spark plugs replace DODGE DURANGO 2000 1.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: DURANGO, Model: DODGE DURANGO 2000 1.GPages: 193, PDF Size: 5.65 MB

Page 9 of 193

Downloaded from www.Manualslib.com manuals search engine CONDITION POSSIBLE CAUSE CORRECTION

ENGINE LOSS OF POWER 1. Incorrect ignition timing. 1. Refer to Group 8D, Ignition

System.

2. Worn or burned distributor rotor. 2. Replace distributor rotor.

3. Worn distributor shaft. 3. Refer to Group 8D, Ignition

System.

4. Dirty or incorrectly gapped spark

plugs.4. Refer to Group 8D, Ignition

System.

5. Dirt or water in fuel system. 5. Clean system and replace fuel

filter.

6. Faulty fuel pump. 6. Refer to Group 14, Fuel System.

7. Blown cylinder head gasket. 7. Replace cylinder head gasket.

8. Low compression. 8. Test compression, repair as

necessary.

9. Burned, warped or pitted valves. 9. Replace as necessary.

10. Plugged or restricted exhaust

system.10. Inspect and replace as

necessary.

11. Faulty ignition cables. 11. Replace as necessary.

12. Faulty coil. 12. Refer to Group 8D, Ignition

System.

13. Incorrect cam timing. 13. Refer to Valve Timing in this

section.

ENGINE MISSES ON

ACCELERATION1. Spark plugs dirty or incorrectly

gapped.1. Refer to Group 8D, Ignition

System.

2. Incorrect ignition timing. 2. Refer to Group 8D, Ignition

System.

3. Dirt in fuel system. 3. Clean fuel system.

4. Burned, warped or pitted valves. 4. Replcae as necessary.

5. Faulty coil. 5. Refer to Group 8D, Ignition

System.

6. Incorrect cam timing. 6. Refer to Valve Timing in this

section.

ENGINE MISSES AT HIGH SPEED 1. Spark plugs dirty or incorrectly

gapped.1. Refer to Group 8D, Ignition

System.

2. Worn Distributor Shaft. 2. Refer to Group 8D, Ignition

System.

3. Worn or burned distributor rotor. 3. Replace distributor rotor.

4. Faulty coil. 4. Refer to Group 8D, Ignition

System.

5. Incorrect ignition timing. 5. Refer to Group 8D, Ignition

System.

6. Dirt or water in fuel system. 6. Clean system and replace fuel

filter.

7. Incorrect cam timing. 7. Refer to Valve Timing in this

section.

DN4.7L ENGINE 9 - 9

DIAGNOSIS AND TESTING (Continued)

Page 11 of 193

Downloaded from www.Manualslib.com manuals search engine SERVICE DIAGNOSISÐLUBRICATION

CONDITION POSSIBLE CAUSES CORRECTION

OIL LEAKS 1. Gaskets and O-Rings. 1.

(a) Misaligned or damaged. (a) Replace as necessary.

(b) Loose fasteners, broken or

porous metal parts.(b) Tighten fasteners, Repair or

replace metal parts.

2. Crankshaft rear seal 2. Replace as necessary.

3. Crankshaft seal flange.

Scratched, nicked or grooved.3. Polish or replace crankshaft.

4. Oil pan flange cracked. 4. Replace oil pan.

5. Timing chain cover seal,

damaged or misaligned.5. Replace seal.

6. Scratched or damaged vibration

damper hub.6. Polish or replace damper.

OIL PRESSURE DROP 1. Low oil level. 1. Check and correct oil level.

2. Faulty oil pressure sending unit. 2. Replace sending unit.

3. Low oil pressure. 3. Check pump and bearing

clearance.

4. Clogged oil filter. 4. Replace oil filter.

5. Worn oil pump. 5. Replace as necessary.

6. Thin or diluted oil. 6. Change oil and filter.

7. Excessive bearing clearance. 7. Replace as necessary.

8. Oil pump relief valve stuck. 8. Clean or replace relief valve.

9. Oil pump suction tube loose or

damaged.9. Replace as necessary.

OIL PUMPING AT RINGS; SPARK

PLUGS FOULING1. Worn or damaged rings. 1. Hone cylinder bores and replace

rings.

2. Carbon in oil ring slots. 2. Replace rings.

3. Incorrect ring size installed. 3. Replace rings.

4. Worn valve guides. 4. Ream guides and replace valves.

5. Leaking intake gasket. 5. Replace intake gaskets.

6. Leaking valve guide seals. 6. Replace valve guide seals.

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPM is observed the area of the

suspected leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

DN4.7L ENGINE 9 - 11

DIAGNOSIS AND TESTING (Continued)

Page 19 of 193

Downloaded from www.Manualslib.com manuals search engine (6) Identify the fluid in the cylinders (i.e. coolant,

fuel, oil, etc.).

(7) Make sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt engine oil into the cylinders to lubricate

the walls. This will prevent damage on restart.

(10) Install new spark plugs.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil.

(15) Connect the negative cable to the battery.

(16) Start the engine and check for any leaks.

VALVE SERVICE

REFACING

NOTE: Valve seats that are worn or burned can be

reworked, provided that correct angle and seat

width are maintained. Otherwise the cylinder head

must be replaced.

NOTE: When refacing valves and valve seats, it is

important that the correct size valve guide pilot be

used for reseating stones. A true and complete sur-

face must be obtained.

(1) Using a suitable dial indicator measure the

center of the valve seat Total run out must not

exceed 0.051 mm (0.002 in).

(2) Apply a small amount of Prussian blue to the

valve seat, insert the valve into the cylinder head,

while applying light pressure on the valve rotate the

valve. Remove the valve and examine the valve face.

If the blue is transferred below the top edge of the

valve face, lower the valve seat using a 15 degree

stone. If the blue is transferred to the bottom edge of

the valve face, raise the valve seat using a 65 degree

stone.

(3) When the seat is properly positioned the width

of the intake seat must be 1.75 ± 2.36 mm (0.0689 ±

0.0928 in.) and the exhaust seat must be 1.71 ± 2.32

mm (0.0673 ± 0.0911 in.).

(4) Check the valve spring installed height after

refacing the valve and seat. The installed height for

both intake and exhaust valve springs must not

exceed 41.44 mm (1.6315 in.).

(5) The valve seat and valve face must maintain a

face angle of 44.5 ± 45 degrees angle.

ENGINE TIMINGÐVERIFICATION

CAUTION: The 4.7L is a non free-wheeling design

engine. Therefore, correct engine timing is critical.

NOTE: Components referred to as left hand or right

hand are as viewed from the drivers position inside

the vehicle.

