bolt pattern DODGE DURANGO 1998 1.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: DURANGO, Model: DODGE DURANGO 1998 1.GPages: 193, PDF Size: 5.65 MB

Page 26 of 193

Downloaded from www.Manualslib.com manuals search engine (5) Install bearing cap and connecting rod on the

journal and tighten bolts to 27 N´m (20 ft. lbs.) plus a

90É turn. DO NOT rotate crankshaft. Plastigage will

smear, resulting in inaccurate indication.

(6) Remove the bearing cap and determine amount

of bearing-to-journal clearance by measuring the

width of compressed Plastigage (Fig. 29). Refer to

Engine Specifications for the proper clearance.Plas-

tigage should indicate the same clearance

across the entire width of the insert. If the

clearance varies, it may be caused by either a

tapered journal, bent connecting rod or foreign

material trapped between the insert and cap or

rod.

(7) If the correct clearance is indicated, replace-

ment of the bearing inserts is not necessary. Remove

the Plastigage from crankshaft journal and bearing

insert. Proceed with installation.

(8) If bearing-to-journal clearance exceeds the

specification, determin which services bearing set to

use the bearing sizes are as follows:

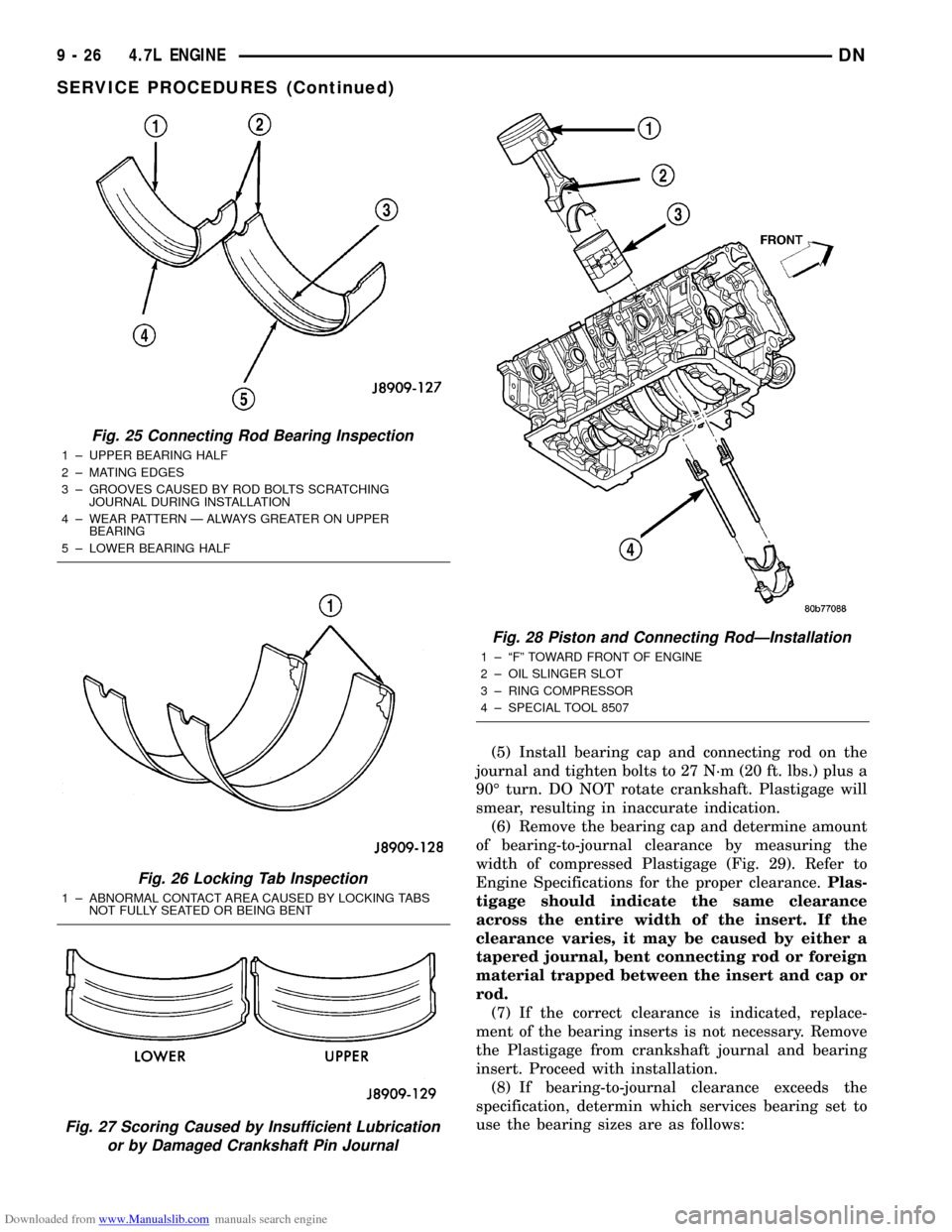

Fig. 25 Connecting Rod Bearing Inspection

1 ± UPPER BEARING HALF

2 ± MATING EDGES

3 ± GROOVES CAUSED BY ROD BOLTS SCRATCHING

JOURNAL DURING INSTALLATION

4 ± WEAR PATTERN Ð ALWAYS GREATER ON UPPER

BEARING

5 ± LOWER BEARING HALF

Fig. 26 Locking Tab Inspection

1 ± ABNORMAL CONTACT AREA CAUSED BY LOCKING TABS

NOT FULLY SEATED OR BEING BENT

Fig. 27 Scoring Caused by Insufficient Lubrication

or by Damaged Crankshaft Pin Journal

Fig. 28 Piston and Connecting RodÐInstallation

1 ± ªFº TOWARD FRONT OF ENGINE

2 ± OIL SLINGER SLOT

3 ± RING COMPRESSOR

4 ± SPECIAL TOOL 8507

9 - 26 4.7L ENGINEDN

SERVICE PROCEDURES (Continued)

