lock DODGE DURANGO 2015 3.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2015, Model line: DURANGO, Model: DODGE DURANGO 2015 3.GPages: 689, PDF Size: 20.05 MB

Page 565 of 689

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not fully tighten the lug nuts until the vehicle has

been lowered. Failure to follow this warning may

result in personal injury.

8. Lower the vehicle by turning the jack screw counter-

clockwise, and remove the jack and wheel blocks.

9. Finish tightening the lug nuts. Push down on the

wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice. Refer to Torque

Specifications in this section for proper lug nut torque.

If in doubt about the correct tightness, have them

checked with a torque wrench by your authorized

dealer or at a service station.

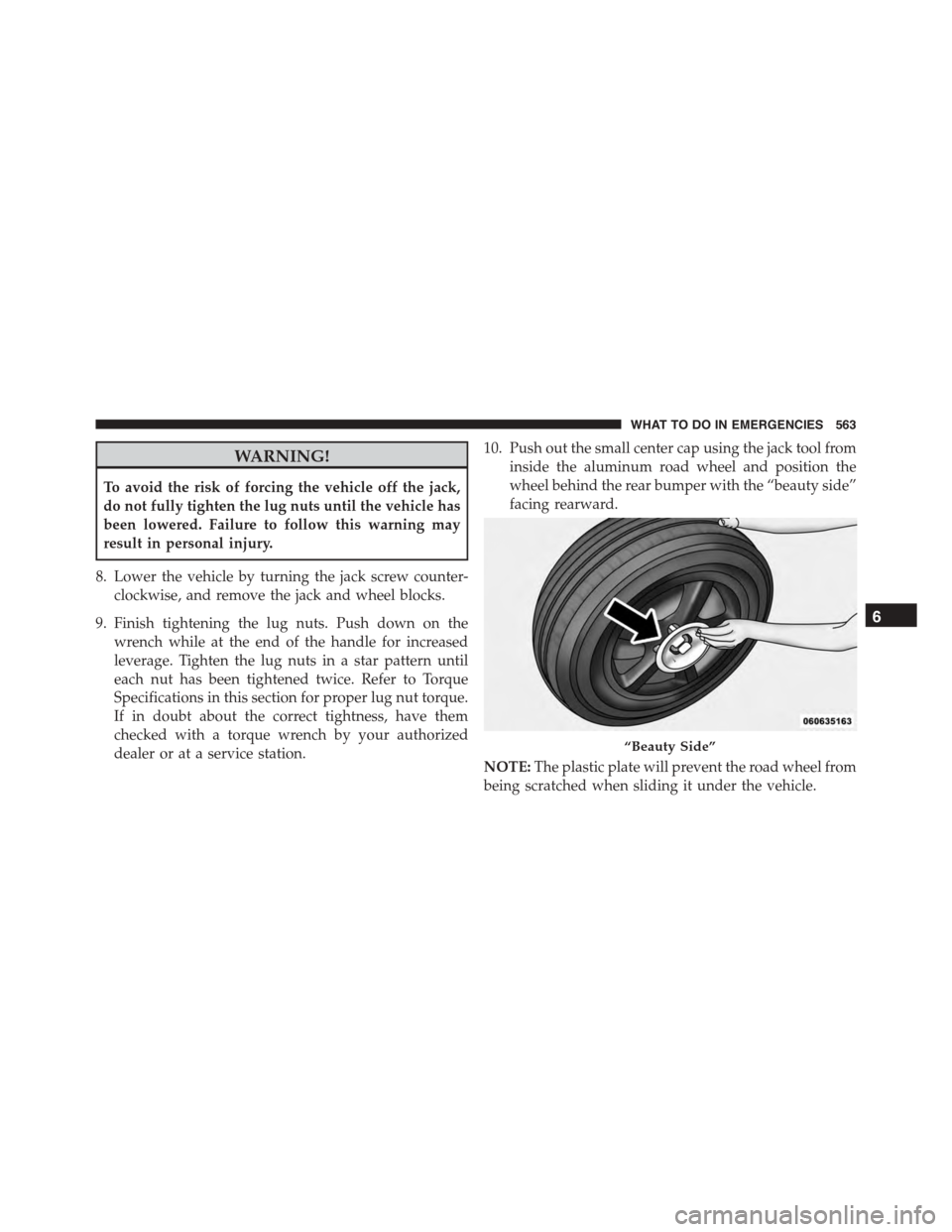

10. Push out the small center cap using the jack tool from

inside the aluminum road wheel and position the

wheel behind the rear bumper with the “beauty side”

