5.9 l engine DODGE DURANGO 1999 1.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: DURANGO, Model: DODGE DURANGO 1999 1.GPages: 193, PDF Size: 5.65 MB

Page 1 of 193

Downloaded from www.Manualslib.com manuals search engine ENGINE

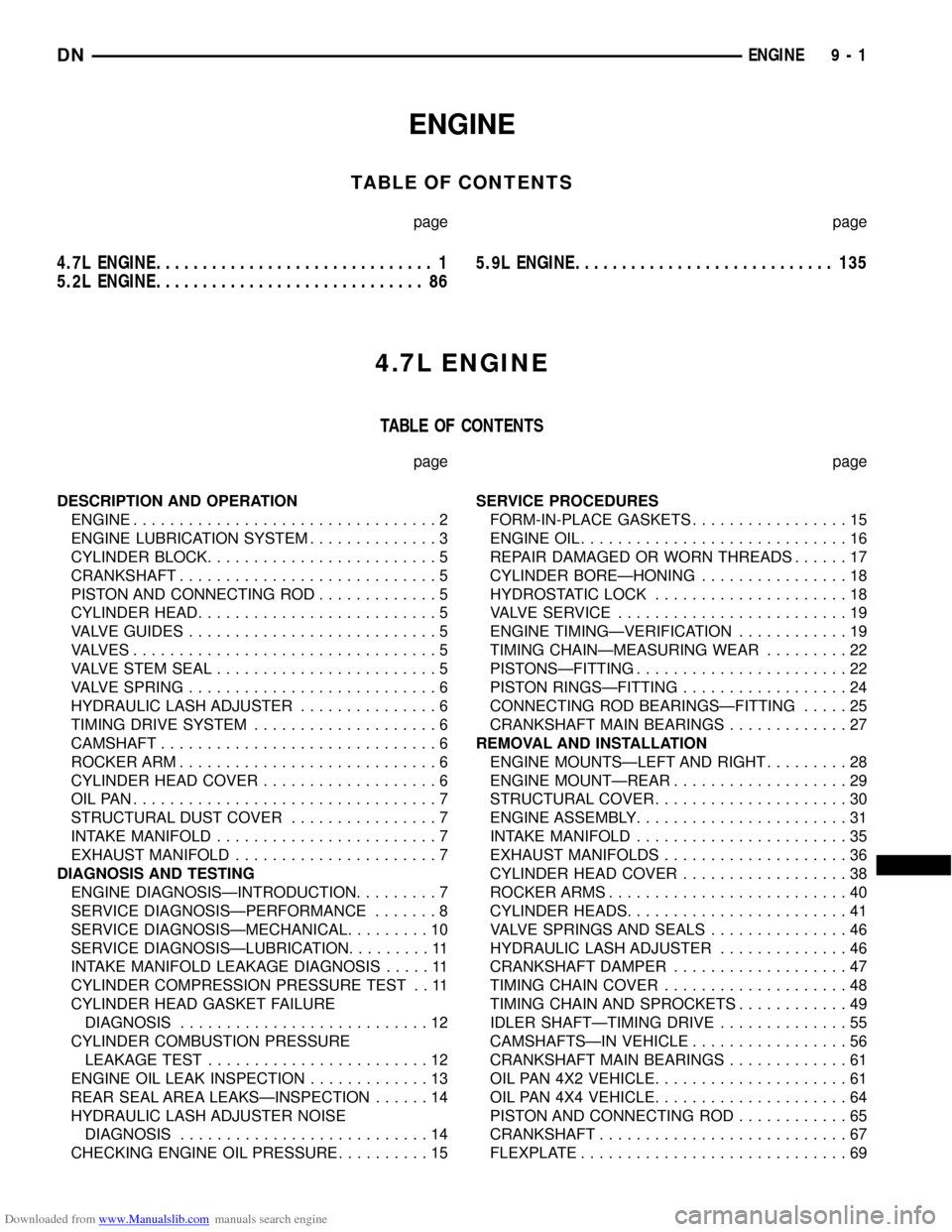

TABLE OF CONTENTS

page page

4.7L ENGINE.............................. 1

5.2L ENGINE............................. 865.9L ENGINE............................ 135

4.7L ENGINE

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

ENGINE.................................2

ENGINE LUBRICATION SYSTEM..............3

CYLINDER BLOCK.........................5

CRANKSHAFT............................5

PISTON AND CONNECTING ROD.............5

CYLINDER HEAD..........................5

VALVE GUIDES...........................5

VALVES.................................5

VALVE STEM SEAL........................5

VALVE SPRING...........................6

HYDRAULIC LASH ADJUSTER...............6

TIMING DRIVE SYSTEM....................6

CAMSHAFT..............................6

ROCKER ARM............................6

CYLINDER HEAD COVER...................6

OILPAN.................................7

STRUCTURAL DUST COVER................7

INTAKE MANIFOLD........................7

EXHAUST MANIFOLD......................7

DIAGNOSIS AND TESTING

ENGINE DIAGNOSISÐINTRODUCTION.........7

SERVICE DIAGNOSISÐPERFORMANCE.......8

SERVICE DIAGNOSISÐMECHANICAL.........10

SERVICE DIAGNOSISÐLUBRICATION.........11

INTAKE MANIFOLD LEAKAGE DIAGNOSIS.....11

CYLINDER COMPRESSION PRESSURE TEST . . 11

CYLINDER HEAD GASKET FAILURE

DIAGNOSIS...........................12

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST........................12

ENGINE OIL LEAK INSPECTION.............13

REAR SEAL AREA LEAKSÐINSPECTION......14

HYDRAULIC LASH ADJUSTER NOISE

DIAGNOSIS...........................14

CHECKING ENGINE OIL PRESSURE..........15SERVICE PROCEDURES

FORM-IN-PLACE GASKETS.................15

ENGINE OIL.............................16

REPAIR DAMAGED OR WORN THREADS......17

CYLINDER BOREÐHONING................18

HYDROSTATIC LOCK.....................18

VALVE SERVICE.........................19

ENGINE TIMINGÐVERIFICATION............19

TIMING CHAINÐMEASURING WEAR.........22

PISTONSÐFITTING.......................22

PISTON RINGSÐFITTING..................24

CONNECTING ROD BEARINGSÐFITTING.....25

CRANKSHAFT MAIN BEARINGS.............27

REMOVAL AND INSTALLATION

ENGINE MOUNTSÐLEFT AND RIGHT.........28

ENGINE MOUNTÐREAR...................29

STRUCTURAL COVER.....................30

ENGINE ASSEMBLY.......................31

INTAKE MANIFOLD.......................35

EXHAUST MANIFOLDS....................36

CYLINDER HEAD COVER..................38

ROCKER ARMS..........................40

CYLINDER HEADS........................41

VALVE SPRINGS AND SEALS...............46

HYDRAULIC LASH ADJUSTER..............46

CRANKSHAFT DAMPER...................47

TIMING CHAIN COVER....................48

TIMING CHAIN AND SPROCKETS............49

IDLER SHAFTÐTIMING DRIVE..............55

CAMSHAFTSÐIN VEHICLE.................56

CRANKSHAFT MAIN BEARINGS.............61

OIL PAN 4X2 VEHICLE.....................61

OIL PAN 4X4 VEHICLE.....................64

PISTON AND CONNECTING ROD............65

CRANKSHAFT...........................67

FLEXPLATE.............................69

DNENGINE 9 - 1

Page 76 of 193

Downloaded from www.Manualslib.com manuals search engine PISTON AND CONNECTING ROD

CLEANING

CAUTION: DO NOT use a wire wheel or other abra-

sive cleaning devise to clean the pistons or con-

necting rods. The pistons have a Moly coating, this

coating must not be damaged.

(1) Using a suitable cleaning solvent clean the pis-

tons in warm water and towel dry.

(2) Use a wood or plastic scraper to clean the ring

land grooves.

CAUTION: DO NOT remove the piston pin from the

piston and connecting rod assembly.

