engine DODGE DURANGO 1998 1.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: DURANGO, Model: DODGE DURANGO 1998 1.GPages: 193, PDF Size: 5.65 MB

Page 121 of 193

Downloaded from www.Manualslib.com manuals search engine (6) To align the bearing cap, use cap slot, align-

ment dowel and cap bolts. DO NOT remove excess

material after assembly. DO NOT strike rear cap

more than 2 times for proper engagement.

(7) Install the rear main bearing cap with cleaned

and oiled cap bolts. Alternately tighten ALL cap bolts

to 115 N´m (85 ft. lbs.) torque.

(8) Install oil pump.

(9) Apply MopartSilicone Rubber Adhesive Seal-

ant, or equivalent, at bearing cap to block joint to

provide cap to block and oil pan sealing (Fig. 72).

Apply enough sealant until a small amount is

squeezed out. Withdraw nozzle and wipe excess seal-

ant off the oil pan seal groove.

(10) Immediately install the oil pan.

LOWER SEAL

REMOVAL

(1) Remove the oil pan.

(2) Remove the oil pump from the rear main bear-

ing cap.

(3) Remove the rear main bearing cap and discard

the old lower seal.

INSTALLATION

(1) Clean the rear main cap mating surfaces

including the oil pan gasket groove.

(2) Carefully install a new upper seal (refer to

Upper Seal Replacement - Crankshaft Installed pro-

cedure above).

(3) Lightly oil the new lower seal lips with engine

oil.

(4) Install a new lower seal in bearing cap with

the white paint facing the rear of engine.

(5) Apply 5 mm (0.20 in) drop of MopartGasket

Maker, or equivalent, on each side of the rear main

bearing cap (Fig. 71). DO NOT over apply sealant or

allow the sealant to contact the rubber seal. Assem-

ble bearing cap to cylinder block immediately after

sealant application.

(6) To align the bearing cap, use cap slot, align-

ment dowel and cap bolts. DO NOT remove excess

material after assembly. DO NOT strike rear cap

more than 2 times for proper engagement.

(7) Install the rear main bearing cap with cleaned

and oiled cap bolts. Alternately tighten the cap bolts

to 115 N´m (85 ft. lbs.) torque.

(8) Install oil pump.

(9) Apply MopartSilicone Rubber Adhesive Seal-

ant, or equivalent, at bearing cap to block joint to

provide cap to block and oil pan sealing (Fig. 72).

Apply enough sealant until a small amount is

squeezed out. Withdraw nozzle and wipe excess seal-

ant off the oil pan seal groove.

(10) Immediately install the oil pan.

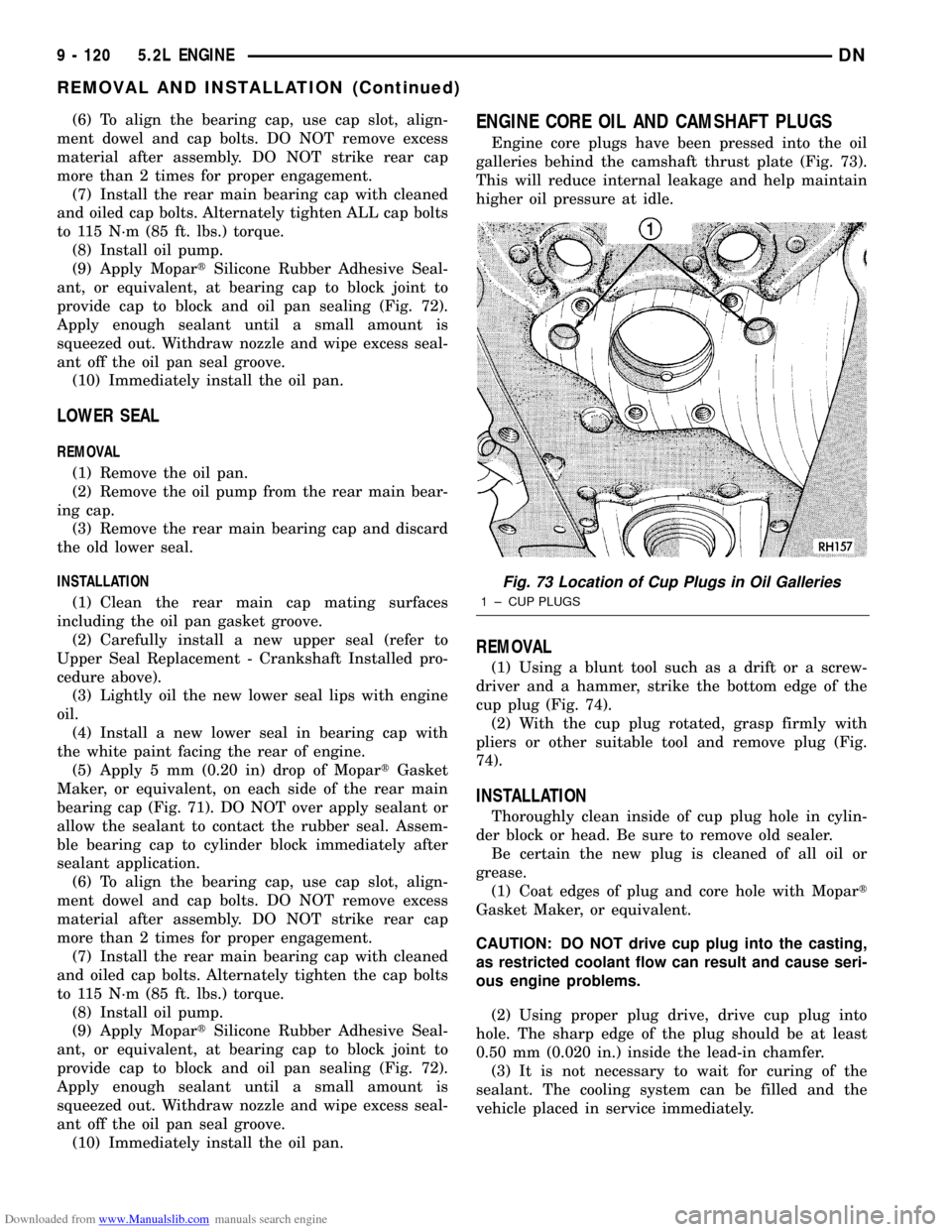

ENGINE CORE OIL AND CAMSHAFT PLUGS

Engine core plugs have been pressed into the oil

galleries behind the camshaft thrust plate (Fig. 73).

This will reduce internal leakage and help maintain

higher oil pressure at idle.