facing rearward.

NOTE:The plastic plate will prevent the road wheel from

being scratched when sliding it under the vehicle.

“Beauty Side”

6

WHAT TO DO IN EMERGENCIES 563

Page 566 of 689

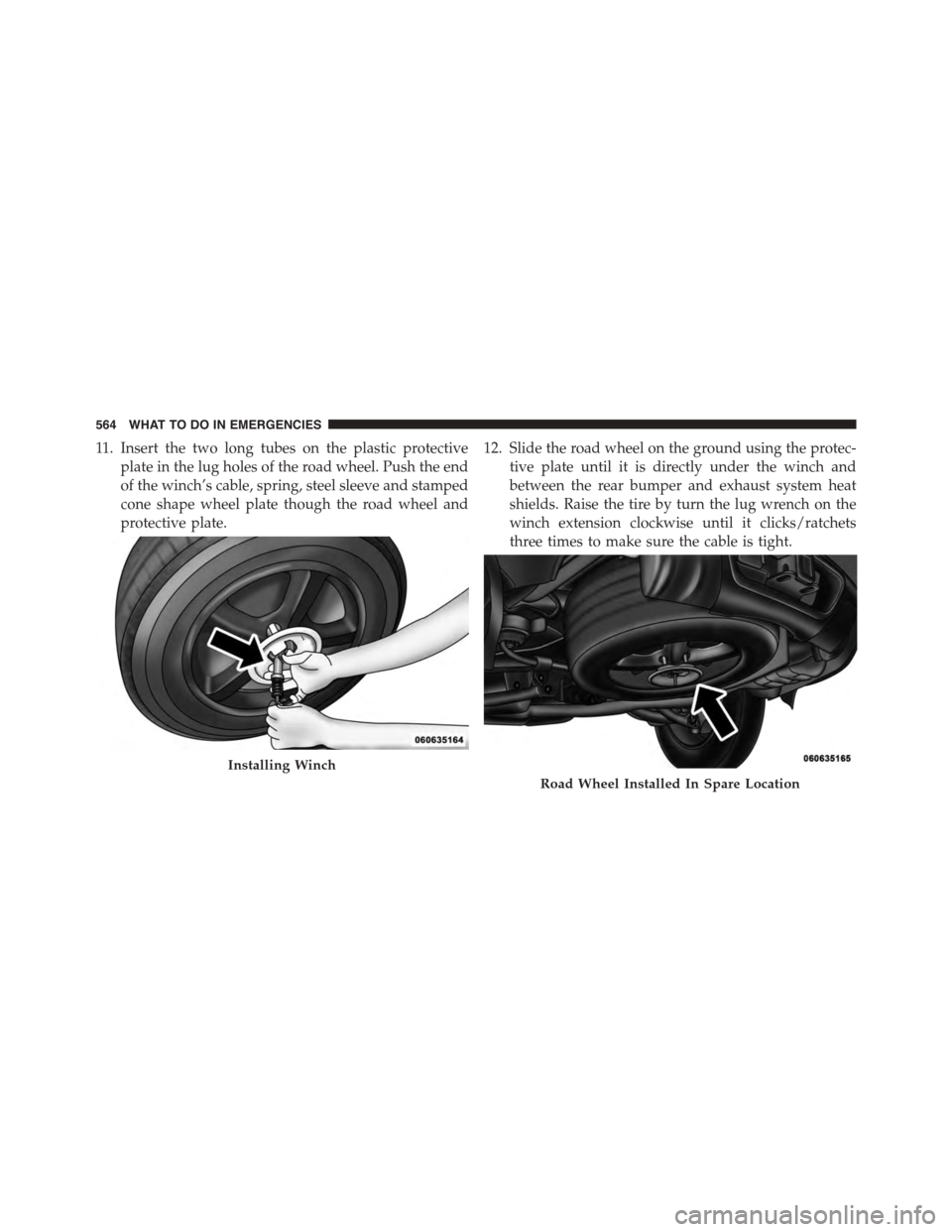

11. Insert the two long tubes on the plastic protective

plate in the lug holes of the road wheel. Push the end

of the winch’s cable, spring, steel sleeve and stamped

cone shape wheel plate though the road wheel and

protective plate.

12. Slide the road wheel on the ground using the protec-

tive plate until it is directly under the winch and

between the rear bumper and exhaust system heat

shields. Raise the tire by turn the lug wrench on the

winch extension clockwise until it clicks/ratchets

three times to make sure the cable is tight.

Installing Winch

Road Wheel Installed In Spare Location

564 WHAT TO DO IN EMERGENCIES

Page 567 of 689

NOTE:Double check to ensure the tire is snug against the

underbody of the vehicle. Damage to the winch cable

may result if the vehicle is driven with the tire loose.

WARNING!

Do not use power tools to winch the tire up or down.

Impact-type tools may damage the winch mecha-

nism.

13. Lower the jack to the fully closed position. Return the

tools to the proper positions in the tool bag. Fold the

flap on the tool bag under the tools and roll the tools

in the bag underneath the others. Use the Velcro

straps to secure the tool bag to the jack with the lug

wrench on the forward side of the jack. Expand the

jack on the bracket by turning the thumb screw

clockwise until it is tight to prevent rattles.

14. Reinstall the plastic plug into the floor of the cargo

area. Roll up and store the Jack, Tool Kit and Tire

Changing Instructions. Reinstall the cover for the jack

in the rear storage bin.

15. Have the aluminum road wheel and tire repaired as

soon as possible and properly secure the spare tire,

jack and tool kit.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided.