INSPECTION

Check the crankshaft connecting rod journal for

excessive wear, taper and scoring.

Check the pistons for taper and elliptical shape

before they are fitted into the cylinder bore.

Replace any piston and connecting rod not meeting

the specifications.

OIL PAN

CLEANING

(1) Clean oil pan in solvent and wipe dry with a

clean cloth.

(2) Clean the oil pan gasket surface.DO NOTuse

a grinder wheel or other abrasive tool to clean seal-

ing surface.

(3) Clean oil screen and tube thoroughly in clean

solvent.

INSPECTION

(1) Inspect oil drain plug and plug hole for

stripped or damaged threads. Repair as necessary.

(2) Inspect the oil pan mounting flange for bends

or distortion. Straighten flange, if necessary.

OIL PUMP

CLEANING

(1) Wash all parts in a suitable solvent.

INSPECTION

CAUTION: Oil pump pressure relief valve and

spring should not be removed from the oil pump. If

the these components are disassembled andùr

removed from the pump the entire oil pump assem-

bly must be replaced.(1) Clean all parts thoroughly. Mating surface of

the oil pump housing should be smooth. If the pump

cover is scratched or grooved the oil pump assembly

should be replaced.

(2) Lay a straight edge across the pump cover sur-

face (Fig. 137). If a 0.025 mm (0.001 in.) feeler gauge

can be inserted between the cover and the straight

edge the oil pump assembly should be replaced.

(3) Measure the thickness of the outer rotor (Fig.

138). If the outer rotor thickness measures at 12.005

mm (0.400 in.) or less the oil pump assembly must be

replaced.

(4) Measure the diameter of the outer rotor. If the

outer rotor diameter measures at 85.925 mm (0.400

in.) or less the oil pump assembly must be replaced.

(5) Measure the thickness of the inner rotor (Fig.

139). If the inner rotor thickness measures at 12.005

mm (0.400 in.) or less then the oil pump assembly

must be replaced.

(6) Slide outer rotor into the body of the oil pump.

Press the outer rotor to one side of the oil pump body

and measure clearance between the outer rotor and

the body (Fig. 140). If the measurement is 0.47mm

(0.0186 in.) or more the oil pump assembly must be

replaced.

(7) Install the inner rotor in the into the oil pump

body. Measure the clearance between the inner and

outer rotors (Fig. 141). If the clearance between the

rotors is .150 mm (0.006 in.) or more the oil pump

assembly must be replaced.

(8) Place a straight edge across the body of the oil

pump (between the bolt holes), if a feeler gauge of

.095 mm (0.0038 in.) or greater can be inserted

between the straightedge and the rotors, the pump

must be replaced (Fig. 142).

NOTE: 4.7 Oil pump is released as an assembly.

There are no DaimlerChrysler part numbers for Sub-

Assembly components. In the event the oil pump is

not functioning or out of specification it must be

replaced as an assembly.

CYLINDER BLOCK

CLEANING

Thoroughly clean the oil pan and engine block gas-

ket surfaces.

Use compressed air to clean out:

²The galley at the oil filter adaptor hole.

²The front and rear oil galley holes.

²The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply

Loctite PST pipe sealant with Teflon 592 to the

threads of the front and rear oil galley plugs. Tighten

the plugs to 34 N´m (25 ft. lbs.) torque.

9 - 76 4.7L ENGINEDN

CLEANING AND INSPECTION (Continued)

Page 79 of 193

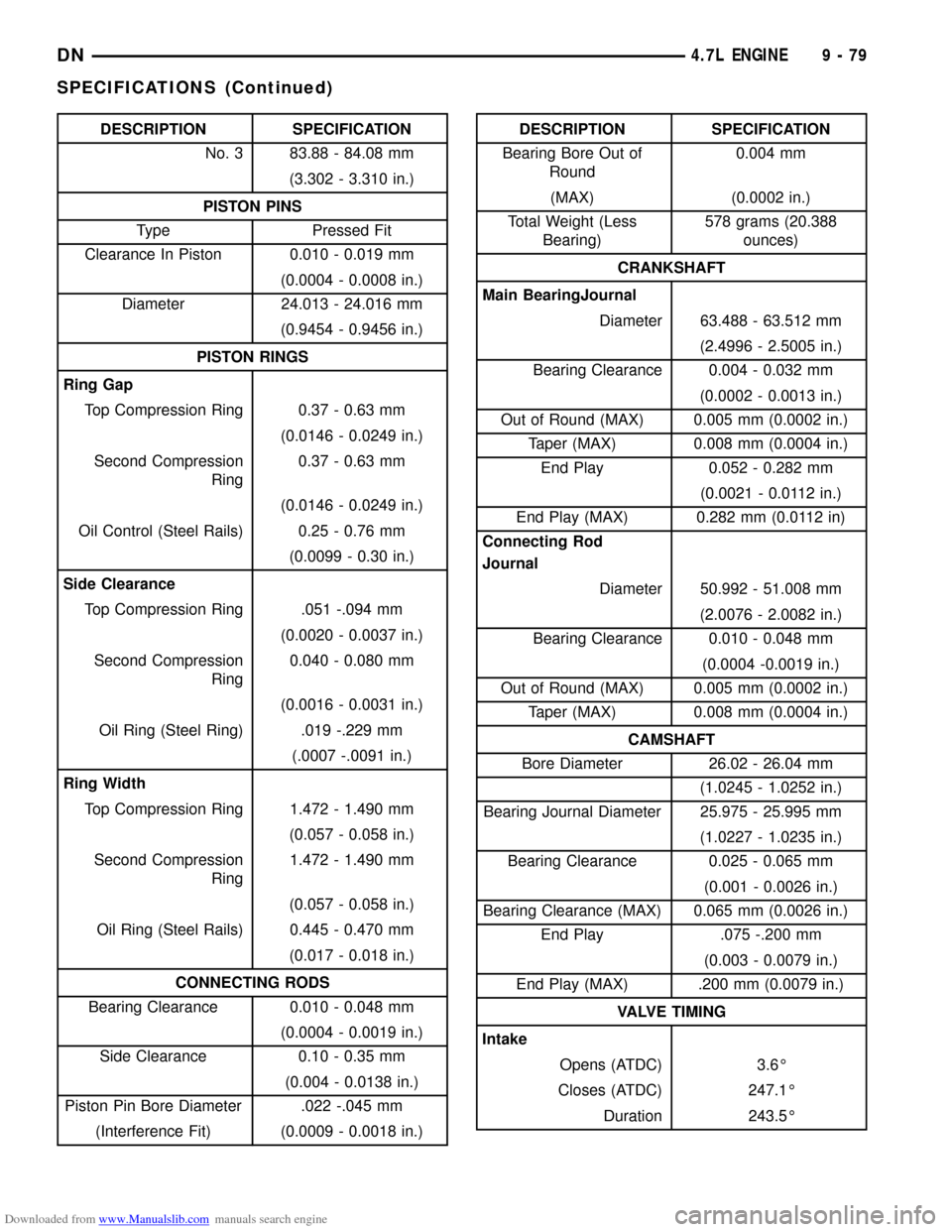

Downloaded from www.Manualslib.com manuals search engine DESCRIPTION SPECIFICATION

No. 3 83.88 - 84.08 mm

(3.302 - 3.310 in.)

PISTON PINS

Type Pressed Fit

Clearance In Piston 0.010 - 0.019 mm

(0.0004 - 0.0008 in.)

Diameter 24.013 - 24.016 mm

(0.9454 - 0.9456 in.)

PISTON RINGS

Ring Gap

Top Compression Ring 0.37 - 0.63 mm

(0.0146 - 0.0249 in.)

Second Compression

Ring0.37 - 0.63 mm

(0.0146 - 0.0249 in.)

Oil Control (Steel Rails) 0.25 - 0.76 mm

(0.0099 - 0.30 in.)

Side Clearance

Top Compression Ring .051 -.094 mm

(0.0020 - 0.0037 in.)

Second Compression

Ring0.040 - 0.080 mm

(0.0016 - 0.0031 in.)

