ECU DODGE DURANGO 2006 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: DURANGO, Model: DODGE DURANGO 2006 2.GPages: 440, PDF Size: 6.63 MB

Page 253 of 440

If the key is not ON then the shift will not take place and

no position indicator lights will be on or flashing.

NV 244 Generation II Transfer Case Operating

Information / Precautions

The NV 244 Generation II is an electric shift transfer case

and is operated by the 4WD Control Switch, which is

located on the instrument panel.

The NV 244 Generation II transfer case provides 4 mode

positions - Normal all-wheel-drive high range, four-

wheel-drive LOCK, four-wheel-drive low range, and

neutral.

This transfer case is equipped with an inter-axle differ-

ential that allows driving the vehicle in the normal

all-wheel-drive position (AWD) at all times on any given

road surface, including dry hard surfaced roads. The

AWD mode allows the front and rear wheels to rotate at

different speeds. This eliminates driveline binding and

component wear normally associated with driving thevehicle in the 4LOCK position on dry hard surfaced

roads. This feature provides the safety, security, and

convenience of operating in all-wheel drive at all times

regardless of road conditions.

When additional traction is required, the 4LOCK and

4LO positions can be used to lock the front and rear

driveshafts together through the transfer case inter-axle

differential and force the front and rear wheels to rotate

at the same speed. This is accomplished by rotating the

4WD Control Switch to these positions. The 4LOCK and

4LO positions are intended for loose, slippery road

surfaces only. Driving in the 4LOCK and 4LO positions

on dry hard surfaced roads may cause increased tire wear

and damage to the driveline components.

The transfer case Neutral (N) position is selected by

depressing the recessed button located on the lower left

hand corner of the 4WD Control Switch.

STARTING AND OPERATING 253

5

Page 294 of 440

Inflation Pressure (Cold)

This is the cold tire inflation pressure for your vehicle for

all loading conditions up to full GAWR.

Curb Weight

The curb weight of a vehicle is defined as the total weight

of the vehicle with all fluids, including vehicle fuel, at full

capacity conditions, and with no occupants or cargo

loaded into the vehicle. The front and rear curb weight

values are determined by weighing your vehicle on a

commercial scale before any occupants or cargo are

added.

Loading

The actual total weight and the weight of the front and

rear of your vehicle at the ground can best be determined

by weighing it when it is loaded and ready for operation.

The entire vehicle should first be weighed on a commer-

cial scale to insure that the GVWR has not been exceeded.

The weight on the front and rear of the vehicle shouldthen be determined separately to be sure that the load is

properly distributed over front and rear axle. Weighing

the vehicle may show that the GAWR of either the front

or rear axles has been exceeded but the total load is

within the specified GVWR. If so, weight must be shifted

from front to rear or rear to front as appropriate until the

specified weight limitations are met.

Store heavier items down low and be sure that the weight

is distributed equally. Stow all loose items securely before

driving.

Improper weight distribution can have an adverse effect

on the way your vehicle steers and handles and the way

the brakes operate.

294 STARTING AND OPERATING

Page 301 of 440

CAUTION!

•Avoid towing a trailer for the first 500 miles (805

km) of vehicle operation. Doing so may damage

your vehicle.

•During the first 500 miles (805 km) of trailer

towing, limit your speed to 50 mph (80 km/h).

Perform the maintenance listed in Section 8 of this

manual. When towing a trailer, never exceed the GAWR,

or GCWR, ratings.

WARNING!

Improper towing can lead to an injury accident.

Follow these guidelines to make your trailer towing

as safe as possible:

Make certain that the load is secured in the trailer

and will not shift during travel. When trailering

cargo that is not fully secured, dynamic load shifts

can occur that may be difficult for the driver to

control. You could lose control of your vehicle and

have an accident.

•When hauling cargo or towing a trailer, do not over-

load your vehicle or trailer. Overloading can cause a

loss of control, poor performance or damage to brakes,

axle, engine, transmission, steering, suspension, chas-

sis structure or tires.

STARTING AND OPERATING 301

5

Page 317 of 440

WARNING!

•Never allow any lit smoking materials near the

vehicles while removing the cap or filling the

tank.

•Never add fuel to the vehicle when the engine is

running.

•A fire may result if gasoline is pumped into a

portable container that is in a vehicle or on a truck

bed. You could be burned. Always place gas

containers on the ground while filling.

CHANGING A FLAT TIRE

Jack Location

In the Durango, the scissor jack and tire changing tools

are stowed under the second row seat.