6

WHAT TO DO IN EMERGENCIES 565

Page 568 of 689

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped

end of the nut toward the wheel. Lightly tighten the

lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the lug nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in personal injury.

3. Lower the vehicle to the ground by turning the jack

handle counterclockwise.

4. Refer to Torque Table for proper lug nut torque.

5. After 25 miles (40 km) check the lug nut torque with a

torque wrench to ensure that all lug nuts are properly

seated against the wheel.

CAP-LESS FUEL FILL FUNNEL

The funnel for the Cap-Less Fuel System is located with

the jack and tire changing tools. If your vehicle is out of

fuel and an auxiliary fuel can is needed, insert the funnel

into the filler neck and proceed to fill the vehicle.

566 WHAT TO DO IN EMERGENCIES

Page 571 of 689

WARNING!

•Take care to avoid the radiator cooling fan when-

ever the hood is raised. It can start anytime the

ignition switch is ON. You can be injured by

moving fan blades.

•Remove any metal jewelry such as rings, watch

bands and bracelets that could make an inadvertent

electrical contact. You could be seriously injured.

•Batteries contain sulfuric acid that can burn your

skin or eyes and generate hydrogen gas which is

flammable and explosive. Keep open flames or

sparks away from the battery.

NOTE:Be sure that the disconnected ends of the cables

do not touch while still connected to the other vehicle.

1. Set the parking brake, shift the automatic transmission

into PARK and turn the ignition to LOCK.

2. Turn off the heater, radio, and all unnecessary electri-

cal accessories.

3. Remove the protective cover over the remote positive

(+)battery post. Pull upward on the cover to remove

it.

4. If using another vehicle to jump-start the battery, park

the vehicle within the jumper cables reach, set the

parking brake and make sure the ignition is OFF.

