service DODGE DART 2015 PF / 1.G Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2015, Model line: DART, Model: DODGE DART 2015 PF / 1.GPages: 664, PDF Size: 16.96 MB

Page 539 of 664

hose, and place the Tire Service Kit in the vehicle storage

location. Quickly proceed to (D) “Drive Vehicle.”

CAUTION!

•The metal end fitting from Power Plug (8) may get

hot after use, so it should be handled carefully.

•Failure to reinstall the cap on the fitting at the end

of the Sealant Hose (6) can result in sealant con-

tacting your skin, clothing, and the vehicle’s inte-

rior. It can also result in sealant contacting internal

Tire Service Kit components which may cause

permanent damage to the kit.

(D) Drive Vehicle:

Immediately after injecting sealant and inflating the tire,

drive the vehicle 5 miles (8 km) or 10 minutes to ensure

distribution of the Tire Service Kit Sealant within the tire.

Do not exceed 55 mph (90 km/h).

WARNING!

Tire Service Kit is not a permanent flat tire repair.

Have the tire inspected and repaired or replaced after

using Tire Service Kit. Do not exceed 55 mph (90

km/h) until the tire is repaired or replaced. Failure to

follow this warning can result in injuries that are

serious or fatal to you, your passengers, and others

around you.

(E) After Driving:

Pull over to a safe location. Refer to “Whenever You Stop

to Use Tire Service Kit” before continuing.

1. Push in the Mode Select Knob (5) and turn to the Air

Mode position.

2. Uncoil the power plug and insert the plug into the

vehicle’s 12 Volt power outlet.

6

WHAT TO DO IN EMERGENCIES 537

Page 540 of 664

3. Uncoil the Air Pump Hose (7) (black in color) and

screw the fitting at the end of hose (7) onto the valve

stem.

4. Check the pressure in the tire by reading the Pressure

Gauge (3).

If tire pressure is less than 19 psi (1.3 Bar):

The tire is too badly damaged. Do not attempt to drive

the vehicle further. Call for assistance.

If the tire pressure is 19 psi (1.3 Bar) or higher:

1. Press the Power Button (4) to turn on Tire Service Kit

and inflate the tire to the pressure indicated on the tire

and loading information label on the driver-side door

opening.

NOTE:If the tire becomes over-inflated, press the Defla-

tion Button to reduce the tire pressure to the recom-

mended inflation pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem,

reinstall the cap on the valve stem and unplug from 12

Volt outlet.

3. Place the Tire Service Kit in its proper storage area in

the vehicle.

4. Have the tire inspected and repaired or replaced at the

earliest opportunity at an authorized dealer or tire

service center.

5. Remove the Speed Limit sticker from the instrument

panel after the tire has been repaired.

6. Replace the Sealant Bottle (1) and Sealant Hose (6)

assembly at your authorized dealer as soon as pos-

sible. Refer to (F) “Sealant Bottle and Hose Replace-

ment”.

NOTE:When having the tire serviced, advise the autho-

rized dealer or service center that the tire has been sealed

using the Tire Service Kit.

538 WHAT TO DO IN EMERGENCIES

Page 541 of 664

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (6) (clear in color).

2. Locate the round Sealant Bottle release button in the

recessed area under the sealant bottle.

3. Press the Sealant Bottle release button. The Sealant

Bottle (1) will pop up. Remove the bottle and dispose

of it accordingly.

4. Clean any remaining sealant from the Tire Service Kit

housing.

5. Position the new Sealant Bottle (1) in the housing so

that the Sealant Hose (6) aligns with the hose slot in

the front of the housing. Press the bottle into the

housing. An audible click will be heard indicating the

bottle is locked into place.

6. Verify that the cap is installed on the fitting at the end

of the Sealant Hose (6) and return the hose to its

storage area (located on the bottom of the air pump).

7. Return the Tire Service Kit to its storage location in the

vehicle.

JACKING AND TIRE CHANGING

WARNING!

•Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

(Continued)

6

WHAT TO DO IN EMERGENCIES 539

Page 542 of 664

WARNING!(Continued)

•Being under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never put any part of your body

under a vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service center

where it can be raised on a lift.

•Never start or run the engine while the vehicle is

on a jack.

•The jack is designed to be used as a tool for

changing tires only. The jack should not be used to

lift the vehicle for service purposes. The vehicle

should be jacked on a firm level surface only.

Avoid ice or slippery areas.

Jack Location/Spare Tire Stowage — If Equipped

The jack and spare tire are both stowed under an access

cover in the trunk. Follow these steps to access the jack

and spare tire.

1. Open the trunk.

2. Lift the access cover using the pull strap.

540 WHAT TO DO IN EMERGENCIES

Page 545 of 664

Jacking And Changing A Tire

WARNING!

Carefully follow these tire changing warnings to

help prevent personal injury or damage to your

vehicle:

•Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

•Turn on the Hazard Warning flasher.

•Block the wheel diagonally opposite the wheel to

be raised.

