wiring DODGE DURANGO 1998 1.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: DURANGO, Model: DODGE DURANGO 1998 1.GPages: 193, PDF Size: 5.65 MB

Page 8 of 193

Downloaded from www.Manualslib.com manuals search engine SERVICE DIAGNOSISÐPERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery 1. Charge or replace as necessary.

2. Corroded or loose battery

connections.2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to the terminals.

3. Faulty starter. 3. Refer to Group 8A, Battery/

Starter/ Charging System

Diagnostics.

4. Moisture on ignition wires and

distributor cap.4. Wipe wires and cap clean and

dry.

5. Faulty ignition cables. 5. Replace as necessary.

6. Faulty coil or control unit. 6. Refer to Group 8D, Ignition

System.

7. Incorrect spark plug gap. 7. Refer to Group 8D, Ignition

System.

8. Incorrect ignition timing. 8. Refer to Group 8D, Ignition

System.

9. Dirt or water in fuel system. 9. Clean system and replace fuel

filter.

10. Faulty fuel pump, relay or

wiring.10. Refer to Group 14, Fuel System.

ENGINE STALLS OR ROUGH IDLE 1. Idle speed set to low. 1. Refer to Group 14, Fuel System.

2. Idle mixture to lean or to rich. 2. Refer to Group 14, Fuel System.

3. Vacuum leak. 3. Inspect intake manifold and

vacuum hoses, repair or replace as

necessary.

4. Worn or burned distributor rotor. 4. Replace distributor rotor.

5. Incorrect ignition wiring. 5. Install correct wiring.

6. Faulty coil. 6. Refer to Group 8D, Ignition

System.

7. EGR valve leaking. 7. Refer to Group 25, Emissions

Control System.

8. Incorrect cam timing. 8. Refer to Valve Timing in this

section.

9 - 8 4.7L ENGINEDN

DIAGNOSIS AND TESTING (Continued)

Page 33 of 193

Downloaded from www.Manualslib.com manuals search engine (2)4X4 vehiclesInstall locknuts onto the engine

mount brackets. Tighten locknuts to 41 N´m (30 ft.

lbs.).

(3) Remove jack from under the transmission.

(4) Remove Engine Lifting Fixture Special Tool

8347 (Fig. 47).

(5) Remove Special Tools 8400 Lifting Studs.

(6) Position generator wiring behind the oil dip-

stick tube, then install the oil dipstick tube upper

mounting bolt.

(7) Connect both left and right side body ground

straps.(8) Install power steering pump.

(9) Connect fuel supply line quick connect fitting.

(10) Connect the vacuum lines at the throttle body

and intake manifold.

(11) Connect engine harness at the following

points (Fig. 46) :

²Intake Air Temperature (IAT) Sensor

²Idle Air Control (IAC) Motor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure (MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

(12) Position and install heater hoses and tubes

onto intake manifold.

(13) Install the heater hoses onto the heater core

and the engine front cover.

(14) Install generator.

(15) Install A/C condenser, radiator and transmis-

sion oil cooler as an assembly.

(16) Connect radiator upper and lower hoses.

(17) Connect the transmission oil cooler lines to

the radiator.

(18) Install accessory drive belt, fan assembly and

shroud.

(19) Install A/C compressor. Tighten the A/C com-

pressor and generator M10 mounting bolts 40±68N´M

(30±50 ft. lbs.) and the M8 bolts 22±34 N´m (200±300

in. lbs.).