WARNING!

Do not allow vehicles to touch each other as this

could establish a ground connection and personal

injury could result.

6

WHAT TO DO IN EMERGENCIES 569

Page 578 of 689

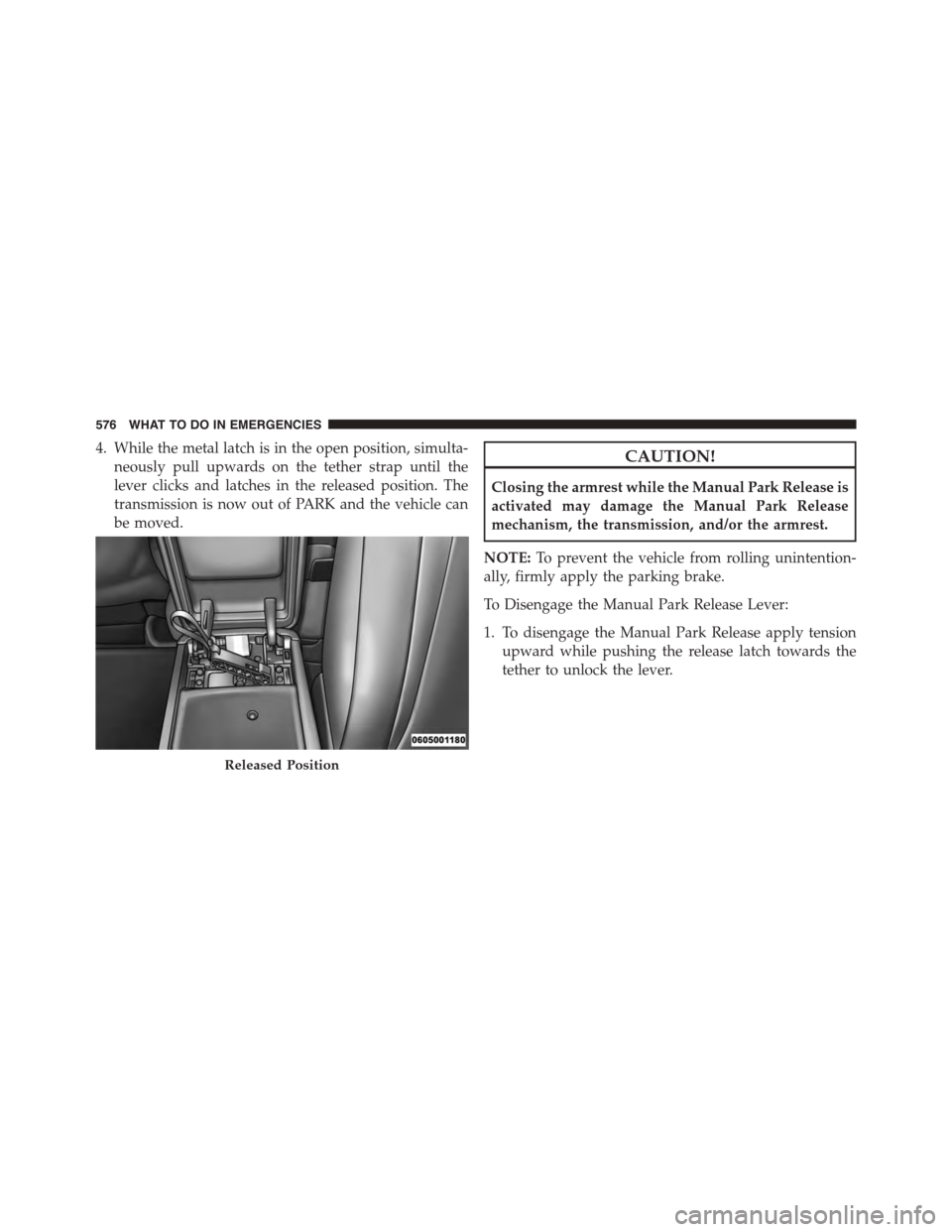

4. While the metal latch is in the open position, simulta-

neously pull upwards on the tether strap until the

lever clicks and latches in the released position. The

transmission is now out of PARK and the vehicle can

be moved.