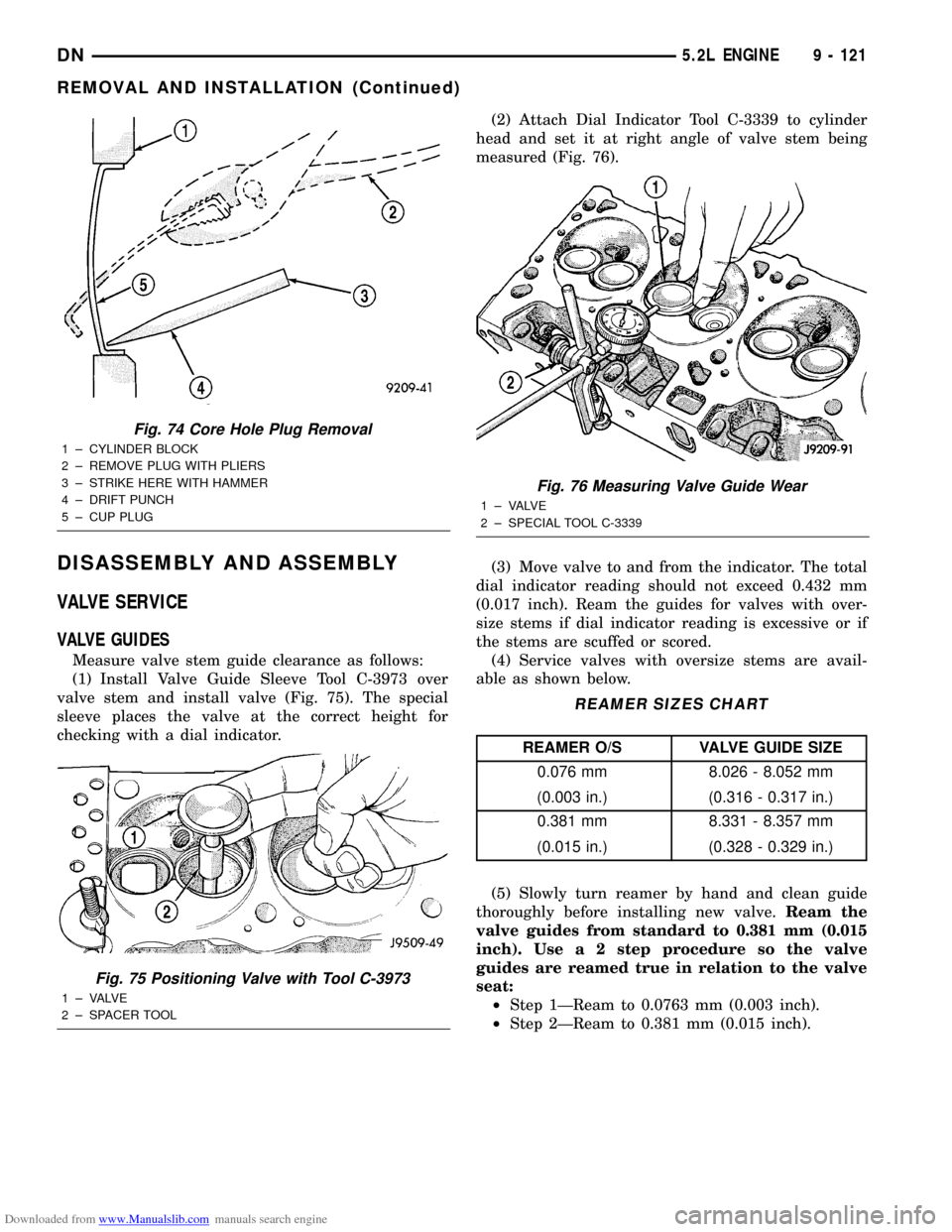

REMOVAL

(1) Using a blunt tool such as a drift or a screw-

driver and a hammer, strike the bottom edge of the

cup plug (Fig. 74).

(2) With the cup plug rotated, grasp firmly with

pliers or other suitable tool and remove plug (Fig.

74).

INSTALLATION

Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Be certain the new plug is cleaned of all oil or

grease.

(1) Coat edges of plug and core hole with Mopart

Gasket Maker, or equivalent.

CAUTION: DO NOT drive cup plug into the casting,

as restricted coolant flow can result and cause seri-

ous engine problems.

(2) Using proper plug drive, drive cup plug into

hole. The sharp edge of the plug should be at least

0.50 mm (0.020 in.) inside the lead-in chamfer.

(3) It is not necessary to wait for curing of the

sealant. The cooling system can be filled and the

vehicle placed in service immediately.

Fig. 73 Location of Cup Plugs in Oil Galleries

1 ± CUP PLUGS

9 - 120 5.2L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 122 of 193

Downloaded from www.Manualslib.com manuals search engine DISASSEMBLY AND ASSEMBLY

VALVE SERVICE

VALVE GUIDES

Measure valve stem guide clearance as follows:

(1) Install Valve Guide Sleeve Tool C-3973 over

valve stem and install valve (Fig. 75). The special

sleeve places the valve at the correct height for

checking with a dial indicator.(2) Attach Dial Indicator Tool C-3339 to cylinder

head and set it at right angle of valve stem being

measured (Fig. 76).

(3) Move valve to and from the indicator. The total

dial indicator reading should not exceed 0.432 mm

(0.017 inch). Ream the guides for valves with over-

size stems if dial indicator reading is excessive or if

the stems are scuffed or scored.

(4) Service valves with oversize stems are avail-

able as shown below.

(5) Slowly turn reamer by hand and clean guide

thoroughly before installing new valve.Ream the

valve guides from standard to 0.381 mm (0.015

inch). Use a 2 step procedure so the valve

guides are reamed true in relation to the valve

seat:

²Step 1ÐReam to 0.0763 mm (0.003 inch).

²Step 2ÐReam to 0.381 mm (0.015 inch).

Fig. 74 Core Hole Plug Removal

1 ± CYLINDER BLOCK

2 ± REMOVE PLUG WITH PLIERS

3 ± STRIKE HERE WITH HAMMER

4 ± DRIFT PUNCH

5 ± CUP PLUG

Fig. 75 Positioning Valve with Tool C-3973

1 ± VALVE

2 ± SPACER TOOL

Fig. 76 Measuring Valve Guide Wear

1 ± VALVE

2 ± SPECIAL TOOL C-3339

REAMER SIZES CHART

REAMER O/S VALVE GUIDE SIZE

0.076 mm 8.026 - 8.052 mm

(0.003 in.) (0.316 - 0.317 in.)

0.381 mm 8.331 - 8.357 mm

(0.015 in.) (0.328 - 0.329 in.)

DN5.2L ENGINE 9 - 121

REMOVAL AND INSTALLATION (Continued)