Oil Ring (Steel Ring) .019 -.229 mm

(.0007 -.0091 in.)

Ring Width

Top Compression Ring 1.472 - 1.490 mm

(0.057 - 0.058 in.)

Second Compression

Ring1.472 - 1.490 mm

(0.057 - 0.058 in.)

Oil Ring (Steel Rails) 0.445 - 0.470 mm

(0.017 - 0.018 in.)

CONNECTING RODS

Bearing Clearance 0.010 - 0.048 mm

(0.0004 - 0.0019 in.)

Side Clearance 0.10 - 0.35 mm

(0.004 - 0.0138 in.)

Piston Pin Bore Diameter .022 -.045 mm

(Interference Fit) (0.0009 - 0.0018 in.)DESCRIPTION SPECIFICATION

Bearing Bore Out of

Round0.004 mm

(MAX) (0.0002 in.)

Total Weight (Less

Bearing)578 grams (20.388

ounces)

CRANKSHAFT

Main BearingJournal

Diameter 63.488 - 63.512 mm

(2.4996 - 2.5005 in.)

Bearing Clearance 0.004 - 0.032 mm

(0.0002 - 0.0013 in.)

Out of Round (MAX) 0.005 mm (0.0002 in.)

Taper (MAX) 0.008 mm (0.0004 in.)

End Play 0.052 - 0.282 mm

(0.0021 - 0.0112 in.)

End Play (MAX) 0.282 mm (0.0112 in)

Connecting Rod

Journal

Diameter 50.992 - 51.008 mm

(2.0076 - 2.0082 in.)

Bearing Clearance 0.010 - 0.048 mm

(0.0004 -0.0019 in.)

Out of Round (MAX) 0.005 mm (0.0002 in.)

Taper (MAX) 0.008 mm (0.0004 in.)

CAMSHAFT

Bore Diameter 26.02 - 26.04 mm

(1.0245 - 1.0252 in.)

Bearing Journal Diameter 25.975 - 25.995 mm

(1.0227 - 1.0235 in.)

Bearing Clearance 0.025 - 0.065 mm

(0.001 - 0.0026 in.)

Bearing Clearance (MAX) 0.065 mm (0.0026 in.)

End Play .075 -.200 mm

(0.003 - 0.0079 in.)

End Play (MAX) .200 mm (0.0079 in.)

VALVE TIMING

Intake

Opens (ATDC) 3.6É

Closes (ATDC) 247.1É

Duration 243.5É

DN4.7L ENGINE 9 - 79

SPECIFICATIONS (Continued)

Page 81 of 193

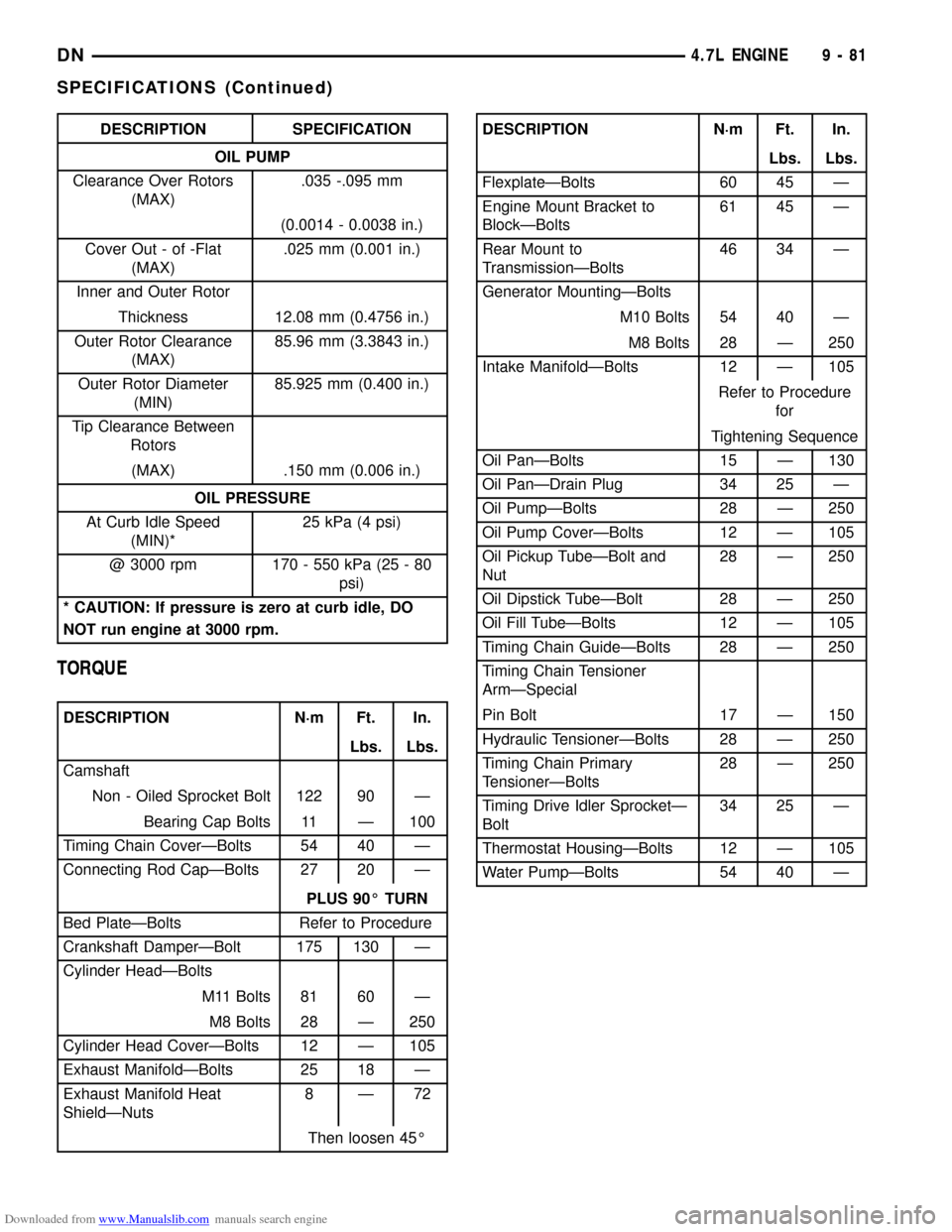

Downloaded from www.Manualslib.com manuals search engine DESCRIPTION SPECIFICATION

OIL PUMP

Clearance Over Rotors

(MAX).035 -.095 mm

(0.0014 - 0.0038 in.)

Cover Out - of -Flat

(MAX).025 mm (0.001 in.)

Inner and Outer Rotor

Thickness 12.08 mm (0.4756 in.)

Outer Rotor Clearance

(MAX)85.96 mm (3.3843 in.)

Outer Rotor Diameter

(MIN)85.925 mm (0.400 in.)

Tip Clearance Between

Rotors

(MAX) .150 mm (0.006 in.)

OIL PRESSURE

At Curb Idle Speed

(MIN)*25 kPa (4 psi)

@ 3000 rpm 170 - 550 kPa (25 - 80

psi)

* CAUTION: If pressure is zero at curb idle, DO

NOT run engine at 3000 rpm.

