Power steering DODGE DURANGO 1999 1.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: DURANGO, Model: DODGE DURANGO 1999 1.GPages: 193, PDF Size: 5.65 MB

Page 32 of 193

Downloaded from www.Manualslib.com manuals search engine ²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold absolute pressure (MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

(31) Disconnect the vacuum lines at the throttle

body and intake manifold.

(32) Release fuel rail pressure then disconnect the

fuel supply quick connect fitting at the fuel rail.

Refer toFUEL SYSTEM for procedure.

(33) Remove power steering pump and position out

of the way.

(34) Install Special Tools 8400 Lifting Studs, into

the cylinder heads.

(35) Install Engine Lifting Fixture Special Tool

8347 (Fig. 47) following these steps.

²Holding the lifting fixture at a slight angle, slide

the large bore in the front plate over the hex portion

of the lifting stud.

²Position the two remaining fixture arms onto

the two Special Tools 8400 Lifting Studs, in the cyl-

inder heads.

²Pull foward and upward on the lifting fixture so

that the lifting stud rest in the slotted area below the

large bore.²Secure the lifting fixture to the three studs

using three 7/16 ± 14 N/C locknuts.

²Make sure the lifting loop in the lifting fixture is

in the last hole (closest to the throttle body) to min-

imize the angle of engine during removal.

(36) Disconnect body ground strap at the right side

cowl (Fig. 48).

(37) Disconnect body ground strap at the left side

cowl (Fig. 49).

NOTE: It will be necessary to support the transmis-

sion in order to remove the engine.

(38) Position a suitable jack under the transmis-

sion.

(39) Remove engine from the vehicle.

INSTALLATION

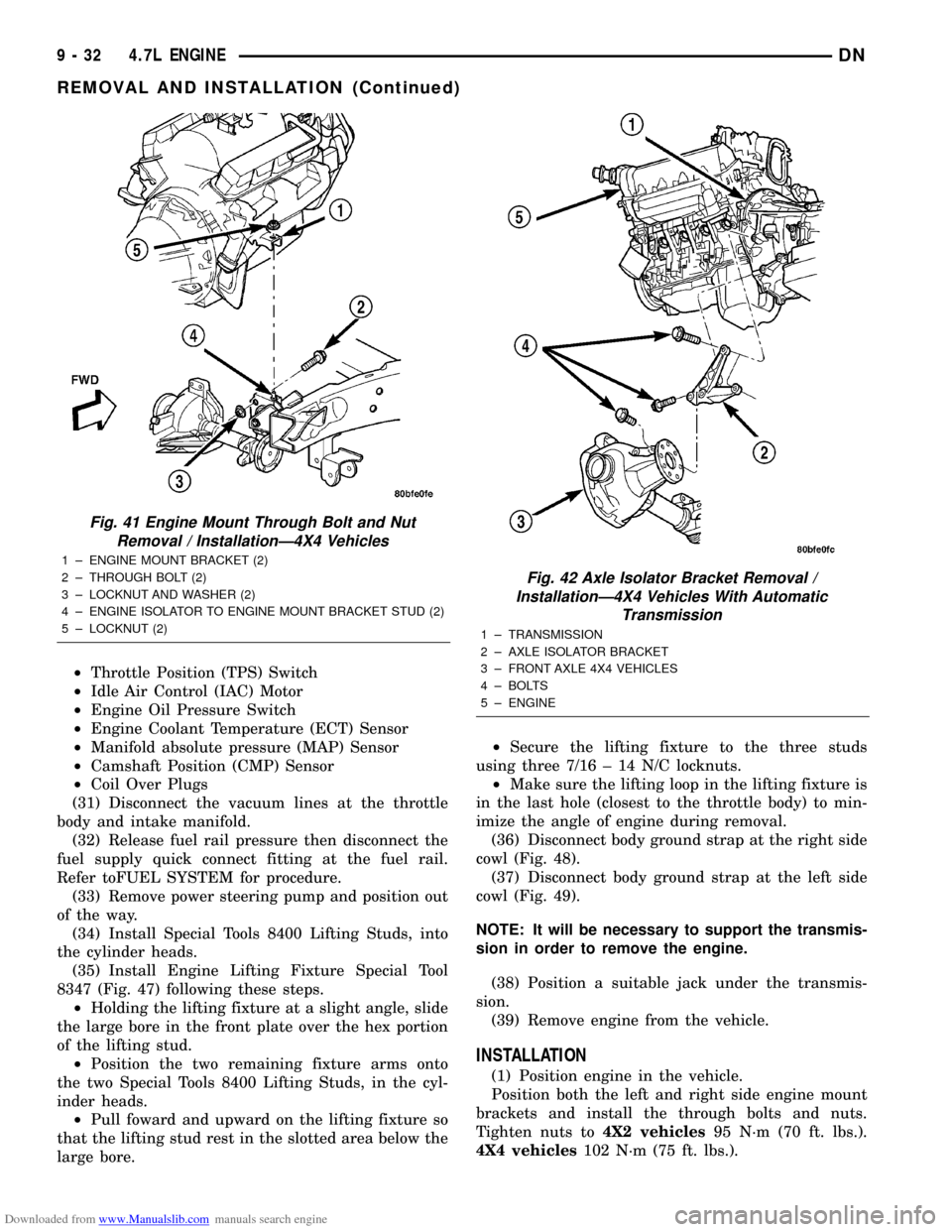

(1) Position engine in the vehicle.

Position both the left and right side engine mount

brackets and install the through bolts and nuts.

Tighten nuts to4X2 vehicles95 N´m (70 ft. lbs.).

4X4 vehicles102 N´m (75 ft. lbs.).

Fig. 41 Engine Mount Through Bolt and Nut

Removal / InstallationÐ4X4 Vehicles

1 ± ENGINE MOUNT BRACKET (2)

2 ± THROUGH BOLT (2)

3 ± LOCKNUT AND WASHER (2)

4 ± ENGINE ISOLATOR TO ENGINE MOUNT BRACKET STUD (2)

5 ± LOCKNUT (2)

