torque DODGE DURANGO 2013 3.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2013, Model line: DURANGO, Model: DODGE DURANGO 2013 3.GPages: 140, PDF Size: 4.38 MB

Page 89 of 140

ALL-WHEEL DRIVE OPERATION

Single-Speed Operating Instructions/Precautions

•

This system contains a single-speed (HI range only) transfer case, which provides conve-

nient full-time all-wheel drive. No driver interaction is required. The Brake Traction Control

(BTC) System, which combines standard ABS and Traction Control, provides resistance to

any wheel that is slipping to allow additional torque transfer to wheels with traction.

NOTE:

This system is not appropriate for conditions where AWD LOW range is recommended. Refer to

“Off-Road Driving Tips” in “Starting and Operating” on the DVD for further information.

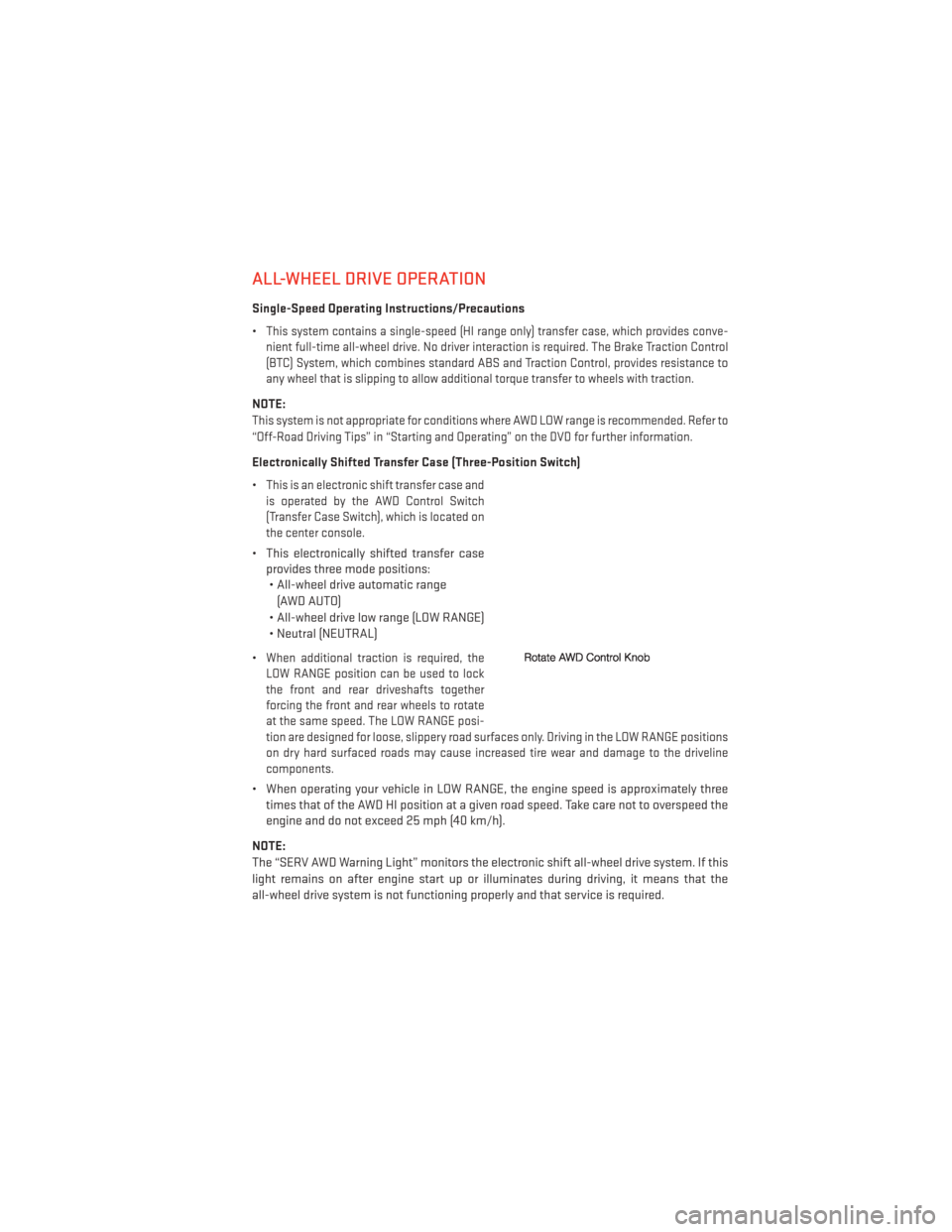

Electronically Shifted Transfer Case (Three-Position Switch)

•

This is an electronic shift transfer case and

is operated by the AWD Control Switch

(Transfer Case Switch), which is located on

the center console.

• This electronically shifted transfer case provides three mode positions:• All-wheel drive automatic range

(AWD AUTO)

• All-wheel drive low range (LOW RANGE)

• Neutral (NEUTRAL)

•

When additional traction is required, the

LOW RANGE position can be used to lock

the front and rear driveshafts together

forcing the front and rear wheels to rotate

at the same speed. The LOW RANGE posi-

tion are designed for loose, slippery road surfaces only. Driving in the LOW RANGE positions

on dry hard surfaced roads may cause increased tire wear and damage to the driveline

components.

• When operating your vehicle in LOW RANGE, the engine speed is approximately three times that of the AWD HI position at a given road speed. Take care not to overspeed the

engine and do not exceed 25 mph (40 km/h).

NOTE:

The “SERV AWD Warning Light” monitors the electronic shift all-wheel drive system. If this

light remains on after engine start up or illuminates during driving, it means that the

all-wheel drive system is not functioning properly and that service is required.