NOTE: The blue link plates on the chains and the

dots on the camshaft drive sprockets may not line

up during the timing verification procedure. The

blue link plates are lined up with the sprocket dots

only when re-timing the complete timing drive.

Once the timing drive is rotated blue link-to-dot

alignment is no longer valid.

Engine base timing can be verified by the following

procedure:

(1) Remove the cylinder head covers. Refer to the

procedure in this section.

(2) Using a mirror, locate the TDC arrow on the

front cover (Fig. 11). Rotate the crankshaft until the

mark on the crankshaft damper is aligned with the

TDC arrow on the front cover. The engine is now at

TDC.

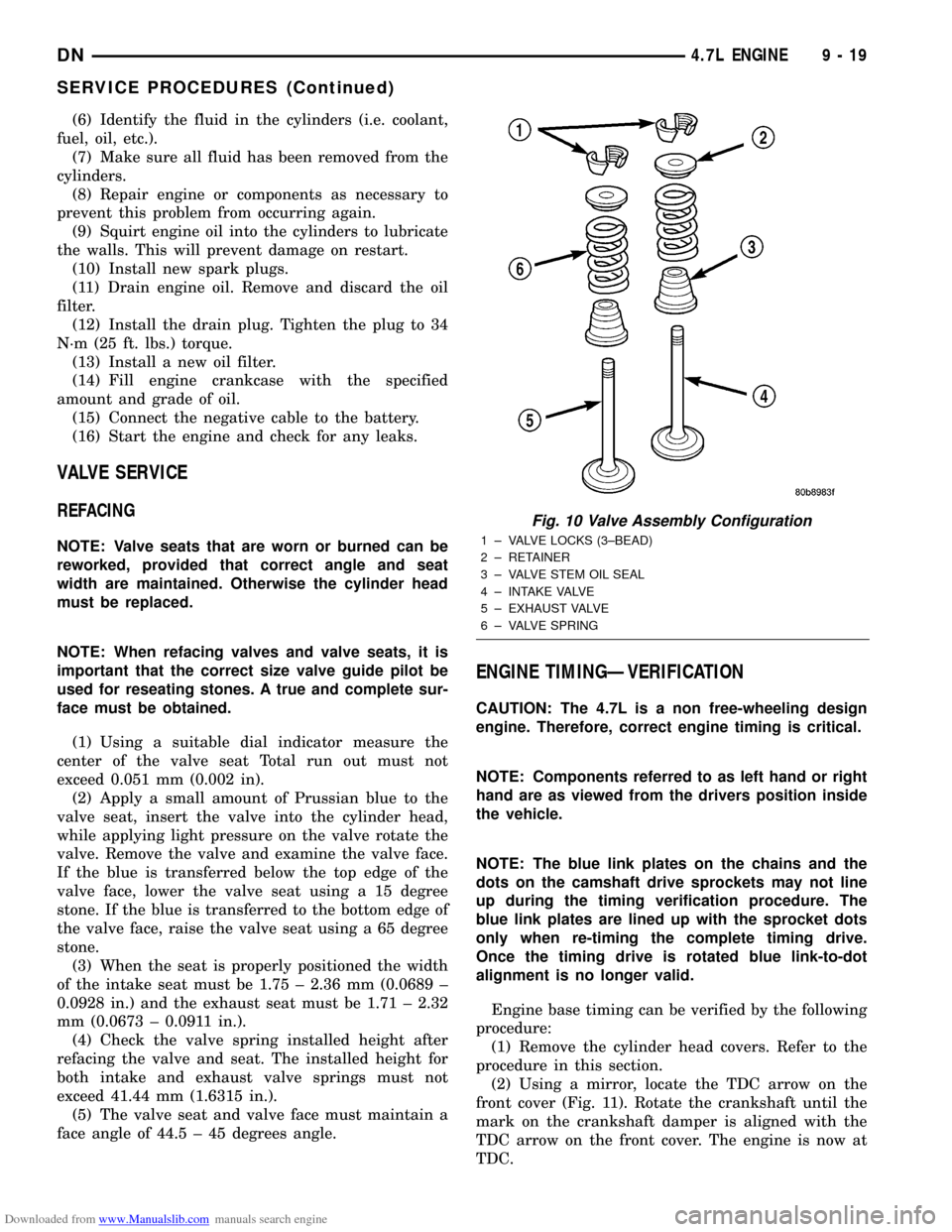

Fig. 10 Valve Assembly Configuration

1 ± VALVE LOCKS (3±BEAD)

2 ± RETAINER

3 ± VALVE STEM OIL SEAL

4 ± INTAKE VALVE

5 ± EXHAUST VALVE

6 ± VALVE SPRING

DN4.7L ENGINE 9 - 19

SERVICE PROCEDURES (Continued)

Page 92 of 193

Downloaded from www.Manualslib.com manuals search engine Scrape or wire brush all gasket surfaces to remove

all loose material. Inspect stamped parts to ensure

gasket rails are flat. Flatten rails with a hammer on

a flat plate, if required. Gasket surfaces must be free

of oil and dirt. Make sure the old gasket material is

removed from blind attaching holes.

GASKET APPLICATION

Assembling parts using a form-in-place gasket

requires care.

Mopar Silicone Rubber Adhesive Sealant should be

applied in a continuous bead approximately 3 mm

(0.12 inch) in diameter. All mounting holes must be

circled. For corner sealing,a3or6mm(1/8 or 1/4

inch) drop is placed in the center of the gasket con-

tact area. Uncured sealant may be removed with a

shop towel. Components should be torqued in place

while the sealant is still wet to the touch (within 10

minutes). The use of a locating dowel is recom-

mended during assembly to prevent smearing the

material off location.

Mopar Gasket Maker should be applied sparingly

to one gasket surface. The sealant diameter should

be 1.00 mm (0.04 inch) or less. Be certain the mate-

rial surrounds each mounting hole. Excess material

can easily be wiped off. Components should be

torqued in place within 15 minutes. The use of a

locating dowel is recommended during assembly to

prevent smearing the material off location.

ENGINE PERFORMANCE

It is important that the vehicle is operating to its

optimum performance level to maintain fuel economy

and the lowest emission levels. If vehicle is not oper-

ating to these standards, refer to Engine Diagnosis

outlined in this section. The following procedures can

assist in achieving the proper engine diagnosis.

(1) Test cranking amperage draw. Refer to Electri-

cal Group 8B, Cold Cranking Test.

(2) Check intake manifold bolt torque.

(3) Perform cylinder compression test. Refer to

Cylinder Compression Pressure Test in the Engine

Diagnosis area of this section.

(4) Clean or replace spark plugs as necessary and

adjust gap as specified in Electrical Group 8D.

Tighten to specifications.