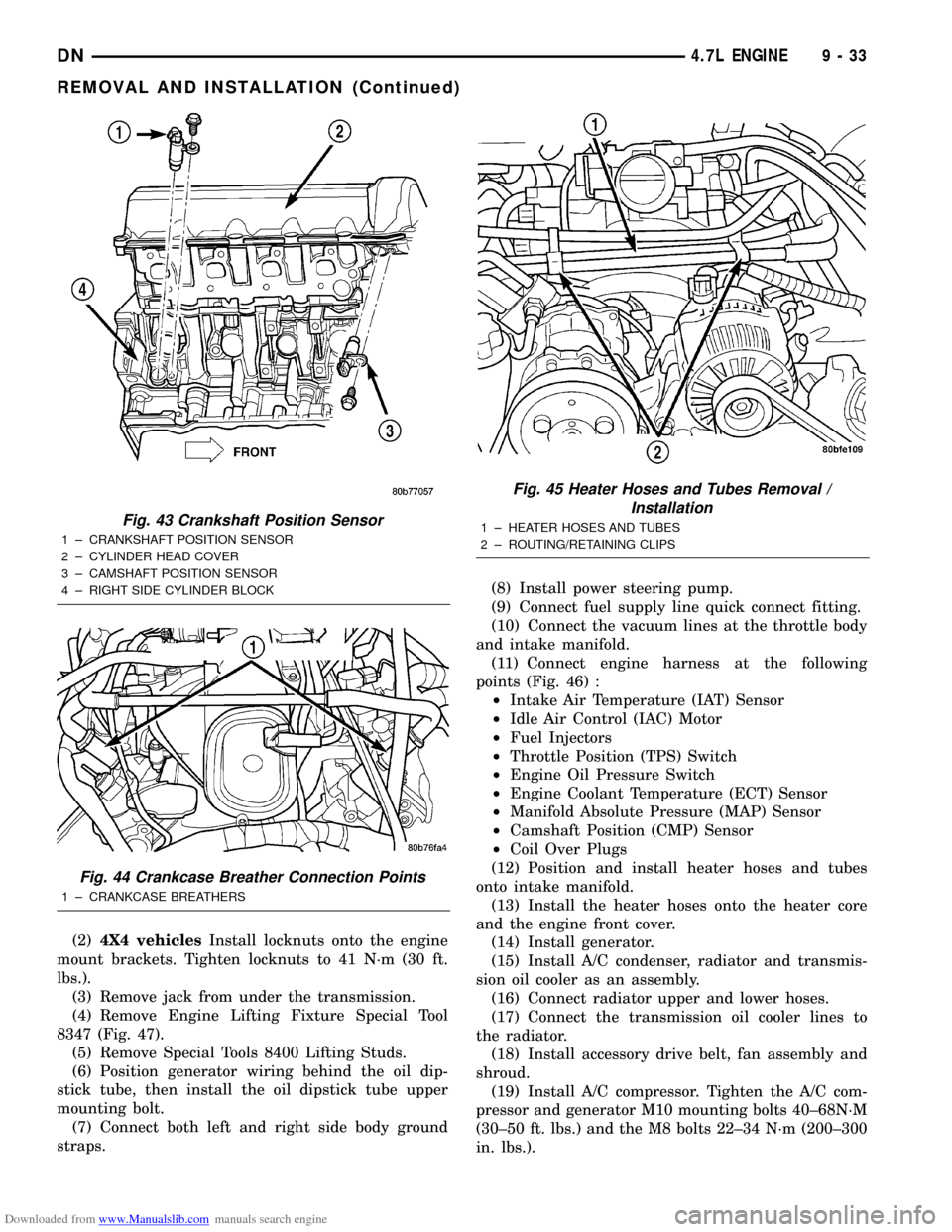

Fig. 42 Axle Isolator Bracket Removal /

InstallationÐ4X4 Vehicles With Automatic

Transmission

1 ± TRANSMISSION

2 ± AXLE ISOLATOR BRACKET

3 ± FRONT AXLE 4X4 VEHICLES

4 ± BOLTS

5 ± ENGINE

9 - 32 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 33 of 193

Downloaded from www.Manualslib.com manuals search engine (2)4X4 vehiclesInstall locknuts onto the engine

mount brackets. Tighten locknuts to 41 N´m (30 ft.

lbs.).

(3) Remove jack from under the transmission.

(4) Remove Engine Lifting Fixture Special Tool

8347 (Fig. 47).

(5) Remove Special Tools 8400 Lifting Studs.

(6) Position generator wiring behind the oil dip-

stick tube, then install the oil dipstick tube upper

mounting bolt.

(7) Connect both left and right side body ground

straps.(8) Install power steering pump.

(9) Connect fuel supply line quick connect fitting.

(10) Connect the vacuum lines at the throttle body

and intake manifold.

(11) Connect engine harness at the following

points (Fig. 46) :

²Intake Air Temperature (IAT) Sensor

²Idle Air Control (IAC) Motor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure (MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

(12) Position and install heater hoses and tubes

onto intake manifold.

(13) Install the heater hoses onto the heater core

and the engine front cover.

(14) Install generator.

(15) Install A/C condenser, radiator and transmis-

sion oil cooler as an assembly.

(16) Connect radiator upper and lower hoses.

(17) Connect the transmission oil cooler lines to

the radiator.

(18) Install accessory drive belt, fan assembly and

shroud.

(19) Install A/C compressor. Tighten the A/C com-

pressor and generator M10 mounting bolts 40±68N´M

(30±50 ft. lbs.) and the M8 bolts 22±34 N´m (200±300

in. lbs.).

Fig. 43 Crankshaft Position Sensor

1 ± CRANKSHAFT POSITION SENSOR

2 ± CYLINDER HEAD COVER

3 ± CAMSHAFT POSITION SENSOR

4 ± RIGHT SIDE CYLINDER BLOCK

Fig. 44 Crankcase Breather Connection Points

1 ± CRANKCASE BREATHERS

Fig. 45 Heater Hoses and Tubes Removal /

Installation

1 ± HEATER HOSES AND TUBES

2 ± ROUTING/RETAINING CLIPS

DN4.7L ENGINE 9 - 33

REMOVAL AND INSTALLATION (Continued)

Page 41 of 193

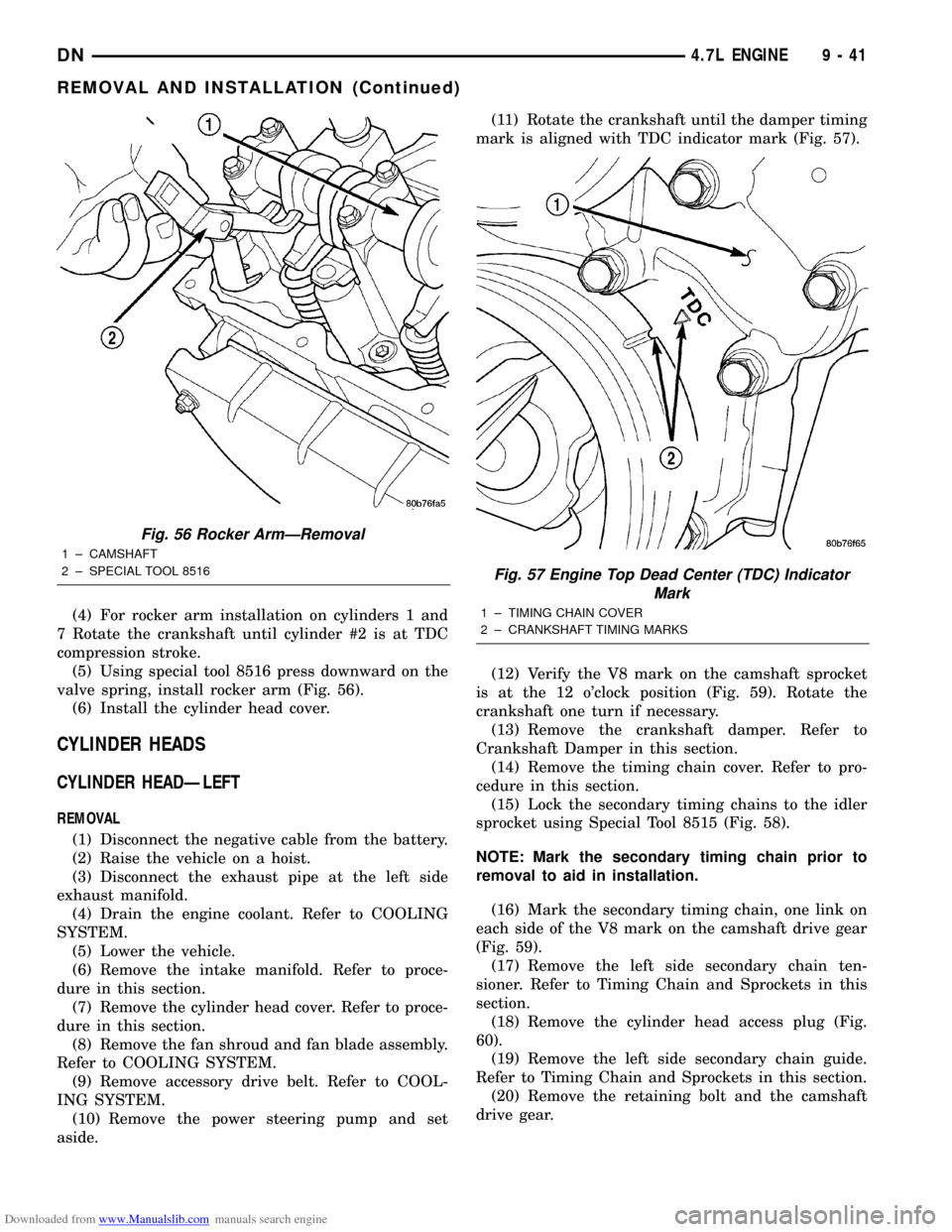

Downloaded from www.Manualslib.com manuals search engine (4) For rocker arm installation on cylinders 1 and

7 Rotate the crankshaft until cylinder #2 is at TDC

compression stroke.

