head light DODGE DURANGO 1998 1.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: DURANGO, Model: DODGE DURANGO 1998 1.GPages: 193, PDF Size: 5.65 MB

Page 153 of 193

Downloaded from www.Manualslib.com manuals search engine Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

CYLINDER BOREÐHONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light

scuffing, scoring and scratches. Usually, a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

(3) Honing should be done by moving the hone up

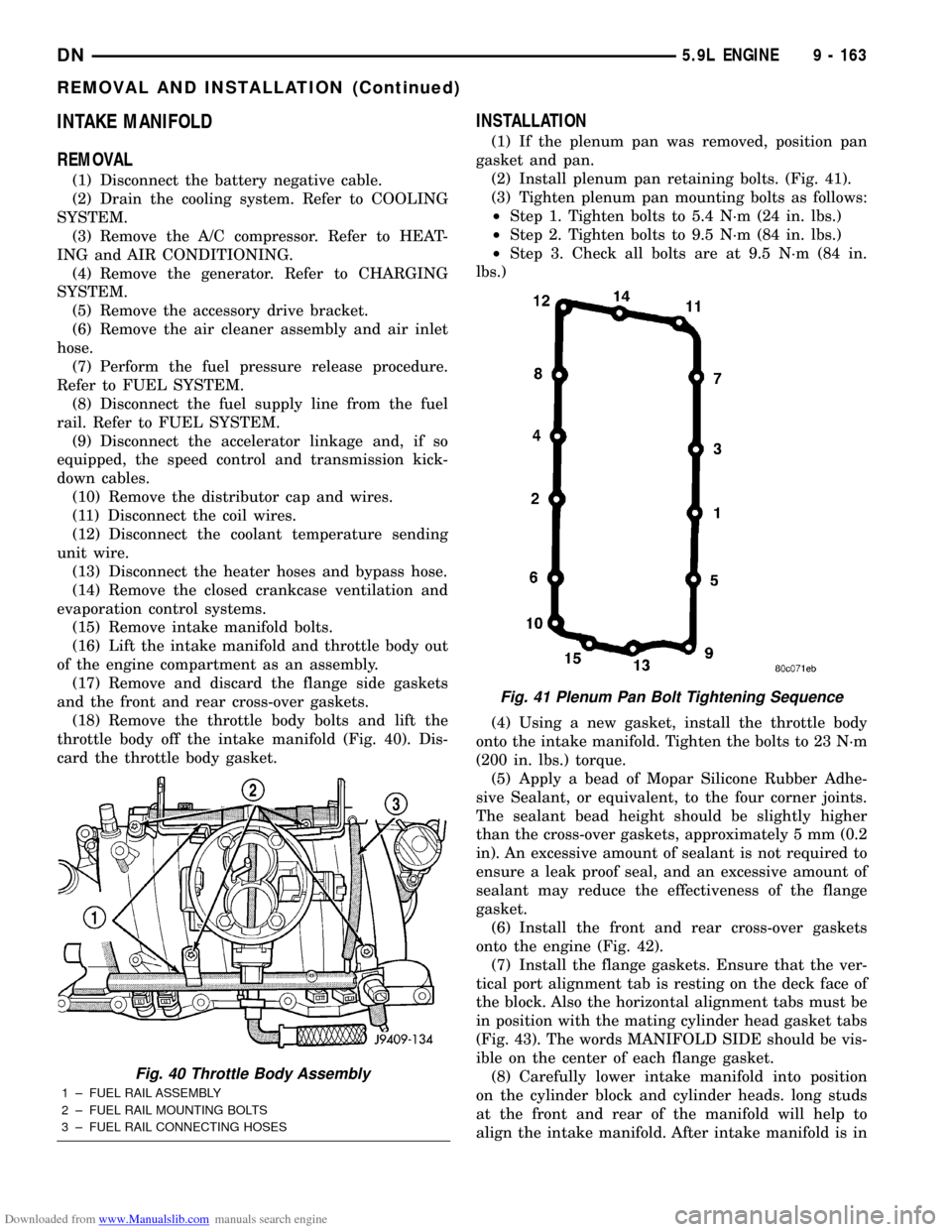

and down fast enough to get a crosshatch pattern.The hone marks should INTERSECT at 50É to 60É

for proper seating of rings (Fig. 17).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

HYDROSTATIC LOCK

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(refer to Group 14, Fuel System).

(2) Disconnect the battery negative cable.

(3) Inspect air cleaner, induction system and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the plugs from the

engine.