TORQUE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Camshaft

Non - Oiled Sprocket Bolt 122 90 Ð

Bearing Cap Bolts 11 Ð 100

Timing Chain CoverÐBolts 54 40 Ð

Connecting Rod CapÐBolts 27 20 Ð

PLUS 90É TURN

Bed PlateÐBolts Refer to Procedure

Crankshaft DamperÐBolt 175 130 Ð

Cylinder HeadÐBolts

M11 Bolts 81 60 Ð

M8 Bolts 28 Ð 250

Cylinder Head CoverÐBolts 12 Ð 105

Exhaust ManifoldÐBolts 25 18 Ð

Exhaust Manifold Heat

ShieldÐNuts8Ð72

Then loosen 45É

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

FlexplateÐBolts 60 45 Ð

Engine Mount Bracket to

BlockÐBolts61 45 Ð

Rear Mount to

TransmissionÐBolts46 34 Ð

Generator MountingÐBolts

M10 Bolts 54 40 Ð

M8 Bolts 28 Ð 250

Intake ManifoldÐBolts 12 Ð 105

Refer to Procedure

for

Tightening Sequence

Oil PanÐBolts 15 Ð 130

Oil PanÐDrain Plug 34 25 Ð

Oil PumpÐBolts 28 Ð 250

Oil Pump CoverÐBolts 12 Ð 105

Oil Pickup TubeÐBolt and

Nut28 Ð 250

Oil Dipstick TubeÐBolt 28 Ð 250

Oil Fill TubeÐBolts 12 Ð 105

Timing Chain GuideÐBolts 28 Ð 250

Timing Chain Tensioner

ArmÐSpecial

Pin Bolt 17 Ð 150

Hydraulic TensionerÐBolts 28 Ð 250

Timing Chain Primary

TensionerÐBolts28 Ð 250

Timing Drive Idler SprocketÐ

Bolt34 25 Ð

Thermostat HousingÐBolts 12 Ð 105

Water PumpÐBolts 54 40 Ð

DN4.7L ENGINE 9 - 81

SPECIFICATIONS (Continued)

Page 105 of 193

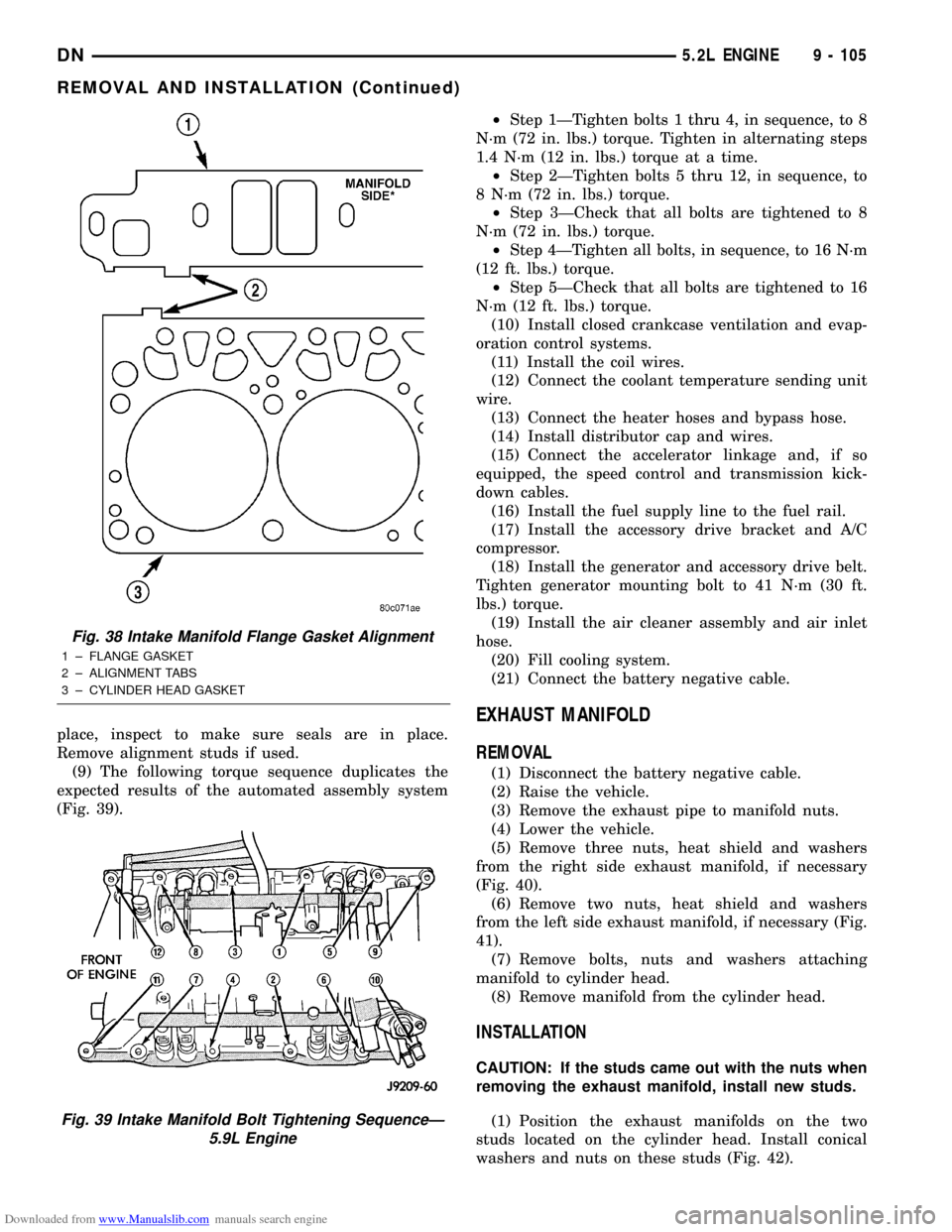

Downloaded from www.Manualslib.com manuals search engine place, inspect to make sure seals are in place.

Remove alignment studs if used.

(9) The following torque sequence duplicates the

expected results of the automated assembly system

(Fig. 39).²Step 1ÐTighten bolts 1 thru 4, in sequence, to 8

N´m (72 in. lbs.) torque. Tighten in alternating steps

1.4 N´m (12 in. lbs.) torque at a time.

²Step 2ÐTighten bolts 5 thru 12, in sequence, to

8 N´m (72 in. lbs.) torque.

²Step 3ÐCheck that all bolts are tightened to 8

N´m (72 in. lbs.) torque.

²Step 4ÐTighten all bolts, in sequence, to 16 N´m

(12 ft. lbs.) torque.

²Step 5ÐCheck that all bolts are tightened to 16

N´m (12 ft. lbs.) torque.

(10) Install closed crankcase ventilation and evap-

oration control systems.

(11) Install the coil wires.

(12) Connect the coolant temperature sending unit

wire.

(13) Connect the heater hoses and bypass hose.

(14) Install distributor cap and wires.

(15) Connect the accelerator linkage and, if so

equipped, the speed control and transmission kick-

down cables.

(16) Install the fuel supply line to the fuel rail.

(17) Install the accessory drive bracket and A/C

compressor.

(18) Install the generator and accessory drive belt.

Tighten generator mounting bolt to 41 N´m (30 ft.

lbs.) torque.

(19) Install the air cleaner assembly and air inlet

hose.

(20) Fill cooling system.

(21) Connect the battery negative cable.