(5) Using special tool 8516 press downward on the

valve spring, install rocker arm (Fig. 56).

(6) Install the cylinder head cover.

CYLINDER HEADS

CYLINDER HEADÐLEFT

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the left side

exhaust manifold.

(4) Drain the engine coolant. Refer to COOLING

SYSTEM.

(5) Lower the vehicle.

(6) Remove the intake manifold. Refer to proce-

dure in this section.

(7) Remove the cylinder head cover. Refer to proce-

dure in this section.

(8) Remove the fan shroud and fan blade assembly.

Refer to COOLING SYSTEM.

(9) Remove accessory drive belt. Refer to COOL-

ING SYSTEM.

(10) Remove the power steering pump and set

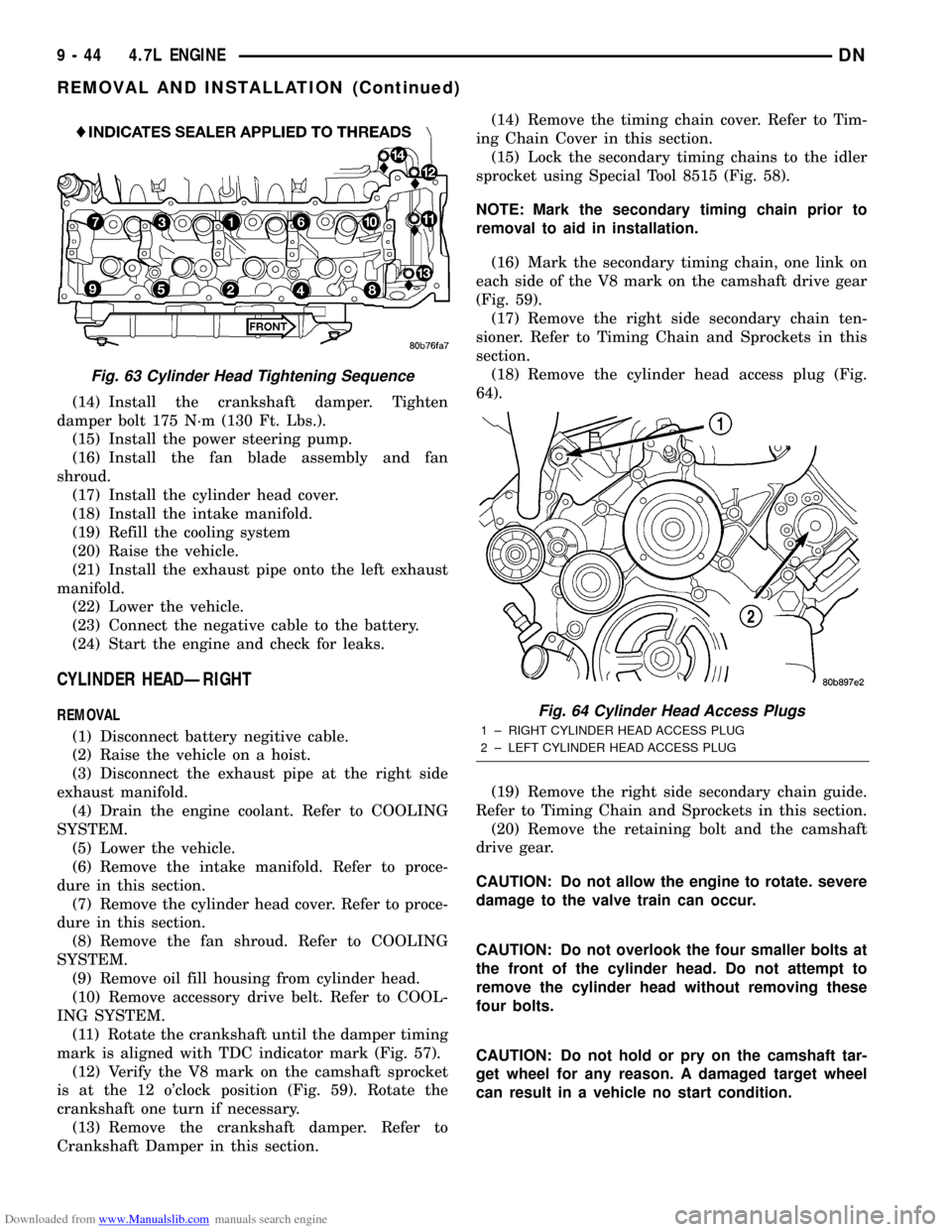

aside.(11) Rotate the crankshaft until the damper timing

mark is aligned with TDC indicator mark (Fig. 57).

(12) Verify the V8 mark on the camshaft sprocket

is at the 12 o'clock position (Fig. 59). Rotate the

crankshaft one turn if necessary.

(13) Remove the crankshaft damper. Refer to

Crankshaft Damper in this section.

(14) Remove the timing chain cover. Refer to pro-

cedure in this section.

(15) Lock the secondary timing chains to the idler

sprocket using Special Tool 8515 (Fig. 58).

NOTE: Mark the secondary timing chain prior to

removal to aid in installation.

(16) Mark the secondary timing chain, one link on

each side of the V8 mark on the camshaft drive gear

(Fig. 59).

(17) Remove the left side secondary chain ten-

sioner. Refer to Timing Chain and Sprockets in this

section.

(18) Remove the cylinder head access plug (Fig.

60).

(19) Remove the left side secondary chain guide.

Refer to Timing Chain and Sprockets in this section.

(20) Remove the retaining bolt and the camshaft

drive gear.

Fig. 56 Rocker ArmÐRemoval

1 ± CAMSHAFT

2 ± SPECIAL TOOL 8516

Fig. 57 Engine Top Dead Center (TDC) Indicator

Mark

1 ± TIMING CHAIN COVER

2 ± CRANKSHAFT TIMING MARKS

DN4.7L ENGINE 9 - 41

REMOVAL AND INSTALLATION (Continued)

Page 44 of 193

Downloaded from www.Manualslib.com manuals search engine (14) Install the crankshaft damper. Tighten

damper bolt 175 N´m (130 Ft. Lbs.).

(15) Install the power steering pump.

(16) Install the fan blade assembly and fan

shroud.

(17) Install the cylinder head cover.

(18) Install the intake manifold.

(19) Refill the cooling system

(20) Raise the vehicle.

(21) Install the exhaust pipe onto the left exhaust

manifold.

(22) Lower the vehicle.

(23) Connect the negative cable to the battery.