(5) Test resistance of spark plug cables. Refer to

Electrical Group 8D, Spark Plug Cables.

(6) Inspect the primary wires. Test coil output volt-

age and primary resistance. Replace parts as neces-

sary. Refer to Electrical Group 8D, for specifications.

(7) Test fuel pump for pressure. Refer to Group 14,

Fuel System Specifications.

(8) The air filter elements should be replaced as

specified in Lubrication and Maintenance, Group 0.(9) Inspect crankcase ventilation system as out

lined in Group 0, Lubrication and Maintenance. For

emission controls see Group 25, Emission Controls

for service procedures.

(10) Road test vehicle as a final test.

ENGINE OIL

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

In gasoline engines, use an engine oil that is API

Service Grade Certified (Fig. 11). Standard engine oil

identification notations have been adopted to aid in

the proper selection of engine oil. The identifying

notations are located on the label of engine oil plastic

bottles and the top of engine oil cans. MOPAR only

provides engine oil that conforms to this certification.

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. SAE 10W-30 specifies a multiple

viscosity engine oil. These are specified with a dual

SAE viscosity grade which indicates the cold-to-hot

temperature viscosity range. When choosing an

engine oil, consider the range of temperatures the

vehicle will be operated in before the next oil change.

Select an engine oil that is best suited to your area's

Fig. 11 Engine Oil Container Standard Notations

9 - 92 5.2L ENGINEDN

SERVICE PROCEDURES (Continued)

Page 95 of 193

Downloaded from www.Manualslib.com manuals search engine (4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

HYDROSTATIC LOCK

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(refer to Group 14, Fuel System).

(2) Disconnect the battery negative cable.

(3) Inspect air cleaner, induction system and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the plugs from the

engine.

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (i.e. coolant,

fuel, oil, etc.).

(7) Make sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt engine oil into the cylinders to lubricate

the walls. This will prevent damage on restart.

(10) Install new spark plugs.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil.

(15) Connect the negative cable to the battery.

(16) Start the engine and check for any leaks.

VALVE TIMING

(1) Turn crankshaft until the No.6 exhaust valve is

closing and No.6 intake valve is opening.(2) Insert a 6.350 mm (1/4 inch) spacer between

rocker arm pad and stem tip of No.1 intake valve.

Allow spring load to bleed tappet down giving in

effect a solid tappet.

(3) Install a dial indicator so plunger contacts

valve spring retainer as nearly perpendicular as pos-

sible. Zero the indicator.

(4) Rotate the crankshaft clockwise (normal run-

ning direction) until the valve has lifted 0.863 mm

(0.034 inch). The timing of the crankshaft should

now read from 10É before top dead center to 2É after

top dead center. Remove spacer.

CAUTION: DO NOT turn crankshaft any further

clockwise as valve spring might bottom and result

in serious damage.

If reading is not within specified limits:

²Check sprocket index marks.

²Inspect timing chain for wear.

²Check accuracy of DC mark on timing indicator.

VALVE SERVICE

VALVE CLEANING

Clean valves thoroughly. Discard burned, warped

and cracked valves.

Remove carbon and varnish deposits from inside of

valve guides with a reliable guide cleaner.

VALVE INSPECTION

Measure valve stems for wear. If wear exceeds

0.051 mm (0.002 inch), replace the valve.

VALVE GUIDES

Measure valve stem guide clearance as follows:

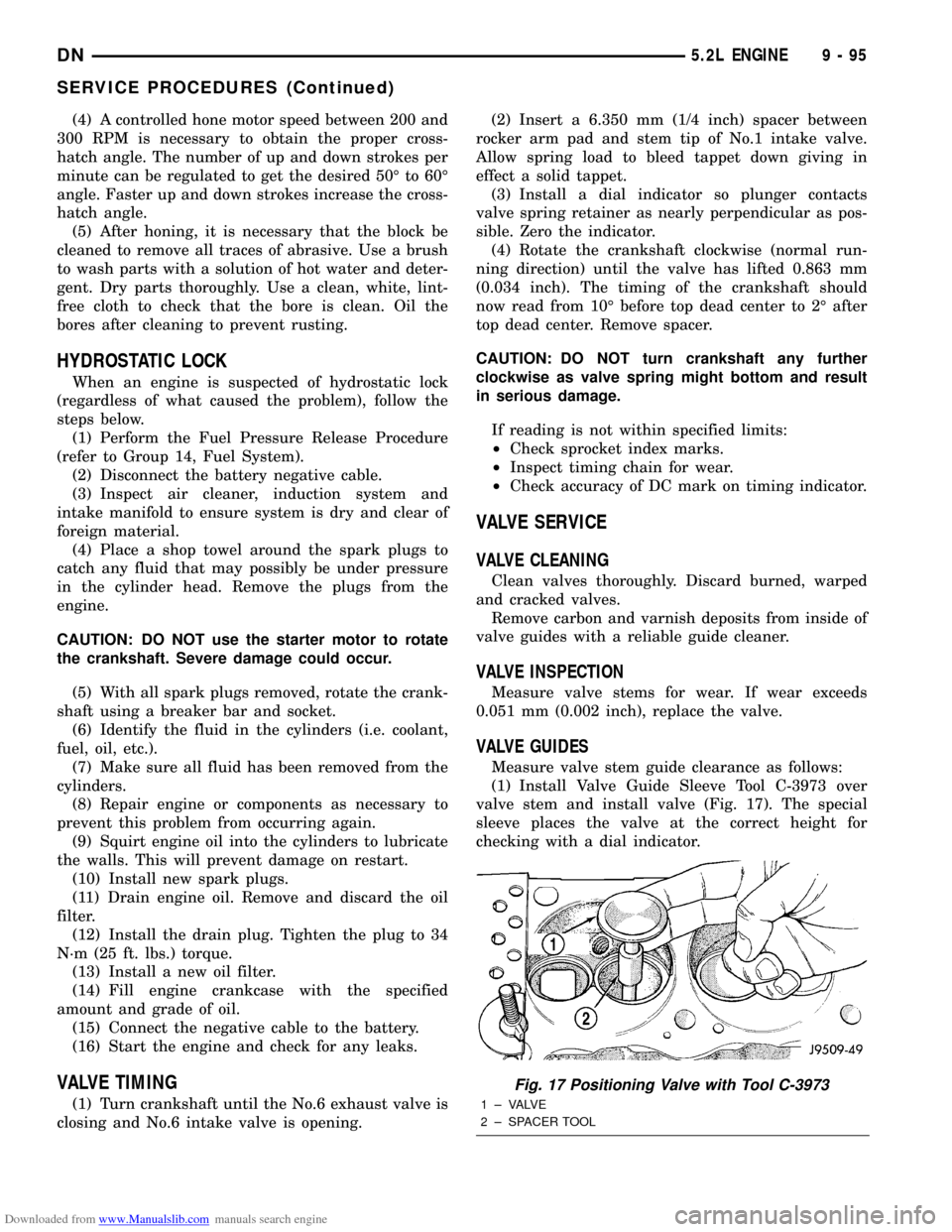

(1) Install Valve Guide Sleeve Tool C-3973 over

valve stem and install valve (Fig. 17). The special

sleeve places the valve at the correct height for

checking with a dial indicator.

