low oil pressure DODGE DURANGO 2000 1.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: DURANGO, Model: DODGE DURANGO 2000 1.GPages: 193, PDF Size: 5.65 MB

Page 19 of 193

Downloaded from www.Manualslib.com manuals search engine (6) Identify the fluid in the cylinders (i.e. coolant,

fuel, oil, etc.).

(7) Make sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt engine oil into the cylinders to lubricate

the walls. This will prevent damage on restart.

(10) Install new spark plugs.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil.

(15) Connect the negative cable to the battery.

(16) Start the engine and check for any leaks.

VALVE SERVICE

REFACING

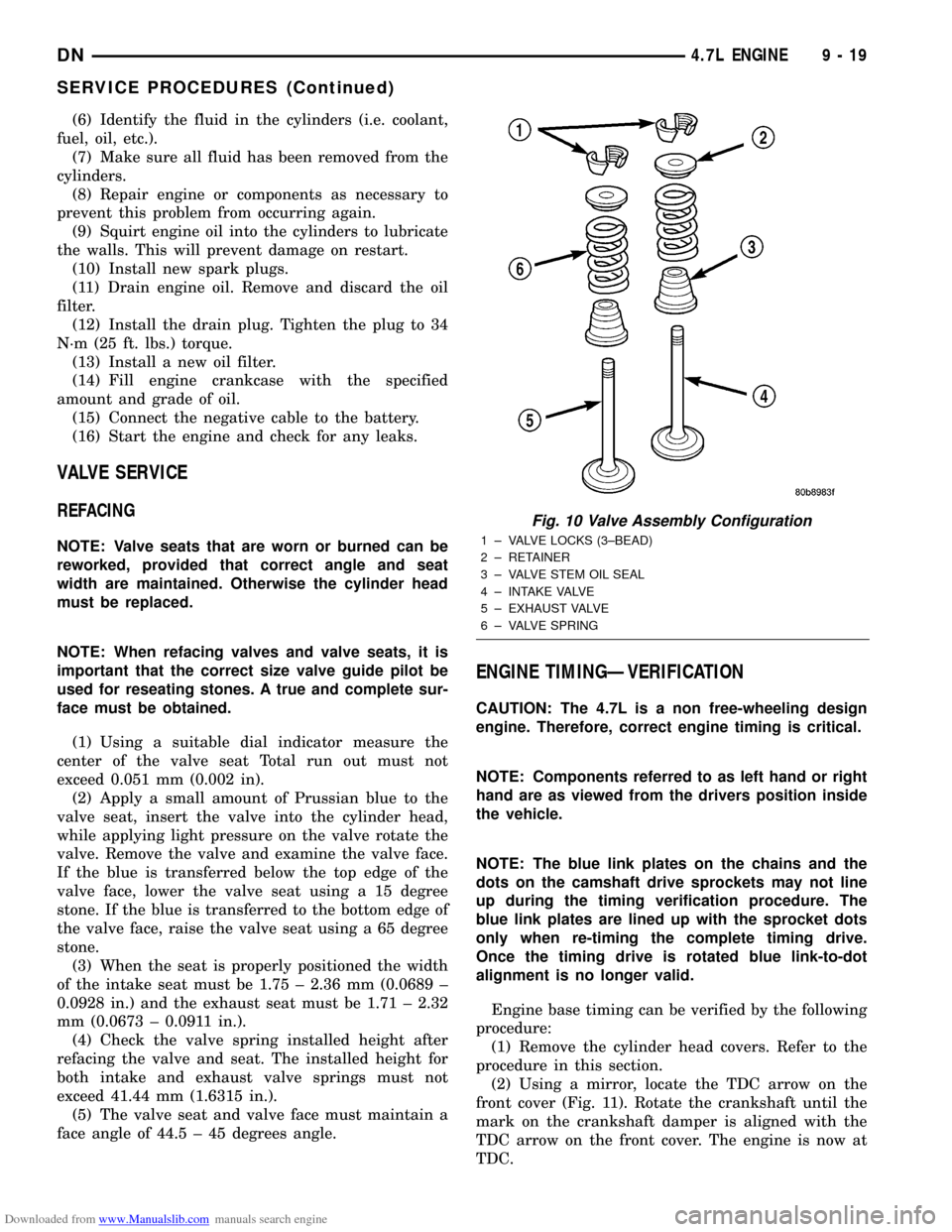

NOTE: Valve seats that are worn or burned can be

reworked, provided that correct angle and seat

width are maintained. Otherwise the cylinder head

must be replaced.

NOTE: When refacing valves and valve seats, it is

important that the correct size valve guide pilot be

used for reseating stones. A true and complete sur-

face must be obtained.

(1) Using a suitable dial indicator measure the

center of the valve seat Total run out must not

exceed 0.051 mm (0.002 in).

(2) Apply a small amount of Prussian blue to the

valve seat, insert the valve into the cylinder head,

while applying light pressure on the valve rotate the

valve. Remove the valve and examine the valve face.

If the blue is transferred below the top edge of the

valve face, lower the valve seat using a 15 degree

stone. If the blue is transferred to the bottom edge of

the valve face, raise the valve seat using a 65 degree

stone.

(3) When the seat is properly positioned the width

of the intake seat must be 1.75 ± 2.36 mm (0.0689 ±

0.0928 in.) and the exhaust seat must be 1.71 ± 2.32

mm (0.0673 ± 0.0911 in.).

(4) Check the valve spring installed height after

refacing the valve and seat. The installed height for

both intake and exhaust valve springs must not

exceed 41.44 mm (1.6315 in.).

(5) The valve seat and valve face must maintain a

face angle of 44.5 ± 45 degrees angle.

ENGINE TIMINGÐVERIFICATION

CAUTION: The 4.7L is a non free-wheeling design

engine. Therefore, correct engine timing is critical.

NOTE: Components referred to as left hand or right

hand are as viewed from the drivers position inside

the vehicle.

NOTE: The blue link plates on the chains and the

dots on the camshaft drive sprockets may not line

up during the timing verification procedure. The

blue link plates are lined up with the sprocket dots

only when re-timing the complete timing drive.

Once the timing drive is rotated blue link-to-dot

alignment is no longer valid.

Engine base timing can be verified by the following

procedure:

(1) Remove the cylinder head covers. Refer to the

procedure in this section.

(2) Using a mirror, locate the TDC arrow on the

front cover (Fig. 11). Rotate the crankshaft until the

mark on the crankshaft damper is aligned with the

TDC arrow on the front cover. The engine is now at

TDC.

Fig. 10 Valve Assembly Configuration

1 ± VALVE LOCKS (3±BEAD)

2 ± RETAINER

3 ± VALVE STEM OIL SEAL

4 ± INTAKE VALVE

5 ± EXHAUST VALVE

6 ± VALVE SPRING

DN4.7L ENGINE 9 - 19

SERVICE PROCEDURES (Continued)

Page 32 of 193

Downloaded from www.Manualslib.com manuals search engine ²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold absolute pressure (MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

(31) Disconnect the vacuum lines at the throttle

body and intake manifold.

(32) Release fuel rail pressure then disconnect the

fuel supply quick connect fitting at the fuel rail.

Refer toFUEL SYSTEM for procedure.