(24) Start the engine and check for leaks.

CYLINDER HEADÐRIGHT

REMOVAL

(1) Disconnect battery negitive cable.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the right side

exhaust manifold.

(4) Drain the engine coolant. Refer to COOLING

SYSTEM.

(5) Lower the vehicle.

(6) Remove the intake manifold. Refer to proce-

dure in this section.

(7) Remove the cylinder head cover. Refer to proce-

dure in this section.

(8) Remove the fan shroud. Refer to COOLING

SYSTEM.

(9) Remove oil fill housing from cylinder head.

(10) Remove accessory drive belt. Refer to COOL-

ING SYSTEM.

(11) Rotate the crankshaft until the damper timing

mark is aligned with TDC indicator mark (Fig. 57).

(12) Verify the V8 mark on the camshaft sprocket

is at the 12 o'clock position (Fig. 59). Rotate the

crankshaft one turn if necessary.

(13) Remove the crankshaft damper. Refer to

Crankshaft Damper in this section.(14) Remove the timing chain cover. Refer to Tim-

ing Chain Cover in this section.

(15) Lock the secondary timing chains to the idler

sprocket using Special Tool 8515 (Fig. 58).

NOTE: Mark the secondary timing chain prior to

removal to aid in installation.

(16) Mark the secondary timing chain, one link on

each side of the V8 mark on the camshaft drive gear

(Fig. 59).

(17) Remove the right side secondary chain ten-

sioner. Refer to Timing Chain and Sprockets in this

section.

(18) Remove the cylinder head access plug (Fig.

64).

(19) Remove the right side secondary chain guide.

Refer to Timing Chain and Sprockets in this section.

(20) Remove the retaining bolt and the camshaft

drive gear.

CAUTION: Do not allow the engine to rotate. severe

damage to the valve train can occur.

CAUTION: Do not overlook the four smaller bolts at

the front of the cylinder head. Do not attempt to

remove the cylinder head without removing these

four bolts.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel for any reason. A damaged target wheel

can result in a vehicle no start condition.

Fig. 63 Cylinder Head Tightening Sequence

Fig. 64 Cylinder Head Access Plugs

1 ± RIGHT CYLINDER HEAD ACCESS PLUG

2 ± LEFT CYLINDER HEAD ACCESS PLUG

9 - 44 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 49 of 193

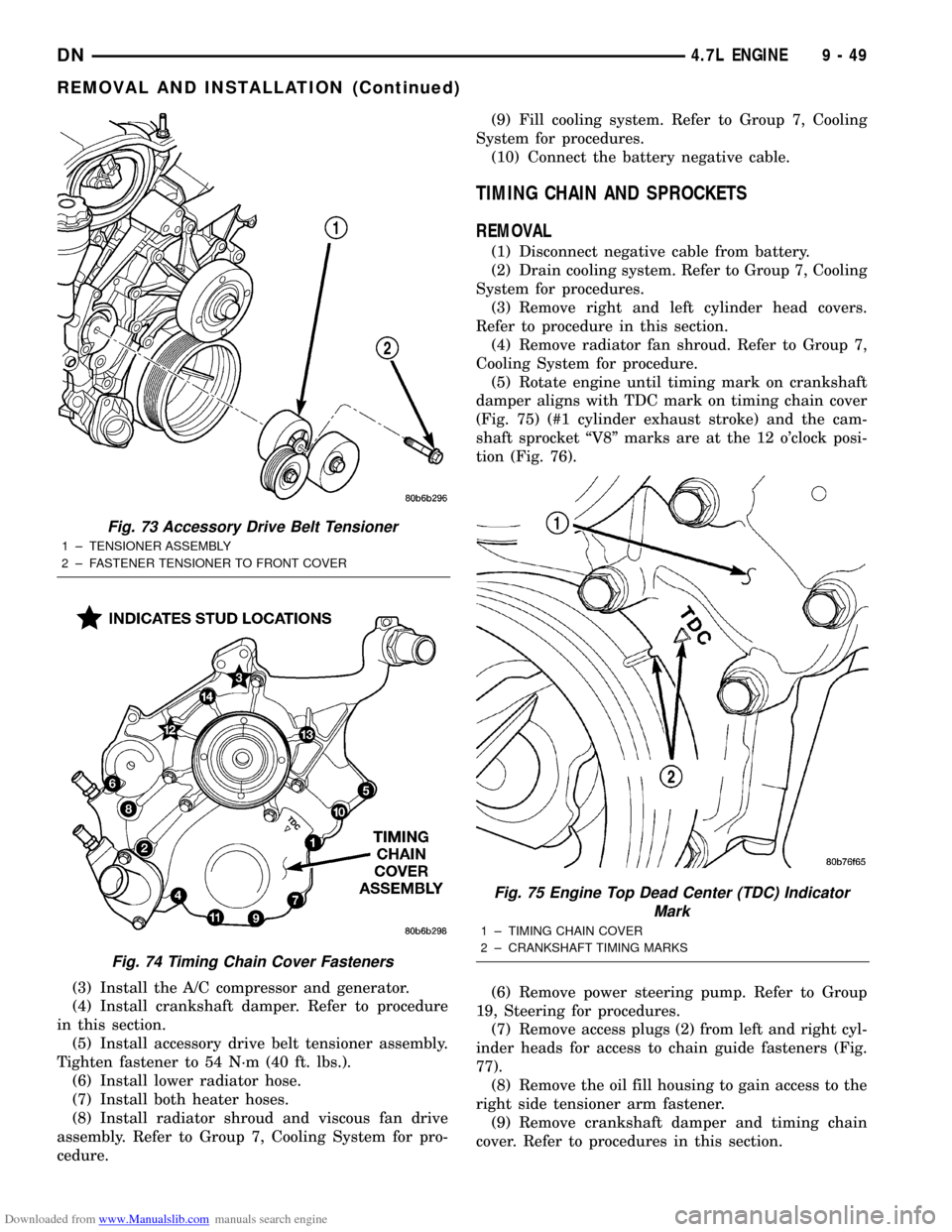

Downloaded from www.Manualslib.com manuals search engine (3) Install the A/C compressor and generator.

(4) Install crankshaft damper. Refer to procedure

in this section.

(5) Install accessory drive belt tensioner assembly.

Tighten fastener to 54 N´m (40 ft. lbs.).

(6) Install lower radiator hose.

(7) Install both heater hoses.

(8) Install radiator shroud and viscous fan drive

assembly. Refer to Group 7, Cooling System for pro-

cedure.(9) Fill cooling system. Refer to Group 7, Cooling

System for procedures.

(10) Connect the battery negative cable.

TIMING CHAIN AND SPROCKETS

REMOVAL

(1) Disconnect negative cable from battery.

(2) Drain cooling system. Refer to Group 7, Cooling

System for procedures.

(3) Remove right and left cylinder head covers.

Refer to procedure in this section.

(4) Remove radiator fan shroud. Refer to Group 7,

Cooling System for procedure.

(5) Rotate engine until timing mark on crankshaft

damper aligns with TDC mark on timing chain cover

(Fig. 75) (#1 cylinder exhaust stroke) and the cam-

shaft sprocket ªV8º marks are at the 12 o'clock posi-

tion (Fig. 76).

(6) Remove power steering pump. Refer to Group

19, Steering for procedures.

(7) Remove access plugs (2) from left and right cyl-

inder heads for access to chain guide fasteners (Fig.

77).

(8) Remove the oil fill housing to gain access to the

right side tensioner arm fastener.