EXHAUST MANIFOLD

REMOVAL

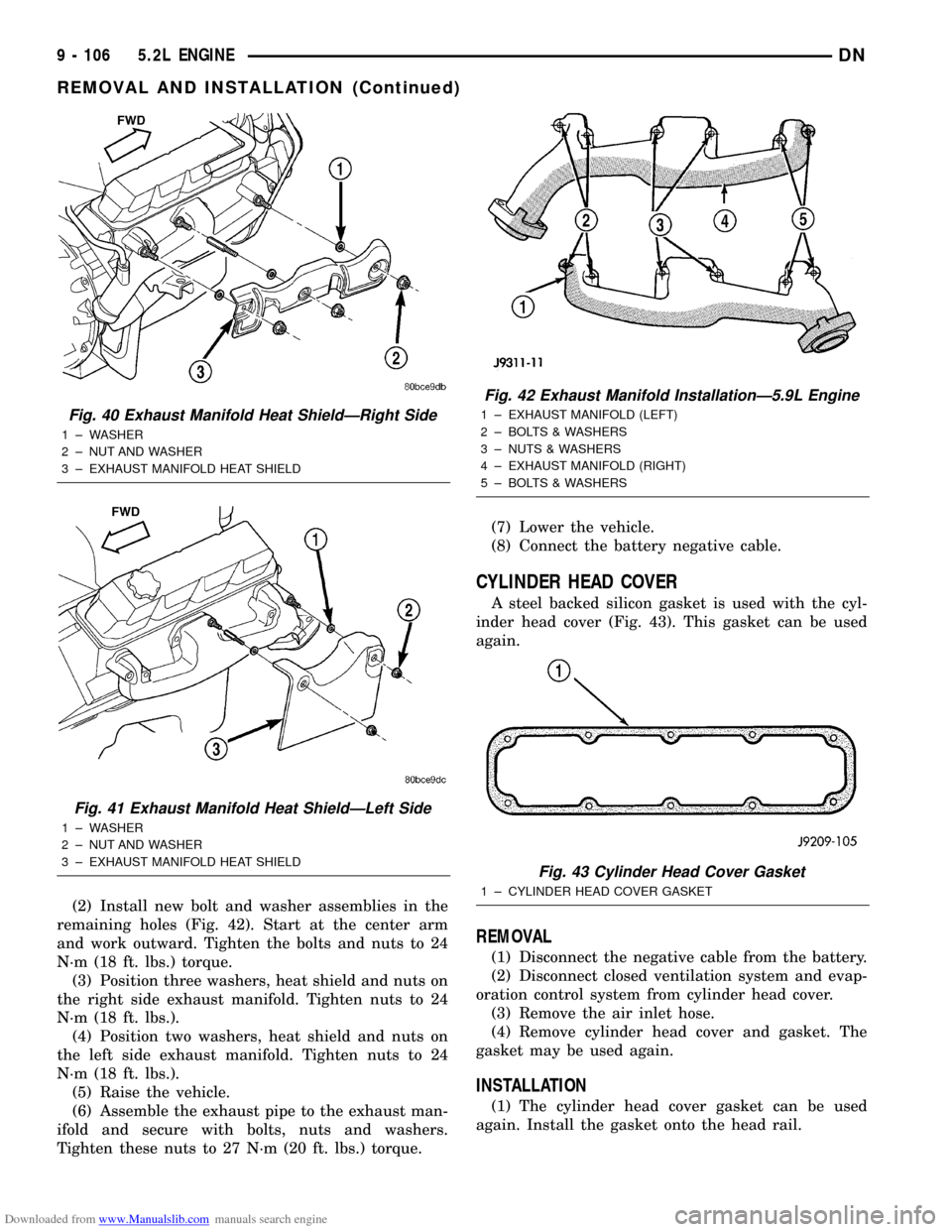

(1) Disconnect the battery negative cable.

(2) Raise the vehicle.

(3) Remove the exhaust pipe to manifold nuts.

(4) Lower the vehicle.

(5) Remove three nuts, heat shield and washers

from the right side exhaust manifold, if necessary

(Fig. 40).

(6) Remove two nuts, heat shield and washers

from the left side exhaust manifold, if necessary (Fig.

41).

(7) Remove bolts, nuts and washers attaching

manifold to cylinder head.

(8) Remove manifold from the cylinder head.

INSTALLATION

CAUTION: If the studs came out with the nuts when

removing the exhaust manifold, install new studs.

(1) Position the exhaust manifolds on the two

studs located on the cylinder head. Install conical

washers and nuts on these studs (Fig. 42).

Fig. 38 Intake Manifold Flange Gasket Alignment

1 ± FLANGE GASKET

2 ± ALIGNMENT TABS

3 ± CYLINDER HEAD GASKET

Fig. 39 Intake Manifold Bolt Tightening SequenceÐ

5.9L Engine

DN5.2L ENGINE 9 - 105

REMOVAL AND INSTALLATION (Continued)

Page 106 of 193

Downloaded from www.Manualslib.com manuals search engine (2) Install new bolt and washer assemblies in the

remaining holes (Fig. 42). Start at the center arm

and work outward. Tighten the bolts and nuts to 24

N´m (18 ft. lbs.) torque.

(3) Position three washers, heat shield and nuts on

the right side exhaust manifold. Tighten nuts to 24

N´m (18 ft. lbs.).

(4) Position two washers, heat shield and nuts on

the left side exhaust manifold. Tighten nuts to 24

N´m (18 ft. lbs.).

(5) Raise the vehicle.

(6) Assemble the exhaust pipe to the exhaust man-

ifold and secure with bolts, nuts and washers.

Tighten these nuts to 27 N´m (20 ft. lbs.) torque.(7) Lower the vehicle.

(8) Connect the battery negative cable.

CYLINDER HEAD COVER

A steel backed silicon gasket is used with the cyl-

inder head cover (Fig. 43). This gasket can be used

again.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Disconnect closed ventilation system and evap-

oration control system from cylinder head cover.

(3) Remove the air inlet hose.

(4) Remove cylinder head cover and gasket. The

gasket may be used again.

INSTALLATION

(1) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.

Fig. 40 Exhaust Manifold Heat ShieldÐRight Side

1 ± WASHER

2 ± NUT AND WASHER

3 ± EXHAUST MANIFOLD HEAT SHIELD

Fig. 41 Exhaust Manifold Heat ShieldÐLeft Side

1 ± WASHER

2 ± NUT AND WASHER

3 ± EXHAUST MANIFOLD HEAT SHIELD

Fig. 42 Exhaust Manifold InstallationÐ5.9L Engine

1 ± EXHAUST MANIFOLD (LEFT)

2 ± BOLTS & WASHERS

3 ± NUTS & WASHERS

4 ± EXHAUST MANIFOLD (RIGHT)