(33) Remove power steering pump and position out

of the way.

(34) Install Special Tools 8400 Lifting Studs, into

the cylinder heads.

(35) Install Engine Lifting Fixture Special Tool

8347 (Fig. 47) following these steps.

²Holding the lifting fixture at a slight angle, slide

the large bore in the front plate over the hex portion

of the lifting stud.

²Position the two remaining fixture arms onto

the two Special Tools 8400 Lifting Studs, in the cyl-

inder heads.

²Pull foward and upward on the lifting fixture so

that the lifting stud rest in the slotted area below the

large bore.²Secure the lifting fixture to the three studs

using three 7/16 ± 14 N/C locknuts.

²Make sure the lifting loop in the lifting fixture is

in the last hole (closest to the throttle body) to min-

imize the angle of engine during removal.

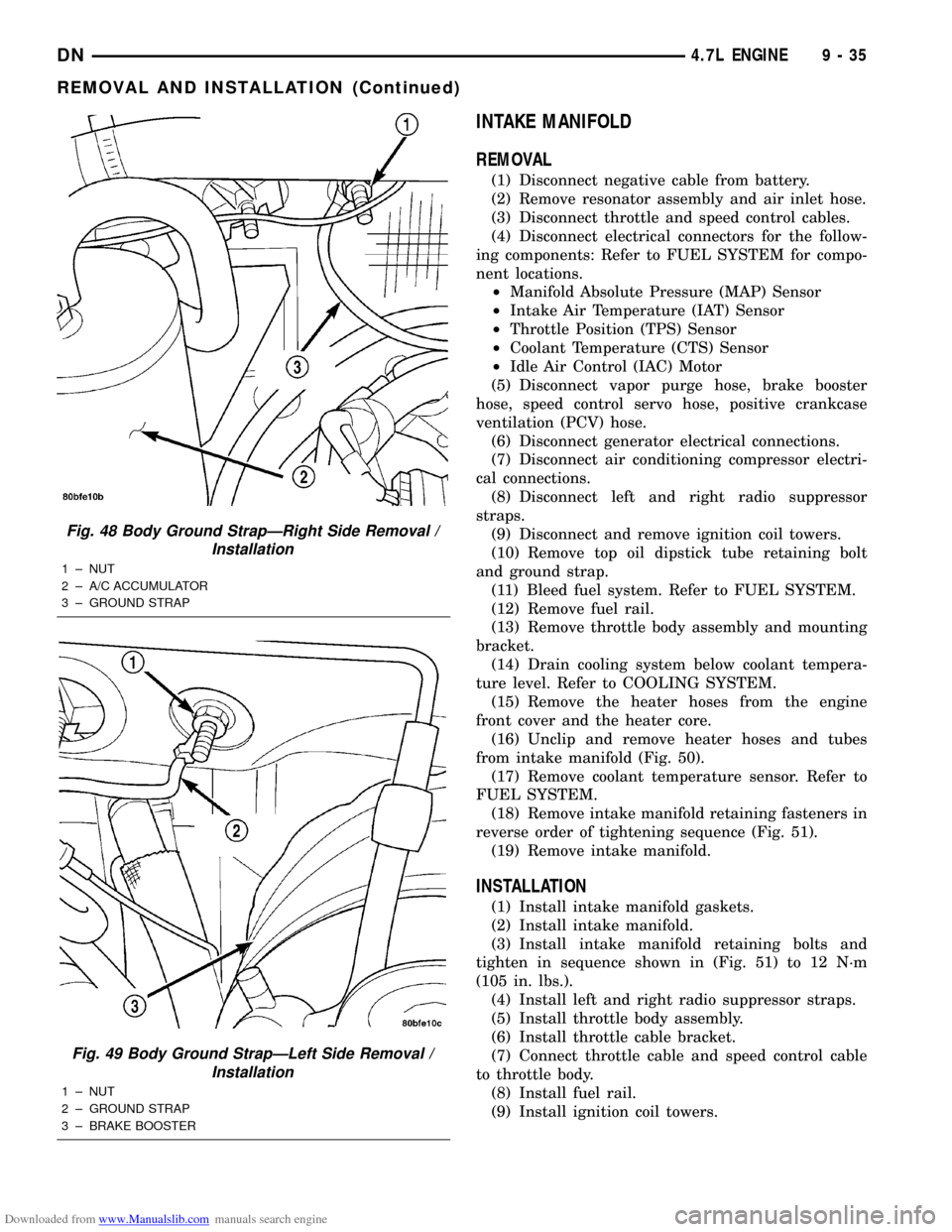

(36) Disconnect body ground strap at the right side

cowl (Fig. 48).

(37) Disconnect body ground strap at the left side

cowl (Fig. 49).

NOTE: It will be necessary to support the transmis-

sion in order to remove the engine.

(38) Position a suitable jack under the transmis-

sion.

(39) Remove engine from the vehicle.