Page 123 of 193

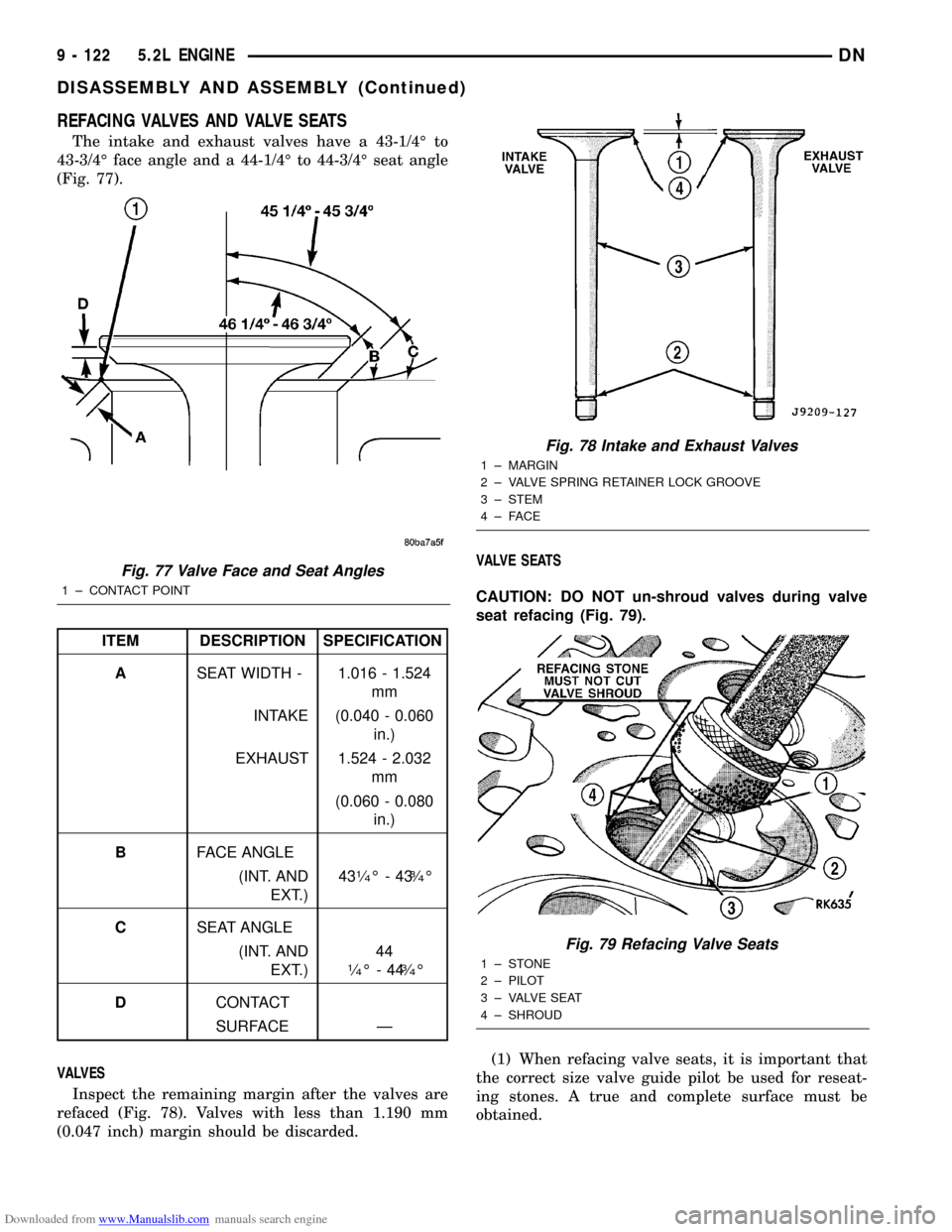

Downloaded from www.Manualslib.com manuals search engine REFACING VALVES AND VALVE SEATS

The intake and exhaust valves have a 43-1/4É to

43-3/4É face angle and a 44-1/4É to 44-3/4É seat angle

(Fig. 77).

VALVES

Inspect the remaining margin after the valves are

refaced (Fig. 78). Valves with less than 1.190 mm

(0.047 inch) margin should be discarded.VALVE SEATS

CAUTION: DO NOT un-shroud valves during valve

seat refacing (Fig. 79).

(1) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained.

Fig. 77 Valve Face and Seat Angles

1 ± CONTACT POINT

ITEM DESCRIPTION SPECIFICATION

ASEAT WIDTH - 1.016 - 1.524

mm

INTAKE (0.040 - 0.060

in.)

EXHAUST 1.524 - 2.032

mm

(0.060 - 0.080

in.)

BFACE ANGLE

(INT. AND

EXT.)43

1¤4É-433¤4É

CSEAT ANGLE

(INT. AND

EXT.)44

1¤4É-443¤4É

DCONTACT

SURFACE Ð

Fig. 78 Intake and Exhaust Valves

1 ± MARGIN

2 ± VALVE SPRING RETAINER LOCK GROOVE

3 ± STEM

4±FACE

Fig. 79 Refacing Valve Seats

1±STONE

2 ± PILOT

3 ± VALVE SEAT

4 ± SHROUD

9 - 122 5.2L ENGINEDN

DISASSEMBLY AND ASSEMBLY (Continued)

Page 124 of 193

Downloaded from www.Manualslib.com manuals search engine (2) Measure the concentricity of valve seat using a

dial indicator. Total runout should not exceed 0.051

mm (0.002 inch) total indicator reading.

(3) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seat LIGHTLY with Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to the top edge of valve face, lower valve seat

with a 15É stone. If the blue is transferred to bottom

edge of valve face raise valve seat with a 60É stone.

(4) When seat is properly positioned the width of

intake seats should be 1.016-1.524 mm (0.040-0.060

inch). The width of the exhaust seats should be

1.524-2.032 mm (0.060-0.080 inch).

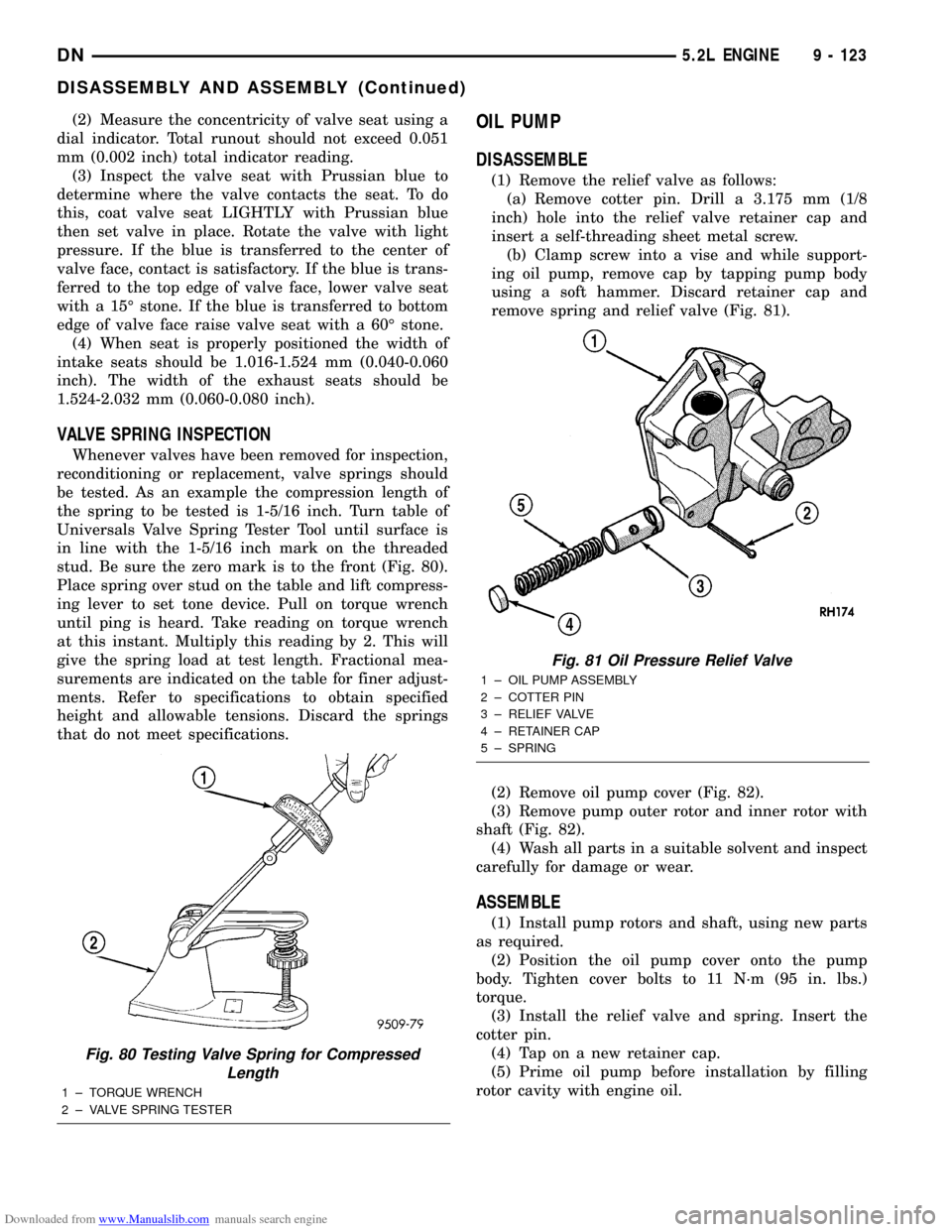

VALVE SPRING INSPECTION

Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should

be tested. As an example the compression length of

the spring to be tested is 1-5/16 inch. Turn table of

Universals Valve Spring Tester Tool until surface is

in line with the 1-5/16 inch mark on the threaded

stud. Be sure the zero mark is to the front (Fig. 80).

Place spring over stud on the table and lift compress-

ing lever to set tone device. Pull on torque wrench

until ping is heard. Take reading on torque wrench

at this instant. Multiply this reading by 2. This will

give the spring load at test length. Fractional mea-

surements are indicated on the table for finer adjust-

ments. Refer to specifications to obtain specified

height and allowable tensions. Discard the springs

that do not meet specifications.