Page 27 of 193

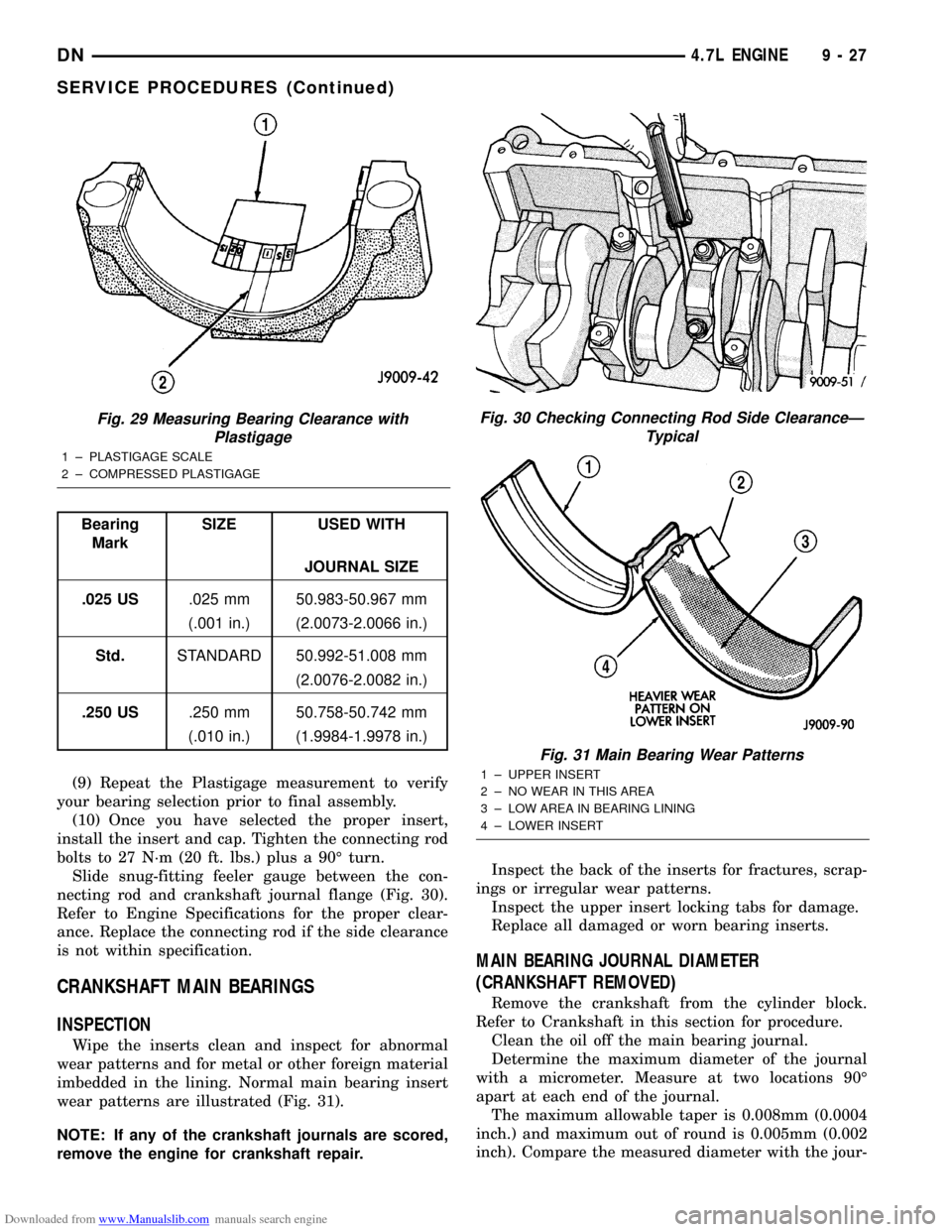

Downloaded from www.Manualslib.com manuals search engine (9) Repeat the Plastigage measurement to verify

your bearing selection prior to final assembly.

(10) Once you have selected the proper insert,

install the insert and cap. Tighten the connecting rod

bolts to 27 N´m (20 ft. lbs.) plus a 90É turn.

Slide snug-fitting feeler gauge between the con-

necting rod and crankshaft journal flange (Fig. 30).

Refer to Engine Specifications for the proper clear-

ance. Replace the connecting rod if the side clearance

is not within specification.

CRANKSHAFT MAIN BEARINGS

INSPECTION

Wipe the inserts clean and inspect for abnormal

wear patterns and for metal or other foreign material

imbedded in the lining. Normal main bearing insert

wear patterns are illustrated (Fig. 31).

NOTE: If any of the crankshaft journals are scored,

remove the engine for crankshaft repair.Inspect the back of the inserts for fractures, scrap-