Fig. 17 Positioning Valve with Tool C-3973

1 ± VALVE

2 ± SPACER TOOL

DN5.2L ENGINE 9 - 95

SERVICE PROCEDURES (Continued)

Page 107 of 193

Downloaded from www.Manualslib.com manuals search engine (2) Position the cylinder head cover onto the gas-

ket. Tighten the bolts to 11 N´m (95 in. lbs.) torque.

(3) Install closed crankcase ventilation system and

evaporation control system.

(4) Install the air inlet hose.

(5) Connect the negative cable to the battery.

ROCKER ARMS AND PUSH RODS

REMOVAL

(1) Remove cylinder head cover and gasket. Refer

to Cylinder Head Cover in this section for correct

procedure.

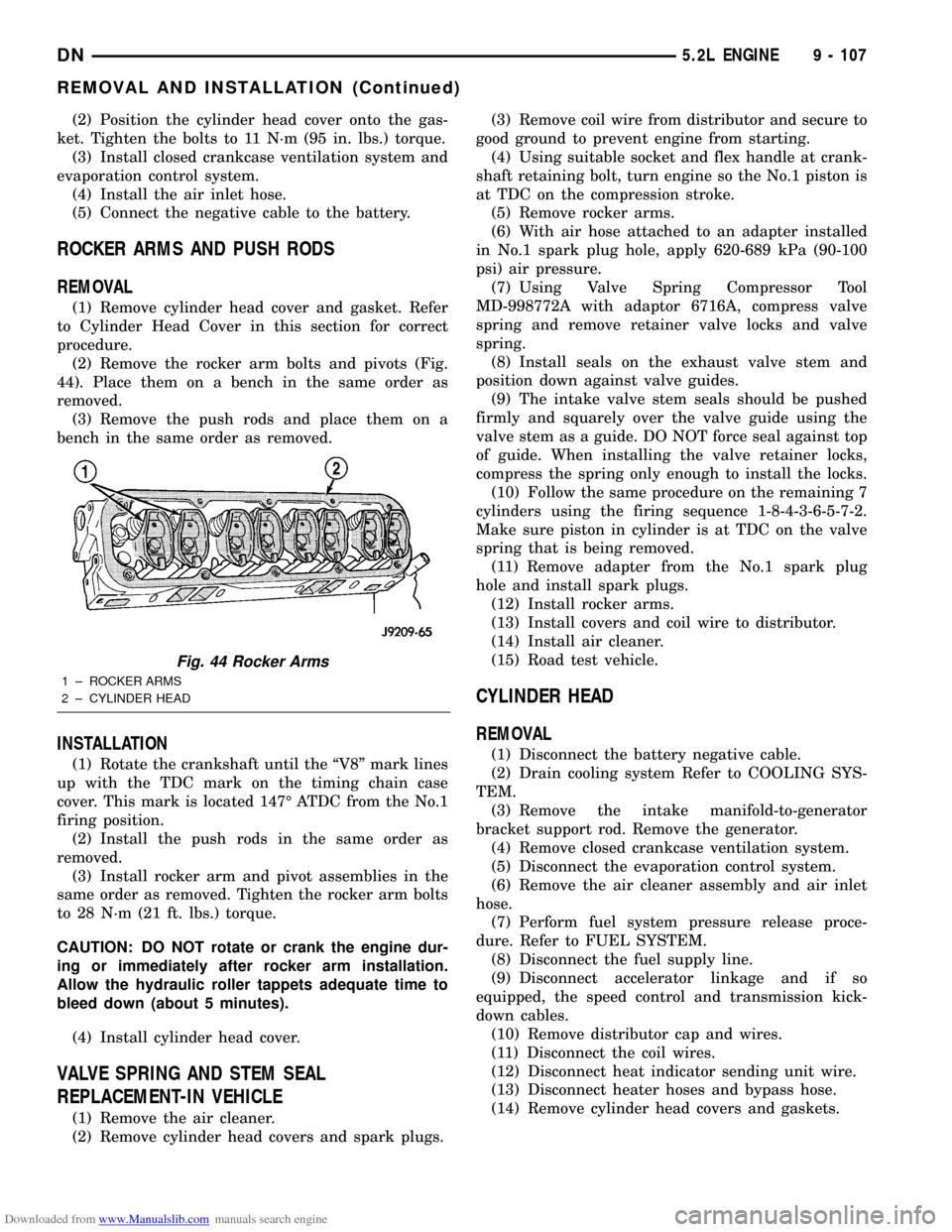

(2) Remove the rocker arm bolts and pivots (Fig.

44). Place them on a bench in the same order as

removed.

(3) Remove the push rods and place them on a

bench in the same order as removed.

INSTALLATION

(1) Rotate the crankshaft until the ªV8º mark lines

up with the TDC mark on the timing chain case

cover. This mark is located 147É ATDC from the No.1

firing position.

(2) Install the push rods in the same order as

removed.

(3) Install rocker arm and pivot assemblies in the

same order as removed. Tighten the rocker arm bolts

to 28 N´m (21 ft. lbs.) torque.

CAUTION: DO NOT rotate or crank the engine dur-

ing or immediately after rocker arm installation.

Allow the hydraulic roller tappets adequate time to

bleed down (about 5 minutes).

(4) Install cylinder head cover.

VALVE SPRING AND STEM SEAL

REPLACEMENT-IN VEHICLE

(1) Remove the air cleaner.

(2) Remove cylinder head covers and spark plugs.(3) Remove coil wire from distributor and secure to

good ground to prevent engine from starting.

(4) Using suitable socket and flex handle at crank-

shaft retaining bolt, turn engine so the No.1 piston is

at TDC on the compression stroke.

(5) Remove rocker arms.

(6) With air hose attached to an adapter installed

in No.1 spark plug hole, apply 620-689 kPa (90-100

psi) air pressure.

(7) Using Valve Spring Compressor Tool

MD-998772A with adaptor 6716A, compress valve

spring and remove retainer valve locks and valve

spring.

(8) Install seals on the exhaust valve stem and

position down against valve guides.