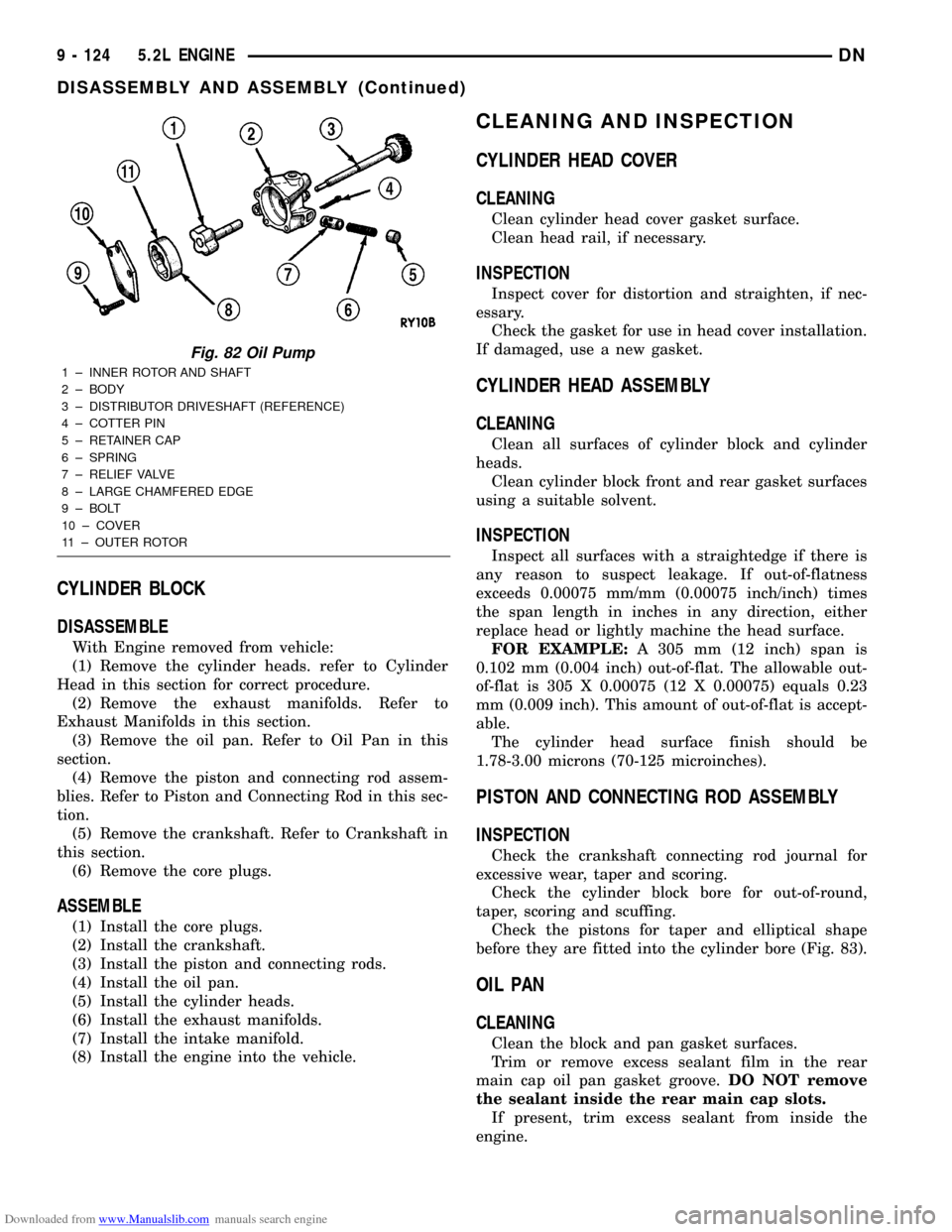

OIL PUMP

DISASSEMBLE

(1) Remove the relief valve as follows:

(a) Remove cotter pin. Drill a 3.175 mm (1/8

inch) hole into the relief valve retainer cap and

insert a self-threading sheet metal screw.

(b) Clamp screw into a vise and while support-

ing oil pump, remove cap by tapping pump body

using a soft hammer. Discard retainer cap and

remove spring and relief valve (Fig. 81).

(2) Remove oil pump cover (Fig. 82).

(3) Remove pump outer rotor and inner rotor with

shaft (Fig. 82).

(4) Wash all parts in a suitable solvent and inspect

carefully for damage or wear.

ASSEMBLE

(1) Install pump rotors and shaft, using new parts

as required.

(2) Position the oil pump cover onto the pump

body. Tighten cover bolts to 11 N´m (95 in. lbs.)

torque.

(3) Install the relief valve and spring. Insert the

cotter pin.

(4) Tap on a new retainer cap.

(5) Prime oil pump before installation by filling

rotor cavity with engine oil.

Fig. 80 Testing Valve Spring for Compressed

Length

1 ± TORQUE WRENCH

2 ± VALVE SPRING TESTER

Fig. 81 Oil Pressure Relief Valve

1 ± OIL PUMP ASSEMBLY

2 ± COTTER PIN

3 ± RELIEF VALVE

4 ± RETAINER CAP

5 ± SPRING

DN5.2L ENGINE 9 - 123

DISASSEMBLY AND ASSEMBLY (Continued)

Page 125 of 193

Downloaded from www.Manualslib.com manuals search engine CYLINDER BLOCK

DISASSEMBLE

With Engine removed from vehicle:

(1) Remove the cylinder heads. refer to Cylinder

Head in this section for correct procedure.

(2) Remove the exhaust manifolds. Refer to

Exhaust Manifolds in this section.

(3) Remove the oil pan. Refer to Oil Pan in this

section.

(4) Remove the piston and connecting rod assem-

blies. Refer to Piston and Connecting Rod in this sec-

tion.

(5) Remove the crankshaft. Refer to Crankshaft in

this section.

(6) Remove the core plugs.

ASSEMBLE

(1) Install the core plugs.

(2) Install the crankshaft.

(3) Install the piston and connecting rods.

(4) Install the oil pan.

(5) Install the cylinder heads.

(6) Install the exhaust manifolds.

(7) Install the intake manifold.

(8) Install the engine into the vehicle.

CLEANING AND INSPECTION

CYLINDER HEAD COVER

CLEANING

Clean cylinder head cover gasket surface.

Clean head rail, if necessary.

INSPECTION

Inspect cover for distortion and straighten, if nec-

essary.

Check the gasket for use in head cover installation.

If damaged, use a new gasket.

CYLINDER HEAD ASSEMBLY

CLEANING

Clean all surfaces of cylinder block and cylinder

heads.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

INSPECTION

Inspect all surfaces with a straightedge if there is

any reason to suspect leakage. If out-of-flatness

exceeds 0.00075 mm/mm (0.00075 inch/inch) times

the span length in inches in any direction, either

replace head or lightly machine the head surface.

FOR EXAMPLE:A 305 mm (12 inch) span is

0.102 mm (0.004 inch) out-of-flat. The allowable out-

of-flat is 305 X 0.00075 (12 X 0.00075) equals 0.23

mm (0.009 inch). This amount of out-of-flat is accept-

able.

The cylinder head surface finish should be

1.78-3.00 microns (70-125 microinches).