5 ± BOLTS & WASHERS

Fig. 43 Cylinder Head Cover Gasket

1 ± CYLINDER HEAD COVER GASKET

9 - 106 5.2L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 130 of 193

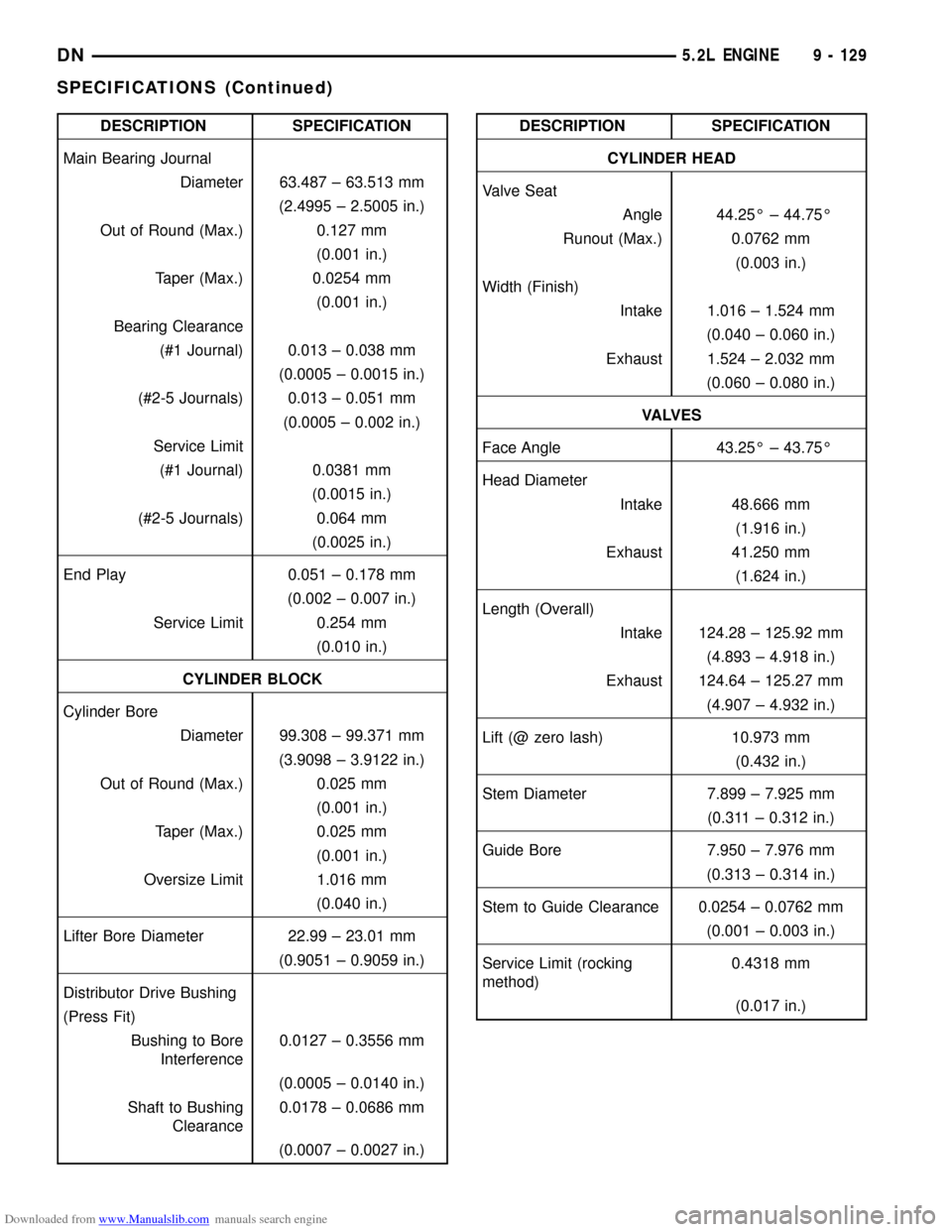

Downloaded from www.Manualslib.com manuals search engine DESCRIPTION SPECIFICATION

Main Bearing Journal

Diameter 63.487 ± 63.513 mm

(2.4995 ± 2.5005 in.)

Out of Round (Max.) 0.127 mm

(0.001 in.)

Taper (Max.) 0.0254 mm

(0.001 in.)

Bearing Clearance

(#1 Journal) 0.013 ± 0.038 mm

(0.0005 ± 0.0015 in.)

(#2-5 Journals) 0.013 ± 0.051 mm

(0.0005 ± 0.002 in.)

Service Limit

(#1 Journal) 0.0381 mm

(0.0015 in.)

(#2-5 Journals) 0.064 mm

(0.0025 in.)

End Play 0.051 ± 0.178 mm

(0.002 ± 0.007 in.)

Service Limit 0.254 mm

(0.010 in.)

CYLINDER BLOCK

Cylinder Bore

Diameter 99.308 ± 99.371 mm

(3.9098 ± 3.9122 in.)

Out of Round (Max.) 0.025 mm

(0.001 in.)

Taper (Max.) 0.025 mm

(0.001 in.)

Oversize Limit 1.016 mm

(0.040 in.)

Lifter Bore Diameter 22.99 ± 23.01 mm

(0.9051 ± 0.9059 in.)

Distributor Drive Bushing

(Press Fit)

Bushing to Bore

Interference0.0127 ± 0.3556 mm

(0.0005 ± 0.0140 in.)

Shaft to Bushing

Clearance0.0178 ± 0.0686 mm

(0.0007 ± 0.0027 in.)DESCRIPTION SPECIFICATION

CYLINDER HEAD

Valve Seat

Angle 44.25É ± 44.75É

Runout (Max.) 0.0762 mm

(0.003 in.)

Width (Finish)

Intake 1.016 ± 1.524 mm

(0.040 ± 0.060 in.)

Exhaust 1.524 ± 2.032 mm

(0.060 ± 0.080 in.)

VA LV E S

Face Angle 43.25É ± 43.75É

Head Diameter

Intake 48.666 mm

(1.916 in.)

Exhaust 41.250 mm

(1.624 in.)

Length (Overall)

Intake 124.28 ± 125.92 mm

(4.893 ± 4.918 in.)

Exhaust 124.64 ± 125.27 mm

(4.907 ± 4.932 in.)

Lift (@ zero lash) 10.973 mm

(0.432 in.)

Stem Diameter 7.899 ± 7.925 mm

(0.311 ± 0.312 in.)

Guide Bore 7.950 ± 7.976 mm

(0.313 ± 0.314 in.)

Stem to Guide Clearance 0.0254 ± 0.0762 mm

(0.001 ± 0.003 in.)

Service Limit (rocking

method)0.4318 mm

(0.017 in.)

DN5.2L ENGINE 9 - 129

SPECIFICATIONS (Continued)

Page 132 of 193

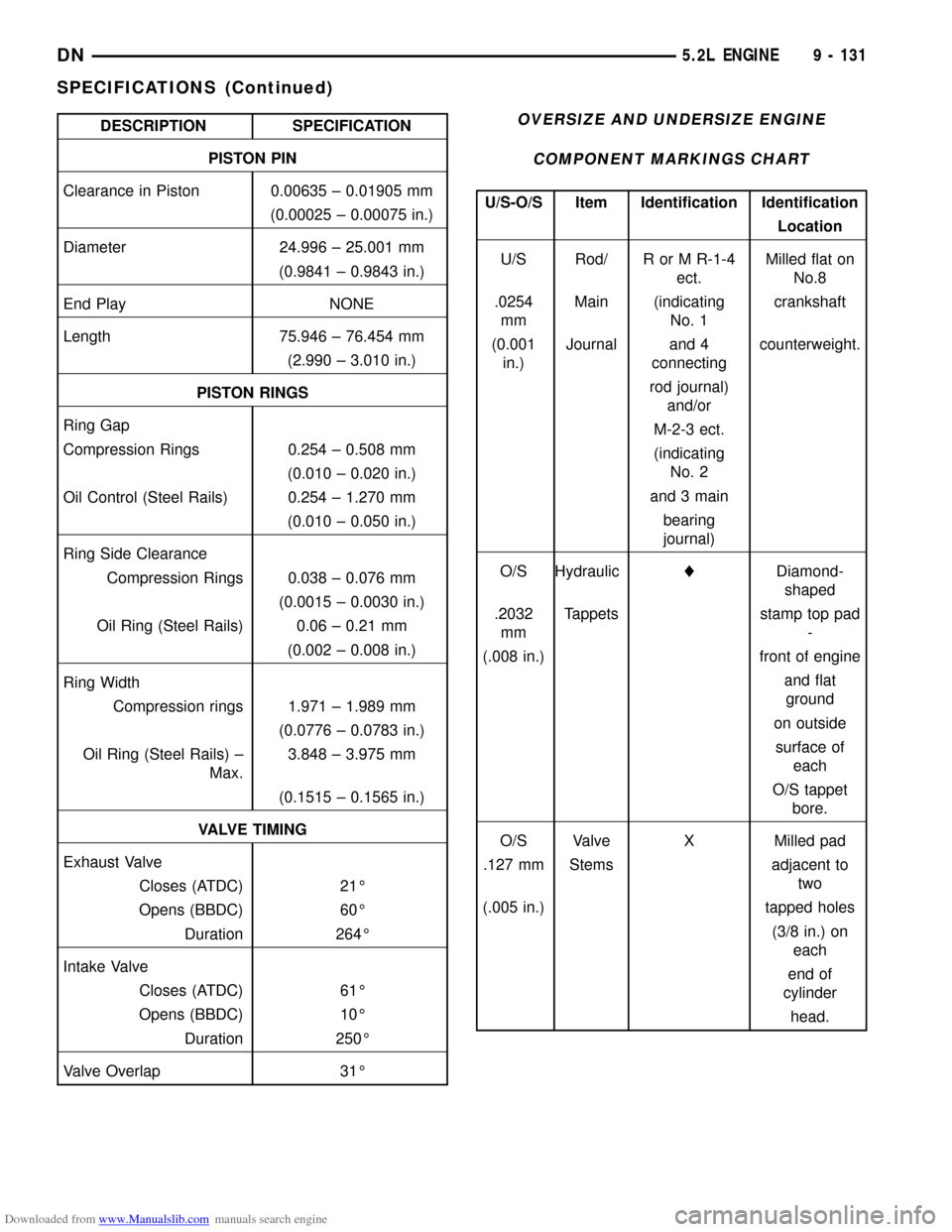

Downloaded from www.Manualslib.com manuals search engine DESCRIPTION SPECIFICATION

PISTON PIN

Clearance in Piston 0.00635 ± 0.01905 mm

(0.00025 ± 0.00075 in.)