OFF-ROAD CAPABILITIES

87

Page 105 of 140

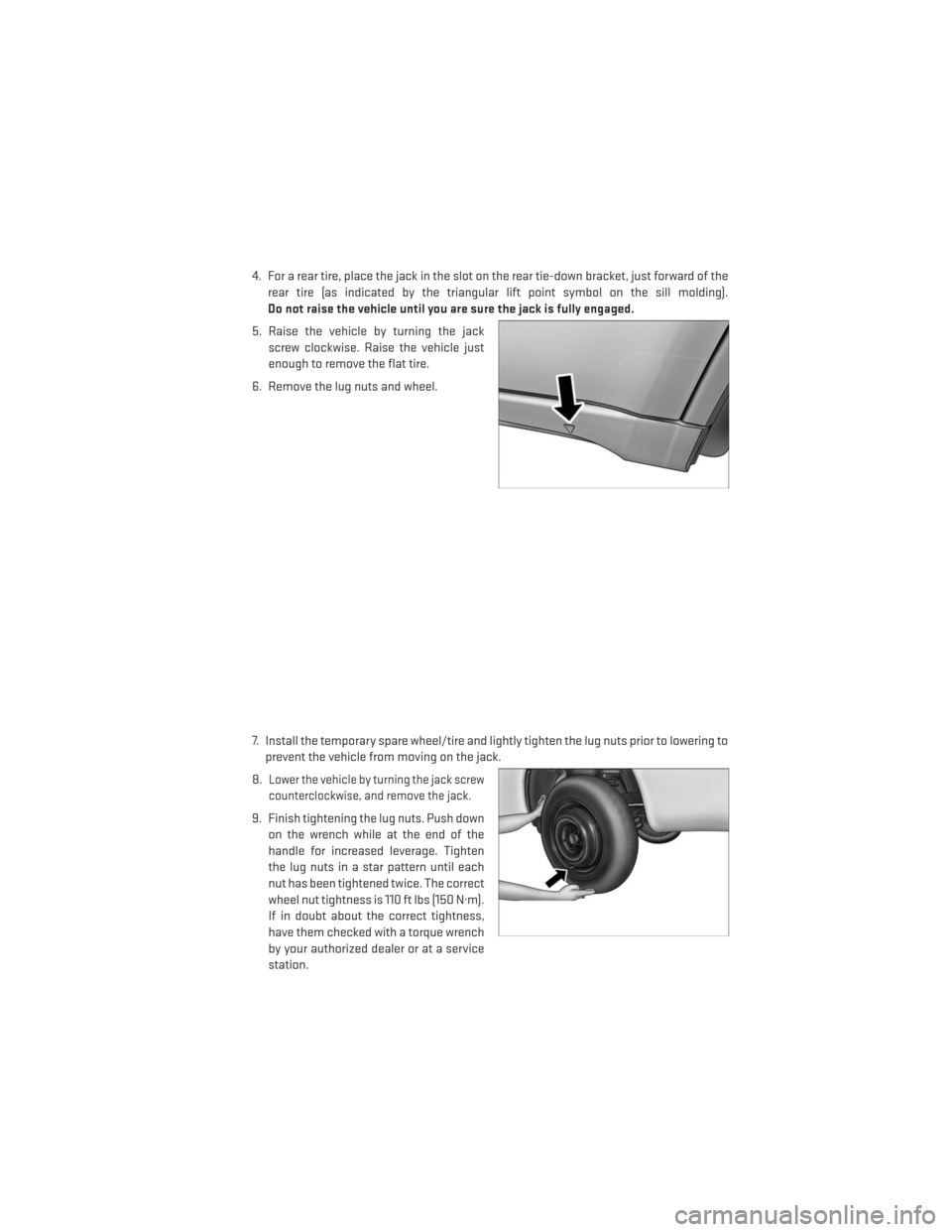

4. For a rear tire, place the jack in the slot on the rear tie-down bracket, just forward of therear tire (as indicated by the triangular lift point symbol on the sill molding).

Do not raise the vehicle until you are sure the jack is fully engaged.

5. Raise the vehicle by turning the jack screw clockwise. Raise the vehicle just

enough to remove the flat tire.