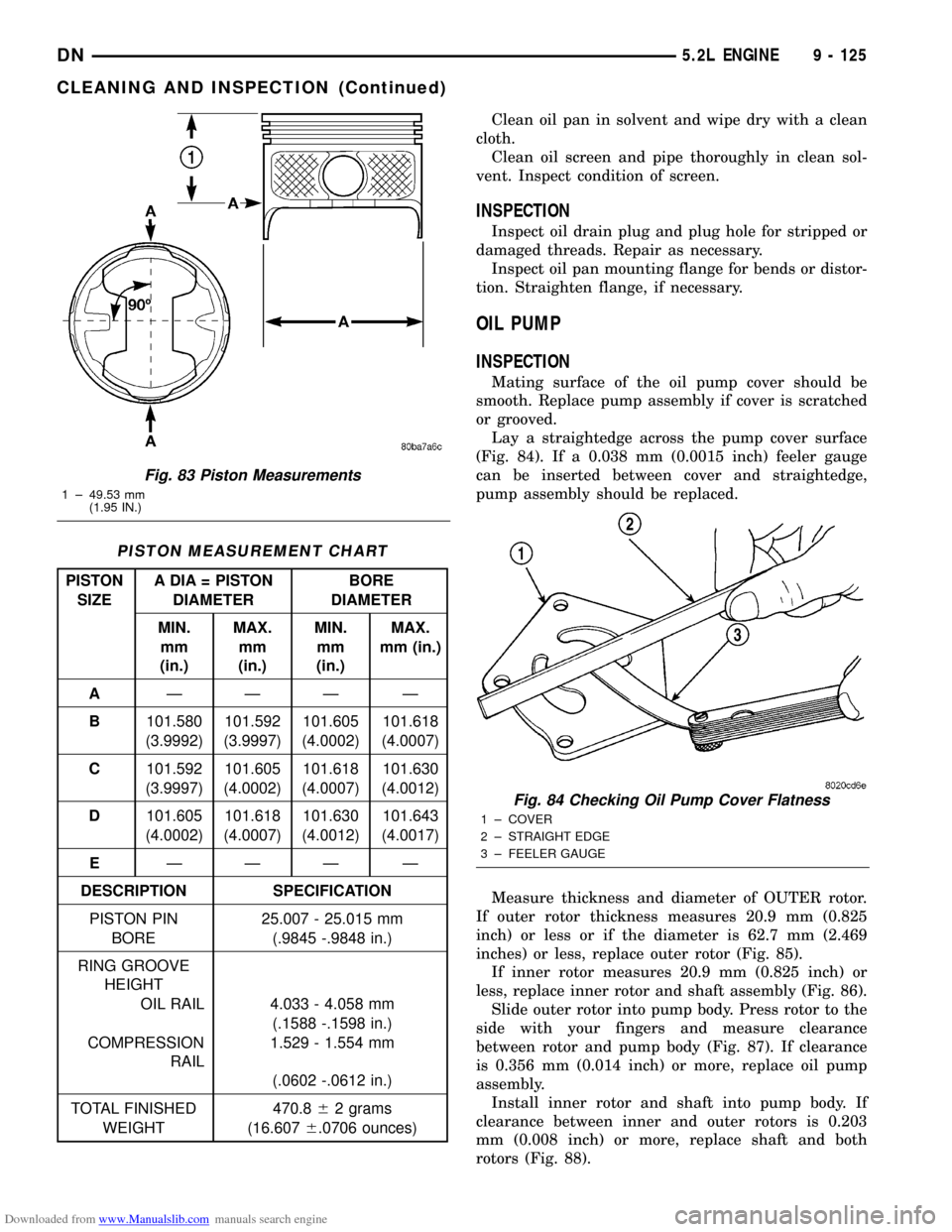

PISTON AND CONNECTING ROD ASSEMBLY

INSPECTION

Check the crankshaft connecting rod journal for

excessive wear, taper and scoring.

Check the cylinder block bore for out-of-round,

taper, scoring and scuffing.

Check the pistons for taper and elliptical shape

before they are fitted into the cylinder bore (Fig. 83).

OIL PAN

CLEANING

Clean the block and pan gasket surfaces.

Trim or remove excess sealant film in the rear

main cap oil pan gasket groove.DO NOT remove

the sealant inside the rear main cap slots.

If present, trim excess sealant from inside the

engine.

Fig. 82 Oil Pump

1 ± INNER ROTOR AND SHAFT

2 ± BODY

3 ± DISTRIBUTOR DRIVESHAFT (REFERENCE)

4 ± COTTER PIN

5 ± RETAINER CAP

6 ± SPRING

7 ± RELIEF VALVE

8 ± LARGE CHAMFERED EDGE

9 ± BOLT

10 ± COVER

11 ± OUTER ROTOR

9 - 124 5.2L ENGINEDN

DISASSEMBLY AND ASSEMBLY (Continued)

Page 126 of 193

Downloaded from www.Manualslib.com manuals search engine Clean oil pan in solvent and wipe dry with a clean

cloth.

Clean oil screen and pipe thoroughly in clean sol-

vent. Inspect condition of screen.

INSPECTION

Inspect oil drain plug and plug hole for stripped or

damaged threads. Repair as necessary.

Inspect oil pan mounting flange for bends or distor-

tion. Straighten flange, if necessary.

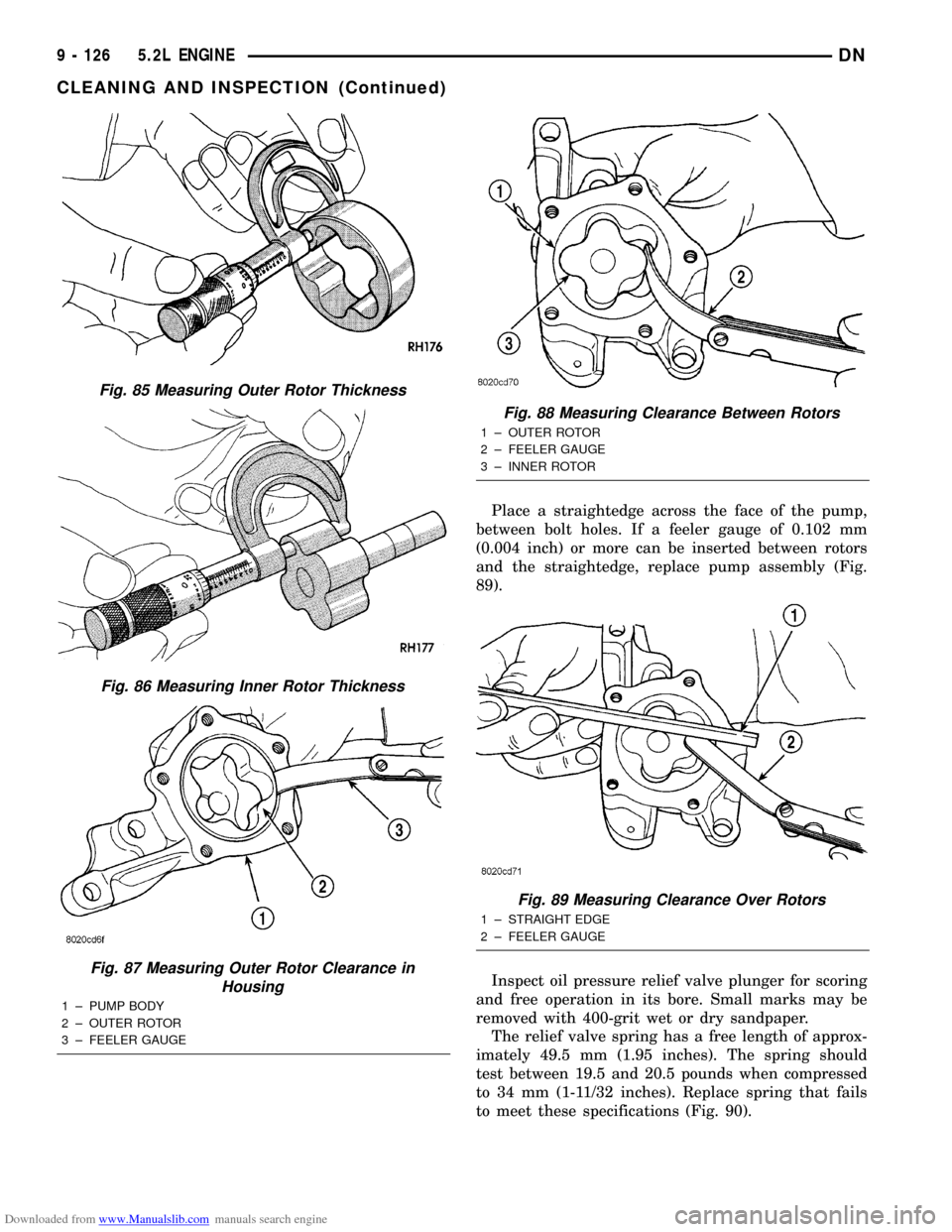

OIL PUMP

INSPECTION

Mating surface of the oil pump cover should be

smooth. Replace pump assembly if cover is scratched

or grooved.