INSTALLATION

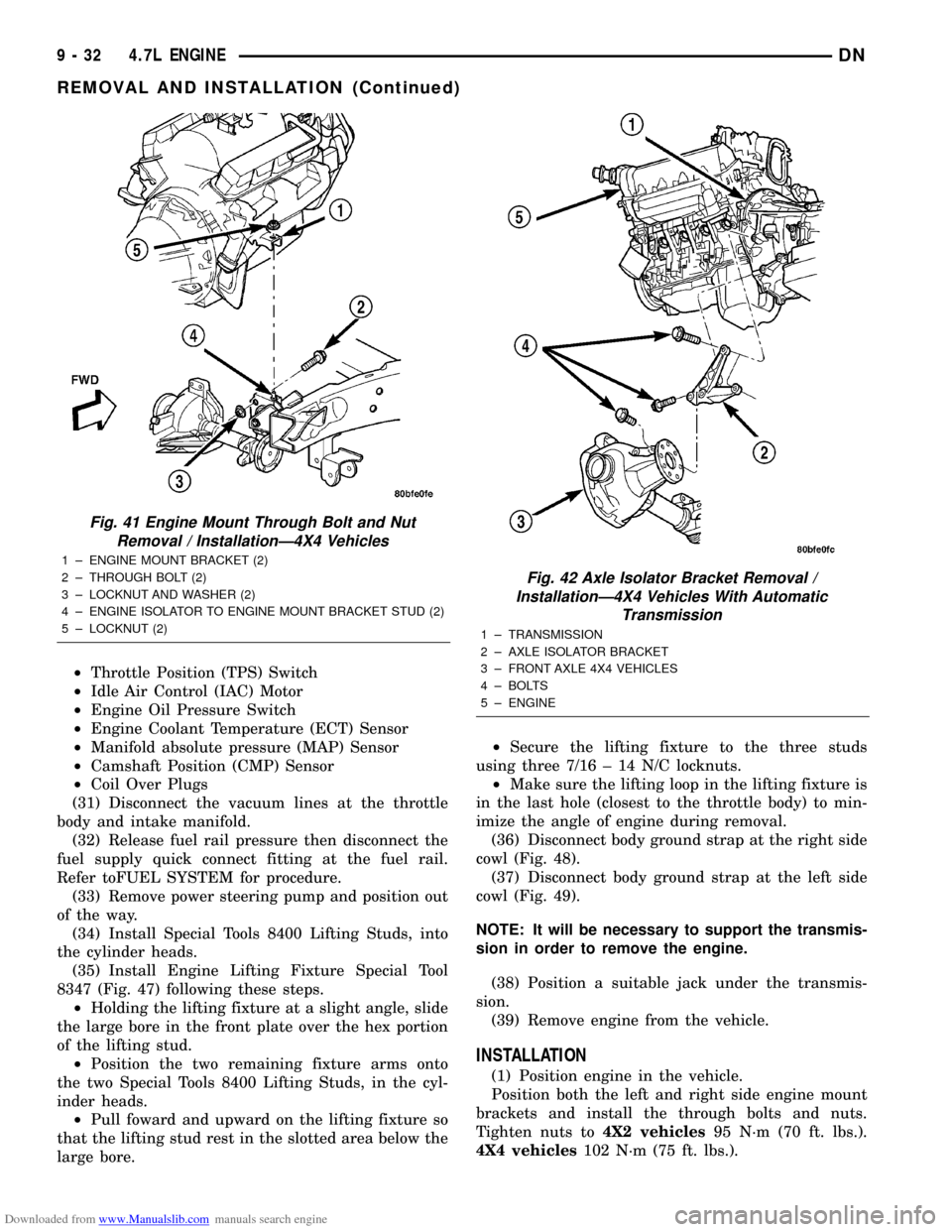

(1) Position engine in the vehicle.

Position both the left and right side engine mount

brackets and install the through bolts and nuts.

Tighten nuts to4X2 vehicles95 N´m (70 ft. lbs.).

4X4 vehicles102 N´m (75 ft. lbs.).

Fig. 41 Engine Mount Through Bolt and Nut

Removal / InstallationÐ4X4 Vehicles

1 ± ENGINE MOUNT BRACKET (2)

2 ± THROUGH BOLT (2)

3 ± LOCKNUT AND WASHER (2)

4 ± ENGINE ISOLATOR TO ENGINE MOUNT BRACKET STUD (2)

5 ± LOCKNUT (2)

Fig. 42 Axle Isolator Bracket Removal /

InstallationÐ4X4 Vehicles With Automatic

Transmission

1 ± TRANSMISSION

2 ± AXLE ISOLATOR BRACKET

3 ± FRONT AXLE 4X4 VEHICLES

4 ± BOLTS

5 ± ENGINE

9 - 32 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 33 of 193

Downloaded from www.Manualslib.com manuals search engine (2)4X4 vehiclesInstall locknuts onto the engine

mount brackets. Tighten locknuts to 41 N´m (30 ft.

lbs.).

(3) Remove jack from under the transmission.

(4) Remove Engine Lifting Fixture Special Tool

8347 (Fig. 47).

(5) Remove Special Tools 8400 Lifting Studs.

(6) Position generator wiring behind the oil dip-

stick tube, then install the oil dipstick tube upper

mounting bolt.

(7) Connect both left and right side body ground

straps.(8) Install power steering pump.

(9) Connect fuel supply line quick connect fitting.

(10) Connect the vacuum lines at the throttle body

and intake manifold.

(11) Connect engine harness at the following

points (Fig. 46) :

²Intake Air Temperature (IAT) Sensor

²Idle Air Control (IAC) Motor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure (MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

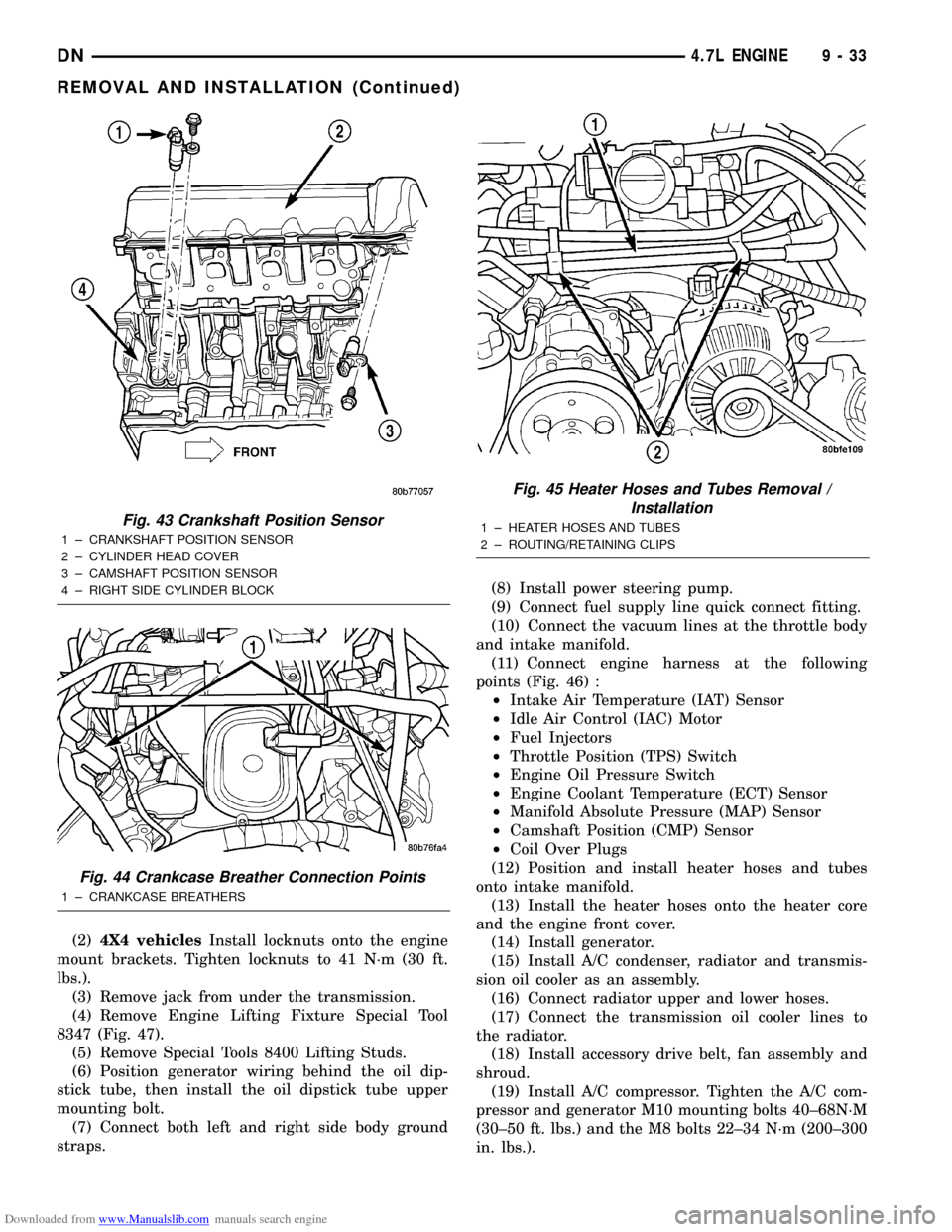

(12) Position and install heater hoses and tubes

onto intake manifold.

(13) Install the heater hoses onto the heater core

and the engine front cover.

(14) Install generator.