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

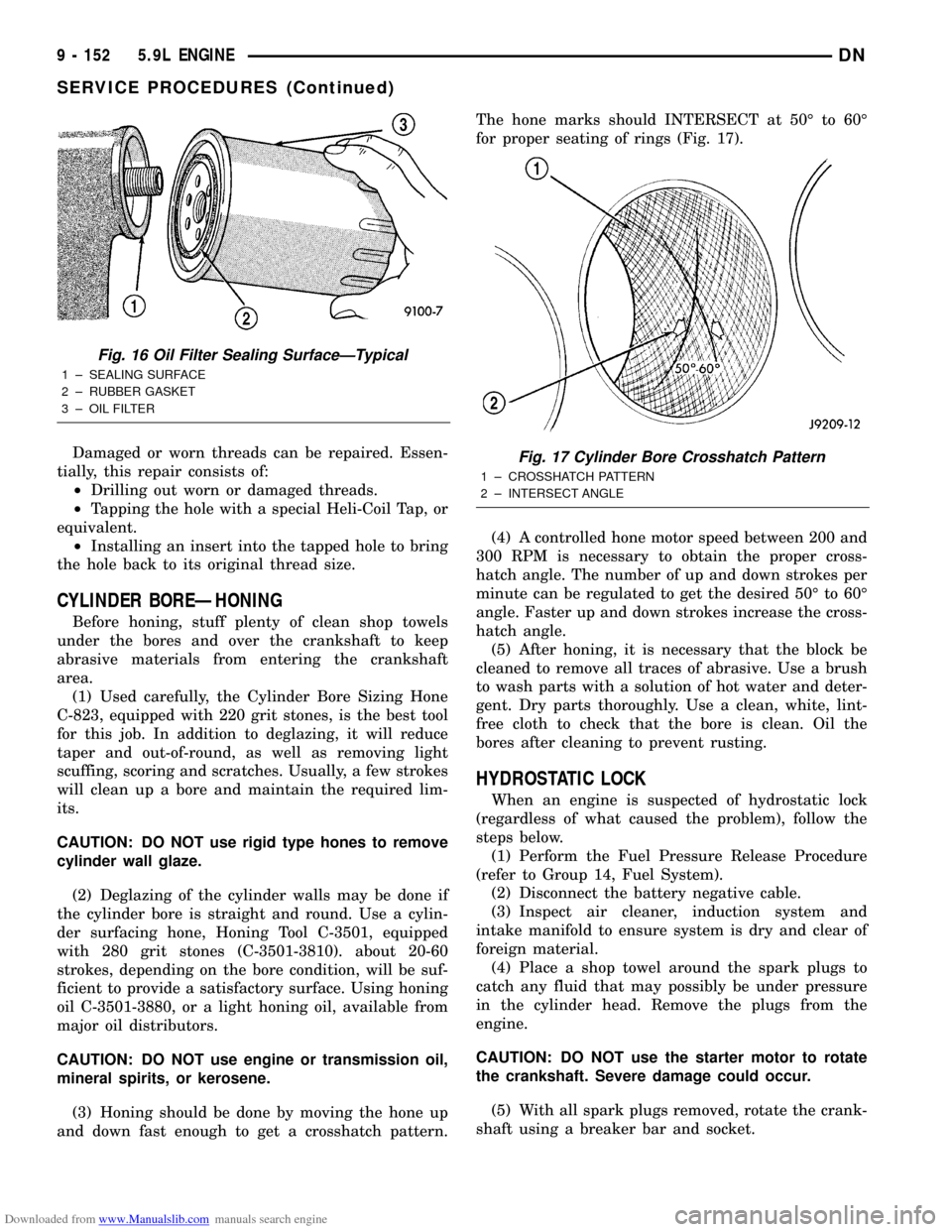

Fig. 16 Oil Filter Sealing SurfaceÐTypical

1 ± SEALING SURFACE

2 ± RUBBER GASKET

3 ± OIL FILTER

Fig. 17 Cylinder Bore Crosshatch Pattern

1 ± CROSSHATCH PATTERN

2 ± INTERSECT ANGLE

9 - 152 5.9L ENGINEDN

SERVICE PROCEDURES (Continued)

Page 164 of 193

Downloaded from www.Manualslib.com manuals search engine INTAKE MANIFOLD

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain the cooling system. Refer to COOLING

SYSTEM.

(3) Remove the A/C compressor. Refer to HEAT-

ING and AIR CONDITIONING.

(4) Remove the generator. Refer to CHARGING

SYSTEM.

(5) Remove the accessory drive bracket.

(6) Remove the air cleaner assembly and air inlet

hose.

(7) Perform the fuel pressure release procedure.

Refer to FUEL SYSTEM.

(8) Disconnect the fuel supply line from the fuel

rail. Refer to FUEL SYSTEM.

(9) Disconnect the accelerator linkage and, if so

equipped, the speed control and transmission kick-

down cables.