Lay a straightedge across the pump cover surface

(Fig. 84). If a 0.038 mm (0.0015 inch) feeler gauge

can be inserted between cover and straightedge,

pump assembly should be replaced.

Measure thickness and diameter of OUTER rotor.

If outer rotor thickness measures 20.9 mm (0.825

inch) or less or if the diameter is 62.7 mm (2.469

inches) or less, replace outer rotor (Fig. 85).

If inner rotor measures 20.9 mm (0.825 inch) or

less, replace inner rotor and shaft assembly (Fig. 86).

Slide outer rotor into pump body. Press rotor to the

side with your fingers and measure clearance

between rotor and pump body (Fig. 87). If clearance

is 0.356 mm (0.014 inch) or more, replace oil pump

assembly.

Install inner rotor and shaft into pump body. If

clearance between inner and outer rotors is 0.203

mm (0.008 inch) or more, replace shaft and both

rotors (Fig. 88).

Fig. 83 Piston Measurements

1 ± 49.53 mm

(1.95 IN.)

PISTON MEASUREMENT CHART

PISTON A DIA = PISTON BORE

SIZE DIAMETER DIAMETER

MIN. MAX. MIN. MAX.

mm

(in.)mm

(in.)mm

(in.)mm (in.)

AÐÐÐ Ð

B101.580 101.592 101.605 101.618

(3.9992) (3.9997) (4.0002) (4.0007)

C101.592 101.605 101.618 101.630

(3.9997) (4.0002) (4.0007) (4.0012)

D101.605 101.618 101.630 101.643

(4.0002) (4.0007) (4.0012) (4.0017)

EÐÐÐ Ð

DESCRIPTION SPECIFICATION

PISTON PIN 25.007 - 25.015 mm

BORE (.9845 -.9848 in.)

RING GROOVE

HEIGHT

OIL RAIL 4.033 - 4.058 mm

(.1588 -.1598 in.)

COMPRESSION

RAIL1.529 - 1.554 mm

(.0602 -.0612 in.)

TOTAL FINISHED 470.862 grams

WEIGHT (16.6076.0706 ounces)

Fig. 84 Checking Oil Pump Cover Flatness

1 ± COVER

2 ± STRAIGHT EDGE

3 ± FEELER GAUGE

DN5.2L ENGINE 9 - 125

CLEANING AND INSPECTION (Continued)

Page 127 of 193

Downloaded from www.Manualslib.com manuals search engine Place a straightedge across the face of the pump,

between bolt holes. If a feeler gauge of 0.102 mm

(0.004 inch) or more can be inserted between rotors

and the straightedge, replace pump assembly (Fig.

89).

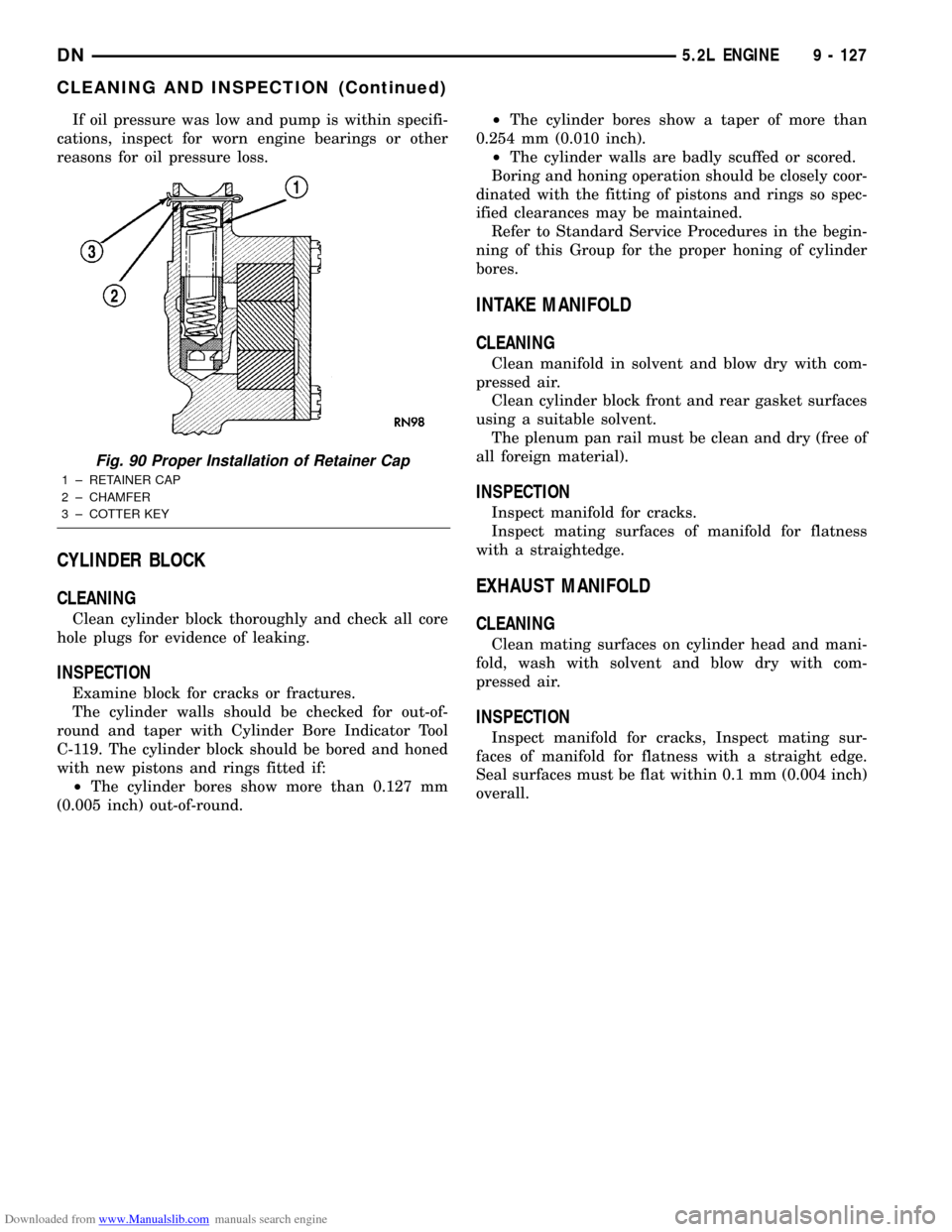

Inspect oil pressure relief valve plunger for scoring

and free operation in its bore. Small marks may be

removed with 400-grit wet or dry sandpaper.

The relief valve spring has a free length of approx-

imately 49.5 mm (1.95 inches). The spring should

test between 19.5 and 20.5 pounds when compressed

to 34 mm (1-11/32 inches). Replace spring that fails

to meet these specifications (Fig. 90).