The jack is secured in place with a winged stud and a

fixed stud. It is very important to secure the jack tightly

in place by engaging the slot in the base to the fixed stud

under the middle seat. The winged stud inserts through

the eyelet in the end of the jack’s worm screw.

WHAT TO DO IN EMERGENCIES 317

6

Page 324 of 440

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle.

Always stow the jack, tools and the extra tire and

wheel in the places provided.

7. Remove wheel blocks. Do not install chrome or alu-

minum wheel center caps on the spare wheel. This may

result in cap damage.

8. Lower the jack to its fully closed position. Stow the

replaced tire, jack, and tools as previously described.

9. Adjust the tire pressure when possible.

NOTE:Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

•Always park on a firm, level surface as far from the edge

of the roadway as possible before raising the vehicle.

•Block the wheel diagonally opposite the wheel to be

raised.

•Apply the parking brake firmly before jacking.

•Never start the engine with the vehicle on a jack.

•Do not let anyone sit in the vehicle when it is on a jack.

•Do not get under the vehicle when it is on a jack.

•Only use the jack in the positions indicated.

•If working on or near a roadway, be extremely careful of

motor traffic.

•To assure that spare tires, flat or inflated are securely

stowed, spares must be stowed with the value stem

facing the ground.

324 WHAT TO DO IN EMERGENCIES

Page 359 of 440

D. Maintain coolant concentration at 50% HOAT ethyl-

ene glycol engine coolant (minimum) and distilled water

for proper corrosion protection of your engine.

E. Make sure that the radiator and coolant bottle over-

flow hoses are not kinked or obstructed.

F. Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean also.

G. The thermostat should not be changed for summer or

winter operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory cooling performance.

Emission Related Components

Fuel System Hoses And Vapor/Vacuum Harnesses

When the vehicle is serviced for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,cracking, checking, tears, cuts, abrasions, and excessive

swelling suggest deterioration of the rubber. Particular

attention should be given to examining hose surfaces

nearest to high heat sources, such as the exhaust mani-

fold.

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

NOTE:Fluids such as oil, power steering fluid, and

brake fluid are used during assembly plant operations to

ease the assembly of hoses to couplings. Therefore, oil

wetness at the hose-coupling area is not necessarily an

indication of leakage. Actual dripping of hot fluid when

systems are under pressure (during vehicle operation),

should be noted before hose is replaced based on leakage.