(10) Remove the distributor cap and wires.

(11) Disconnect the coil wires.

(12) Disconnect the coolant temperature sending

unit wire.

(13) Disconnect the heater hoses and bypass hose.

(14) Remove the closed crankcase ventilation and

evaporation control systems.

(15) Remove intake manifold bolts.

(16) Lift the intake manifold and throttle body out

of the engine compartment as an assembly.

(17) Remove and discard the flange side gaskets

and the front and rear cross-over gaskets.

(18) Remove the throttle body bolts and lift the

throttle body off the intake manifold (Fig. 40). Dis-

card the throttle body gasket.

INSTALLATION

(1) If the plenum pan was removed, position pan

gasket and pan.

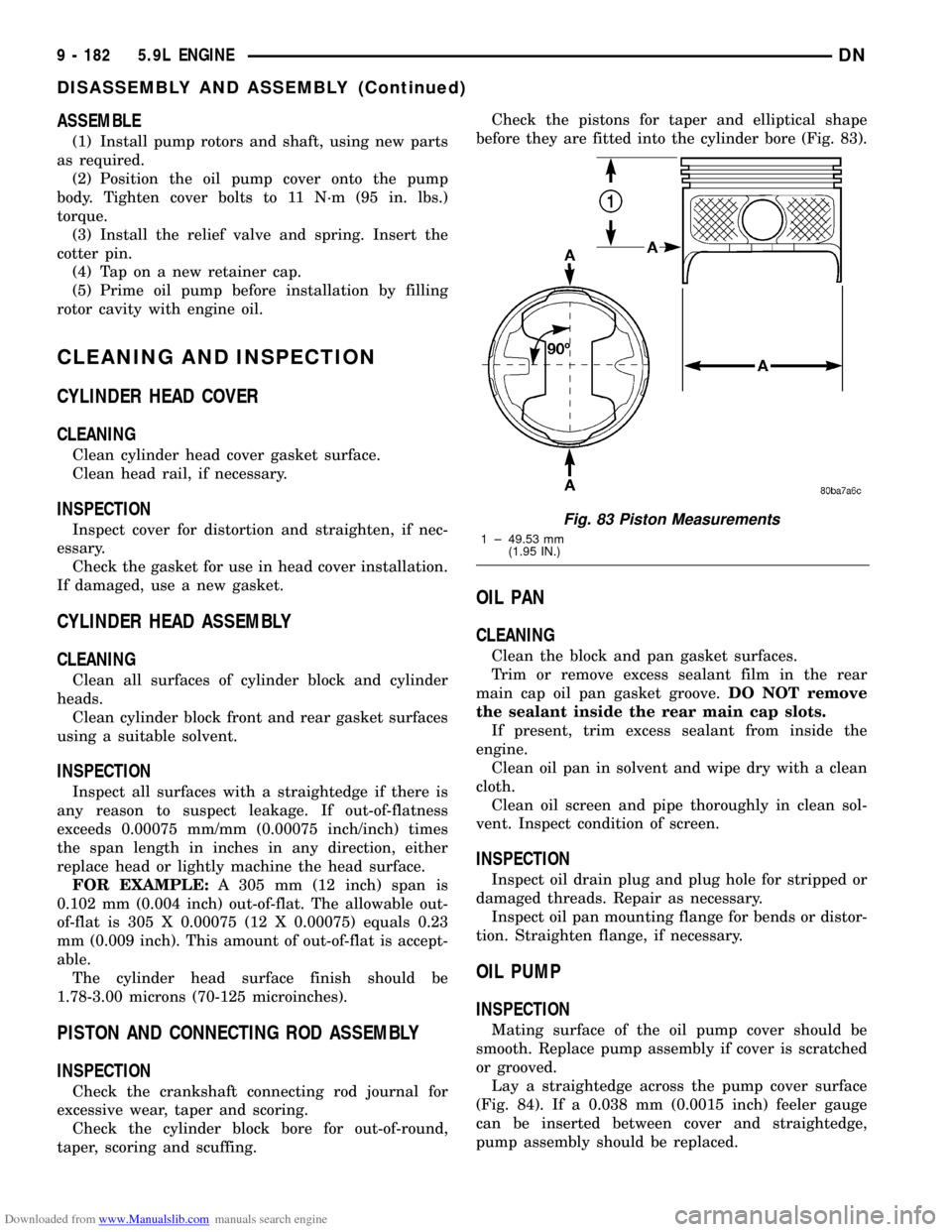

(2) Install plenum pan retaining bolts. (Fig. 41).

(3) Tighten plenum pan mounting bolts as follows:

²Step 1. Tighten bolts to 5.4 N´m (24 in. lbs.)