(15) Install A/C condenser, radiator and transmis-

sion oil cooler as an assembly.

(16) Connect radiator upper and lower hoses.

(17) Connect the transmission oil cooler lines to

the radiator.

(18) Install accessory drive belt, fan assembly and

shroud.

(19) Install A/C compressor. Tighten the A/C com-

pressor and generator M10 mounting bolts 40±68N´M

(30±50 ft. lbs.) and the M8 bolts 22±34 N´m (200±300

in. lbs.).

Fig. 43 Crankshaft Position Sensor

1 ± CRANKSHAFT POSITION SENSOR

2 ± CYLINDER HEAD COVER

3 ± CAMSHAFT POSITION SENSOR

4 ± RIGHT SIDE CYLINDER BLOCK

Fig. 44 Crankcase Breather Connection Points

1 ± CRANKCASE BREATHERS

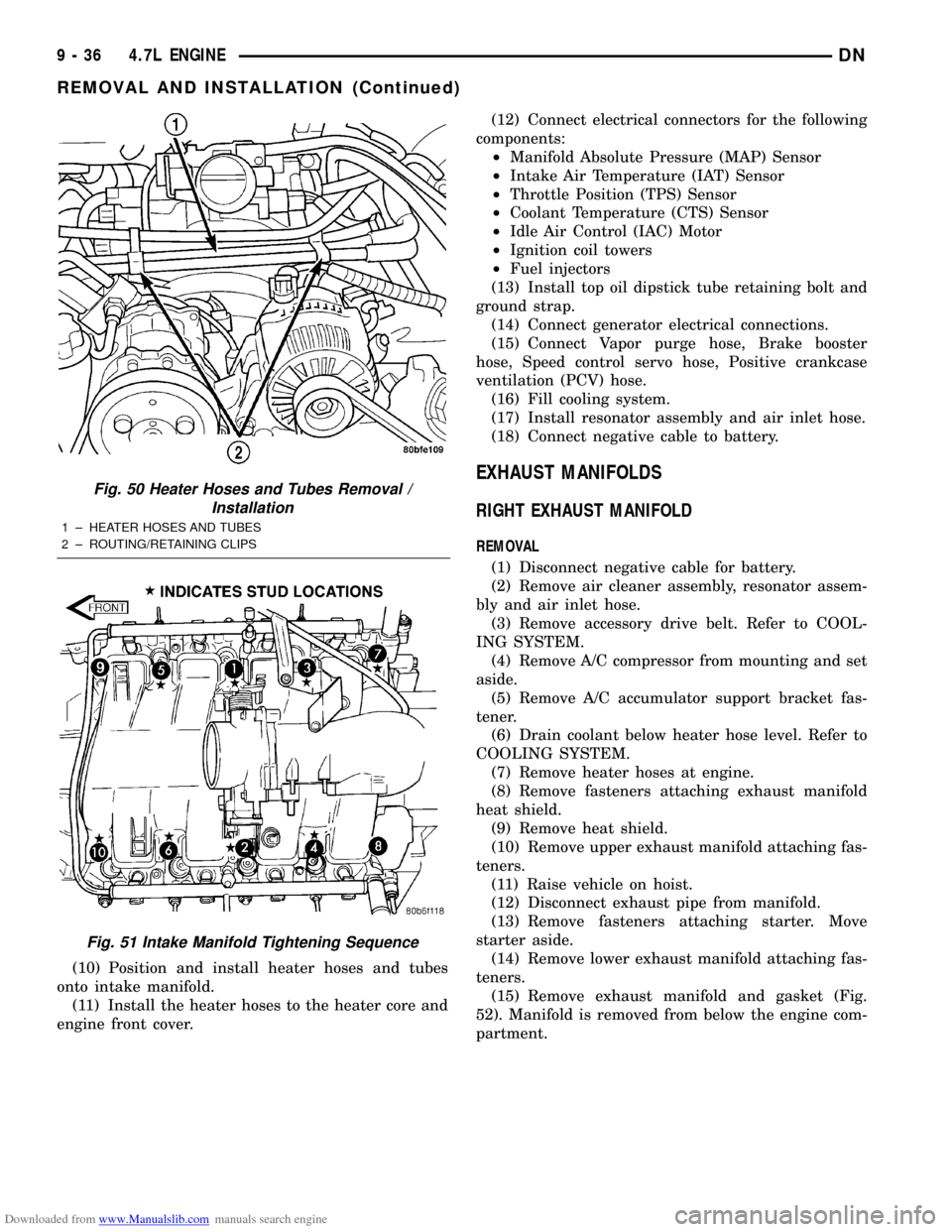

Fig. 45 Heater Hoses and Tubes Removal /

Installation

1 ± HEATER HOSES AND TUBES

2 ± ROUTING/RETAINING CLIPS

DN4.7L ENGINE 9 - 33

REMOVAL AND INSTALLATION (Continued)

Page 35 of 193

Downloaded from www.Manualslib.com manuals search engine INTAKE MANIFOLD

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove resonator assembly and air inlet hose.

(3) Disconnect throttle and speed control cables.

(4) Disconnect electrical connectors for the follow-

ing components: Refer to FUEL SYSTEM for compo-

nent locations.

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

(5) Disconnect vapor purge hose, brake booster

hose, speed control servo hose, positive crankcase

ventilation (PCV) hose.

(6) Disconnect generator electrical connections.

(7) Disconnect air conditioning compressor electri-

cal connections.

(8) Disconnect left and right radio suppressor

straps.

(9) Disconnect and remove ignition coil towers.

(10) Remove top oil dipstick tube retaining bolt

and ground strap.

(11) Bleed fuel system. Refer to FUEL SYSTEM.

(12) Remove fuel rail.

(13) Remove throttle body assembly and mounting

bracket.

(14) Drain cooling system below coolant tempera-

ture level. Refer to COOLING SYSTEM.

(15) Remove the heater hoses from the engine

front cover and the heater core.

(16) Unclip and remove heater hoses and tubes

from intake manifold (Fig. 50).

(17) Remove coolant temperature sensor. Refer to

FUEL SYSTEM.