MAINTAINING YOUR VEHICLE 359

7

Page 382 of 440

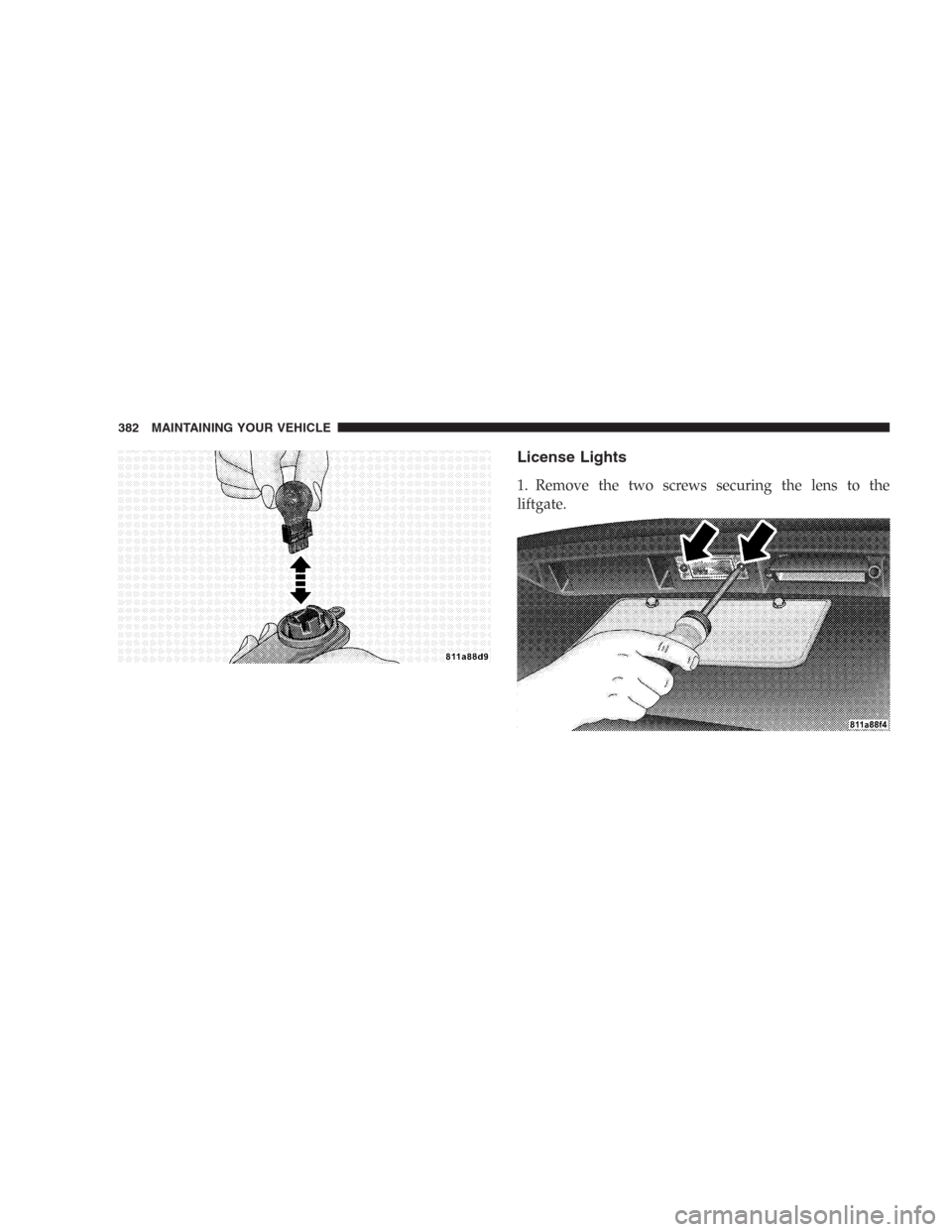

License Lights

1. Remove the two screws securing the lens to the

liftgate.