(9) Remove crankshaft damper and timing chain

cover. Refer to procedures in this section.

Fig. 73 Accessory Drive Belt Tensioner

1 ± TENSIONER ASSEMBLY

2 ± FASTENER TENSIONER TO FRONT COVER

Fig. 74 Timing Chain Cover Fasteners

Fig. 75 Engine Top Dead Center (TDC) Indicator

Mark

1 ± TIMING CHAIN COVER

2 ± CRANKSHAFT TIMING MARKS

DN4.7L ENGINE 9 - 49

REMOVAL AND INSTALLATION (Continued)

Page 55 of 193

Downloaded from www.Manualslib.com manuals search engine (24) Coat the large threaded access plug with

MopartThread Sealant with Teflon, then install

into the right cylinder head and tighten to 81 N´m

(60 ft. lbs.) (Fig. 77).(25) Install the oil fill housing.

(26) Install access plug in left cylinder head (Fig.

77).

(27) Install power steering pump. Refer to Group

19, Steering for procedure.

(28) Install radiator fan shroud. Refer to Group 7,

Cooling System for procedure.

(29) Fill cooling system. Refer to Group 7, Cooling

System for coolant fill procedure.

(30) Connect negative cable to battery.

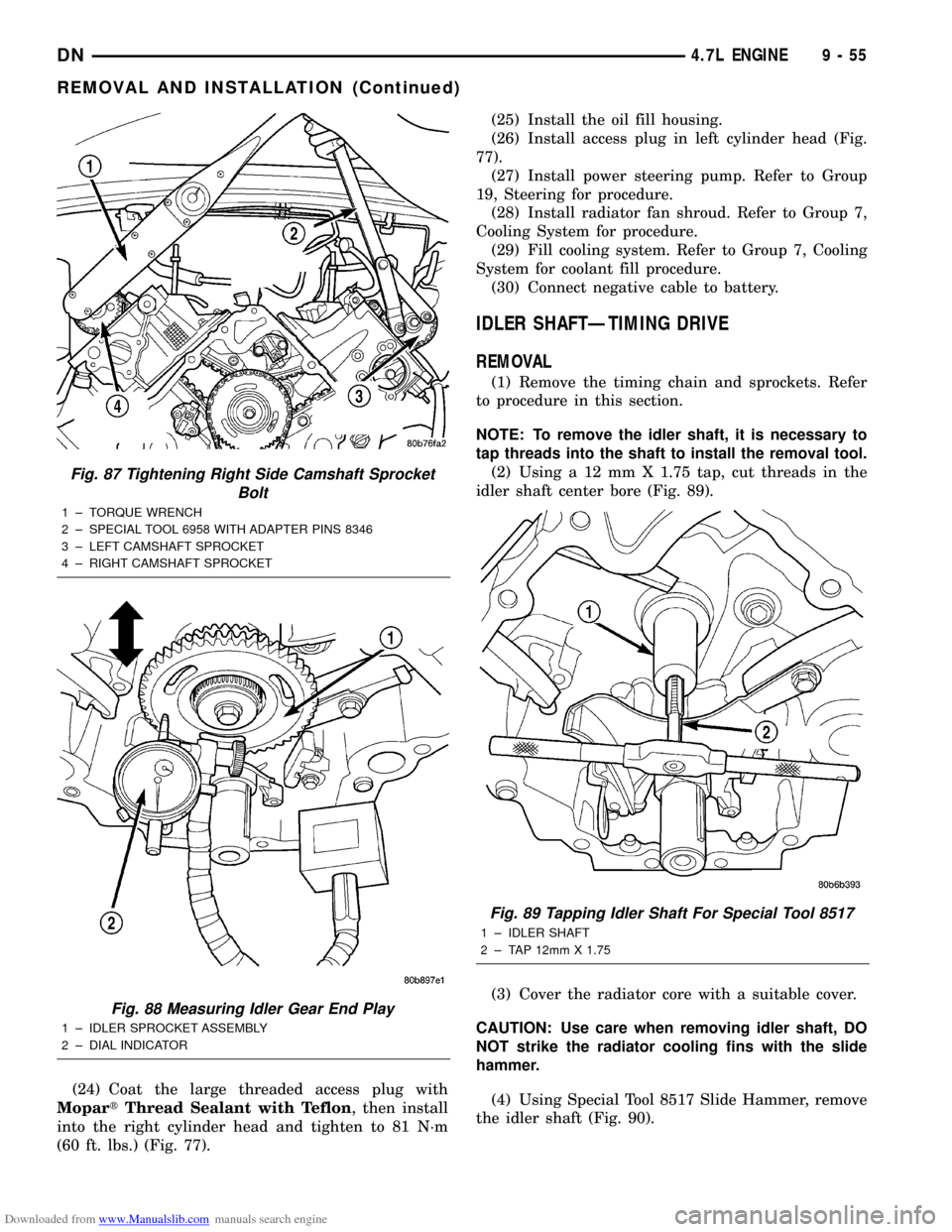

IDLER SHAFTÐTIMING DRIVE

REMOVAL

(1) Remove the timing chain and sprockets. Refer

to procedure in this section.

NOTE: To remove the idler shaft, it is necessary to

tap threads into the shaft to install the removal tool.

(2) Using a 12 mm X 1.75 tap, cut threads in the

idler shaft center bore (Fig. 89).

(3) Cover the radiator core with a suitable cover.

CAUTION: Use care when removing idler shaft, DO

NOT strike the radiator cooling fins with the slide

hammer.

(4) Using Special Tool 8517 Slide Hammer, remove

the idler shaft (Fig. 90).

Fig. 87 Tightening Right Side Camshaft Sprocket

Bolt

1 ± TORQUE WRENCH

2 ± SPECIAL TOOL 6958 WITH ADAPTER PINS 8346

3 ± LEFT CAMSHAFT SPROCKET

4 ± RIGHT CAMSHAFT SPROCKET

Fig. 88 Measuring Idler Gear End Play

1 ± IDLER SPROCKET ASSEMBLY

2 ± DIAL INDICATOR

Fig. 89 Tapping Idler Shaft For Special Tool 8517

1 ± IDLER SHAFT

2 ± TAP 12mm X 1.75

DN4.7L ENGINE 9 - 55

REMOVAL AND INSTALLATION (Continued)

Page 103 of 193

Downloaded from www.Manualslib.com manuals search engine (9) Disconnect the accelerator linkage.

(10) Remove throttle body.

(11) Perform the Fuel System Pressure release

procedure (refer to Group 14, fuel System).

(12) Disconnect the fuel supply line.

(13) Disconnect the starter wires.

(14) Disconnect the oil pressure sending unit wire.

(15) Discharge the air conditioning system, if

equipped (refer to Group 24, Heating and Air Condi-

tioning for service procedures).

(16) Disconnect the air conditioning hoses.

(17) Disconnect the power steering hoses, if

equipped.

(18) Remove starter motor (refer to Group 8B, Bat-

tery/Starter/Generator Service).

(19) Remove the generator (refer to Group 8B, Bat-

tery/Starter/Generator Service).

(20) Raise and support the vehicle on a hoist.

(21) Disconnect exhaust pipe at manifold.

(22) Refer to Group 21, Transmissions for trans-

mission removal.

CAUTION: DO NOT lift the engine by the intake

manifold.

(23) Install an engine lifting fixture.

(24) The engine and front driving axle (engine/ax-

le/transmission) are connected through insulators

and support brackets. Separate the engine as follows:

²LEFT SIDEÐRemove 2 bolts attaching

(engine/pinion nose/transmission) bracket to trans-

mission bell housing. Remove 2 bracket to pinion

nose adaptor bolts. Separate engine from insulator by

removing upper nut washer assembly and bolt from

engine support bracket.