CAUTION!

Closing the armrest while the Manual Park Release is

activated may damage the Manual Park Release

mechanism, the transmission, and/or the armrest.

NOTE:To prevent the vehicle from rolling unintention-

ally, firmly apply the parking brake.

To Disengage the Manual Park Release Lever:

1. To disengage the Manual Park Release apply tension

upward while pushing the release latch towards the

tether to unlock the lever.

Released Position

576 WHAT TO DO IN EMERGENCIES

Page 579 of 689

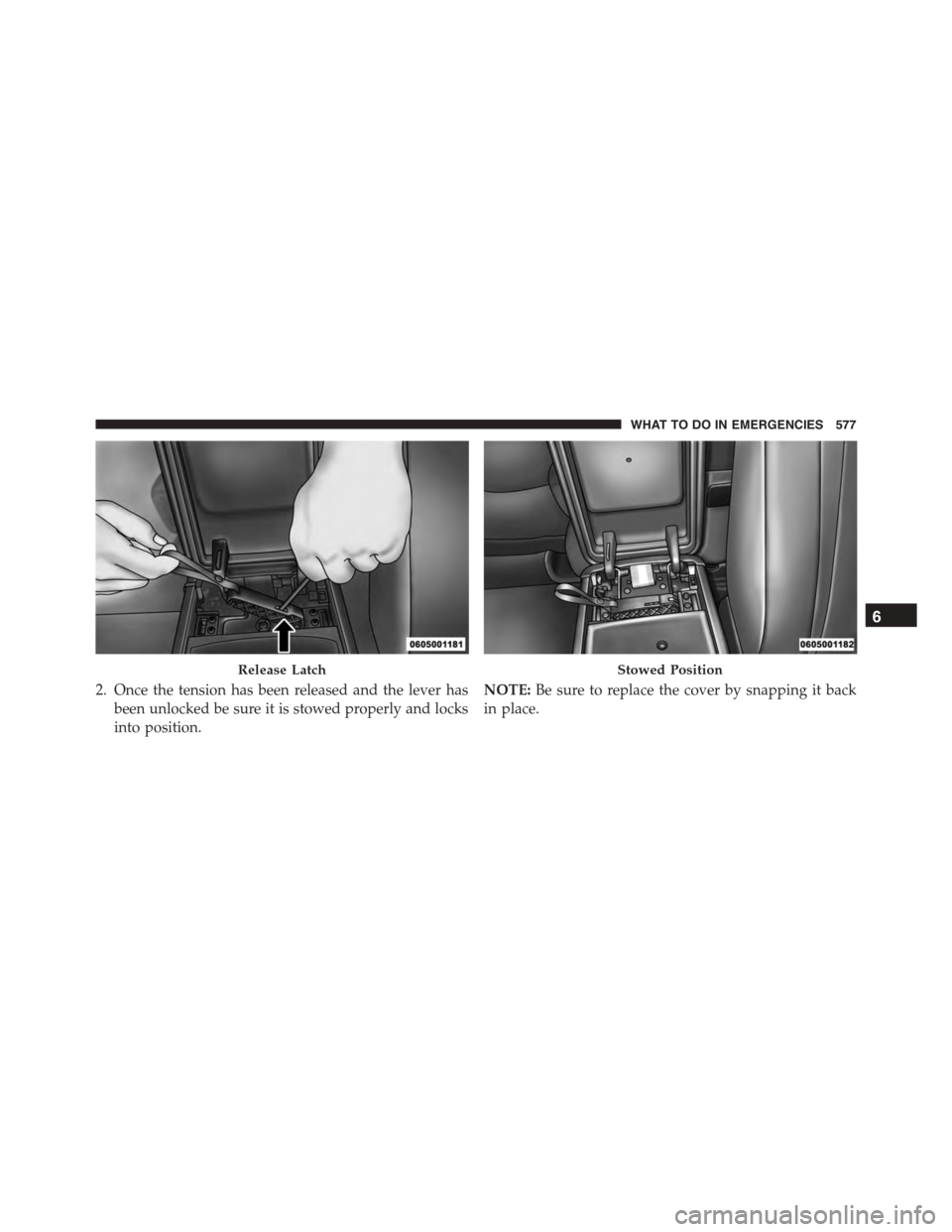

2. Once the tension has been released and the lever has

been unlocked be sure it is stowed properly and locks

into position.