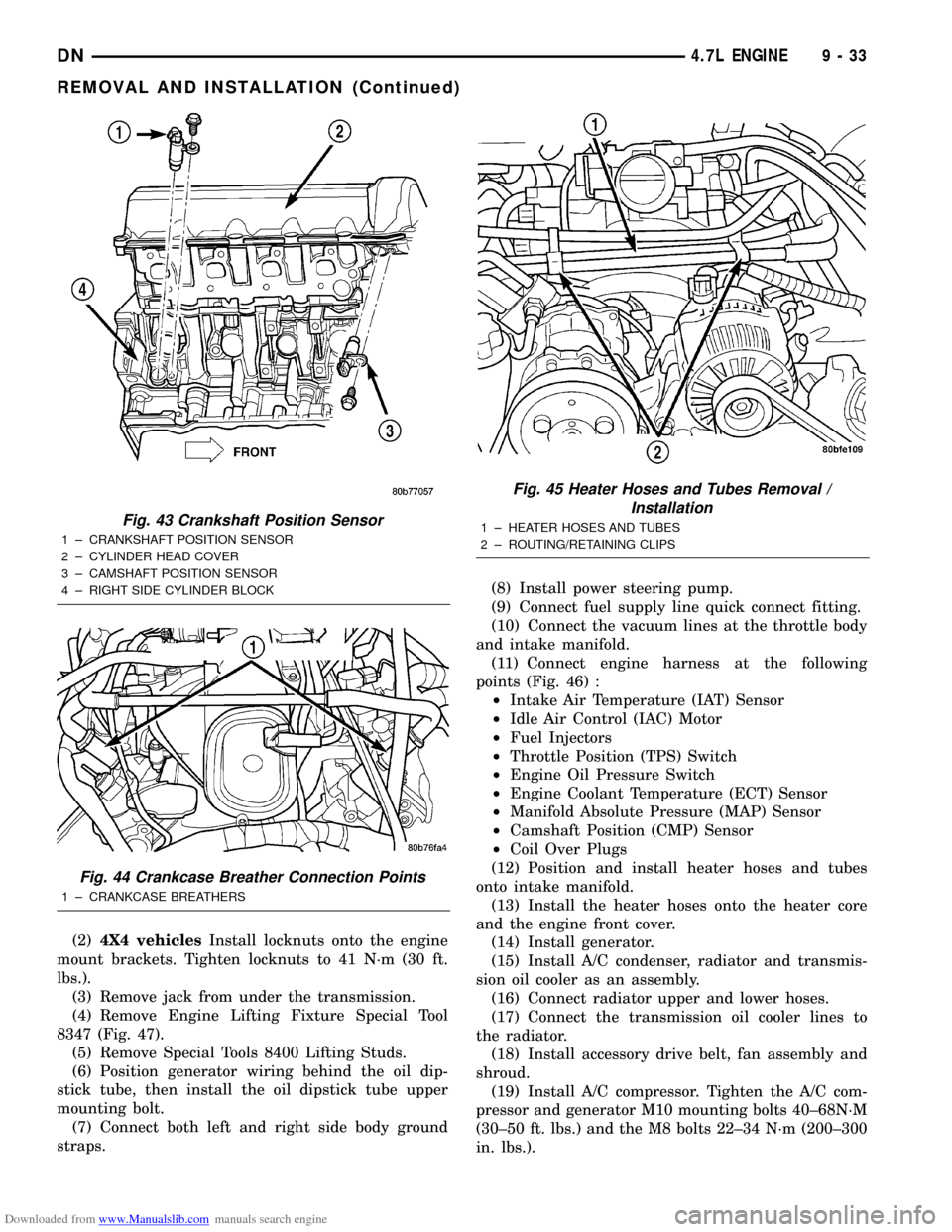

Fig. 43 Crankshaft Position Sensor

1 ± CRANKSHAFT POSITION SENSOR

2 ± CYLINDER HEAD COVER

3 ± CAMSHAFT POSITION SENSOR

4 ± RIGHT SIDE CYLINDER BLOCK

Fig. 44 Crankcase Breather Connection Points

1 ± CRANKCASE BREATHERS

Fig. 45 Heater Hoses and Tubes Removal /

Installation

1 ± HEATER HOSES AND TUBES

2 ± ROUTING/RETAINING CLIPS

DN4.7L ENGINE 9 - 33

REMOVAL AND INSTALLATION (Continued)

Page 103 of 193

Downloaded from www.Manualslib.com manuals search engine (9) Disconnect the accelerator linkage.

(10) Remove throttle body.

(11) Perform the Fuel System Pressure release

procedure (refer to Group 14, fuel System).

(12) Disconnect the fuel supply line.

(13) Disconnect the starter wires.

(14) Disconnect the oil pressure sending unit wire.

(15) Discharge the air conditioning system, if

equipped (refer to Group 24, Heating and Air Condi-

tioning for service procedures).