ings or irregular wear patterns.

Inspect the upper insert locking tabs for damage.

Replace all damaged or worn bearing inserts.

MAIN BEARING JOURNAL DIAMETER

(CRANKSHAFT REMOVED)

Remove the crankshaft from the cylinder block.

Refer to Crankshaft in this section for procedure.

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004

inch.) and maximum out of round is 0.005mm (0.002

inch). Compare the measured diameter with the jour-

Fig. 29 Measuring Bearing Clearance with

Plastigage

1 ± PLASTIGAGE SCALE

2 ± COMPRESSED PLASTIGAGE

Bearing

MarkSIZE USED WITH

JOURNAL SIZE

.025 US.025 mm 50.983-50.967 mm

(.001 in.) (2.0073-2.0066 in.)

Std.STANDARD 50.992-51.008 mm

(2.0076-2.0082 in.)

.250 US.250 mm 50.758-50.742 mm

(.010 in.) (1.9984-1.9978 in.)

Fig. 30 Checking Connecting Rod Side ClearanceÐ

Typical

Fig. 31 Main Bearing Wear Patterns

1 ± UPPER INSERT

2 ± NO WEAR IN THIS AREA

3 ± LOW AREA IN BEARING LINING

4 ± LOWER INSERT

DN4.7L ENGINE 9 - 27

SERVICE PROCEDURES (Continued)