NOTE:Be sure to replace the cover by snapping it back

in place.

Release LatchStowed Position

6

WHAT TO DO IN EMERGENCIES 577

Page 603 of 689

6. Remove the A/C air filter by pulling it straight out of

the housing.

7. Install the A/C air filter with the arrow on the filter

pointing toward the floor. When installing the filter

cover, make sure the retaining tabs fully engage the

cover.

CAUTION!

The A/C air filter is identified with an arrow to

indicate airflow direction through the filter. Failure

to properly install the filter will result in the need to

replace it more often.

8. Reinstall the glove compartment door on the glove

compartment door hinge and reattach the glove com-

partment tension tether by inserting the tether clip in

the glove compartment and sliding the clip away from

the face of the glove compartment door.

9. Push the door to the near closed position to reengage

the glove compartment travel stops.

NOTE:Ensure the glove compartment door hinges and

glove compartment travel stops are fully engaged.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, door hinge pivot points and rollers, liftgate,

tailgate, decklid, sliding doors and hood hinges, should

be lubricated periodically with a lithium based grease,

such as MOPAR® Spray White Lube to assure quiet, easy

operation and to protect against rust and wear. Prior to

the application of any lubricant, the parts concerned

should be wiped clean to remove dust and grit; after

lubricating excess oil and grease should be removed.

Particular attention should also be given to hood latching

components to ensure proper function. When performing

other underhood services, the hood latch, release mecha-

nism and safety catch should be cleaned and lubricated.

7

MAINTAINING YOUR VEHICLE 601

Page 604 of 689

The external lock cylinders should be lubricated twice a

year, preferably in the Fall and Spring. Apply a small

amount of a high quality lubricant, such as MOPAR®

Lock Cylinder Lubricant directly into the lock cylinder.

Windshield Wiper Blades

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild nonabrasive cleaner. This will remove accumula-

tions of salt or road film.

Operation of the wipers on dry glass for long periods

may cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield.

Avoid using the wiper blades to remove frost or ice from

the windshield. Keep the blade rubber out of contact with

petroleum products such as engine oil, gasoline, etc.

NOTE:Life expectancy of wiper blades varies depend-

ing on geographical area and frequency of use. Poor

performance of blades may be present with chattering,

marks, water lines or wet spots. If any of these conditions

are present, clean the wiper blades or replace as neces-

sary.

Rear Wiper Blade Removal/Installation

1. Lift the pivot cap on the rear wiper arm upward, this

will allow the rear wiper blade to be raised off of the

liftgate glass.