382 MAINTAINING YOUR VEHICLE

Page 383 of 440

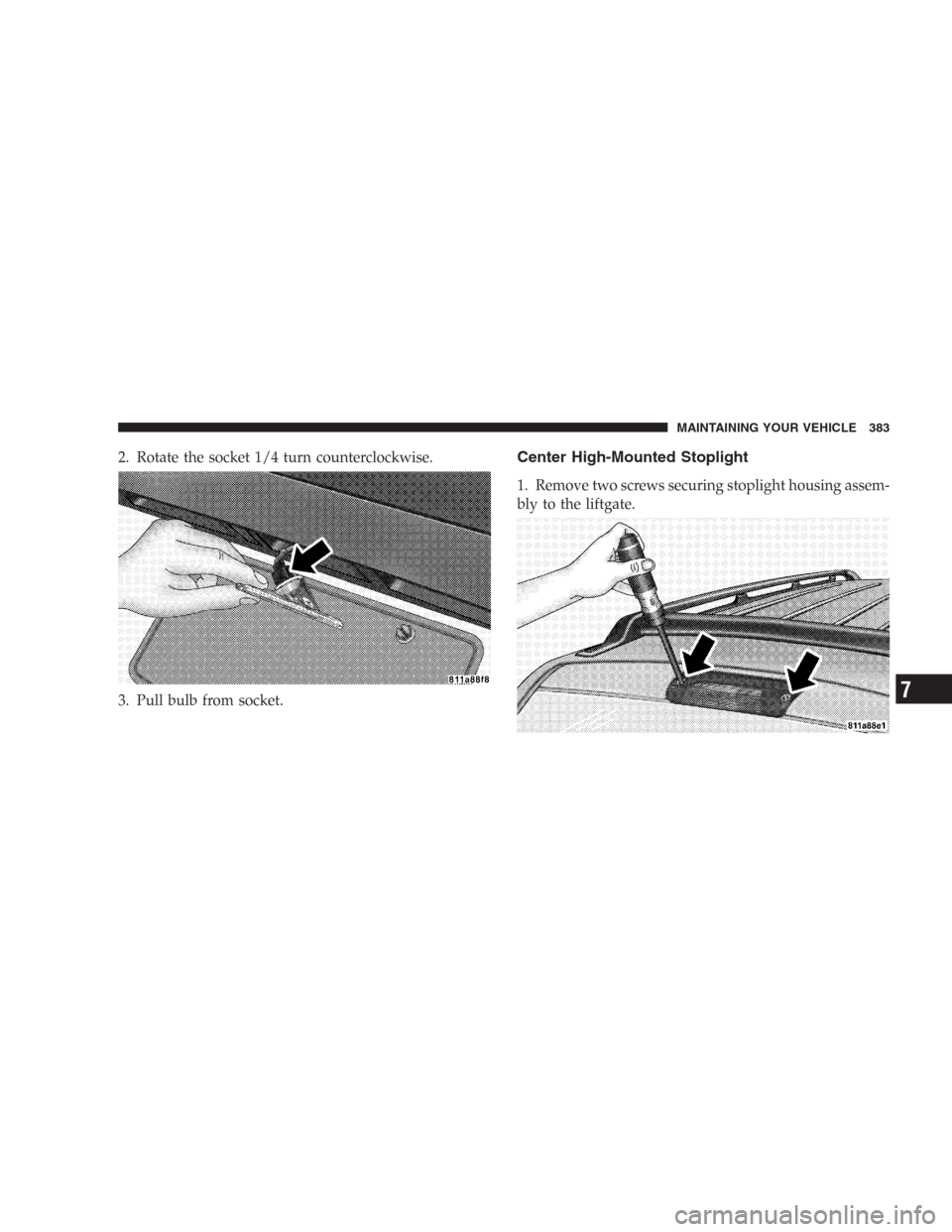

2. Rotate the socket 1/4 turn counterclockwise.

3. Pull bulb from socket.Center High-Mounted Stoplight

1. Remove two screws securing stoplight housing assem-

bly to the liftgate.

MAINTAINING YOUR VEHICLE 383

7

Page 420 of 440

ABS (Anti-Lock Brake System)............186,260

Adding Fuel........................287,316

Air Cleaner, Engine (Engine Air Cleaner Filter) . . . 346

Air Conditioner Maintenance............223,349

Air Conditioning........................ 222

Air Conditioning, Operating Tips............ 234

Air Conditioning, Rear Zone................ 226

Air Conditioning Refrigerant.............349,350

Air Conditioning System................222,349

Air Filter.............................. 346

Air Pressure, Tires....................274,282

Airbag.............................48,191

Airbag Light............................ 61

Alarm, Panic............................ 23

Alarm (Security Alarm).................26,185

Alignment and Balance................... 281

Antenna, Satellite Radio................... 219

Antifreeze (Engine Coolant)...........356,357,385

Anti-Lock Brake System (ABS)............146,260Anti-Lock Warning Light.................. 186

Anti-Theft System.....................26,185

Appearance Care........................ 366

Arming Theft System (Security Alarm)......... 27

Automatic Dimming Mirror...............84,88

Automatic Door Locks..................... 17

Automatic Headlights.................... 133

Automatic Transaxle...................... 245

Automatic Transmission.............242,245,362

Adding Fluid......................... 362

Fluid and Filter Changes................. 363

Fluid Level Check...................... 362

Fluid Type........................363,387

Gear Ranges.......................... 245

Special Additives...................... 364

Torque Converter...................... 249

Axle Fluid............................. 387

Axle Lubrication (Axle Fluid)............... 365

420 INDEX

Page 432 of 440

Replacement Parts....................... 339

Replacement Tires....................... 280

Reporting Safety Defects................... 415

Restraints, Child.......................64,69

Restraints, Occupant...................... 36

Rocking Vehicle When Stuck................ 264

Roof Type Carrier....................... 174

Rotation, Tires.......................... 284

Safety Checks Inside Vehicle................. 76

Safety Checks Outside Vehicle............... 76

Safety Defects, Reporting.................. 415

Safety, Exhaust Gas....................... 33

Safety Information, Tire................... 264

Safety Tips............................. 75

Satellite Radio.......................... 215

Satellite Radio Antenna................... 219

Schedule, Maintenance.................... 391

Seat Belt Maintenance.................... 370Seat Belt Reminder....................... 46

Seat Belts............................36,37

And Pregnant Women................... 47

Child Restraint.......................64,65

Extender............................. 47

Front Seat............................ 37

Inspection............................ 76

Pretensioners.......................... 45

Reminder............................ 184

Seats................................. 111

Adjustment.......................... 111

Heated.............................. 115

Lumbar Support....................... 113

Memory............................. 125

Reclining............................ 112

Security Alarm (Theft Alarm).............26,185

Selection of Coolant (Antifreeze)............. 386

Selection of Oil......................... 343

Sentry Key (Immobilizer)................... 10

432 INDEX