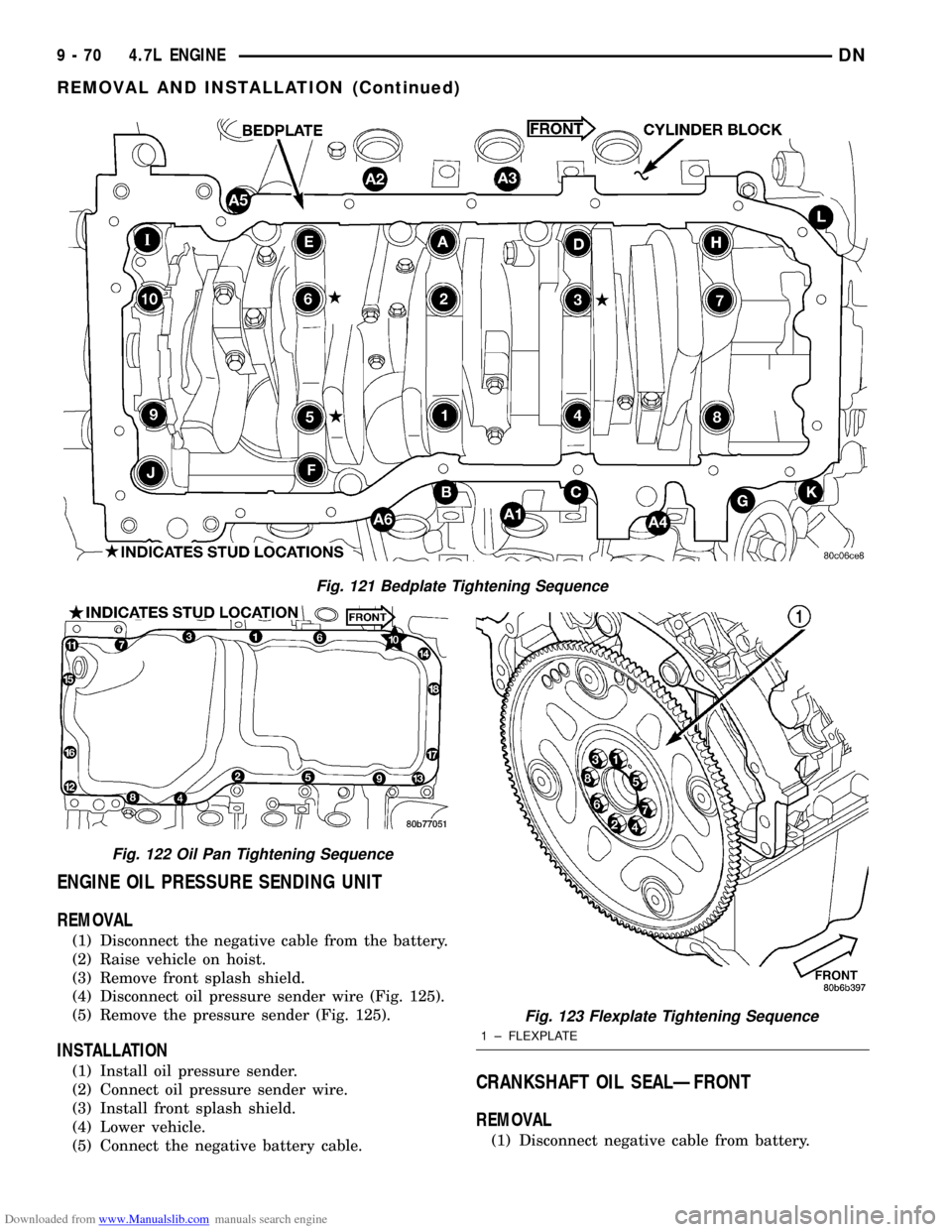

(18) Remove intake manifold retaining fasteners in

reverse order of tightening sequence (Fig. 51).

(19) Remove intake manifold.

INSTALLATION

(1) Install intake manifold gaskets.

(2) Install intake manifold.

(3) Install intake manifold retaining bolts and

tighten in sequence shown in (Fig. 51) to 12 N´m

(105 in. lbs.).

(4) Install left and right radio suppressor straps.

(5) Install throttle body assembly.

(6) Install throttle cable bracket.

(7) Connect throttle cable and speed control cable

to throttle body.

(8) Install fuel rail.

(9) Install ignition coil towers.

Fig. 48 Body Ground StrapÐRight Side Removal /

Installation

1 ± NUT

2 ± A/C ACCUMULATOR

3 ± GROUND STRAP

Fig. 49 Body Ground StrapÐLeft Side Removal /

Installation

1 ± NUT

2 ± GROUND STRAP

3 ± BRAKE BOOSTER

DN4.7L ENGINE 9 - 35

REMOVAL AND INSTALLATION (Continued)

Page 36 of 193

Downloaded from www.Manualslib.com manuals search engine (10) Position and install heater hoses and tubes

onto intake manifold.

(11) Install the heater hoses to the heater core and

engine front cover.(12) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

²Ignition coil towers

²Fuel injectors

(13) Install top oil dipstick tube retaining bolt and

ground strap.

(14) Connect generator electrical connections.

(15) Connect Vapor purge hose, Brake booster

hose, Speed control servo hose, Positive crankcase

ventilation (PCV) hose.

(16) Fill cooling system.

(17) Install resonator assembly and air inlet hose.

(18) Connect negative cable to battery.

EXHAUST MANIFOLDS

RIGHT EXHAUST MANIFOLD

REMOVAL

(1) Disconnect negative cable for battery.

(2) Remove air cleaner assembly, resonator assem-

bly and air inlet hose.

(3) Remove accessory drive belt. Refer to COOL-

ING SYSTEM.

(4) Remove A/C compressor from mounting and set

aside.

(5) Remove A/C accumulator support bracket fas-

tener.

(6) Drain coolant below heater hose level. Refer to

COOLING SYSTEM.

(7) Remove heater hoses at engine.

(8) Remove fasteners attaching exhaust manifold

heat shield.

(9) Remove heat shield.

(10) Remove upper exhaust manifold attaching fas-

teners.

(11) Raise vehicle on hoist.

(12) Disconnect exhaust pipe from manifold.

(13) Remove fasteners attaching starter. Move

starter aside.

(14) Remove lower exhaust manifold attaching fas-

teners.

(15) Remove exhaust manifold and gasket (Fig.

52). Manifold is removed from below the engine com-

partment.

Fig. 50 Heater Hoses and Tubes Removal /

Installation

1 ± HEATER HOSES AND TUBES

2 ± ROUTING/RETAINING CLIPS

Fig. 51 Intake Manifold Tightening Sequence

9 - 36 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 70 of 193

Downloaded from www.Manualslib.com manuals search engine ENGINE OIL PRESSURE SENDING UNIT

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise vehicle on hoist.

(3) Remove front splash shield.

(4) Disconnect oil pressure sender wire (Fig. 125).

(5) Remove the pressure sender (Fig. 125).

INSTALLATION

(1) Install oil pressure sender.

(2) Connect oil pressure sender wire.

(3) Install front splash shield.

(4) Lower vehicle.

(5) Connect the negative battery cable.CRANKSHAFT OIL SEALÐFRONT

REMOVAL

(1) Disconnect negative cable from battery.