(16) Disconnect the air conditioning hoses.

(17) Disconnect the power steering hoses, if

equipped.

(18) Remove starter motor (refer to Group 8B, Bat-

tery/Starter/Generator Service).

(19) Remove the generator (refer to Group 8B, Bat-

tery/Starter/Generator Service).

(20) Raise and support the vehicle on a hoist.

(21) Disconnect exhaust pipe at manifold.

(22) Refer to Group 21, Transmissions for trans-

mission removal.

CAUTION: DO NOT lift the engine by the intake

manifold.

(23) Install an engine lifting fixture.

(24) The engine and front driving axle (engine/ax-

le/transmission) are connected through insulators

and support brackets. Separate the engine as follows:

²LEFT SIDEÐRemove 2 bolts attaching

(engine/pinion nose/transmission) bracket to trans-

mission bell housing. Remove 2 bracket to pinion

nose adaptor bolts. Separate engine from insulator by

removing upper nut washer assembly and bolt from

engine support bracket.

²RIGHT SIDEÐRemove 2 bracket to axle (dis-

connect housing) bolts and a bracket to bell housing

bolt. Separate engine from insulator by removing

upper nut washer assembly and bolt from engine

support bracket.

(25) Lower the vehicle.

(26) Install engine assembly on engine repair

stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment.

(2) Install an engine support fixture.

(3) Raise and support the vehicle on a hoist.

(4) Install the engine front mounts.

(5) Refer to Group, 21 Transmissions for transmis-

sion installation

(6) Install the inspection plate.

(7) Remove transmission support.

(8) Install exhaust pipe to manifold.

(9) Lower the vehicle.

(10) Remove engine lifting fixture.(11) Install the generator (refer to Group 8B, Bat-

tery/Starter/Generator Service).

(12) Install starter motor (refer to Group 8B, Bat-

tery/Starter/Generator Service).

(13) Connect power steering hoses, if equipped.

(14) Connect air conditioning hoses.

(15) Evacuate and charge the air conditioning sys-

tem, if equipped (refer to Group 24, Heater and Air

Conditioning for service procedures).

(16) Using a new gasket, install throttle body.

Tighten the throttle body bolts to 23 N´m (200 in.

lbs.) torque.

(17) Connect the accelerator linkage.

(18) Connect the starter wires.

(19) Connect the oil pressure sending unit wire.

(20) Install the distributor cap and wiring.

(21) Connect the vacuum supply lines to the

intake manifold.

(22) Connect the fuel supply lines.

(23) Install the radiator (refer to Group 7, Cooling

System). Connect the radiator hoses and heater

hoses.

(24) Install fan shroud in position.

(25) Fill cooling system (refer to Group 7, Cooling

System for the proper procedure).

(26) Install the air cleaner.

(27) Install the battery.

(28) Warm engine and adjust.

(29) Install hood and line up with the scribe

marks.

(30) Road test vehicle.

INTAKE MANIFOLD

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain the cooling system. Refer to COOLING

SYSTEM.

(3) Remove the A/C compressor. Refer to HEAT-

ING and AIR CONDITIONING.

(4) Remove the generator. Refer to CHARGING

SYSTEM.

(5) Remove the accessory drive bracket.

(6) Remove the air cleaner assembly and air inlet

hose.

(7) Perform the fuel pressure release procedure.

Refer to FUEL SYSTEM.

(8) Disconnect the fuel supply line from the fuel

rail. Refer to FUEL SYSTEM.

(9) Disconnect the accelerator linkage and, if so

equipped, the speed control and transmission kick-

down cables.

(10) Remove the distributor cap and wires.

(11) Disconnect the coil wires.

(12) Disconnect the coolant temperature sending

unit wire.