²RIGHT SIDEÐRemove 2 bracket to axle (dis-

connect housing) bolts and a bracket to bell housing

bolt. Separate engine from insulator by removing

upper nut washer assembly and bolt from engine

support bracket.

(25) Lower the vehicle.

(26) Install engine assembly on engine repair

stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment.

(2) Install an engine support fixture.

(3) Raise and support the vehicle on a hoist.

(4) Install the engine front mounts.

(5) Refer to Group, 21 Transmissions for transmis-

sion installation

(6) Install the inspection plate.

(7) Remove transmission support.

(8) Install exhaust pipe to manifold.

(9) Lower the vehicle.

(10) Remove engine lifting fixture.(11) Install the generator (refer to Group 8B, Bat-

tery/Starter/Generator Service).

(12) Install starter motor (refer to Group 8B, Bat-

tery/Starter/Generator Service).

(13) Connect power steering hoses, if equipped.

(14) Connect air conditioning hoses.

(15) Evacuate and charge the air conditioning sys-

tem, if equipped (refer to Group 24, Heater and Air

Conditioning for service procedures).

(16) Using a new gasket, install throttle body.

Tighten the throttle body bolts to 23 N´m (200 in.

lbs.) torque.

(17) Connect the accelerator linkage.

(18) Connect the starter wires.

(19) Connect the oil pressure sending unit wire.

(20) Install the distributor cap and wiring.

(21) Connect the vacuum supply lines to the

intake manifold.

(22) Connect the fuel supply lines.

(23) Install the radiator (refer to Group 7, Cooling

System). Connect the radiator hoses and heater

hoses.

(24) Install fan shroud in position.

(25) Fill cooling system (refer to Group 7, Cooling

System for the proper procedure).

(26) Install the air cleaner.

(27) Install the battery.

(28) Warm engine and adjust.

(29) Install hood and line up with the scribe

marks.

(30) Road test vehicle.

INTAKE MANIFOLD

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain the cooling system. Refer to COOLING

SYSTEM.

(3) Remove the A/C compressor. Refer to HEAT-

ING and AIR CONDITIONING.

(4) Remove the generator. Refer to CHARGING

SYSTEM.

(5) Remove the accessory drive bracket.

(6) Remove the air cleaner assembly and air inlet

hose.

(7) Perform the fuel pressure release procedure.

Refer to FUEL SYSTEM.

(8) Disconnect the fuel supply line from the fuel

rail. Refer to FUEL SYSTEM.

(9) Disconnect the accelerator linkage and, if so

equipped, the speed control and transmission kick-

down cables.

(10) Remove the distributor cap and wires.

(11) Disconnect the coil wires.

(12) Disconnect the coolant temperature sending

unit wire.

DN5.2L ENGINE 9 - 103

REMOVAL AND INSTALLATION (Continued)

Page 110 of 193

Downloaded from www.Manualslib.com manuals search engine (7) Position the fan shroud and install the bolts.

Tighten the retainer bolts to 11 N´m (95 in. lbs.)

torque.

(8) Connect the negative cable to the battery.

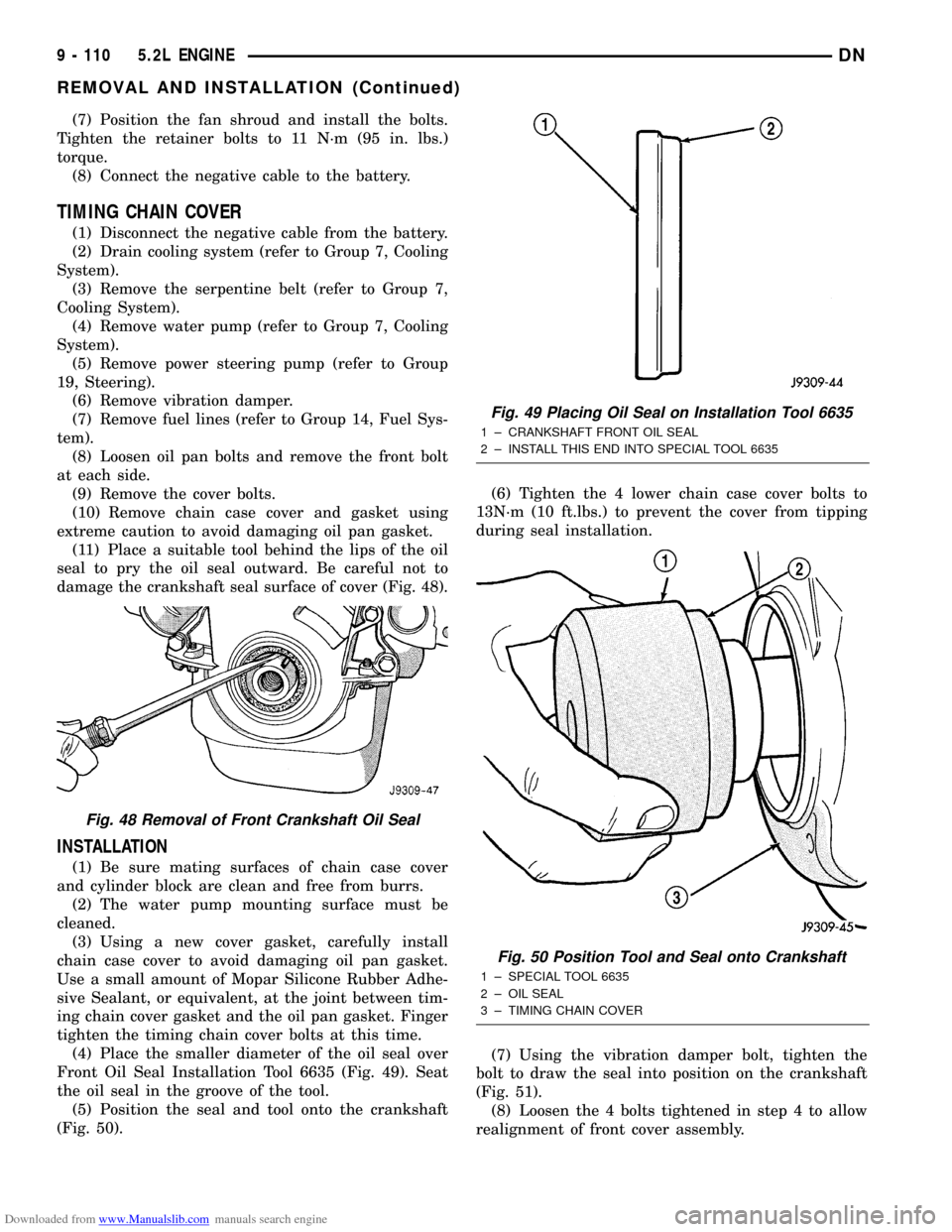

TIMING CHAIN COVER

(1) Disconnect the negative cable from the battery.

(2) Drain cooling system (refer to Group 7, Cooling

System).

(3) Remove the serpentine belt (refer to Group 7,

Cooling System).

(4) Remove water pump (refer to Group 7, Cooling

System).

(5) Remove power steering pump (refer to Group

19, Steering).

(6) Remove vibration damper.

(7) Remove fuel lines (refer to Group 14, Fuel Sys-

tem).

(8) Loosen oil pan bolts and remove the front bolt

at each side.

(9) Remove the cover bolts.