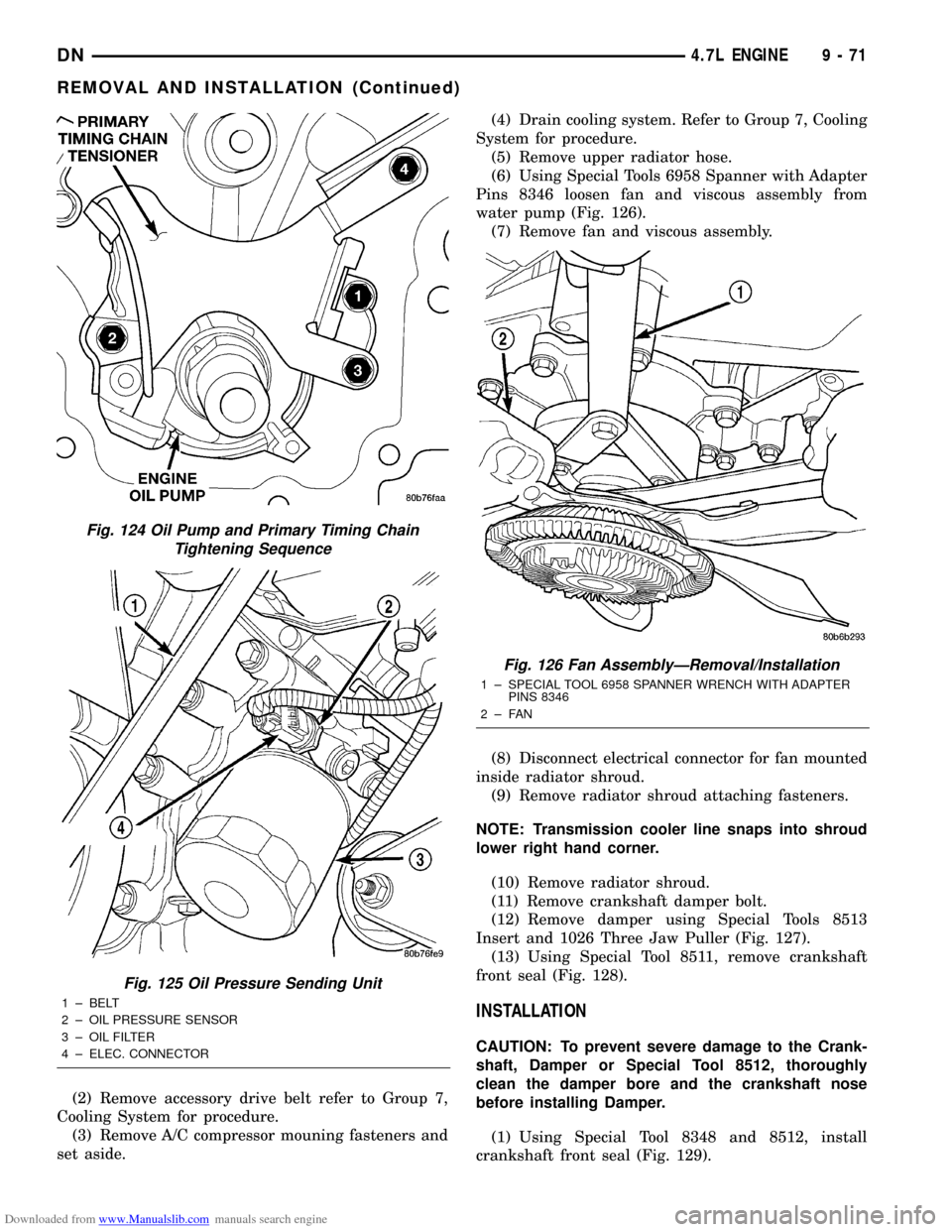

Fig. 121 Bedplate Tightening Sequence

Fig. 122 Oil Pan Tightening Sequence

Fig. 123 Flexplate Tightening Sequence

1 ± FLEXPLATE

9 - 70 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 71 of 193

Downloaded from www.Manualslib.com manuals search engine (2) Remove accessory drive belt refer to Group 7,

Cooling System for procedure.

(3) Remove A/C compressor mouning fasteners and

set aside.(4) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

(5) Remove upper radiator hose.

(6) Using Special Tools 6958 Spanner with Adapter

Pins 8346 loosen fan and viscous assembly from

water pump (Fig. 126).

(7) Remove fan and viscous assembly.

(8) Disconnect electrical connector for fan mounted

inside radiator shroud.

(9) Remove radiator shroud attaching fasteners.

NOTE: Transmission cooler line snaps into shroud

lower right hand corner.

(10) Remove radiator shroud.

(11) Remove crankshaft damper bolt.

(12) Remove damper using Special Tools 8513

Insert and 1026 Three Jaw Puller (Fig. 127).

(13) Using Special Tool 8511, remove crankshaft

front seal (Fig. 128).

INSTALLATION

CAUTION: To prevent severe damage to the Crank-

shaft, Damper or Special Tool 8512, thoroughly

clean the damper bore and the crankshaft nose

before installing Damper.

(1) Using Special Tool 8348 and 8512, install

crankshaft front seal (Fig. 129).

Fig. 124 Oil Pump and Primary Timing Chain

Tightening Sequence

Fig. 125 Oil Pressure Sending Unit

1 ± BELT

2 ± OIL PRESSURE SENSOR

3 ± OIL FILTER

4 ± ELEC. CONNECTOR

Fig. 126 Fan AssemblyÐRemoval/Installation

1 ± SPECIAL TOOL 6958 SPANNER WRENCH WITH ADAPTER

PINS 8346

2±FAN

DN4.7L ENGINE 9 - 71

REMOVAL AND INSTALLATION (Continued)

Page 75 of 193

Downloaded from www.Manualslib.com manuals search engine NOTE: Once the oil pressure relief valve, cup plug,

and pin are removed, the pump assembly must be

replaced.

(3) If it is necessary to remove the pressure relief

valve, drive the roll pin from pump housing and

remove cup plug, spring and valve.

ASSEMBLE

(1) Wash all parts in a suitable solvent and inspect

carefully for damage or wear.

(2) Install inner and outer rotors

(3) Install oil pump cover plate and install cover

bolts and tighten them to 12 N´m (105 in. lbs.).

(4) Prime oil pump before installation by filling

rotor cavity with engine oil.

(5) If oil pressure is low and pump is within spec-

ifications, inspect for worn engine bearings or other

causes for oil pressure loss.

CLEANING AND INSPECTION

INTAKE MANIFOLD

CLEANING

NOTE: There is NO approved repair procedure for

the intake manifold. If severe damage is found dur-

ing inspection, the intake manifold must be

replaced.

Before installing the intake manifold thoroughly

clean the mating surfaces. Use a suitable cleaning

solvent, then air dry.

INSPECTION

(1) Inspect the intake sealing surface for cracks,

nicks and distortion.

(2) Inspect the intake manifold vacuum hose fit-

tings for looseness or blockage.

(3) Inspect the manifold to throttle body mating

surface for cracks, nicks and distortion.

EXHAUST MANIFOLD

CLEANING

(1) Clean the exhaust manifold using a suitable

cleaning solvent, then allow to air dry.

(2) Clean all gasket residue from the manifold

mating surface.

INSPECTION

(1) Inspect the exhaust manifold for cracks in the

mating surface and at every mounting bolt hole.

(2) Using a straight edge and a feeler gauge, check

the mating surface for warp and twist.(3) Inspect the manifold to exhaust pipe mating

surface for cracks, gouges, or other damage that

would prevent sealing.