²Step 2. Tighten bolts to 9.5 N´m (84 in. lbs.)

²Step 3. Check all bolts are at 9.5 N´m (84 in.

lbs.)

(4) Using a new gasket, install the throttle body

onto the intake manifold. Tighten the bolts to 23 N´m

(200 in. lbs.) torque.

(5) Apply a bead of Mopar Silicone Rubber Adhe-

sive Sealant, or equivalent, to the four corner joints.

The sealant bead height should be slightly higher

than the cross-over gaskets, approximately 5 mm (0.2

in). An excessive amount of sealant is not required to

ensure a leak proof seal, and an excessive amount of

sealant may reduce the effectiveness of the flange

gasket.

(6) Install the front and rear cross-over gaskets

onto the engine (Fig. 42).

(7) Install the flange gaskets. Ensure that the ver-

tical port alignment tab is resting on the deck face of

the block. Also the horizontal alignment tabs must be

in position with the mating cylinder head gasket tabs

(Fig. 43). The words MANIFOLD SIDE should be vis-

ible on the center of each flange gasket.

(8) Carefully lower intake manifold into position

on the cylinder block and cylinder heads. long studs

at the front and rear of the manifold will help to

align the intake manifold. After intake manifold is in

Fig. 40 Throttle Body Assembly

1 ± FUEL RAIL ASSEMBLY

2 ± FUEL RAIL MOUNTING BOLTS

3 ± FUEL RAIL CONNECTING HOSES

Fig. 41 Plenum Pan Bolt Tightening Sequence

DN5.9L ENGINE 9 - 163

REMOVAL AND INSTALLATION (Continued)

Page 183 of 193

Downloaded from www.Manualslib.com manuals search engine ASSEMBLE

(1) Install pump rotors and shaft, using new parts

as required.

(2) Position the oil pump cover onto the pump

body. Tighten cover bolts to 11 N´m (95 in. lbs.)

torque.

(3) Install the relief valve and spring. Insert the

cotter pin.

(4) Tap on a new retainer cap.

(5) Prime oil pump before installation by filling

rotor cavity with engine oil.

CLEANING AND INSPECTION

CYLINDER HEAD COVER

CLEANING

Clean cylinder head cover gasket surface.

Clean head rail, if necessary.

INSPECTION

Inspect cover for distortion and straighten, if nec-

essary.

Check the gasket for use in head cover installation.

If damaged, use a new gasket.

CYLINDER HEAD ASSEMBLY

CLEANING

Clean all surfaces of cylinder block and cylinder

heads.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

INSPECTION

Inspect all surfaces with a straightedge if there is

any reason to suspect leakage. If out-of-flatness

exceeds 0.00075 mm/mm (0.00075 inch/inch) times

the span length in inches in any direction, either

replace head or lightly machine the head surface.

FOR EXAMPLE:A 305 mm (12 inch) span is

0.102 mm (0.004 inch) out-of-flat. The allowable out-

of-flat is 305 X 0.00075 (12 X 0.00075) equals 0.23

mm (0.009 inch). This amount of out-of-flat is accept-

able.

The cylinder head surface finish should be

1.78-3.00 microns (70-125 microinches).

PISTON AND CONNECTING ROD ASSEMBLY

INSPECTION

Check the crankshaft connecting rod journal for

excessive wear, taper and scoring.

Check the cylinder block bore for out-of-round,

taper, scoring and scuffing.Check the pistons for taper and elliptical shape

before they are fitted into the cylinder bore (Fig. 83).

OIL PAN

CLEANING

Clean the block and pan gasket surfaces.

Trim or remove excess sealant film in the rear

main cap oil pan gasket groove.DO NOT remove

the sealant inside the rear main cap slots.

If present, trim excess sealant from inside the

engine.

Clean oil pan in solvent and wipe dry with a clean

cloth.

Clean oil screen and pipe thoroughly in clean sol-

vent. Inspect condition of screen.

INSPECTION

Inspect oil drain plug and plug hole for stripped or

damaged threads. Repair as necessary.

Inspect oil pan mounting flange for bends or distor-

tion. Straighten flange, if necessary.

OIL PUMP

INSPECTION

Mating surface of the oil pump cover should be

smooth. Replace pump assembly if cover is scratched

or grooved.

Lay a straightedge across the pump cover surface

(Fig. 84). If a 0.038 mm (0.0015 inch) feeler gauge

can be inserted between cover and straightedge,

pump assembly should be replaced.

Fig. 83 Piston Measurements

1 ± 49.53 mm

(1.95 IN.)

9 - 182 5.9L ENGINEDN

DISASSEMBLY AND ASSEMBLY (Continued)