Fig. 85 Measuring Outer Rotor Thickness

Fig. 86 Measuring Inner Rotor Thickness

Fig. 87 Measuring Outer Rotor Clearance in

Housing

1 ± PUMP BODY

2 ± OUTER ROTOR

3 ± FEELER GAUGE

Fig. 88 Measuring Clearance Between Rotors

1 ± OUTER ROTOR

2 ± FEELER GAUGE

3 ± INNER ROTOR

Fig. 89 Measuring Clearance Over Rotors

1 ± STRAIGHT EDGE

2 ± FEELER GAUGE

9 - 126 5.2L ENGINEDN

CLEANING AND INSPECTION (Continued)

Page 128 of 193

Downloaded from www.Manualslib.com manuals search engine If oil pressure was low and pump is within specifi-

cations, inspect for worn engine bearings or other

reasons for oil pressure loss.

CYLINDER BLOCK

CLEANING

Clean cylinder block thoroughly and check all core

hole plugs for evidence of leaking.

INSPECTION

Examine block for cracks or fractures.

The cylinder walls should be checked for out-of-

round and taper with Cylinder Bore Indicator Tool

C-119. The cylinder block should be bored and honed

with new pistons and rings fitted if:

²The cylinder bores show more than 0.127 mm

(0.005 inch) out-of-round.²The cylinder bores show a taper of more than

0.254 mm (0.010 inch).

²The cylinder walls are badly scuffed or scored.

Boring and honing operation should be closely coor-

dinated with the fitting of pistons and rings so spec-

ified clearances may be maintained.

Refer to Standard Service Procedures in the begin-

ning of this Group for the proper honing of cylinder

bores.

INTAKE MANIFOLD

CLEANING

Clean manifold in solvent and blow dry with com-

pressed air.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

The plenum pan rail must be clean and dry (free of

all foreign material).

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straightedge.

EXHAUST MANIFOLD

CLEANING

Clean mating surfaces on cylinder head and mani-

fold, wash with solvent and blow dry with com-

pressed air.

INSPECTION

Inspect manifold for cracks, Inspect mating sur-

faces of manifold for flatness with a straight edge.

Seal surfaces must be flat within 0.1 mm (0.004 inch)

overall.

Fig. 90 Proper Installation of Retainer Cap

1 ± RETAINER CAP

2 ± CHAMFER

3 ± COTTER KEY

DN5.2L ENGINE 9 - 127

CLEANING AND INSPECTION (Continued)

Page 129 of 193

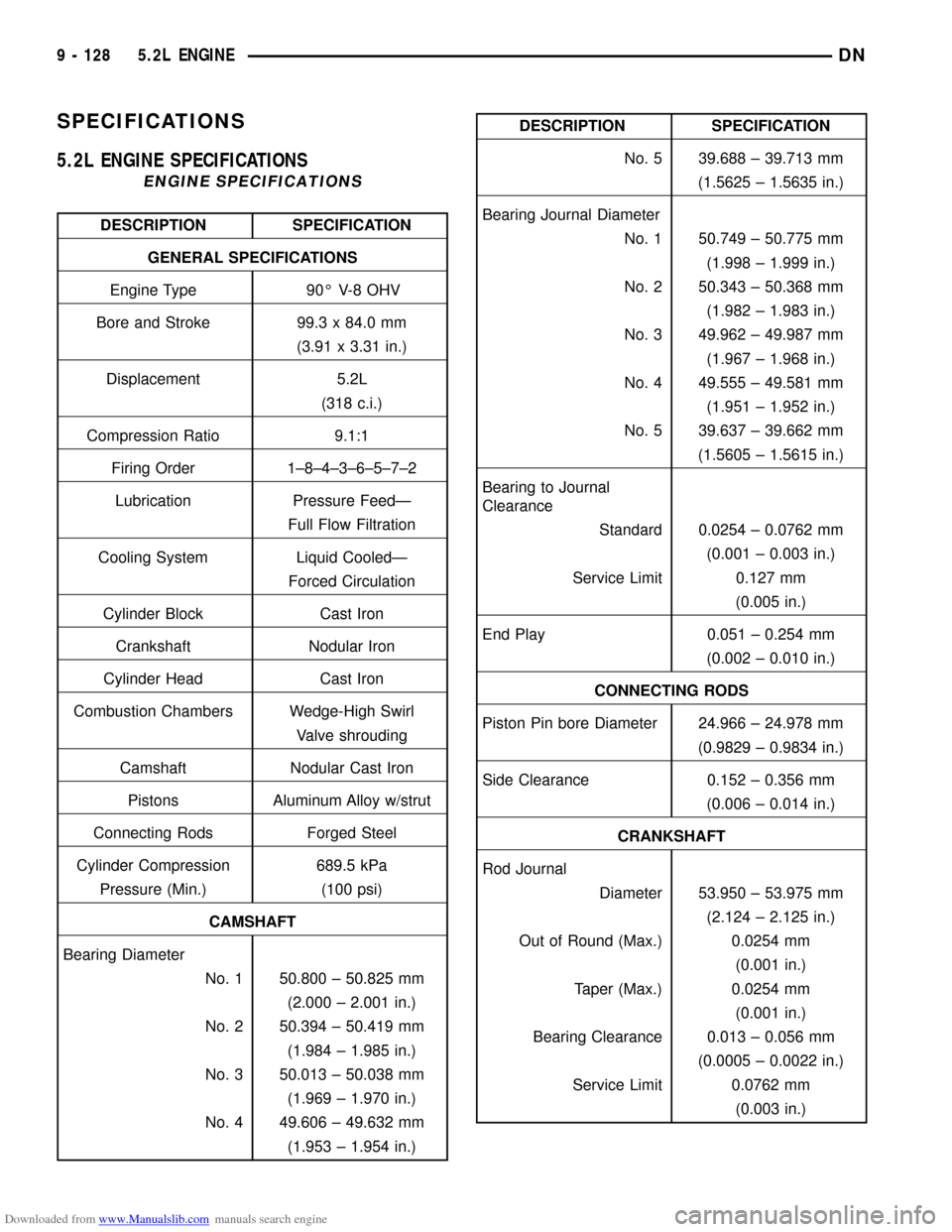

Downloaded from www.Manualslib.com manuals search engine SPECIFICATIONS

5.2L ENGINE SPECIFICATIONS

ENGINE SPECIFICATIONS

DESCRIPTION SPECIFICATION

GENERAL SPECIFICATIONS

Engine Type 90É V-8 OHV

Bore and Stroke 99.3 x 84.0 mm

(3.91 x 3.31 in.)

Displacement 5.2L

(318 c.i.)

Compression Ratio 9.1:1

Firing Order 1±8±4±3±6±5±7±2

Lubrication Pressure FeedÐ

Full Flow Filtration

Cooling System Liquid CooledÐ

Forced Circulation

Cylinder Block Cast Iron

Crankshaft Nodular Iron

Cylinder Head Cast Iron

Combustion Chambers Wedge-High Swirl

Valve shrouding

Camshaft Nodular Cast Iron

Pistons Aluminum Alloy w/strut

Connecting Rods Forged Steel

Cylinder Compression 689.5 kPa

Pressure (Min.) (100 psi)

CAMSHAFT

Bearing Diameter

No. 1 50.800 ± 50.825 mm

(2.000 ± 2.001 in.)

No. 2 50.394 ± 50.419 mm

(1.984 ± 1.985 in.)

No. 3 50.013 ± 50.038 mm

(1.969 ± 1.970 in.)

No. 4 49.606 ± 49.632 mm

(1.953 ± 1.954 in.)

DESCRIPTION SPECIFICATION

No. 5 39.688 ± 39.713 mm

(1.5625 ± 1.5635 in.)

Bearing Journal Diameter

No. 1 50.749 ± 50.775 mm

(1.998 ± 1.999 in.)

No. 2 50.343 ± 50.368 mm

(1.982 ± 1.983 in.)

No. 3 49.962 ± 49.987 mm

(1.967 ± 1.968 in.)