(9) The intake valve stem seals should be pushed

firmly and squarely over the valve guide using the

valve stem as a guide. DO NOT force seal against top

of guide. When installing the valve retainer locks,

compress the spring only enough to install the locks.

(10) Follow the same procedure on the remaining 7

cylinders using the firing sequence 1-8-4-3-6-5-7-2.

Make sure piston in cylinder is at TDC on the valve

spring that is being removed.

(11) Remove adapter from the No.1 spark plug

hole and install spark plugs.

(12) Install rocker arms.

(13) Install covers and coil wire to distributor.

(14) Install air cleaner.

(15) Road test vehicle.

CYLINDER HEAD

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system Refer to COOLING SYS-

TEM.

(3) Remove the intake manifold-to-generator

bracket support rod. Remove the generator.

(4) Remove closed crankcase ventilation system.

(5) Disconnect the evaporation control system.

(6) Remove the air cleaner assembly and air inlet

hose.

(7) Perform fuel system pressure release proce-

dure. Refer to FUEL SYSTEM.

(8) Disconnect the fuel supply line.

(9) Disconnect accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(10) Remove distributor cap and wires.

(11) Disconnect the coil wires.

(12) Disconnect heat indicator sending unit wire.

(13) Disconnect heater hoses and bypass hose.

(14) Remove cylinder head covers and gaskets.

Fig. 44 Rocker Arms

1 ± ROCKER ARMS

2 ± CYLINDER HEAD

DN5.2L ENGINE 9 - 107

REMOVAL AND INSTALLATION (Continued)

Page 108 of 193

Downloaded from www.Manualslib.com manuals search engine (15) Remove intake manifold and throttle body as

an assembly. Discard the flange side gaskets and the

front and rear cross-over gaskets.

(16) Remove exhaust manifolds.

(17) Remove rocker arm assemblies and push rods.

Identify to ensure installation in original locations.

(18) Remove the head bolts from each cylinder

head and remove cylinder heads. Discard the cylin-

der head gasket.

(19) Remove spark plugs.

INSTALLATION

(1) Position the new cylinder head gaskets onto

the cylinder block.

(2) Position the cylinder heads onto head gaskets

and cylinder block.

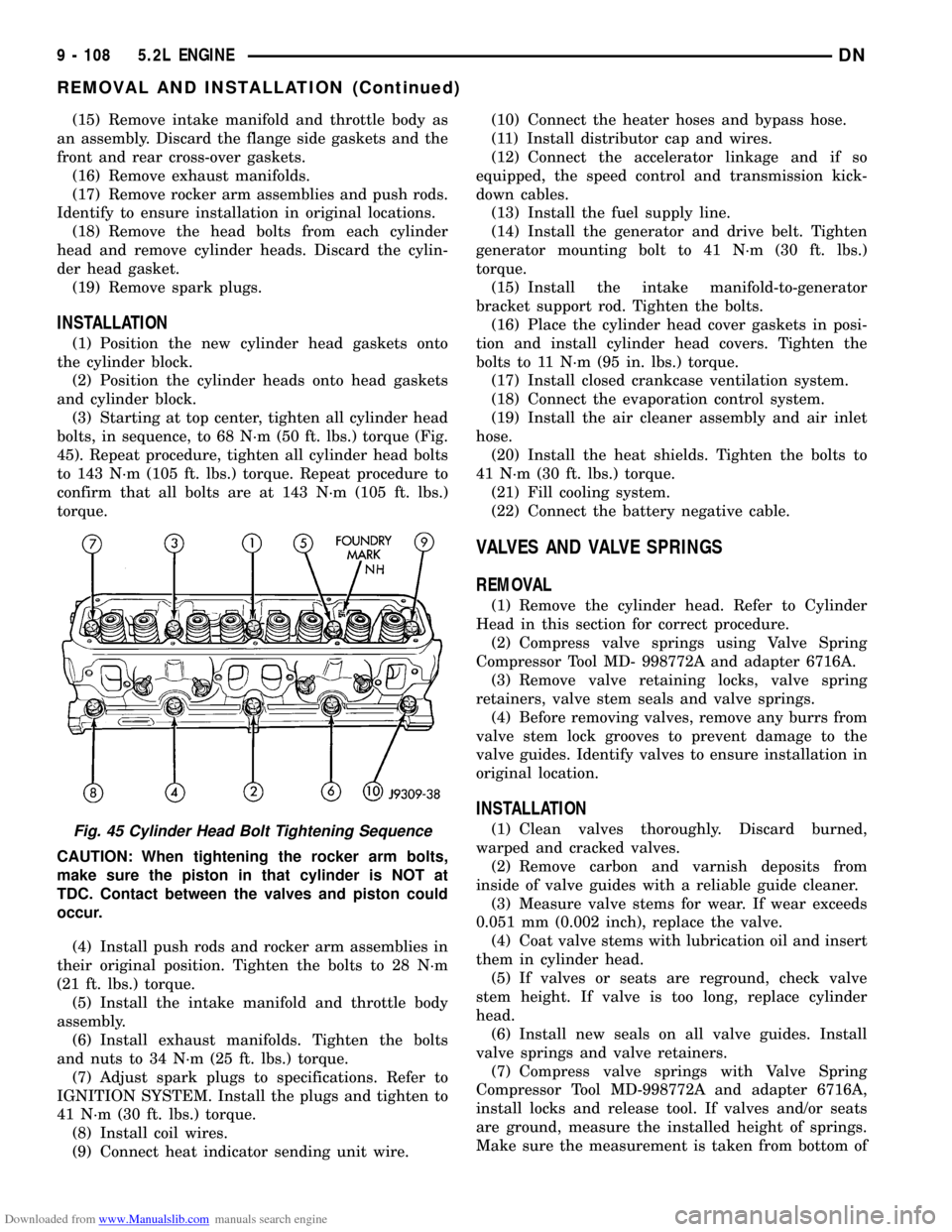

(3) Starting at top center, tighten all cylinder head

bolts, in sequence, to 68 N´m (50 ft. lbs.) torque (Fig.

45). Repeat procedure, tighten all cylinder head bolts

to 143 N´m (105 ft. lbs.) torque. Repeat procedure to

confirm that all bolts are at 143 N´m (105 ft. lbs.)

torque.

CAUTION: When tightening the rocker arm bolts,

make sure the piston in that cylinder is NOT at

TDC. Contact between the valves and piston could

occur.

(4) Install push rods and rocker arm assemblies in

their original position. Tighten the bolts to 28 N´m

(21 ft. lbs.) torque.

(5) Install the intake manifold and throttle body

assembly.

(6) Install exhaust manifolds. Tighten the bolts

and nuts to 34 N´m (25 ft. lbs.) torque.