Diameter 24.996 ± 25.001 mm

(0.9841 ± 0.9843 in.)

End Play NONE

Length 75.946 ± 76.454 mm

(2.990 ± 3.010 in.)

PISTON RINGS

Ring Gap

Compression Rings 0.254 ± 0.508 mm

(0.010 ± 0.020 in.)

Oil Control (Steel Rails) 0.254 ± 1.270 mm

(0.010 ± 0.050 in.)

Ring Side Clearance

Compression Rings 0.038 ± 0.076 mm

(0.0015 ± 0.0030 in.)

Oil Ring (Steel Rails) 0.06 ± 0.21 mm

(0.002 ± 0.008 in.)

Ring Width

Compression rings 1.971 ± 1.989 mm

(0.0776 ± 0.0783 in.)

Oil Ring (Steel Rails) ±

Max.3.848 ± 3.975 mm

(0.1515 ± 0.1565 in.)

VALVE TIMING

Exhaust Valve

Closes (ATDC) 21É

Opens (BBDC) 60É

Duration 264É

Intake Valve

Closes (ATDC) 61É

Opens (BBDC) 10É

Duration 250É

Valve Overlap 31ÉOVERSIZE AND UNDERSIZE ENGINE

COMPONENT MARKINGS CHART

U/S-O/S Item Identification Identification

Location

U/S Rod/ R or M R-1-4

ect.Milled flat on

No.8

.0254

mmMain (indicating

No. 1crankshaft

(0.001

in.)Journal and 4

connectingcounterweight.

rod journal)

and/or

M-2-3 ect.

(indicating

No. 2

and 3 main

bearing

journal)

O/S HydrauliclDiamond-

shaped

.2032

mmTappets stamp top pad

-

(.008 in.) front of engine

and flat

ground

on outside

surface of

each

O/S tappet

bore.

O/S Valve X Milled pad

.127 mm Stems adjacent to

two

(.005 in.) tapped holes

(3/8 in.) on

each

end of

cylinder

head.

DN5.2L ENGINE 9 - 131

SPECIFICATIONS (Continued)

Page 136 of 193

Downloaded from www.Manualslib.com manuals search engine 5.9L ENGINE

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

ENGINE...............................136

ENGINE LUBRICATION SYSTEM............136

EXHAUST MANIFOLD....................139

INTAKE MANIFOLD......................139

CYLINDER HEAD COVER GASKET..........140

CYLINDER HEAD........................140

VALVES AND VALVE SPRINGS.............140

ENGINE OIL PAN........................140

CRANKSHAFT OIL SEALS.................140

PISTON AND CONNECTING ROD...........140

CRANKSHAFT MAIN BEARINGS............141

CRANKSHAFT..........................141

DIAGNOSIS AND TESTING

ENGINE DIAGNOSISÐINTRODUCTION.......141

SERVICE DIAGNOSISÐGASOLINE ENGINES . . 142

INTAKE MANIFOLD LEAKAGE DIAGNOSIS....145

CYLINDER COMPRESSION PRESSURE TEST . 145

CYLINDER HEAD GASKET FAILURE

DIAGNOSIS...........................146

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST.......................146

INSPECTION (ENGINE OIL LEAKS IN

GENERAL)...........................147

REAR SEAL AREA LEAKSÐINSPECTION.....147

HYDRAULIC TAPPETS....................148

ENGINE OIL PRESSURE..................148

SERVICE PROCEDURES

FORM-IN-PLACE GASKETS................149

ENGINE PERFORMANCE.................149

ENGINE OIL............................150

REPAIR DAMAGED OR WORN THREADS.....151

CYLINDER BOREÐHONING...............152

HYDROSTATIC LOCK.....................152

VALVE TIMING..........................153

VALVE SERVICE........................153

MEASURING TIMING CHAIN STRETCH.......155

PISTONSÐFITTING......................156

PISTON RINGSÐFITTING.................156

CONNECTING ROD BEARINGSÐFITTING.....157

CRANKSHAFT MAIN BEARINGSÐFITTING....157

REMOVAL AND INSTALLATION

ENGINE FRONT MOUNTS.................158ENGINE REAR SUPPORT.................160

ENGINE ASSEMBLY......................161

INTAKE MANIFOLD......................163

EXHAUST MANIFOLD....................165

CYLINDER HEAD COVER.................165

ROCKER ARMS AND PUSH RODS..........166

VALVE SPRING AND STEM SEAL

REPLACEMENT-IN VEHICLE.............166

CYLINDER HEAD........................167

VALVES AND VALVE SPRINGS.............167

HYDRAULIC TAPPETS....................168

VIBRATION DAMPER.....................168

TIMING CHAIN COVER...................169

TIMING CHAIN..........................170

CAMSHAFT............................170

CAMSHAFT BEARINGS...................172

DISTRIBUTOR DRIVE SHAFT BUSHING......172

CRANKSHAFT MAIN BEARINGS............174

OILPAN...............................174

PISTON AND CONNECTING ROD ASSEMBLY . . 175

CRANKSHAFT..........................176

OIL PUMP.............................177

CRANKSHAFT OIL SEALÐFRONT...........178

CRANKSHAFT OIL SEALSÐREAR...........179

ENGINE CORE OIL AND CAMSHAFT PLUGS . . 180

DISASSEMBLY AND ASSEMBLY

OIL PUMP.............................181

CLEANING AND INSPECTION

CYLINDER HEAD COVER.................182

CYLINDER HEAD ASSEMBLY..............182

PISTON AND CONNECTING ROD ASSEMBLY . . 182

OILPAN...............................182

OIL PUMP.............................182

CYLINDER BLOCK.......................185

INTAKE MANIFOLD......................185

EXHAUST MANIFOLD....................185

SPECIFICATIONS

5.9L ENGINE SPECIFICATIONS.............185

SPECIFICATIONS........................189

SPECIAL TOOLS

5.9L ENGINE...........................189

DN5.9L ENGINE 9 - 135

Page 137 of 193

Downloaded from www.Manualslib.com manuals search engine DESCRIPTION AND OPERATION

ENGINE

DESCRIPTION

The 5.9 Liter (360 CID) eight-cylinder engine is a

V-Type lightweight, single cam, overhead valve

engine with hydraulic roller tappets. This engine is

designed for unleaded fuel.

The engine lubrication system consists of a rotor

type oil pump and a full flow oil filter.