(10) Remove chain case cover and gasket using

extreme caution to avoid damaging oil pan gasket.

(11) Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of cover (Fig. 48).

INSTALLATION

(1) Be sure mating surfaces of chain case cover

and cylinder block are clean and free from burrs.

(2) The water pump mounting surface must be

cleaned.

(3) Using a new cover gasket, carefully install

chain case cover to avoid damaging oil pan gasket.

Use a small amount of Mopar Silicone Rubber Adhe-

sive Sealant, or equivalent, at the joint between tim-

ing chain cover gasket and the oil pan gasket. Finger

tighten the timing chain cover bolts at this time.

(4) Place the smaller diameter of the oil seal over

Front Oil Seal Installation Tool 6635 (Fig. 49). Seat

the oil seal in the groove of the tool.

(5) Position the seal and tool onto the crankshaft

(Fig. 50).(6) Tighten the 4 lower chain case cover bolts to

13N´m (10 ft.lbs.) to prevent the cover from tipping

during seal installation.

(7) Using the vibration damper bolt, tighten the

bolt to draw the seal into position on the crankshaft

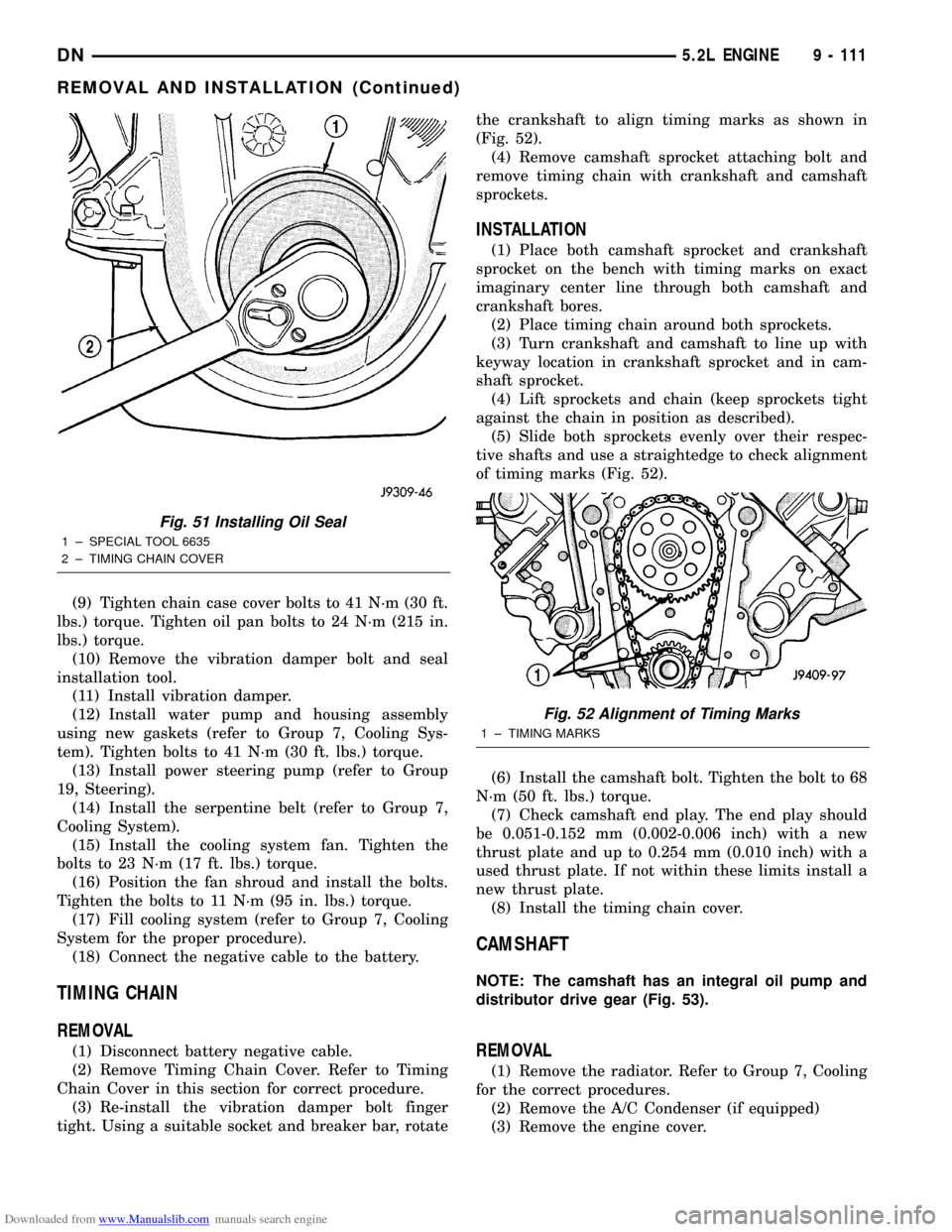

(Fig. 51).

(8) Loosen the 4 bolts tightened in step 4 to allow

realignment of front cover assembly.

Fig. 48 Removal of Front Crankshaft Oil Seal

Fig. 49 Placing Oil Seal on Installation Tool 6635

1 ± CRANKSHAFT FRONT OIL SEAL

2 ± INSTALL THIS END INTO SPECIAL TOOL 6635

Fig. 50 Position Tool and Seal onto Crankshaft

1 ± SPECIAL TOOL 6635

2 ± OIL SEAL

3 ± TIMING CHAIN COVER

9 - 110 5.2L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 111 of 193

Downloaded from www.Manualslib.com manuals search engine (9) Tighten chain case cover bolts to 41 N´m (30 ft.

lbs.) torque. Tighten oil pan bolts to 24 N´m (215 in.

lbs.) torque.

(10) Remove the vibration damper bolt and seal

installation tool.

(11) Install vibration damper.

(12) Install water pump and housing assembly

using new gaskets (refer to Group 7, Cooling Sys-

tem). Tighten bolts to 41 N´m (30 ft. lbs.) torque.

(13) Install power steering pump (refer to Group

19, Steering).

(14) Install the serpentine belt (refer to Group 7,

Cooling System).

(15) Install the cooling system fan. Tighten the

bolts to 23 N´m (17 ft. lbs.) torque.

(16) Position the fan shroud and install the bolts.

Tighten the bolts to 11 N´m (95 in. lbs.) torque.

(17) Fill cooling system (refer to Group 7, Cooling

System for the proper procedure).

(18) Connect the negative cable to the battery.

TIMING CHAIN

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove Timing Chain Cover. Refer to Timing

Chain Cover in this section for correct procedure.

(3) Re-install the vibration damper bolt finger

tight. Using a suitable socket and breaker bar, rotatethe crankshaft to align timing marks as shown in

(Fig. 52).

(4) Remove camshaft sprocket attaching bolt and

remove timing chain with crankshaft and camshaft

sprockets.

INSTALLATION

(1) Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on exact

imaginary center line through both camshaft and

crankshaft bores.

(2) Place timing chain around both sprockets.

(3) Turn crankshaft and camshaft to line up with

keyway location in crankshaft sprocket and in cam-

shaft sprocket.

(4) Lift sprockets and chain (keep sprockets tight

against the chain in position as described).

(5) Slide both sprockets evenly over their respec-

tive shafts and use a straightedge to check alignment

of timing marks (Fig. 52).

(6) Install the camshaft bolt. Tighten the bolt to 68

N´m (50 ft. lbs.) torque.

(7) Check camshaft end play. The end play should

be 0.051-0.152 mm (0.002-0.006 inch) with a new

thrust plate and up to 0.254 mm (0.010 inch) with a

used thrust plate. If not within these limits install a

new thrust plate.