DN5.2L ENGINE 9 - 103

REMOVAL AND INSTALLATION (Continued)

Page 162 of 193

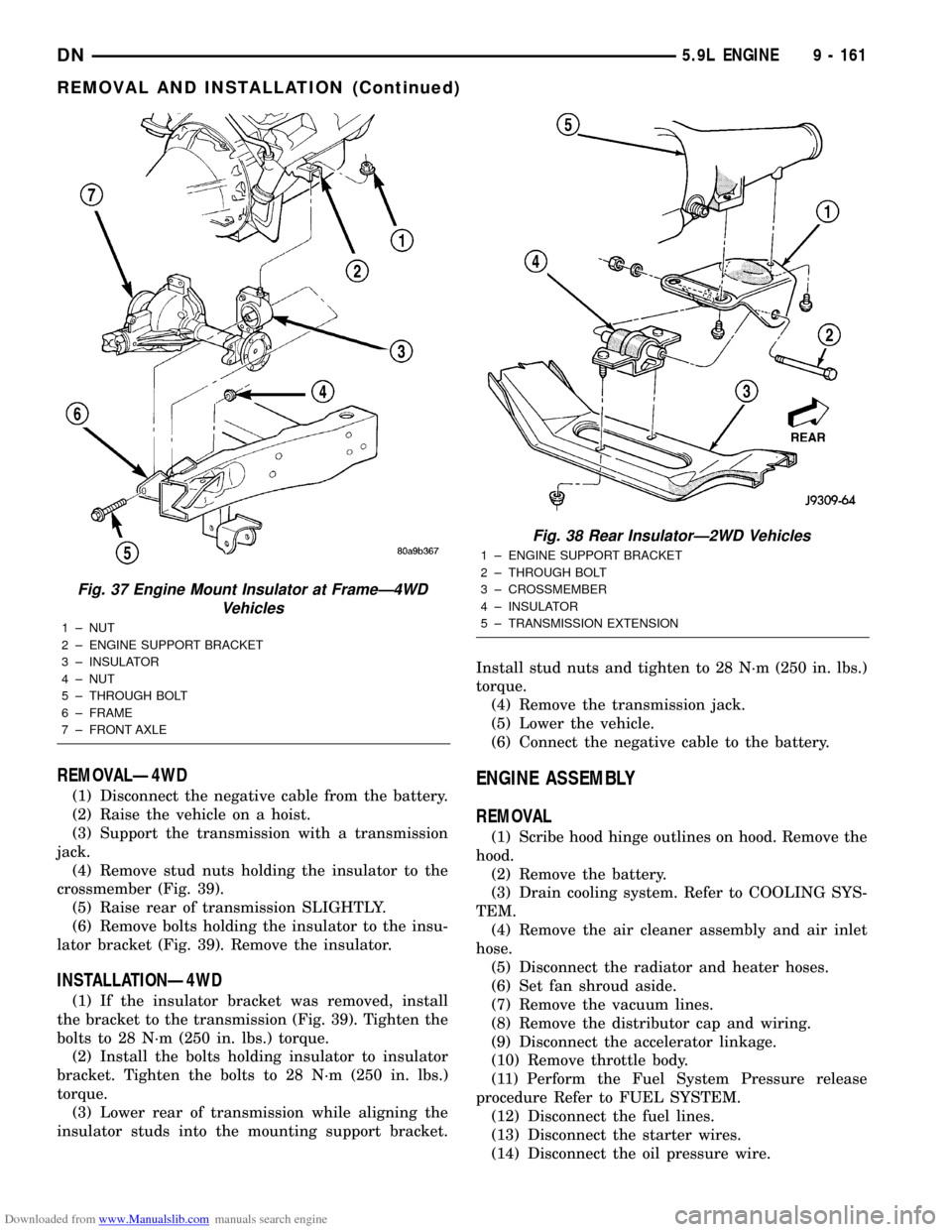

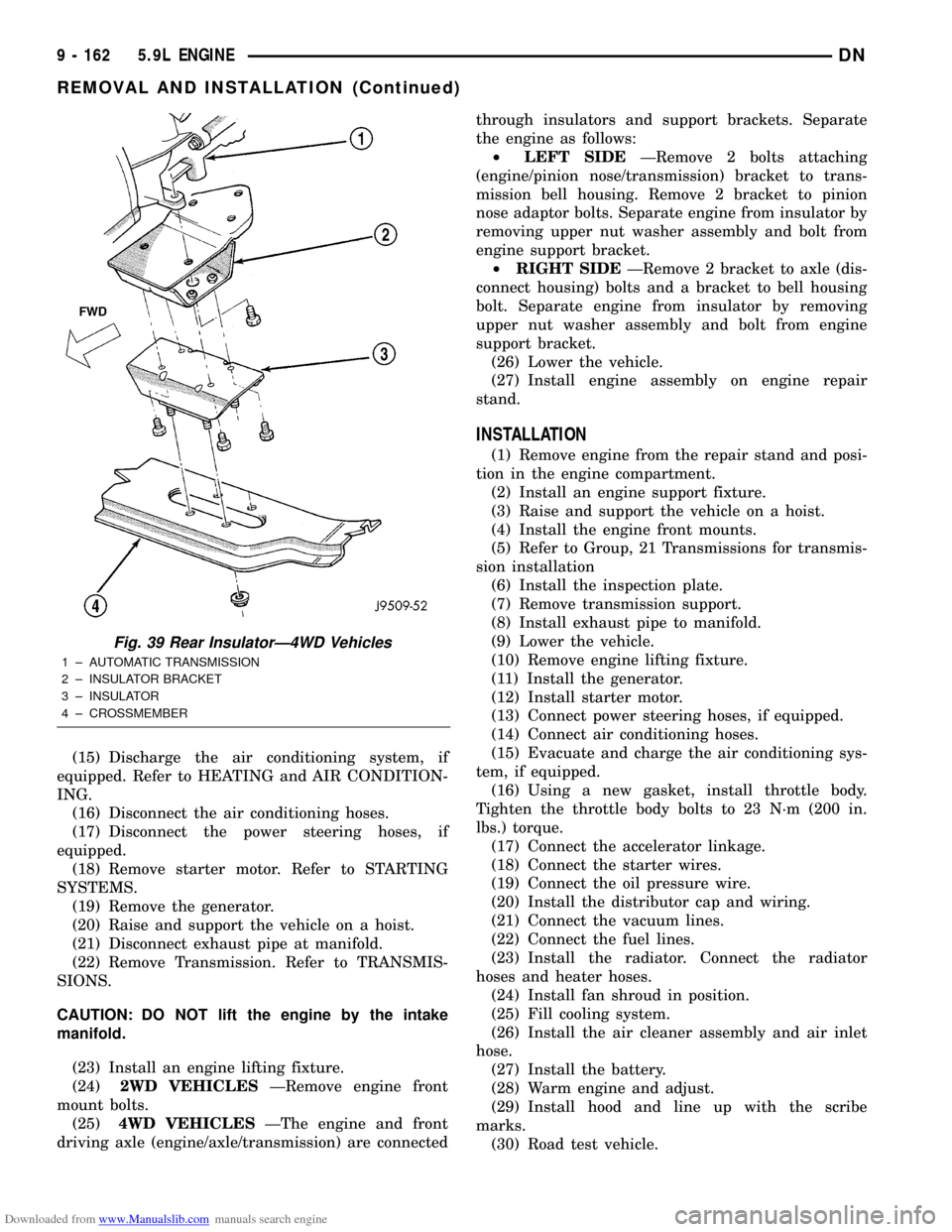

Downloaded from www.Manualslib.com manuals search engine REMOVALÐ4WD

(1) Disconnect the negative cable from the battery.

(2) Raise the vehicle on a hoist.

(3) Support the transmission with a transmission

jack.

(4) Remove stud nuts holding the insulator to the

crossmember (Fig. 39).

(5) Raise rear of transmission SLIGHTLY.

(6) Remove bolts holding the insulator to the insu-

lator bracket (Fig. 39). Remove the insulator.

INSTALLATIONÐ4WD

(1) If the insulator bracket was removed, install

the bracket to the transmission (Fig. 39). Tighten the

bolts to 28 N´m (250 in. lbs.) torque.

(2) Install the bolts holding insulator to insulator

bracket. Tighten the bolts to 28 N´m (250 in. lbs.)

torque.

(3) Lower rear of transmission while aligning the

insulator studs into the mounting support bracket.Install stud nuts and tighten to 28 N´m (250 in. lbs.)

torque.

(4) Remove the transmission jack.

(5) Lower the vehicle.

(6) Connect the negative cable to the battery.