6. Remove the lug nuts and wheel.

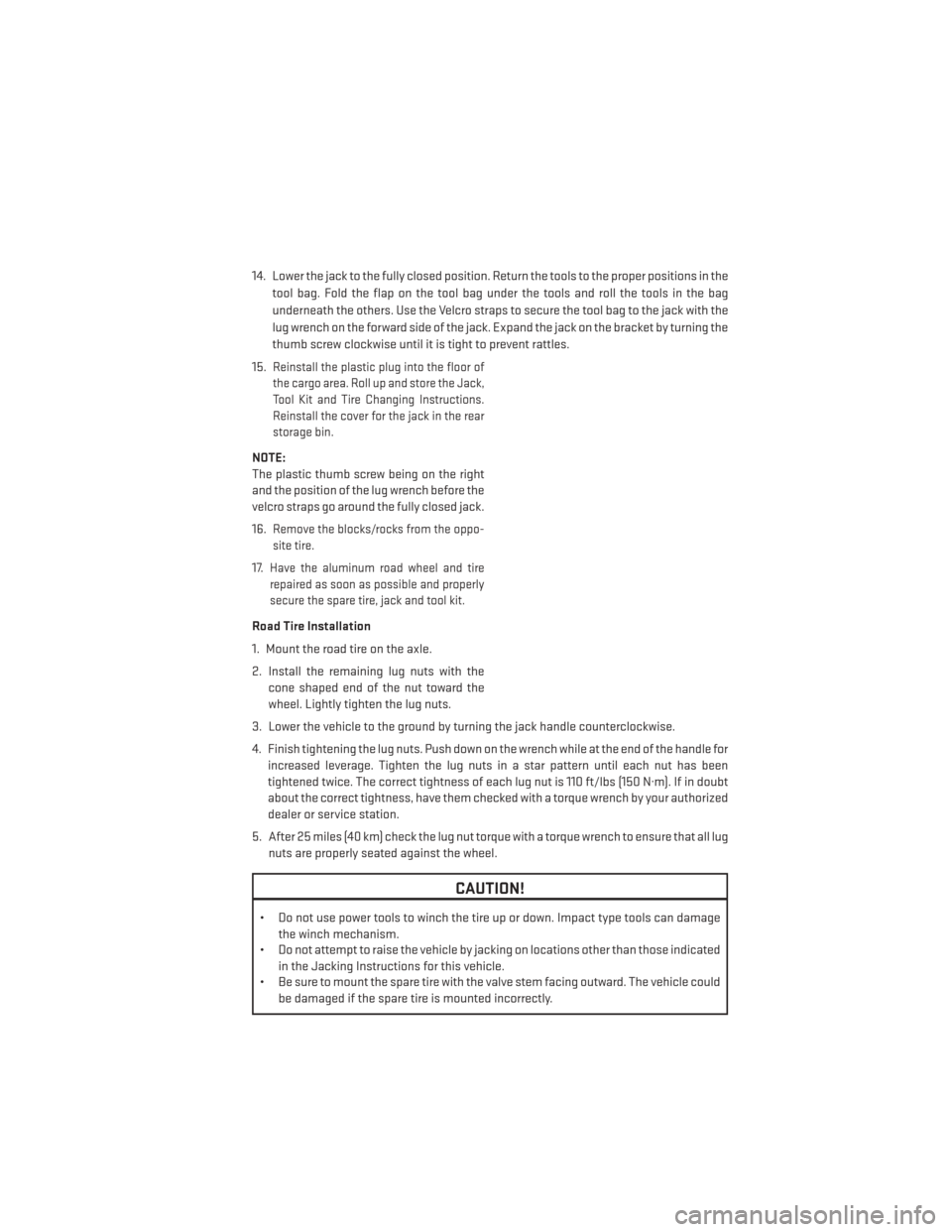

7. Install the temporary spare wheel/tire and lightly tighten the lug nuts prior to lowering to prevent the vehicle from moving on the jack.

8.

Lower the vehicle by turning the jack screw

counterclockwise, and remove the jack.

9. Finish tightening the lug nuts. Push down on the wrench while at the end of the

handle for increased leverage. Tighten

the lug nuts in a star pattern until each

nut has been tightened twice. The correct

wheel nut tightness is 110 ft lbs (150 N·m).

If in doubt about the correct tightness,

have them checked with a torque wrench

by your authorized dealer or at a service

station.

WHAT TO DO IN EMERGENCIES

103

Page 107 of 140

14. Lower the jack to the fully closed position. Return the tools to the proper positions in thetool bag. Fold the flap on the tool bag under the tools and roll the tools in the bag

underneath the others. Use the Velcro straps to secure the tool bag to the jack with the

lug wrench on the forward side of the jack. Expand the jack on the bracket by turning the

thumb screw clockwise until it is tight to prevent rattles.

15.

Reinstall the plastic plug into the floor of

the cargo area. Roll up and store the Jack,

Tool Kit and Tire Changing Instructions.

Reinstall the cover for the jack in the rear

storage bin.

NOTE:

The plastic thumb screw being on the right

and the position of the lug wrench before the

velcro straps go around the fully closed jack.

16.

Remove the blocks/rocks from the oppo-

site tire.

17.Have the aluminum road wheel and tire

repaired as soon as possible and properly

secure the spare tire, jack and tool kit.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage. Tighten the lug nuts in a star pattern until each nut has been

tightened twice. The correct tightness of each lug nut is 110 ft/lbs (150 N·m). If in doubt

about the correct tightness, have them checked with a torque wrench by your authorized

dealer or service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

CAUTION!

• Do not use power tools to winch the tire up or down. Impact type tools can damage the winch mechanism.

• Do not attempt to raise the vehicle by jacking on locations other than those indicated

in the Jacking Instructions for this vehicle.

• Be sure to mount the spare tire with the valve stem facing outward. The vehicle could

be damaged if the spare tire is mounted incorrectly.

WHAT TO DO IN EMERGENCIES

105