602 MAINTAINING YOUR VEHICLE

Page 629 of 689

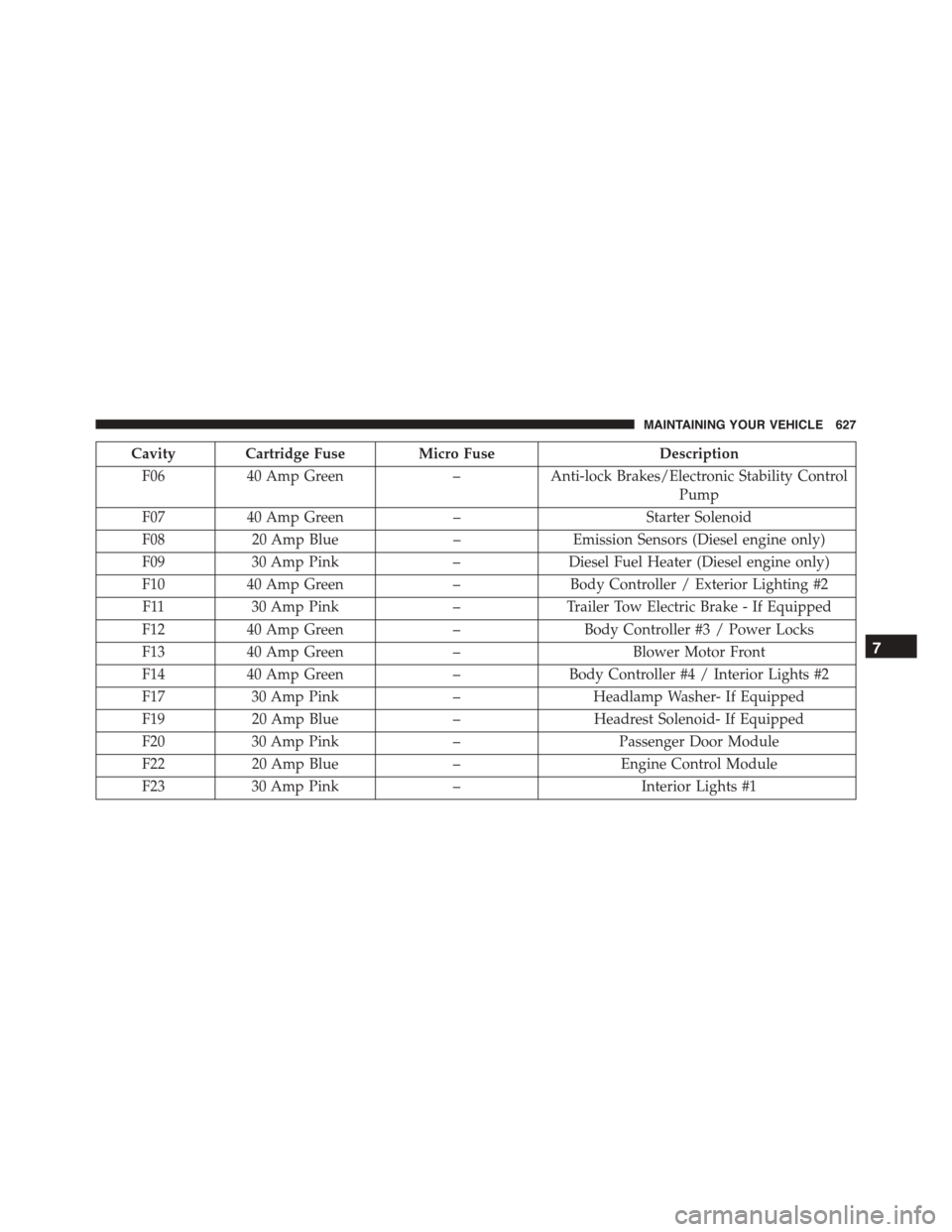

Cavity Cartridge Fuse Micro FuseDescription

F0640 Amp Green–Anti-lock Brakes/Electronic Stability Control

Pump

F0740 Amp Green–Starter Solenoid

F0820 Amp Blue–Emission Sensors (Diesel engine only)

F0930 Amp Pink–Diesel Fuel Heater (Diesel engine only)

F1040 Amp Green–Body Controller / Exterior Lighting #2

F1130 Amp Pink–Trailer Tow Electric Brake - If Equipped

F1240 Amp Green–Body Controller #3 / Power Locks

F1340 Amp Green–Blower Motor Front

F1440 Amp Green–Body Controller #4 / Interior Lights #2

F1730 Amp Pink–Headlamp Washer- If Equipped

F1920 Amp Blue–Headrest Solenoid- If Equipped

F2030 Amp Pink–Passenger Door Module

F2220 Amp Blue–Engine Control Module

F2330 Amp Pink–Interior Lights #1

7

MAINTAINING YOUR VEHICLE 627