CYLINDER HEADS

CLEANING

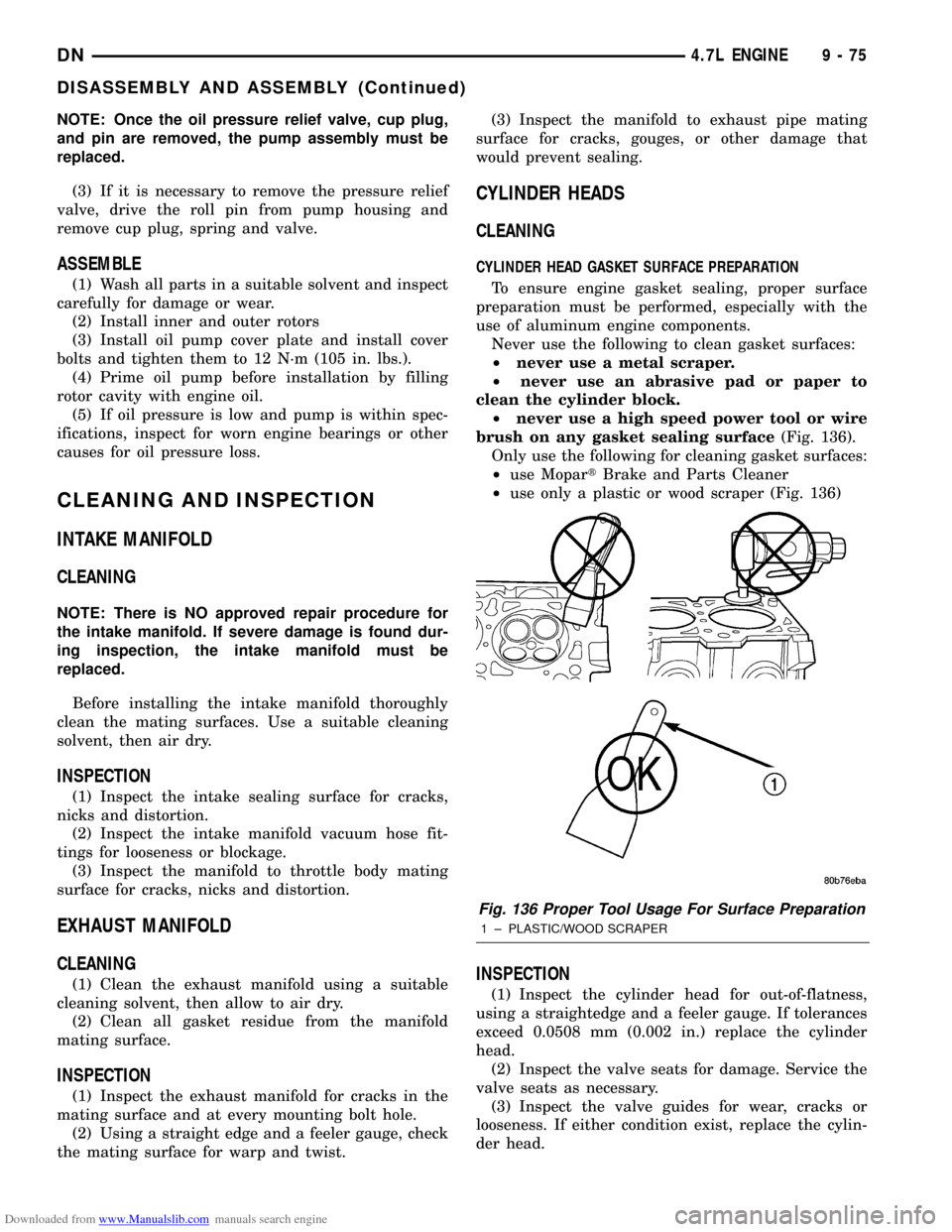

CYLINDER HEAD GASKET SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components.

Never use the following to clean gasket surfaces:

²never use a metal scraper.

²never use an abrasive pad or paper to

clean the cylinder block.

²never use a high speed power tool or wire

brush on any gasket sealing surface(Fig. 136).

Only use the following for cleaning gasket surfaces:

²use MopartBrake and Parts Cleaner

²use only a plastic or wood scraper (Fig. 136)

INSPECTION

(1) Inspect the cylinder head for out-of-flatness,

using a straightedge and a feeler gauge. If tolerances

exceed 0.0508 mm (0.002 in.) replace the cylinder

head.

(2) Inspect the valve seats for damage. Service the

valve seats as necessary.

(3) Inspect the valve guides for wear, cracks or

looseness. If either condition exist, replace the cylin-

der head.

Fig. 136 Proper Tool Usage For Surface Preparation

1 ± PLASTIC/WOOD SCRAPER

DN4.7L ENGINE 9 - 75

DISASSEMBLY AND ASSEMBLY (Continued)

Page 89 of 193

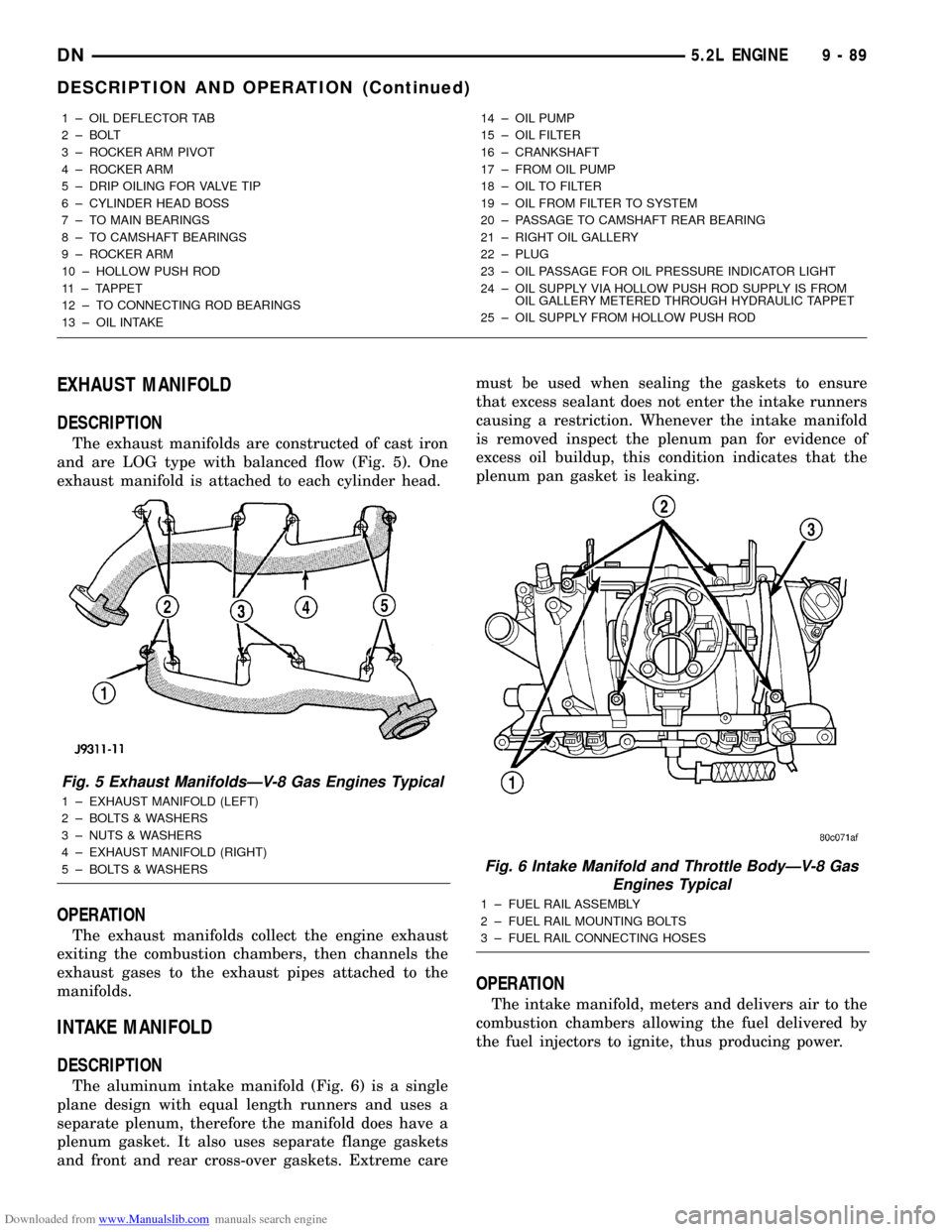

Downloaded from www.Manualslib.com manuals search engine EXHAUST MANIFOLD

DESCRIPTION

The exhaust manifolds are constructed of cast iron

and are LOG type with balanced flow (Fig. 5). One

exhaust manifold is attached to each cylinder head.