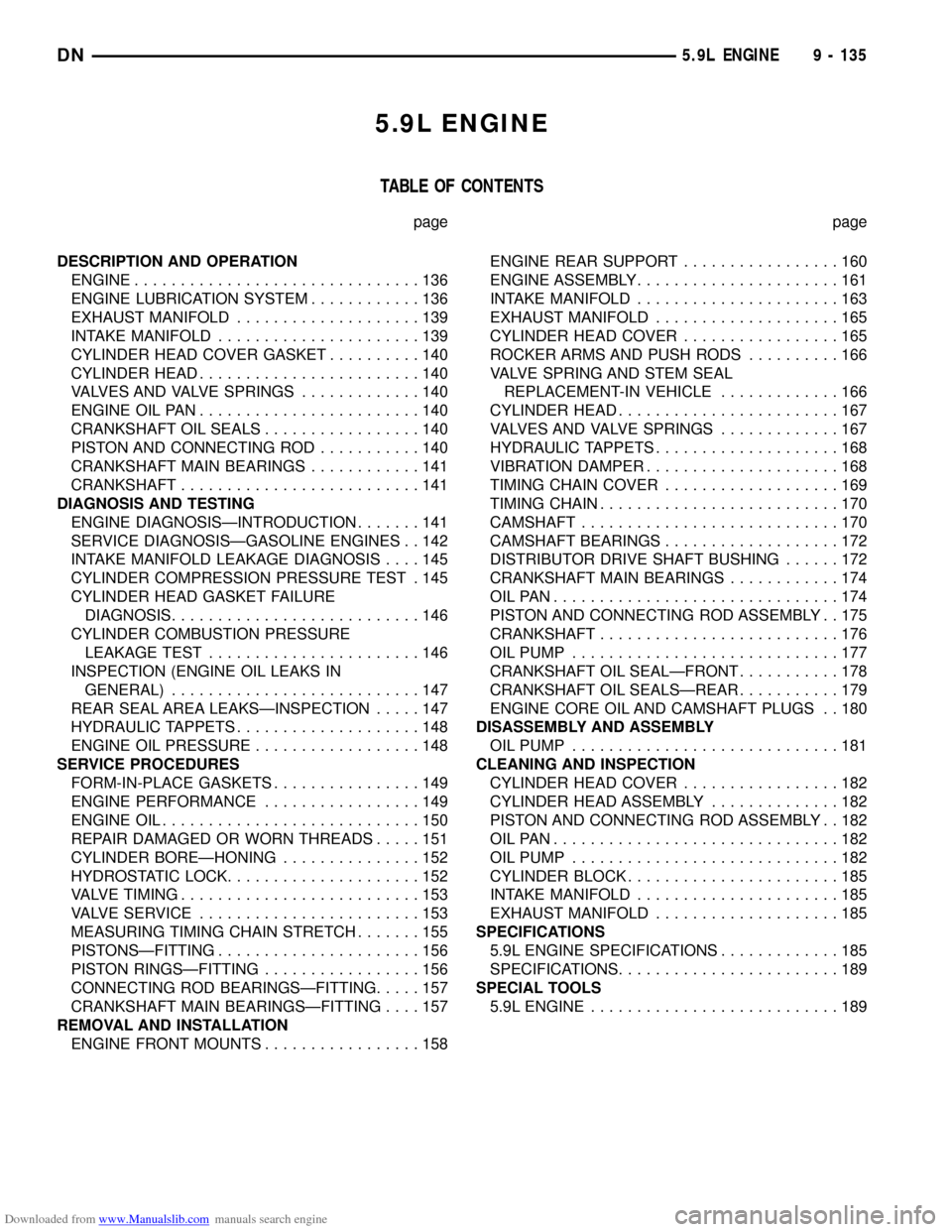

The cylinders are numbered from front to rear; 1,

3, 5, 7 on the left bank and 2, 4, 6, 8 on the right

bank. The firing order is 1-8-4-3-6-5-7-2 (Fig. 1).

The engine serial number is stamped into a

machined pad located on the left, front corner of the

cylinder block. When component part replacement is

necessary, use the engine type and serial number for

reference (Fig. 2).

ENGINE LUBRICATION SYSTEM

DESCRIPTION

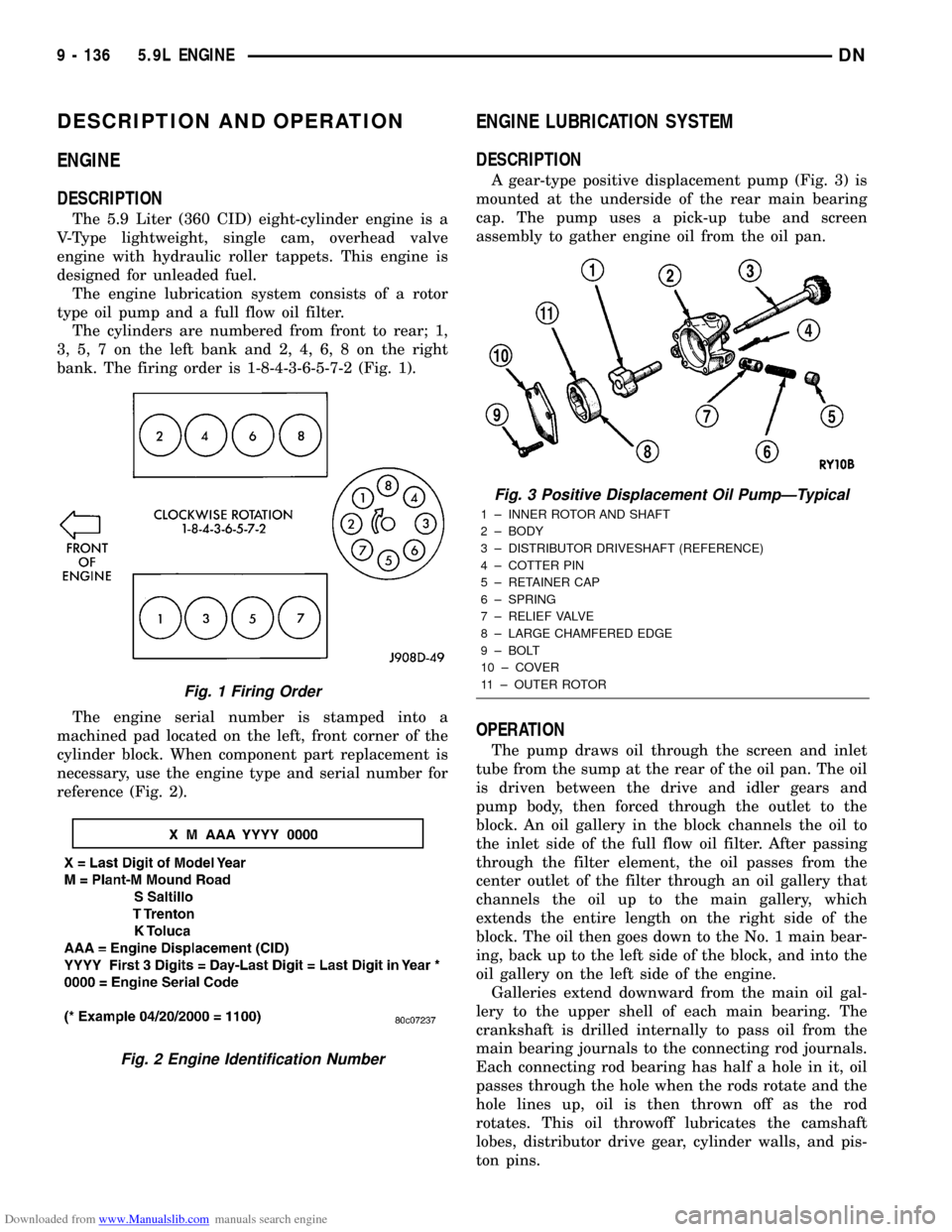

A gear-type positive displacement pump (Fig. 3) is

mounted at the underside of the rear main bearing

cap. The pump uses a pick-up tube and screen

assembly to gather engine oil from the oil pan.

OPERATION

The pump draws oil through the screen and inlet

tube from the sump at the rear of the oil pan. The oil

is driven between the drive and idler gears and

pump body, then forced through the outlet to the

block. An oil gallery in the block channels the oil to

the inlet side of the full flow oil filter. After passing

through the filter element, the oil passes from the

center outlet of the filter through an oil gallery that

channels the oil up to the main gallery, which

extends the entire length on the right side of the

block. The oil then goes down to the No. 1 main bear-

ing, back up to the left side of the block, and into the

oil gallery on the left side of the engine.

Galleries extend downward from the main oil gal-

lery to the upper shell of each main bearing. The

crankshaft is drilled internally to pass oil from the

main bearing journals to the connecting rod journals.

Each connecting rod bearing has half a hole in it, oil

passes through the hole when the rods rotate and the

hole lines up, oil is then thrown off as the rod

rotates. This oil throwoff lubricates the camshaft

lobes, distributor drive gear, cylinder walls, and pis-

ton pins.

Fig. 1 Firing Order

Fig. 2 Engine Identification Number

Fig. 3 Positive Displacement Oil PumpÐTypical

1 ± INNER ROTOR AND SHAFT

2 ± BODY

3 ± DISTRIBUTOR DRIVESHAFT (REFERENCE)

4 ± COTTER PIN

5 ± RETAINER CAP

6 ± SPRING

7 ± RELIEF VALVE

8 ± LARGE CHAMFERED EDGE

9 ± BOLT

10 ± COVER

11 ± OUTER ROTOR

9 - 136 5.9L ENGINEDN