•Set the parking brake firmly and set an automatic

transmission in PARK; a manual transmission in

REVERSE.

•Never start or run the engine with the vehicle on a

jack.

(Continued)

WARNING!(Continued)

•Do not let anyone sit in the vehicle when it is on a

jack.

•Do not get under the vehicle when it is on a jack. If

you need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

•Only use the jack in the positions indicated and for

lifting this vehicle during a tire change.

•If working on or near a roadway, be extremely

careful of motor traffic.

Jack Warning Label

6

WHAT TO DO IN EMERGENCIES 543

Page 550 of 664

9. Lower the vehicle to the ground by turning the jack

handle counterclockwise.

10. Finish tightening the wheel bolts. Push down on the

wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened twice. Refer

to “Torque Specifications” in this section for proper

lug bolt torque. If in doubt about the correct tight-

ness, have them checked with a torque wrench by

your authorized dealer or at a service station.

11. Lower the jack until it is free. Remove the wheel

blocks. Reassemble the lug wrench to the jack assem-

bly and stow it in the spare tire area. Secure the

assembly using the means provided. Release the

parking brake before driving the vehicle.

12. Stow the jack, tools and flat tire.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided. Have the deflated (flat) tire

repaired or replaced immediately.

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with

wheel covers, install two wheel bolts on the wheel

which are on each side of the valve stem. Install the

wheel bolts with the threaded end of the bolt toward

the wheel. Lightly tighten the wheel bolts.

548 WHAT TO DO IN EMERGENCIES

Page 552 of 664

“Torque Specifications” in this section for proper lug

bolt torque. If in doubt about the correct tightness,

have them checked with a torque wrench by your

authorized dealer or service station.

7. Lower the jack until it is free. Remove the wheel

blocks. Reassemble the lug wrench to the jack assem-

bly and stow it in the spare tire area. Secure the

assembly using the means provided. Release the park-

ing brake before driving the vehicle.

8. After 25 miles (40 km) check the wheel bolt torque

with a torque wrench to ensure that all wheel bolts are

properly seated against the wheel.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the threaded

end of the wheel bolt toward the wheel. Lightly

tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the lug nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in personal injury.

3. Lower the vehicle to the ground by turning the jack

handle counterclockwise.

4. Finish tightening the wheel bolts. Push down on the

wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern until

each wheel bolt has been tightened twice. Refer to

“Torque Specifications” in this section for the proper

lug bolt torque. If in doubt about the correct tightness,

have them checked with a torque wrench by your

authorized dealer or service station.