(7) Adjust spark plugs to specifications. Refer to

IGNITION SYSTEM. Install the plugs and tighten to

41 N´m (30 ft. lbs.) torque.

(8) Install coil wires.

(9) Connect heat indicator sending unit wire.(10) Connect the heater hoses and bypass hose.

(11) Install distributor cap and wires.

(12) Connect the accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(13) Install the fuel supply line.

(14) Install the generator and drive belt. Tighten

generator mounting bolt to 41 N´m (30 ft. lbs.)

torque.

(15) Install the intake manifold-to-generator

bracket support rod. Tighten the bolts.

(16) Place the cylinder head cover gaskets in posi-

tion and install cylinder head covers. Tighten the

bolts to 11 N´m (95 in. lbs.) torque.

(17) Install closed crankcase ventilation system.

(18) Connect the evaporation control system.

(19) Install the air cleaner assembly and air inlet

hose.

(20) Install the heat shields. Tighten the bolts to

41 N´m (30 ft. lbs.) torque.

(21) Fill cooling system.

(22) Connect the battery negative cable.

VALVES AND VALVE SPRINGS

REMOVAL

(1) Remove the cylinder head. Refer to Cylinder

Head in this section for correct procedure.

(2) Compress valve springs using Valve Spring

Compressor Tool MD- 998772A and adapter 6716A.

(3) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(4) Before removing valves, remove any burrs from

valve stem lock grooves to prevent damage to the

valve guides. Identify valves to ensure installation in

original location.

INSTALLATION

(1) Clean valves thoroughly. Discard burned,

warped and cracked valves.

(2) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(3) Measure valve stems for wear. If wear exceeds

0.051 mm (0.002 inch), replace the valve.

(4) Coat valve stems with lubrication oil and insert

them in cylinder head.

(5) If valves or seats are reground, check valve

stem height. If valve is too long, replace cylinder

head.

(6) Install new seals on all valve guides. Install

valve springs and valve retainers.

(7) Compress valve springs with Valve Spring

Compressor Tool MD-998772A and adapter 6716A,

install locks and release tool. If valves and/or seats

are ground, measure the installed height of springs.

Make sure the measurement is taken from bottom ofFig. 45 Cylinder Head Bolt Tightening Sequence