No. 4 49.555 ± 49.581 mm

(1.951 ± 1.952 in.)

No. 5 39.637 ± 39.662 mm

(1.5605 ± 1.5615 in.)

Bearing to Journal

Clearance

Standard 0.0254 ± 0.0762 mm

(0.001 ± 0.003 in.)

Service Limit 0.127 mm

(0.005 in.)

End Play 0.051 ± 0.254 mm

(0.002 ± 0.010 in.)

CONNECTING RODS

Piston Pin bore Diameter 24.966 ± 24.978 mm

(0.9829 ± 0.9834 in.)

Side Clearance 0.152 ± 0.356 mm

(0.006 ± 0.014 in.)

CRANKSHAFT

Rod Journal

Diameter 53.950 ± 53.975 mm

(2.124 ± 2.125 in.)

Out of Round (Max.) 0.0254 mm

(0.001 in.)

Taper (Max.) 0.0254 mm

(0.001 in.)

Bearing Clearance 0.013 ± 0.056 mm

(0.0005 ± 0.0022 in.)

Service Limit 0.0762 mm

(0.003 in.)

9 - 128 5.2L ENGINEDN

Page 130 of 193

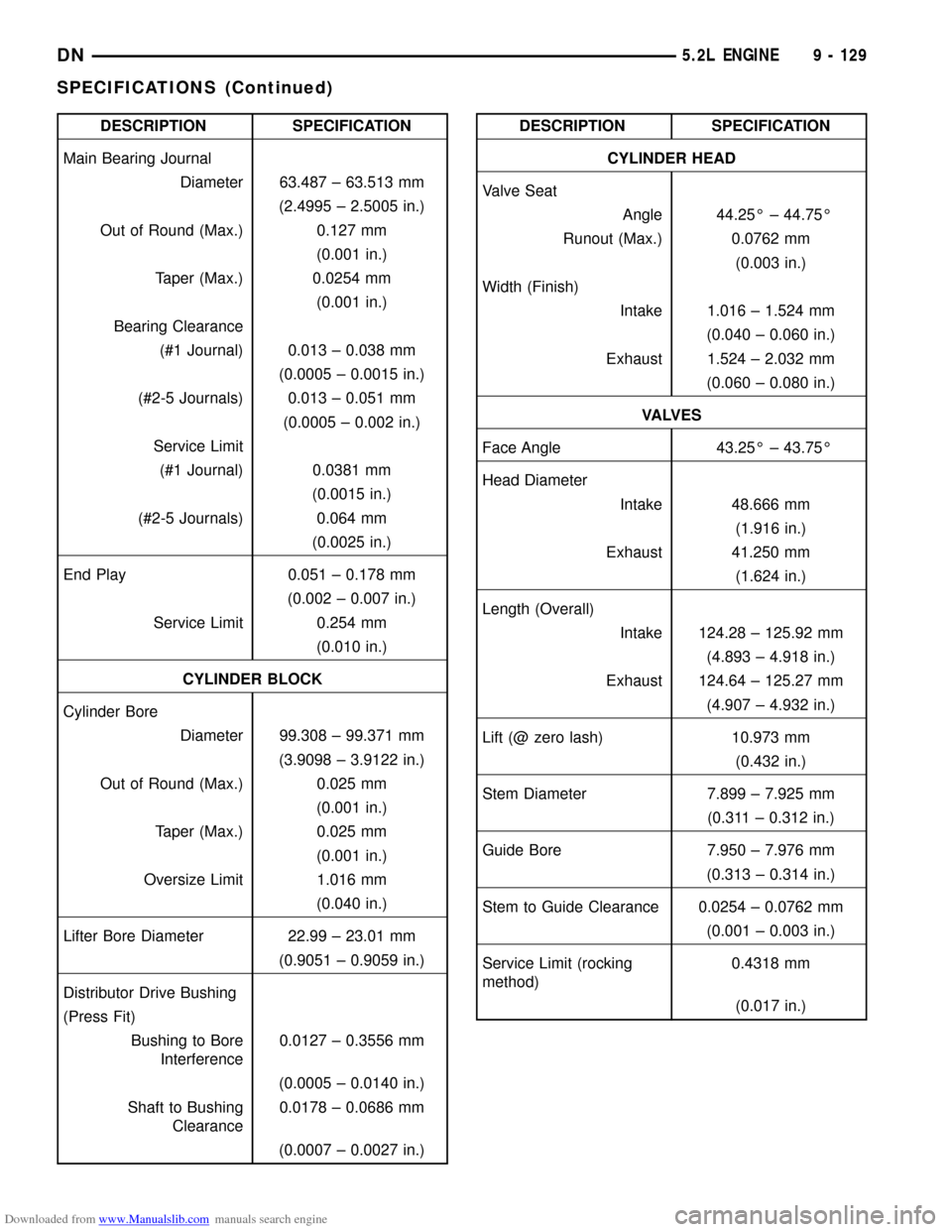

Downloaded from www.Manualslib.com manuals search engine DESCRIPTION SPECIFICATION

Main Bearing Journal

Diameter 63.487 ± 63.513 mm

(2.4995 ± 2.5005 in.)

Out of Round (Max.) 0.127 mm

(0.001 in.)

Taper (Max.) 0.0254 mm

(0.001 in.)

Bearing Clearance

(#1 Journal) 0.013 ± 0.038 mm

(0.0005 ± 0.0015 in.)

(#2-5 Journals) 0.013 ± 0.051 mm

(0.0005 ± 0.002 in.)

Service Limit

(#1 Journal) 0.0381 mm

(0.0015 in.)

(#2-5 Journals) 0.064 mm

(0.0025 in.)

End Play 0.051 ± 0.178 mm

(0.002 ± 0.007 in.)

Service Limit 0.254 mm

(0.010 in.)

CYLINDER BLOCK

Cylinder Bore

Diameter 99.308 ± 99.371 mm

(3.9098 ± 3.9122 in.)

Out of Round (Max.) 0.025 mm

(0.001 in.)

Taper (Max.) 0.025 mm

(0.001 in.)

Oversize Limit 1.016 mm

(0.040 in.)

Lifter Bore Diameter 22.99 ± 23.01 mm

(0.9051 ± 0.9059 in.)

Distributor Drive Bushing

(Press Fit)

Bushing to Bore

Interference0.0127 ± 0.3556 mm

(0.0005 ± 0.0140 in.)

Shaft to Bushing

Clearance0.0178 ± 0.0686 mm

(0.0007 ± 0.0027 in.)DESCRIPTION SPECIFICATION

CYLINDER HEAD

Valve Seat

Angle 44.25É ± 44.75É

Runout (Max.) 0.0762 mm

(0.003 in.)

Width (Finish)

Intake 1.016 ± 1.524 mm

(0.040 ± 0.060 in.)

Exhaust 1.524 ± 2.032 mm

(0.060 ± 0.080 in.)

VA LV E S

Face Angle 43.25É ± 43.75É

Head Diameter

Intake 48.666 mm

(1.916 in.)

Exhaust 41.250 mm

(1.624 in.)

Length (Overall)

Intake 124.28 ± 125.92 mm

(4.893 ± 4.918 in.)

Exhaust 124.64 ± 125.27 mm

(4.907 ± 4.932 in.)

Lift (@ zero lash) 10.973 mm

(0.432 in.)

Stem Diameter 7.899 ± 7.925 mm

(0.311 ± 0.312 in.)

Guide Bore 7.950 ± 7.976 mm

(0.313 ± 0.314 in.)

Stem to Guide Clearance 0.0254 ± 0.0762 mm

(0.001 ± 0.003 in.)

Service Limit (rocking

method)0.4318 mm

(0.017 in.)

DN5.2L ENGINE 9 - 129

SPECIFICATIONS (Continued)