550 WHAT TO DO IN EMERGENCIES

Page 561 of 664

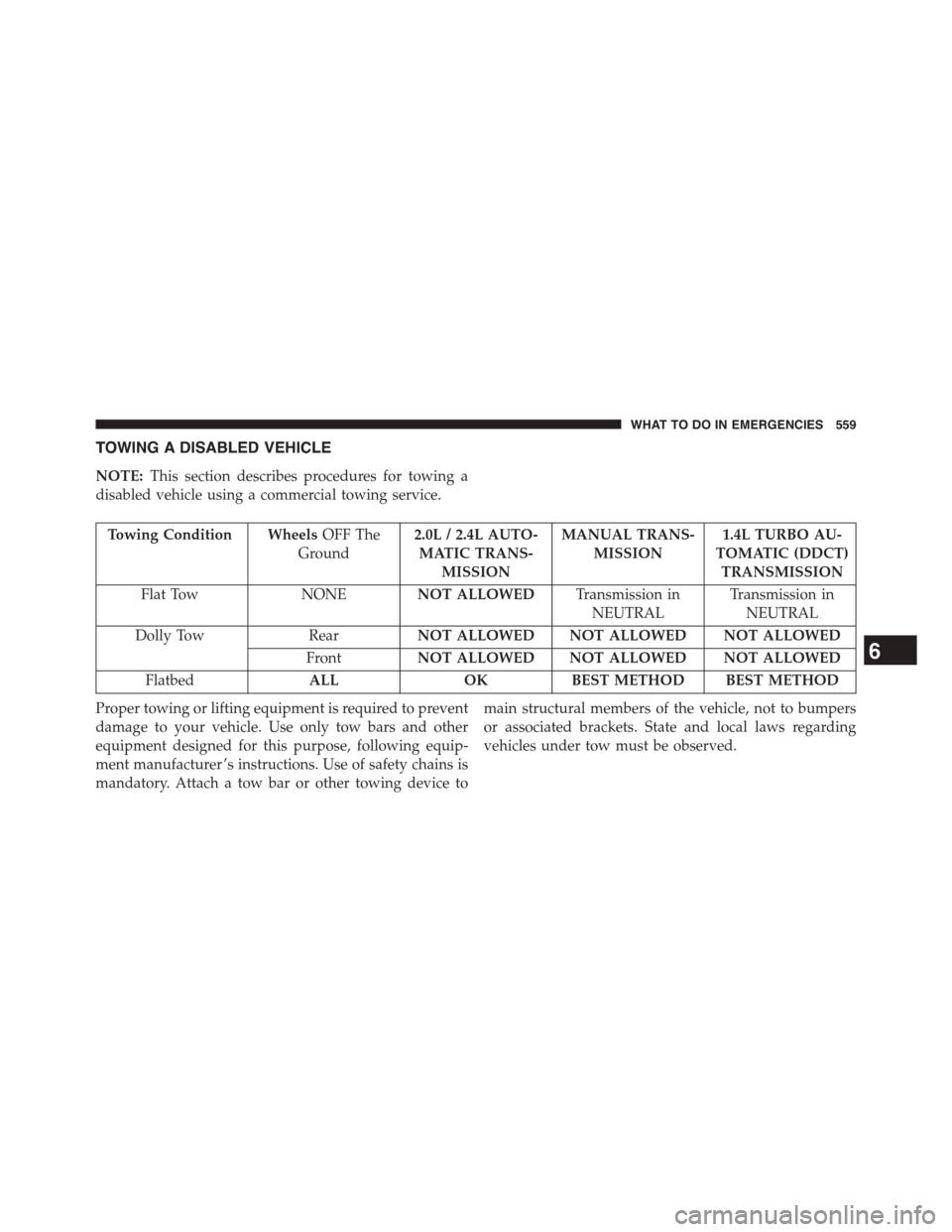

TOWING A DISABLED VEHICLE

NOTE:This section describes procedures for towing a

disabled vehicle using a commercial towing service.

Towing Condition WheelsOFF The

Ground

2.0L / 2.4L AUTO-

MATIC TRANS-

MISSION

MANUAL TRANS-

MISSION

1.4L TURBO AU-

TOMATIC (DDCT)

TRANSMISSION

Flat Tow NONENOT ALLOWEDTransmission in

NEUTRAL

Transmission in

NEUTRAL

Dolly TowRearNOT ALLOWED NOT ALLOWED NOT ALLOWED

FrontNOT ALLOWED NOT ALLOWED NOT ALLOWED

FlatbedALLOKBEST METHOD BEST METHOD

Proper towing or lifting equipment is required to prevent

damage to your vehicle. Use only tow bars and other

equipment designed for this purpose, following equip-

ment manufacturer ’s instructions. Use of safety chains is

mandatory. Attach a tow bar or other towing device to

main structural members of the vehicle, not to bumpers

or associated brackets. State and local laws regarding

vehicles under tow must be observed.

6

WHAT TO DO IN EMERGENCIES 559

Page 565 of 664

MAINTAINING YOUR VEHICLE

CONTENTS

!ENGINE COMPARTMENT — 1.4L TURBO . . . .565

!ENGINE COMPARTMENT — 2.0L..........566

!ENGINE COMPARTMENT — 2.4L..........567

!ONBOARD DIAGNOSTIC SYSTEM — OBD II . .568

▫Loose Fuel Filler Cap Message............568

!EMISSIONS INSPECTION AND MAINTENANCE

PROGRAMS..........................569

!REPLACEMENT PARTS..................570

!DEALER SERVICE......................571

!MAINTENANCE PROCEDURES...........571

▫Engine Oil..........................572

▫Engine Oil Filter......................575

▫Engine Air Cleaner Filter................575

▫Ti re s . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..576

▫Maintenance-Free Battery...............576

▫Air Conditioner Maintenance.............577

▫A/C Air Filter.......................578

▫Body Lubrication.....................580

▫Windshield Wiper Blades...............581

▫Adding Washer Fluid..................581

7

Page 570 of 664

ONBOARD DIAGNOSTIC SYSTEM — OBD II

Your vehicle is equipped with a sophisticated onboard

diagnostic system called OBD II. This system monitors

the performance of the emissions, engine, and automatic

transmission control systems. When these systems are

operating properly, your vehicle will provide excellent

performance and fuel economy, as well as engine emis-

sions well within current government regulations.

If any of these systems require service, the OBD II system

will turn on the “Malfunction Indicator Light” (MIL). It

will also store diagnostic codes and other information to

assist your service technician in making repairs. Al-

though your vehicle will usually be drivable and not

need towing, see your authorized dealer for service as

soon as possible.

CAUTION!

•Prolonged driving with the MIL on could cause

further damage to the emission control system. It

could also affect fuel economy and driveability.

The vehicle must be serviced before any emissions

tests can be performed.

•If the MIL is flashing while the engine is running,

severe catalytic converter damage and power loss

will soon occur. Immediate service is required.

Loose Fuel Filler Cap Message

After fuel is added, the vehicle diagnostic system can

determine if the fuel filler cap is possibly loose or

improperly installed. A “gASCAP” message will be dis-

played in the instrument cluster. Tighten the gas cap until

a#clicking#sound is heard. This is an indication that the

gas cap is properly tightened. Press the trip odometer

RESET button to turn off the message. If the problem

568 MAINTAINING YOUR VEHICLE