9 - 108 5.2L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 143 of 193

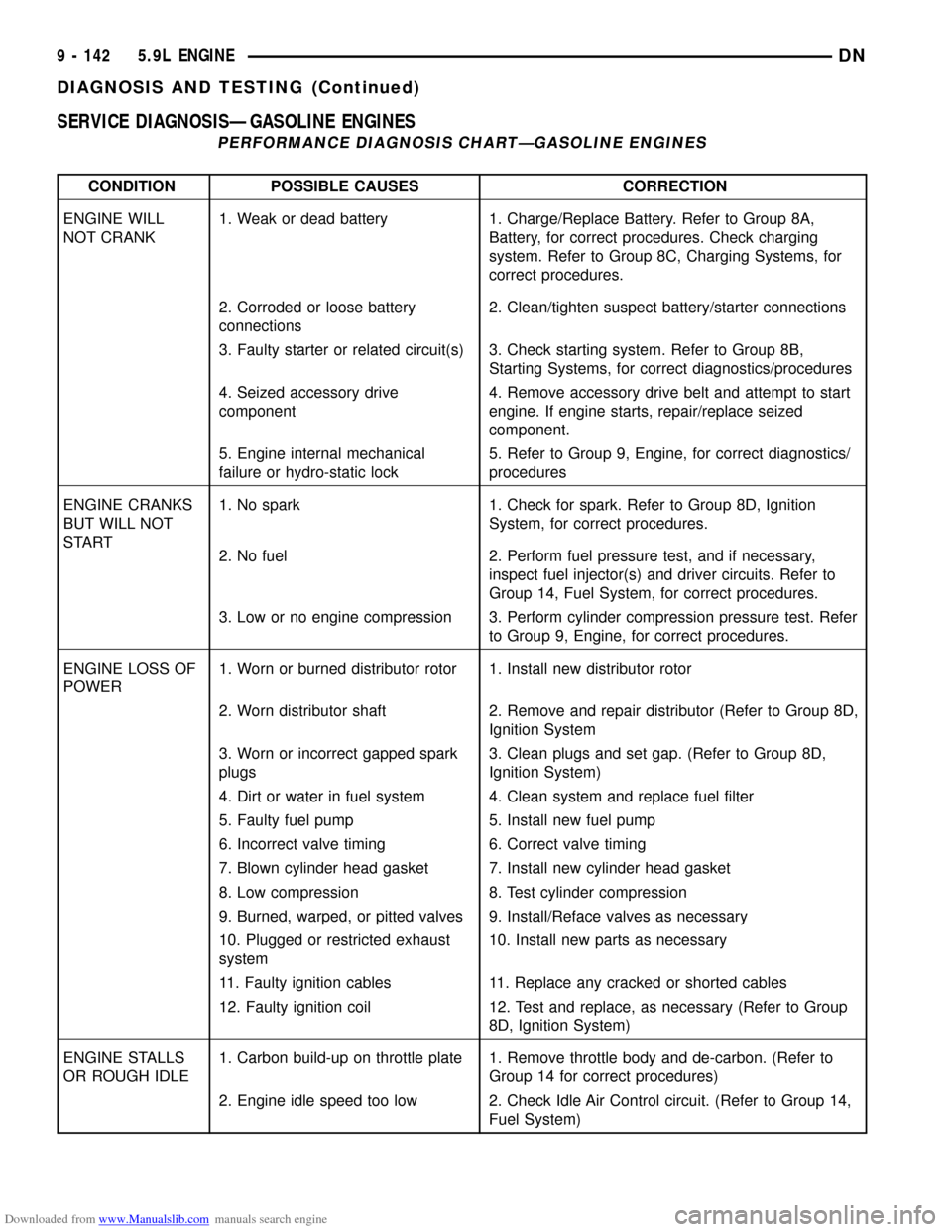

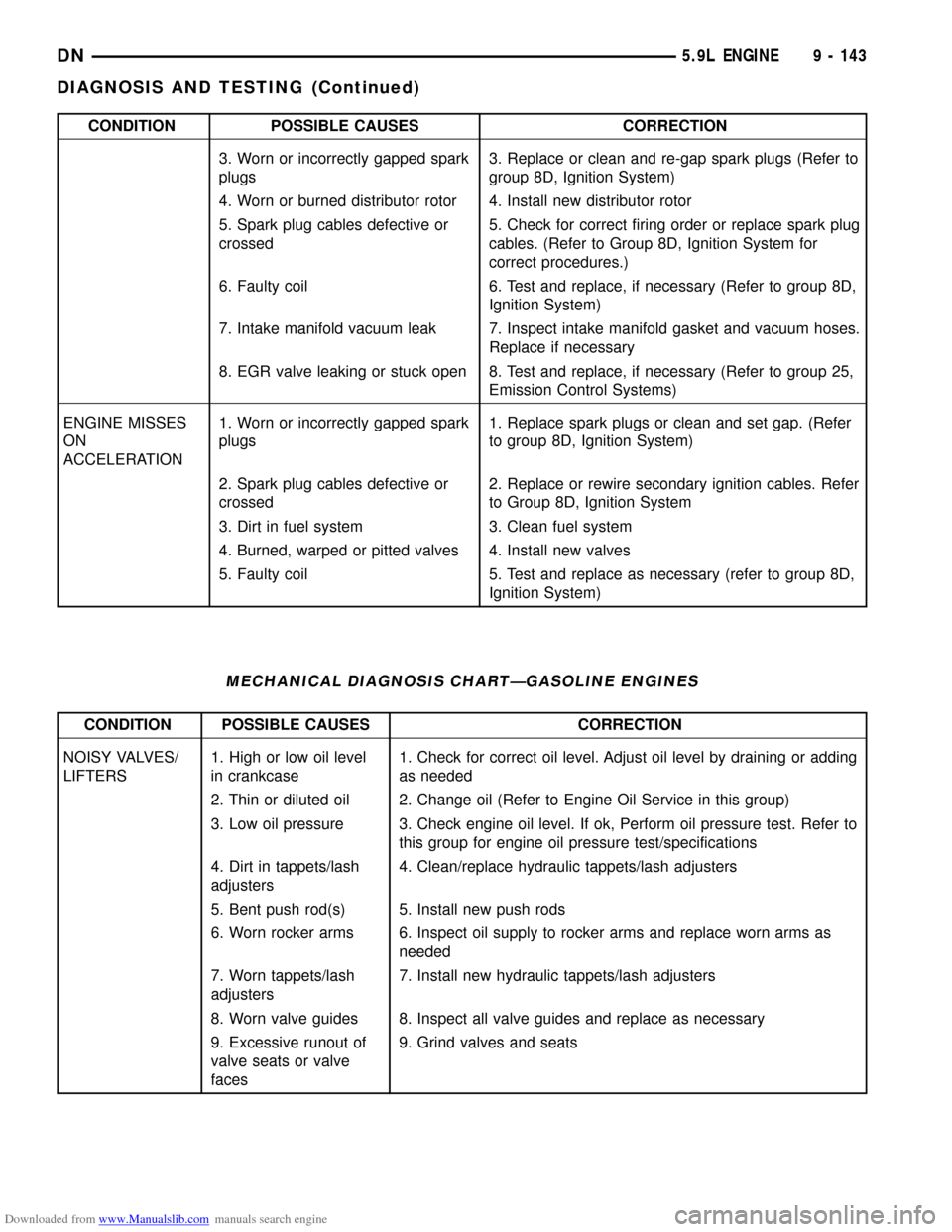

Downloaded from www.Manualslib.com manuals search engine SERVICE DIAGNOSISÐGASOLINE ENGINES

PERFORMANCE DIAGNOSIS CHARTÐGASOLINE ENGINES

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL

NOT CRANK1. Weak or dead battery 1. Charge/Replace Battery. Refer to Group 8A,

Battery, for correct procedures. Check charging

system. Refer to Group 8C, Charging Systems, for

correct procedures.

2. Corroded or loose battery

connections2. Clean/tighten suspect battery/starter connections

3. Faulty starter or related circuit(s) 3. Check starting system. Refer to Group 8B,

Starting Systems, for correct diagnostics/procedures

4. Seized accessory drive

component4. Remove accessory drive belt and attempt to start

engine. If engine starts, repair/replace seized

component.

5. Engine internal mechanical

failure or hydro-static lock5. Refer to Group 9, Engine, for correct diagnostics/

procedures

ENGINE CRANKS

BUT WILL NOT

START1. No spark 1. Check for spark. Refer to Group 8D, Ignition

System, for correct procedures.

2. No fuel 2. Perform fuel pressure test, and if necessary,

inspect fuel injector(s) and driver circuits. Refer to

Group 14, Fuel System, for correct procedures.

3. Low or no engine compression 3. Perform cylinder compression pressure test. Refer

to Group 9, Engine, for correct procedures.

ENGINE LOSS OF

POWER1. Worn or burned distributor rotor 1. Install new distributor rotor

2. Worn distributor shaft 2. Remove and repair distributor (Refer to Group 8D,

Ignition System

3. Worn or incorrect gapped spark

plugs3. Clean plugs and set gap. (Refer to Group 8D,

Ignition System)

4. Dirt or water in fuel system 4. Clean system and replace fuel filter

5. Faulty fuel pump 5. Install new fuel pump

6. Incorrect valve timing 6. Correct valve timing

7. Blown cylinder head gasket 7. Install new cylinder head gasket

8. Low compression 8. Test cylinder compression

9. Burned, warped, or pitted valves 9. Install/Reface valves as necessary

10. Plugged or restricted exhaust

system10. Install new parts as necessary

11. Faulty ignition cables 11. Replace any cracked or shorted cables

12. Faulty ignition coil 12. Test and replace, as necessary (Refer to Group

8D, Ignition System)

ENGINE STALLS

OR ROUGH IDLE1. Carbon build-up on throttle plate 1. Remove throttle body and de-carbon. (Refer to

Group 14 for correct procedures)

2. Engine idle speed too low 2. Check Idle Air Control circuit. (Refer to Group 14,

Fuel System)

9 - 142 5.9L ENGINEDN

DIAGNOSIS AND TESTING (Continued)

Page 144 of 193

Downloaded from www.Manualslib.com manuals search engine CONDITION POSSIBLE CAUSES CORRECTION

3. Worn or incorrectly gapped spark

plugs3. Replace or clean and re-gap spark plugs (Refer to

group 8D, Ignition System)

4. Worn or burned distributor rotor 4. Install new distributor rotor

5. Spark plug cables defective or

crossed5. Check for correct firing order or replace spark plug

cables. (Refer to Group 8D, Ignition System for

correct procedures.)