ENGINE ASSEMBLY

REMOVAL

(1) Scribe hood hinge outlines on hood. Remove the

hood.

(2) Remove the battery.

(3) Drain cooling system. Refer to COOLING SYS-

TEM.

(4) Remove the air cleaner assembly and air inlet

hose.

(5) Disconnect the radiator and heater hoses.

(6) Set fan shroud aside.

(7) Remove the vacuum lines.

(8) Remove the distributor cap and wiring.

(9) Disconnect the accelerator linkage.

(10) Remove throttle body.

(11) Perform the Fuel System Pressure release

procedure Refer to FUEL SYSTEM.

(12) Disconnect the fuel lines.

(13) Disconnect the starter wires.

(14) Disconnect the oil pressure wire.

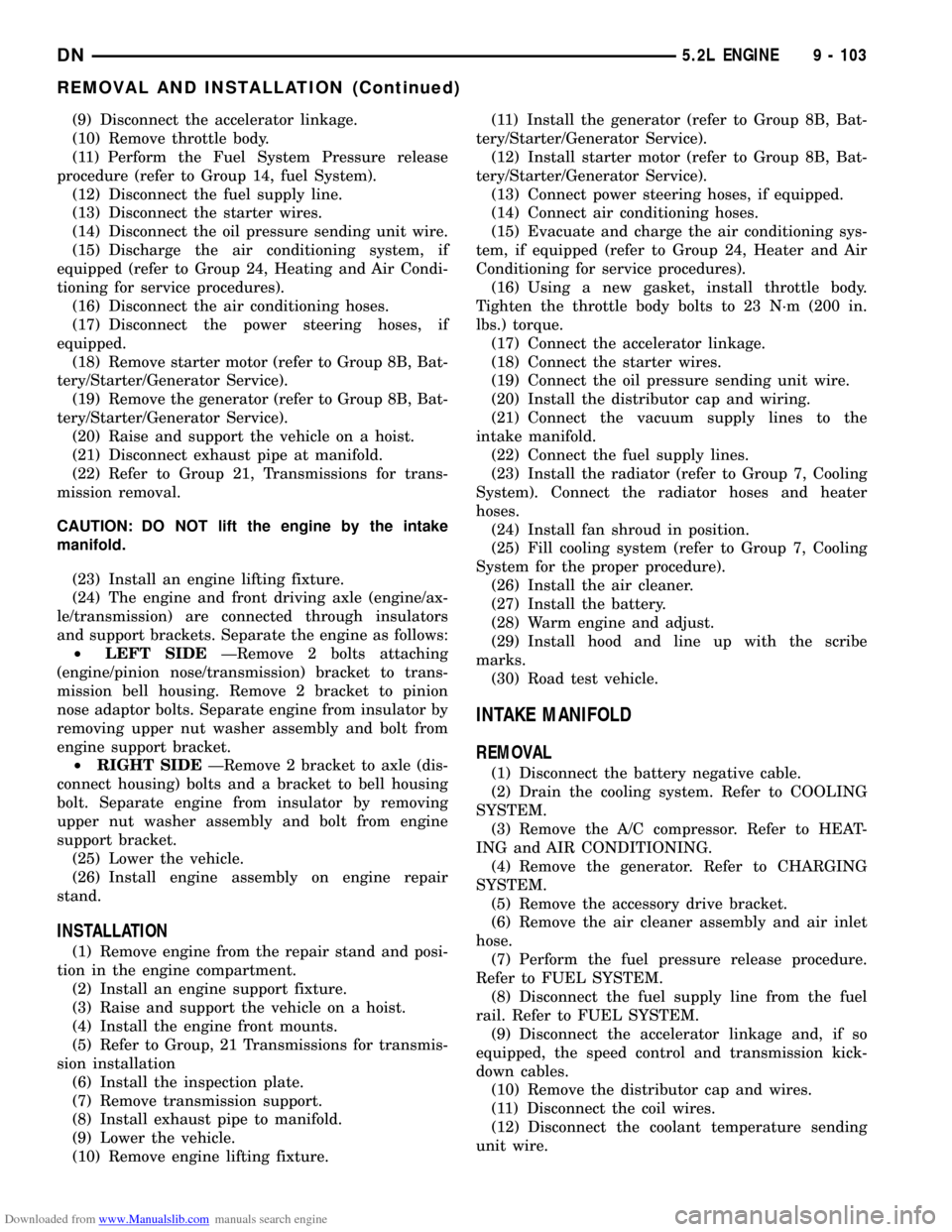

Fig. 37 Engine Mount Insulator at FrameÐ4WD

Vehicles

1 ± NUT

2 ± ENGINE SUPPORT BRACKET

3 ± INSULATOR

4 ± NUT

5 ± THROUGH BOLT

6 ± FRAME

7 ± FRONT AXLE

Fig. 38 Rear InsulatorÐ2WD Vehicles

1 ± ENGINE SUPPORT BRACKET

2 ± THROUGH BOLT

3 ± CROSSMEMBER

4 ± INSULATOR

5 ± TRANSMISSION EXTENSION

DN5.9L ENGINE 9 - 161

REMOVAL AND INSTALLATION (Continued)

Page 163 of 193

Downloaded from www.Manualslib.com manuals search engine (15) Discharge the air conditioning system, if

equipped. Refer to HEATING and AIR CONDITION-

ING.

(16) Disconnect the air conditioning hoses.

(17) Disconnect the power steering hoses, if

equipped.

(18) Remove starter motor. Refer to STARTING

SYSTEMS.

(19) Remove the generator.

(20) Raise and support the vehicle on a hoist.

(21) Disconnect exhaust pipe at manifold.

(22) Remove Transmission. Refer to TRANSMIS-

SIONS.

CAUTION: DO NOT lift the engine by the intake

manifold.

(23) Install an engine lifting fixture.

(24)2WD VEHICLESÐRemove engine front

mount bolts.

(25)4WD VEHICLESÐThe engine and front

driving axle (engine/axle/transmission) are connectedthrough insulators and support brackets. Separate

the engine as follows:

²LEFT SIDEÐRemove 2 bolts attaching

(engine/pinion nose/transmission) bracket to trans-