(8) Install the timing chain cover.

CAMSHAFT

NOTE: The camshaft has an integral oil pump and

distributor drive gear (Fig. 53).

REMOVAL

(1) Remove the radiator. Refer to Group 7, Cooling

for the correct procedures.

(2) Remove the A/C Condenser (if equipped)

(3) Remove the engine cover.

Fig. 51 Installing Oil Seal

1 ± SPECIAL TOOL 6635

2 ± TIMING CHAIN COVER

Fig. 52 Alignment of Timing Marks

1 ± TIMING MARKS

DN5.2L ENGINE 9 - 111

REMOVAL AND INSTALLATION (Continued)

Page 163 of 193

Downloaded from www.Manualslib.com manuals search engine (15) Discharge the air conditioning system, if

equipped. Refer to HEATING and AIR CONDITION-

ING.

(16) Disconnect the air conditioning hoses.

(17) Disconnect the power steering hoses, if

equipped.

(18) Remove starter motor. Refer to STARTING

SYSTEMS.

(19) Remove the generator.

(20) Raise and support the vehicle on a hoist.

(21) Disconnect exhaust pipe at manifold.

(22) Remove Transmission. Refer to TRANSMIS-

SIONS.

CAUTION: DO NOT lift the engine by the intake

manifold.

(23) Install an engine lifting fixture.

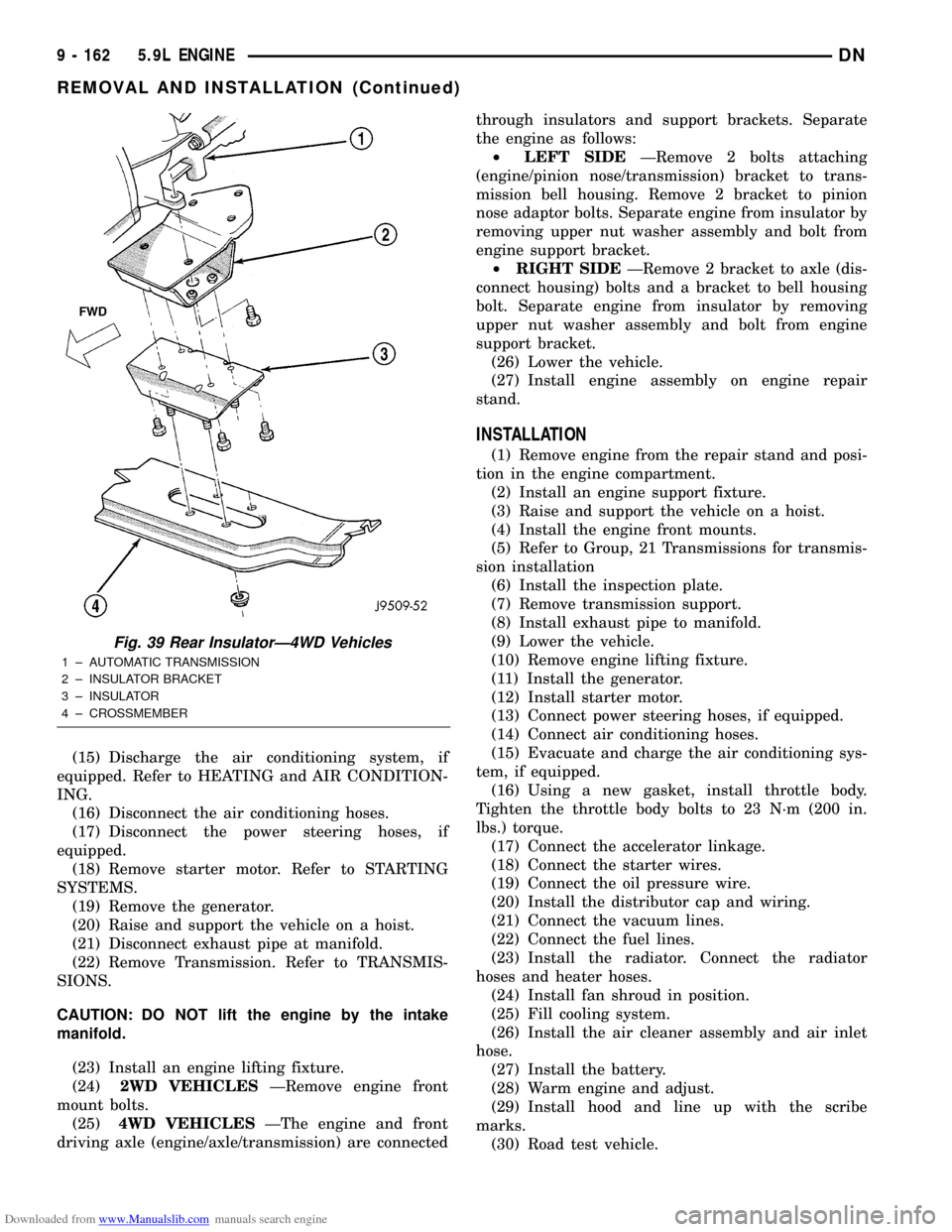

(24)2WD VEHICLESÐRemove engine front

mount bolts.

(25)4WD VEHICLESÐThe engine and front

driving axle (engine/axle/transmission) are connectedthrough insulators and support brackets. Separate

the engine as follows:

²LEFT SIDEÐRemove 2 bolts attaching

(engine/pinion nose/transmission) bracket to trans-

mission bell housing. Remove 2 bracket to pinion

nose adaptor bolts. Separate engine from insulator by

removing upper nut washer assembly and bolt from

engine support bracket.

²RIGHT SIDEÐRemove 2 bracket to axle (dis-

connect housing) bolts and a bracket to bell housing

bolt. Separate engine from insulator by removing

upper nut washer assembly and bolt from engine

support bracket.

(26) Lower the vehicle.

(27) Install engine assembly on engine repair

stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment.

(2) Install an engine support fixture.

(3) Raise and support the vehicle on a hoist.

(4) Install the engine front mounts.

(5) Refer to Group, 21 Transmissions for transmis-

sion installation

(6) Install the inspection plate.

(7) Remove transmission support.

(8) Install exhaust pipe to manifold.

(9) Lower the vehicle.

(10) Remove engine lifting fixture.

(11) Install the generator.

(12) Install starter motor.

(13) Connect power steering hoses, if equipped.

(14) Connect air conditioning hoses.

(15) Evacuate and charge the air conditioning sys-

tem, if equipped.

(16) Using a new gasket, install throttle body.

Tighten the throttle body bolts to 23 N´m (200 in.

lbs.) torque.

(17) Connect the accelerator linkage.

(18) Connect the starter wires.

(19) Connect the oil pressure wire.

(20) Install the distributor cap and wiring.

(21) Connect the vacuum lines.

(22) Connect the fuel lines.

(23) Install the radiator. Connect the radiator

hoses and heater hoses.

(24) Install fan shroud in position.

(25) Fill cooling system.

(26) Install the air cleaner assembly and air inlet

hose.

(27) Install the battery.

(28) Warm engine and adjust.

(29) Install hood and line up with the scribe

marks.

(30) Road test vehicle.

Fig. 39 Rear InsulatorÐ4WD Vehicles

1 ± AUTOMATIC TRANSMISSION

2 ± INSULATOR BRACKET

3 ± INSULATOR

4 ± CROSSMEMBER

9 - 162 5.9L ENGINEDN

REMOVAL AND INSTALLATION (Continued)