OPERATION

The exhaust manifolds collect the engine exhaust

exiting the combustion chambers, then channels the

exhaust gases to the exhaust pipes attached to the

manifolds.

INTAKE MANIFOLD

DESCRIPTION

The aluminum intake manifold (Fig. 6) is a single

plane design with equal length runners and uses a

separate plenum, therefore the manifold does have a

plenum gasket. It also uses separate flange gaskets

and front and rear cross-over gaskets. Extreme caremust be used when sealing the gaskets to ensure

that excess sealant does not enter the intake runners

causing a restriction. Whenever the intake manifold

is removed inspect the plenum pan for evidence of

excess oil buildup, this condition indicates that the

plenum pan gasket is leaking.

OPERATION

The intake manifold, meters and delivers air to the

combustion chambers allowing the fuel delivered by

the fuel injectors to ignite, thus producing power.

1 ± OIL DEFLECTOR TAB

2 ± BOLT

3 ± ROCKER ARM PIVOT

4 ± ROCKER ARM

5 ± DRIP OILING FOR VALVE TIP

6 ± CYLINDER HEAD BOSS

7 ± TO MAIN BEARINGS

8 ± TO CAMSHAFT BEARINGS

9 ± ROCKER ARM

10 ± HOLLOW PUSH ROD

11 ± TAPPET

12 ± TO CONNECTING ROD BEARINGS

13 ± OIL INTAKE14 ± OIL PUMP

15 ± OIL FILTER

16 ± CRANKSHAFT

17 ± FROM OIL PUMP

18 ± OIL TO FILTER

19 ± OIL FROM FILTER TO SYSTEM

20 ± PASSAGE TO CAMSHAFT REAR BEARING

21 ± RIGHT OIL GALLERY

22 ± PLUG

23 ± OIL PASSAGE FOR OIL PRESSURE INDICATOR LIGHT

24 ± OIL SUPPLY VIA HOLLOW PUSH ROD SUPPLY IS FROM

OIL GALLERY METERED THROUGH HYDRAULIC TAPPET

25 ± OIL SUPPLY FROM HOLLOW PUSH ROD

Fig. 5 Exhaust ManifoldsÐV-8 Gas Engines Typical

1 ± EXHAUST MANIFOLD (LEFT)

2 ± BOLTS & WASHERS

3 ± NUTS & WASHERS

4 ± EXHAUST MANIFOLD (RIGHT)

5 ± BOLTS & WASHERS

Fig. 6 Intake Manifold and Throttle BodyÐV-8 Gas

Engines Typical

1 ± FUEL RAIL ASSEMBLY

2 ± FUEL RAIL MOUNTING BOLTS

3 ± FUEL RAIL CONNECTING HOSES

DN5.2L ENGINE 9 - 89

DESCRIPTION AND OPERATION (Continued)

Page 92 of 193

Downloaded from www.Manualslib.com manuals search engine Scrape or wire brush all gasket surfaces to remove

all loose material. Inspect stamped parts to ensure

gasket rails are flat. Flatten rails with a hammer on

a flat plate, if required. Gasket surfaces must be free

of oil and dirt. Make sure the old gasket material is

removed from blind attaching holes.

GASKET APPLICATION

Assembling parts using a form-in-place gasket

requires care.

Mopar Silicone Rubber Adhesive Sealant should be

applied in a continuous bead approximately 3 mm

(0.12 inch) in diameter. All mounting holes must be

circled. For corner sealing,a3or6mm(1/8 or 1/4

inch) drop is placed in the center of the gasket con-

tact area. Uncured sealant may be removed with a

shop towel. Components should be torqued in place

while the sealant is still wet to the touch (within 10

minutes). The use of a locating dowel is recom-

mended during assembly to prevent smearing the

material off location.

Mopar Gasket Maker should be applied sparingly

to one gasket surface. The sealant diameter should

be 1.00 mm (0.04 inch) or less. Be certain the mate-

rial surrounds each mounting hole. Excess material

can easily be wiped off. Components should be

torqued in place within 15 minutes. The use of a

locating dowel is recommended during assembly to

prevent smearing the material off location.

ENGINE PERFORMANCE

It is important that the vehicle is operating to its

optimum performance level to maintain fuel economy

and the lowest emission levels. If vehicle is not oper-

ating to these standards, refer to Engine Diagnosis

outlined in this section. The following procedures can

assist in achieving the proper engine diagnosis.

(1) Test cranking amperage draw. Refer to Electri-

cal Group 8B, Cold Cranking Test.

(2) Check intake manifold bolt torque.

(3) Perform cylinder compression test. Refer to

Cylinder Compression Pressure Test in the Engine

Diagnosis area of this section.

(4) Clean or replace spark plugs as necessary and

adjust gap as specified in Electrical Group 8D.

Tighten to specifications.

(5) Test resistance of spark plug cables. Refer to

Electrical Group 8D, Spark Plug Cables.

(6) Inspect the primary wires. Test coil output volt-

age and primary resistance. Replace parts as neces-

sary. Refer to Electrical Group 8D, for specifications.

(7) Test fuel pump for pressure. Refer to Group 14,

Fuel System Specifications.

(8) The air filter elements should be replaced as

specified in Lubrication and Maintenance, Group 0.(9) Inspect crankcase ventilation system as out

lined in Group 0, Lubrication and Maintenance. For

emission controls see Group 25, Emission Controls

for service procedures.

(10) Road test vehicle as a final test.

ENGINE OIL

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

In gasoline engines, use an engine oil that is API

Service Grade Certified (Fig. 11). Standard engine oil

identification notations have been adopted to aid in

the proper selection of engine oil. The identifying

notations are located on the label of engine oil plastic

bottles and the top of engine oil cans. MOPAR only

provides engine oil that conforms to this certification.

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. SAE 10W-30 specifies a multiple

viscosity engine oil. These are specified with a dual

SAE viscosity grade which indicates the cold-to-hot

temperature viscosity range. When choosing an

engine oil, consider the range of temperatures the

vehicle will be operated in before the next oil change.

Select an engine oil that is best suited to your area's

Fig. 11 Engine Oil Container Standard Notations

9 - 92 5.2L ENGINEDN

SERVICE PROCEDURES (Continued)