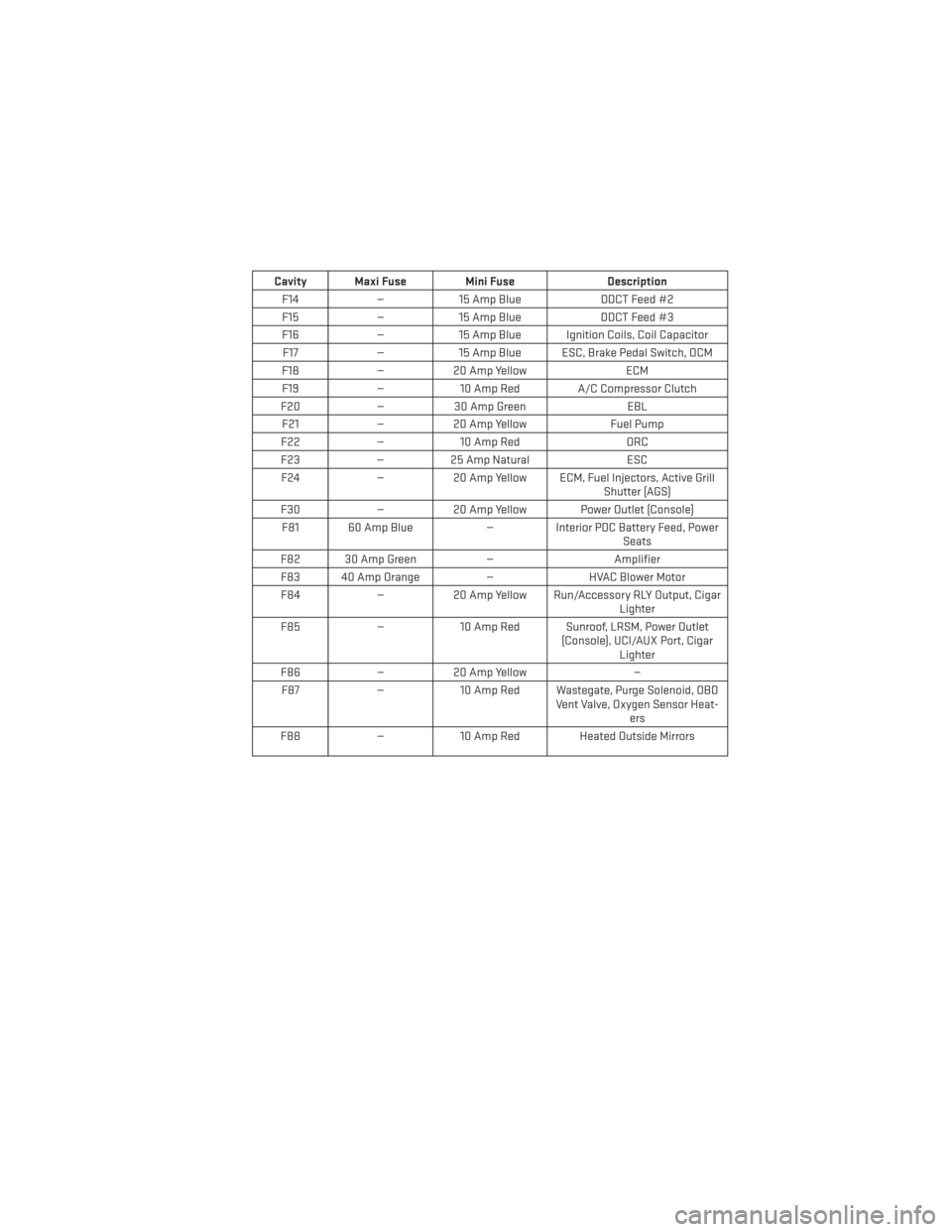

Cavity Maxi Fuse Mini FuseDescription

F14 —15 Amp Blue DDCT Feed #2

F15 —15 Amp Blue DDCT Feed #3

F16 —15 Amp Blue Ignition Coils, Coil Capacitor

F17 —15 Amp Blue ESC, Brake Pedal Switch, OCM

F18 —20 Amp Yellow ECM

F19 —10 Amp Red A/C Compressor Clutch

F20 —30 Amp Green EBL

F21 —20 Amp Yellow Fuel Pump

F22 —10 Amp Red ORC

F23 —25 Amp Natural ESC

F24 —20 Amp Yellow ECM, Fuel Injectors, Active Grill

Shutter (AGS)

F30 —20 Amp Yellow Power Outlet (Console)

F81 60 Amp Blue —Interior PDC Battery Feed, Power

Seats

F82 30 Amp Green —Amplifier

F83 40 Amp Orange —HVAC Blower Motor

F84 —20 Amp Yellow Run/Accessory RLY Output, Cigar

Lighter

F85 —10 Amp Red Sunroof, LRSM, Power Outlet

(Console), UCI/AUX Port, CigarLighter

F86 —20 Amp Yellow —

F87 —10 Amp Red Wastegate, Purge Solenoid, OBD

Vent Valve, Oxygen Sensor Heat-ers

F88 —10 Amp Red Heated Outside Mirrors

MAINTAINING YOUR VEHICLE

117