mission bell housing. Remove 2 bracket to pinion

nose adaptor bolts. Separate engine from insulator by

removing upper nut washer assembly and bolt from

engine support bracket.

²RIGHT SIDEÐRemove 2 bracket to axle (dis-

connect housing) bolts and a bracket to bell housing

bolt. Separate engine from insulator by removing

upper nut washer assembly and bolt from engine

support bracket.

(26) Lower the vehicle.

(27) Install engine assembly on engine repair

stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment.

(2) Install an engine support fixture.

(3) Raise and support the vehicle on a hoist.

(4) Install the engine front mounts.

(5) Refer to Group, 21 Transmissions for transmis-

sion installation

(6) Install the inspection plate.

(7) Remove transmission support.

(8) Install exhaust pipe to manifold.

(9) Lower the vehicle.

(10) Remove engine lifting fixture.

(11) Install the generator.

(12) Install starter motor.

(13) Connect power steering hoses, if equipped.

(14) Connect air conditioning hoses.

(15) Evacuate and charge the air conditioning sys-

tem, if equipped.

(16) Using a new gasket, install throttle body.

Tighten the throttle body bolts to 23 N´m (200 in.

lbs.) torque.

(17) Connect the accelerator linkage.

(18) Connect the starter wires.

(19) Connect the oil pressure wire.

(20) Install the distributor cap and wiring.

(21) Connect the vacuum lines.

(22) Connect the fuel lines.

(23) Install the radiator. Connect the radiator

hoses and heater hoses.

(24) Install fan shroud in position.

(25) Fill cooling system.

(26) Install the air cleaner assembly and air inlet

hose.

(27) Install the battery.

(28) Warm engine and adjust.

(29) Install hood and line up with the scribe

marks.

(30) Road test vehicle.

Fig. 39 Rear InsulatorÐ4WD Vehicles

1 ± AUTOMATIC TRANSMISSION

2 ± INSULATOR BRACKET

3 ± INSULATOR

4 ± CROSSMEMBER

9 - 162 5.9L ENGINEDN

REMOVAL AND INSTALLATION (Continued)