6. Faulty coil 6. Test and replace, if necessary (Refer to group 8D,

Ignition System)

7. Intake manifold vacuum leak 7. Inspect intake manifold gasket and vacuum hoses.

Replace if necessary

8. EGR valve leaking or stuck open 8. Test and replace, if necessary (Refer to group 25,

Emission Control Systems)

ENGINE MISSES

ON

ACCELERATION1. Worn or incorrectly gapped spark

plugs1. Replace spark plugs or clean and set gap. (Refer

to group 8D, Ignition System)

2. Spark plug cables defective or

crossed2. Replace or rewire secondary ignition cables. Refer

to Group 8D, Ignition System

3. Dirt in fuel system 3. Clean fuel system

4. Burned, warped or pitted valves 4. Install new valves

5. Faulty coil 5. Test and replace as necessary (refer to group 8D,

Ignition System)

MECHANICAL DIAGNOSIS CHARTÐGASOLINE ENGINES

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES/

LIFTERS1. High or low oil level

in crankcase1. Check for correct oil level. Adjust oil level by draining or adding

as needed

2. Thin or diluted oil 2. Change oil (Refer to Engine Oil Service in this group)

3. Low oil pressure 3. Check engine oil level. If ok, Perform oil pressure test. Refer to

this group for engine oil pressure test/specifications

4. Dirt in tappets/lash

adjusters4. Clean/replace hydraulic tappets/lash adjusters

5. Bent push rod(s) 5. Install new push rods

6. Worn rocker arms 6. Inspect oil supply to rocker arms and replace worn arms as

needed

7. Worn tappets/lash

adjusters7. Install new hydraulic tappets/lash adjusters

8. Worn valve guides 8. Inspect all valve guides and replace as necessary

9. Excessive runout of

valve seats or valve

faces9. Grind valves and seats

DN5.9L ENGINE 9 - 143

DIAGNOSIS AND TESTING (Continued)

Page 146 of 193

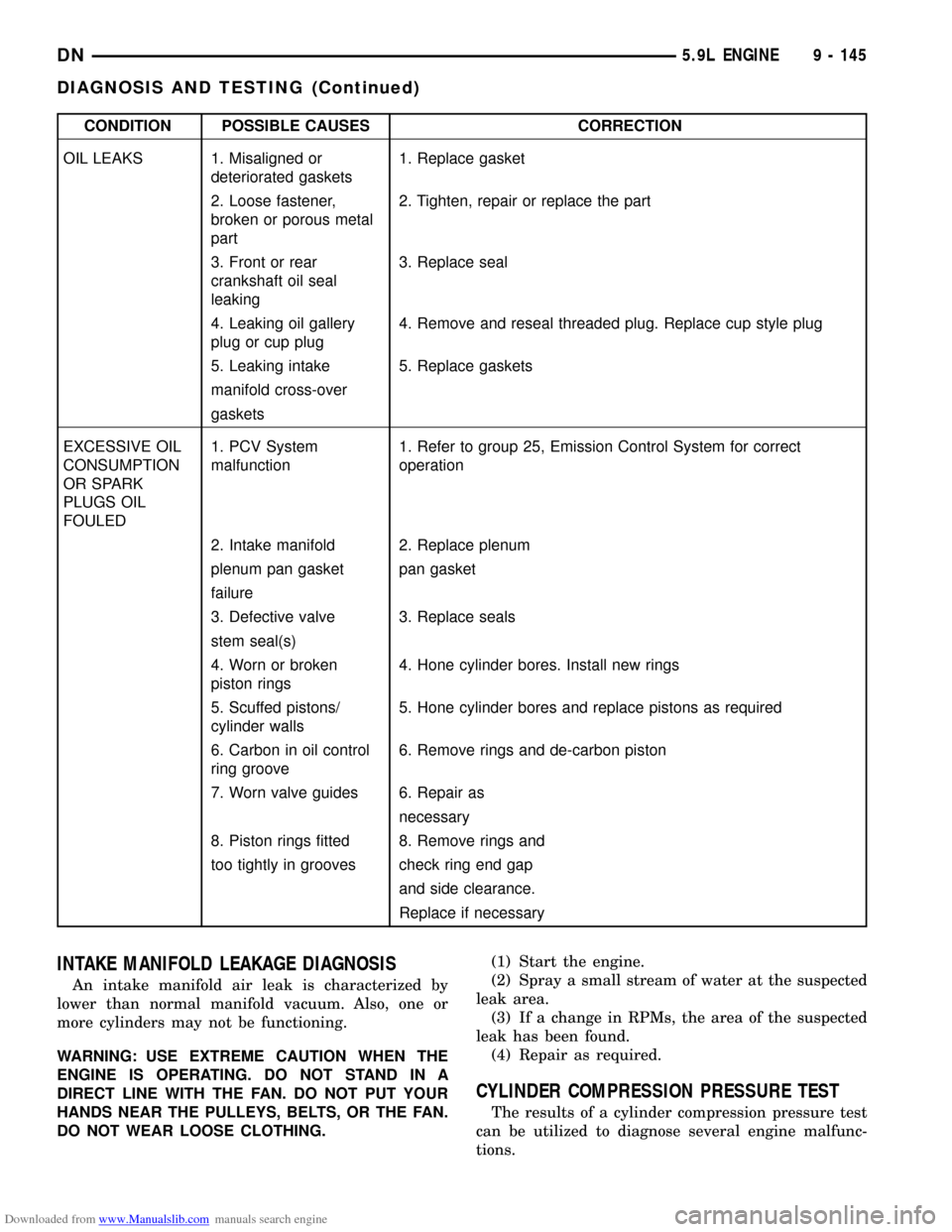

Downloaded from www.Manualslib.com manuals search engine CONDITION POSSIBLE CAUSES CORRECTION

OIL LEAKS 1. Misaligned or

deteriorated gaskets1. Replace gasket

2. Loose fastener,

broken or porous metal

part2. Tighten, repair or replace the part

3. Front or rear

crankshaft oil seal

leaking3. Replace seal

4. Leaking oil gallery

plug or cup plug4. Remove and reseal threaded plug. Replace cup style plug

5. Leaking intake 5. Replace gaskets

manifold cross-over

gaskets

EXCESSIVE OIL

CONSUMPTION

OR SPARK

PLUGS OIL

FOULED1. PCV System

malfunction1. Refer to group 25, Emission Control System for correct

operation

2. Intake manifold 2. Replace plenum

plenum pan gasket pan gasket

failure

3. Defective valve 3. Replace seals

stem seal(s)

4. Worn or broken

piston rings4. Hone cylinder bores. Install new rings

5. Scuffed pistons/

cylinder walls5. Hone cylinder bores and replace pistons as required

6. Carbon in oil control

ring groove6. Remove rings and de-carbon piston

7. Worn valve guides 6. Repair as

necessary

8. Piston rings fitted 8. Remove rings and

too tightly in grooves check ring end gap

and side clearance.

Replace if necessary

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS, OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.(1) Start the engine.

(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPMs, the area of the suspected

leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

DN5.9L ENGINE 9 - 145

DIAGNOSIS AND TESTING (Continued)